Sound barrier smoke exhaust sound absorber and closed sound barrier

A technology of sound barrier and sound absorbing body, which is applied in heating mode, noise suppression, noise absorption device and other directions, can solve the problems of large smoke exhaust resistance, hidden danger of smoke exhaust, and limited noise reduction performance of rotating louvers. Guarantees noise reduction performance and improves the effect of noise reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]In order to enable those in the art to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments. Obviously, the embodiments described are only a portion of the embodiments of the present invention, and not all embodiments. Without conflict, embodiments of the present invention and features in embodiments may be combined with each other.

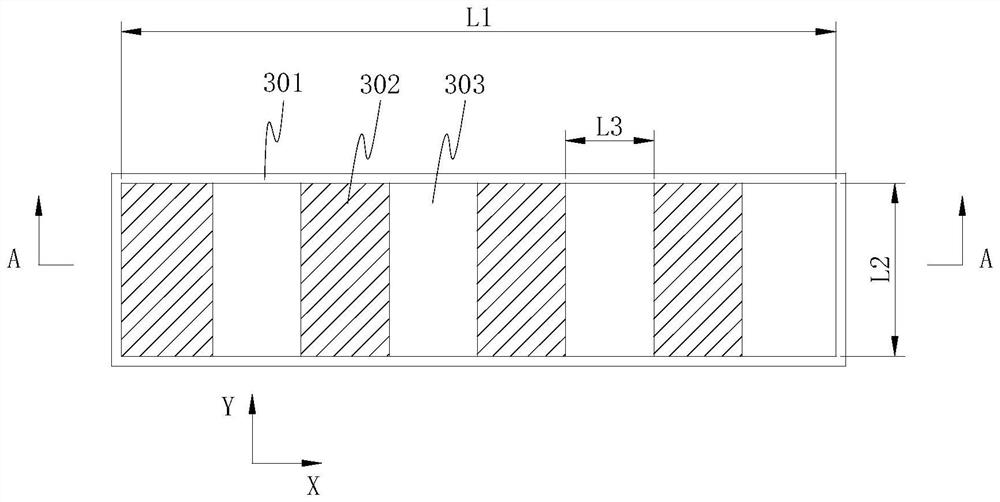

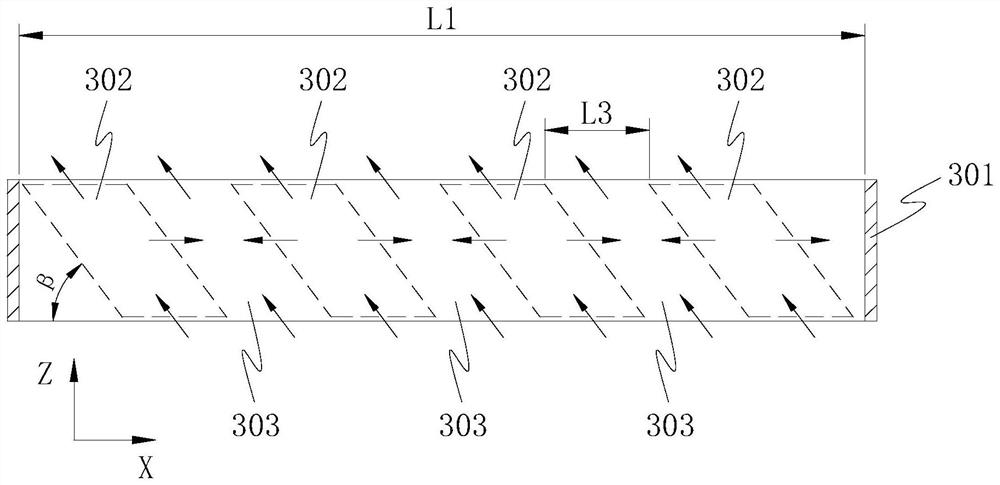

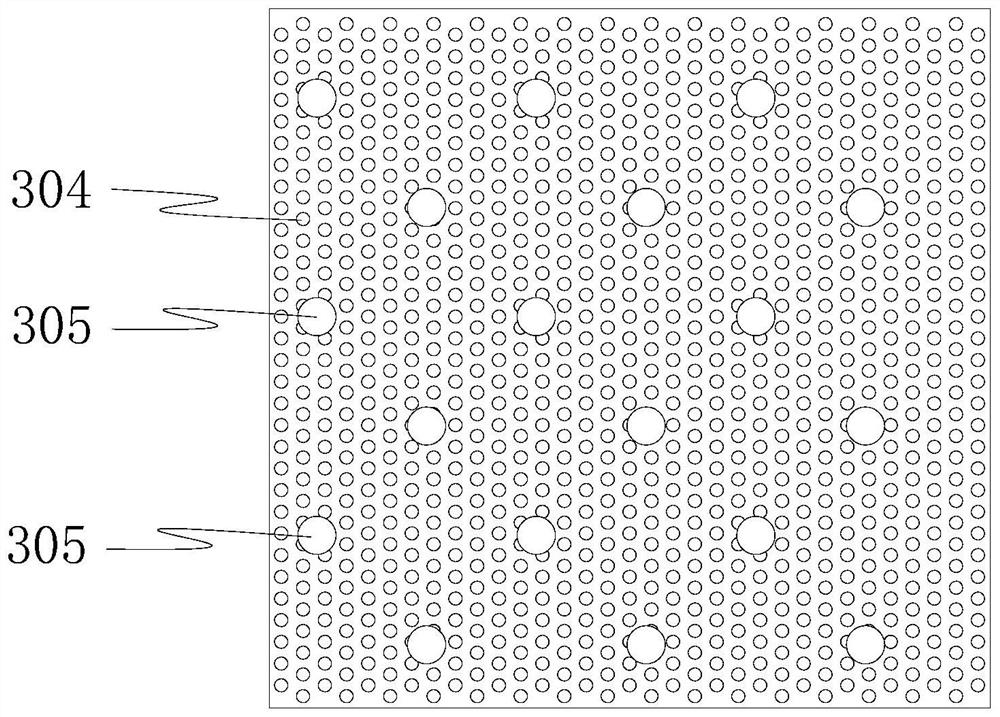

[0029] See Figure 1 、 Figure 2 、 Figure 3 , embodiments of the present invention provides a sound barrier smoke exhaust sound absorber, for setting a closed sound barrier with a transverse width of 9900mm for smoke extraction and suction; comprising a square ring frame 301, the outer frame 301 is uniformly provided along its transversely several exhaust sound absorbing sheets 302; the exhaust sound absorbing film 302 is tilted and extended along the longitudinal extension of the outer frame 301, and the adjacent exhaust sound absorber 302 for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com