Method for preparing three-dimensional fluid channel in transparent material

A technology of transparent materials and fluid channels, applied in manufacturing tools, welding equipment, laser welding equipment, etc., can solve the problems of different corrosion rates and low overall rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below by embodiment the present invention will be further described, but should not limit protection scope of the present invention with this.

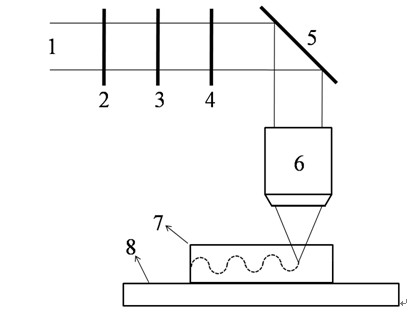

[0017] see first figure 1 . figure 1 It is a diagram of a device for preparing a uniform three-dimensional fluid channel by using a circularly polarized femtosecond laser in the present invention. The beam 1 output by the femtosecond laser has a center wavelength of 800 nm, a pulse width of 40 fs, and a repetition rate of 250 kHz. The light beam after passing through the polarizer 2 is linearly polarized light. Adjust the direction of the optical axis of the quarter glass slide 3 to make it 45° to the polarization direction of the incident linearly polarized light, thereby converting the linearly polarized light into circularly polarized light. Use the neutral attenuator 4 to control the energy of the beam at 1-2 μJ. After passing through the mirror 5, the light beam is focused 6 on the sample 7 by a microscope objective le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com