In-situ self-assembled slapper ignition component and preparation method thereof

A shock sheet and self-assembly technology, applied in the direction of offensive equipment, detonators, etc., can solve the problems of high cost, difficult weapon system, low processing efficiency of shock sheet detonators, etc., to achieve enhanced mechanical properties, simplified process, simplified preparation and The effect of the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further elaborated below in conjunction with the accompanying drawings.

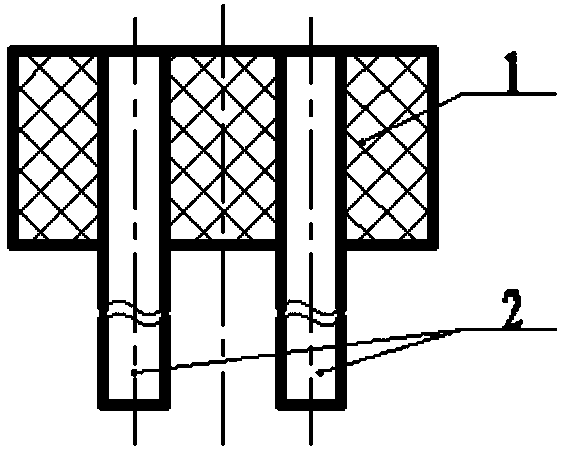

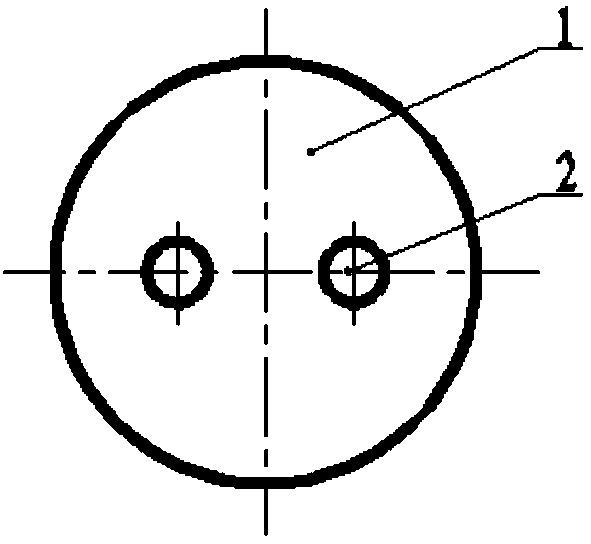

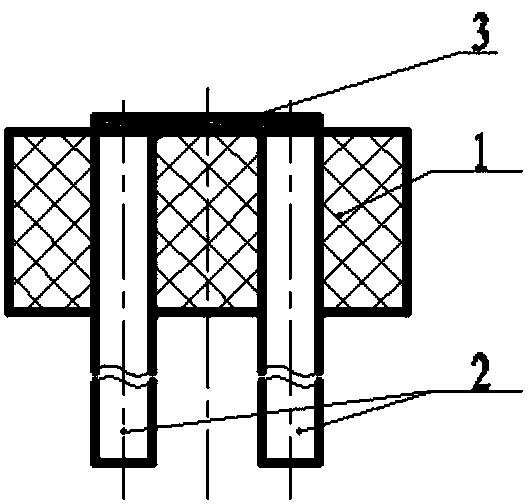

[0031] like Figure 1 to Figure 5 As shown, an in-situ self-assembled impact plate ignition assembly according to an embodiment of the present invention includes an alumina ceramic substrate 1 provided with pins 2, a metal copper explosion foil 3, a polychlorinated p-xylylene fly sheet layer 4, and a photolithography The glue structure layer 5 and the acceleration chamber 6; preferably, the pin 2 is a Kovar pin electrode. The metal copper explosion foil 3 is arranged on the alumina ceramic substrate 1; the polychlorinated p-xylene flying sheet layer 4 is arranged on the metal copper explosion foil 3; the photoresist structure layer 5 is arranged on the The polychlorinated p-xylene flying sheet layer 4; the acceleration chamber 6 is set in the photoresist structure layer 5. The integration of the entire impact plate ignition component is based on alumina ceramics wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com