Fume exhaust layout structure for subway platform and screen door system

A technology for subway platform and layout structure, which is applied in the directions of stations, smoke removal, railway car body parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

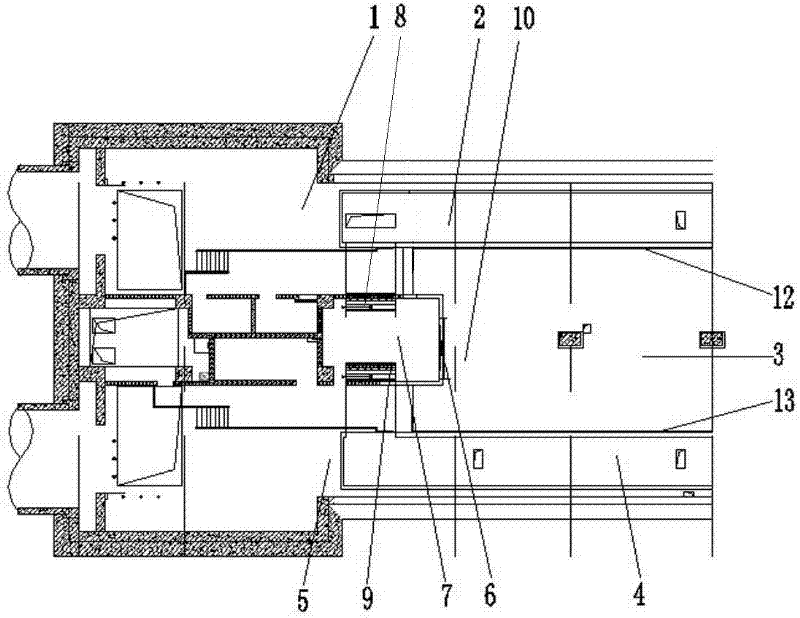

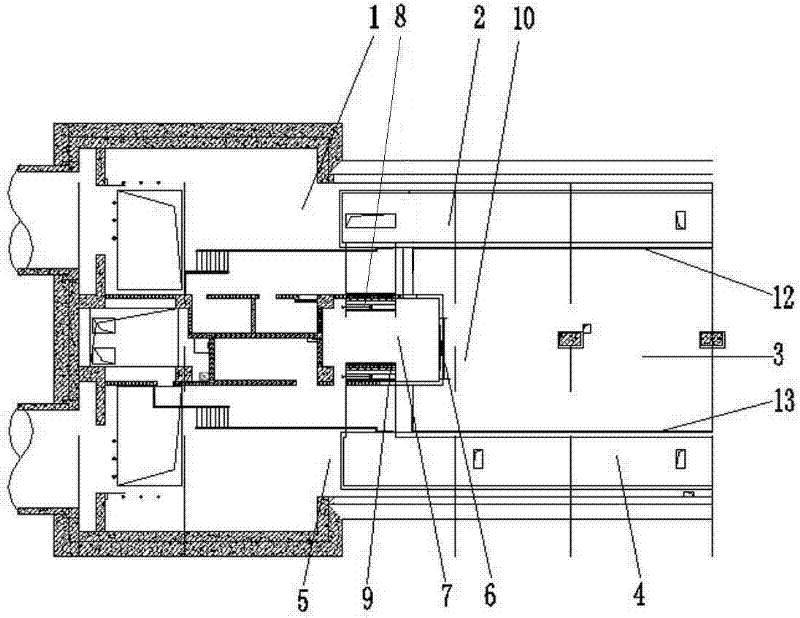

[0018] Embodiment one: if figure 1 As shown, track 1 and track 5 are the tracks of the up and down subway, which are located on both sides of the platform waiting area 3 . Screen doors 12, 13 are located on both sides of the platform waiting area 3. The platform waiting area 3 is provided with a heat exhaust air pipe 2 and a heat exhaust air pipe 4 respectively above the track, and the two heat exhaust air pipes are respectively connected to the heat exhaust chamber 7 and the heat exhaust fan system located on one side of the platform waiting area. Air valves 8 and 9 are respectively provided at the joints of the exhaust heat pipes 2 and 4 with the heat discharge chamber 7 to control the working state of the exhaust heat pipes 2 and 4 . The heat exhausting chamber 7 has a centralized smoke exhaust port 6 on the side surface adjacent to the waiting platform area, that is, the opening of the concentrated smoke exhaust port 6 leads to the platform waiting area 3, and the form of...

Embodiment 2

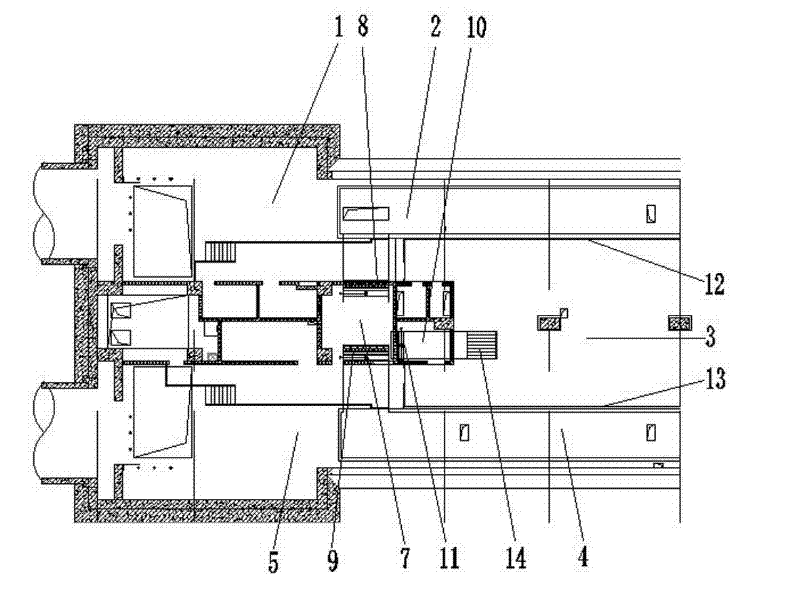

[0019] Embodiment two: if figure 2 As shown, the concentrated smoke exhaust port 6 is connected with a smoke exhaust pipe 10, and the joint between the smoke exhaust pipe 10 and the heat exhaust chamber 7 is provided with a damper 11, and the damper 11 controls the work of the smoke exhaust pipe 10 and the centralized exhaust vent 14. state. The air valves 8 and 9 at the joints between the exhaust heat ducts 2 and 4 and the heat exhaust chamber 7 should be located at the height of the exhaust chamber 7, so that the heat exhaust effect in the rail area is better. The setting form of the heat exhaust air duct 10 can be changed according to the form of the concentrated smoke exhaust port 6. If the concentrated smoke exhaust port 6 is composed of a plurality of small smoke exhaust ports, the heat exhaust air duct 10 can also be made up of a plurality of small exhaust vents. The heat exhaust air pipe group composed of hot air pipes.

[0020] In the above-mentioned embodiment, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com