A pmut unit driven by an embedded arched film and its preparation method

A film-driven, arch-shaped technology, applied in the field of ultrasonic transducers, can solve problems such as the reduction of emission sound pressure and reception sensitivity, restrict the development of PMUT ultra-high frequency, and PMUT chip damage and failure, and achieve the improvement of emission and reception sound pressure capabilities , large amplitude, high mechanical deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

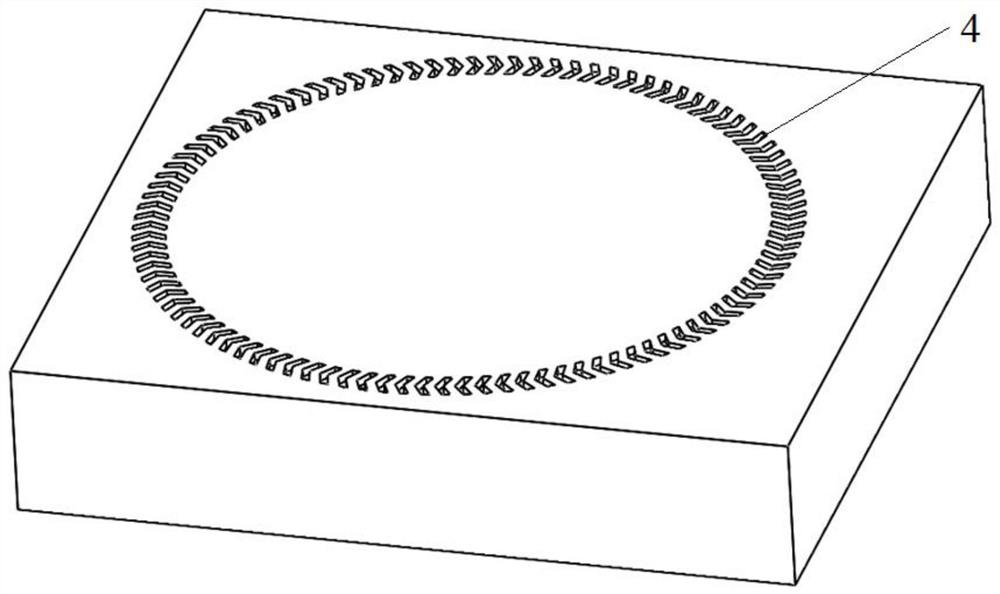

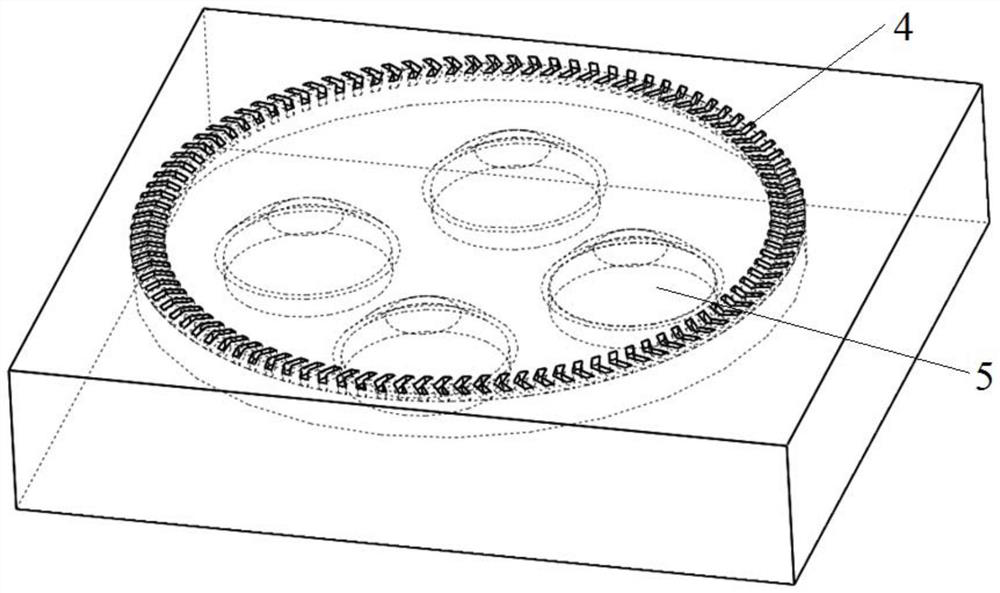

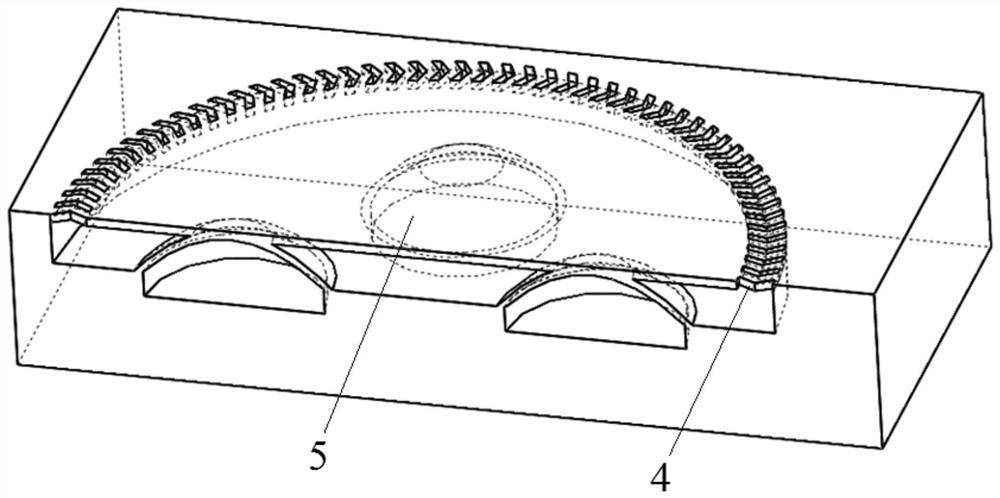

[0061] Embodiment 1 refers to Figure 1a , Figure 1b , Figure 1c and image 3 , a PMUT unit driven by an embedded arched film, which consists of a vibrating film 1, a driving layer 2 and a substrate 3 arranged in sequence from top to bottom. The driving layer 2 includes a supporting structure 2-1 and a driving structure 2-2, and the lining The bottom 3 includes a back cavity 3-1 and a base 3-2, wherein the back cavity 3-1 is surrounded by the driving layer 2 and the base 3-2. A plurality of release holes 4 are opened on the vibrating membrane 1 .

[0062] The vibrating membrane 1 is made of the top layer of silicon on the SOI sheet. The vibrating membrane 1 is realized by release technology, has good mechanical strength, is in direct contact with the coupling fluid, and pushes the external coupling fluid to emit ultrasonic waves by transmitting the mechanical deformation of the embedded arched driving layer. Or a large-span movable membrane structure that receives sound ...

Embodiment 2

[0077] refer to Figure 2a to Figure 2c , The difference between this embodiment and Embodiment 1 is that a plurality of embedded arched driving membranes 5 are arranged in concentric rings. The release hole 4 is circular, and the release hole 4 forms a plurality of concentric circles, and the concentric circles are located directly above the gap between two adjacent embedded arched driving membranes 5 .

[0078] A plurality of embedded arched driving membranes 5 can also be regularly arranged in a rectangular or polygonal shape. When the planar shape of the embedded arches is concentric, the release holes need to be modified accordingly. The modification of these shapes can be flexibly set according to the specific design, and details will not be repeated here.

[0079] refer to Figure 6a , Figure 6b and Figure 6c , the fabrication process of the PMUT driven by the embedded arched film is as follows:

[0080] Step 1: Select the SOI silicon wafer. The SOI silicon wafer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com