Manufacturing method for STI isolation structure

An isolation structure and wet etching technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as film residue, STI structure corner shape is steep, and affects device chip circuit characteristics, etc., to achieve corrosion The effect of fast speed and avoiding side wall problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

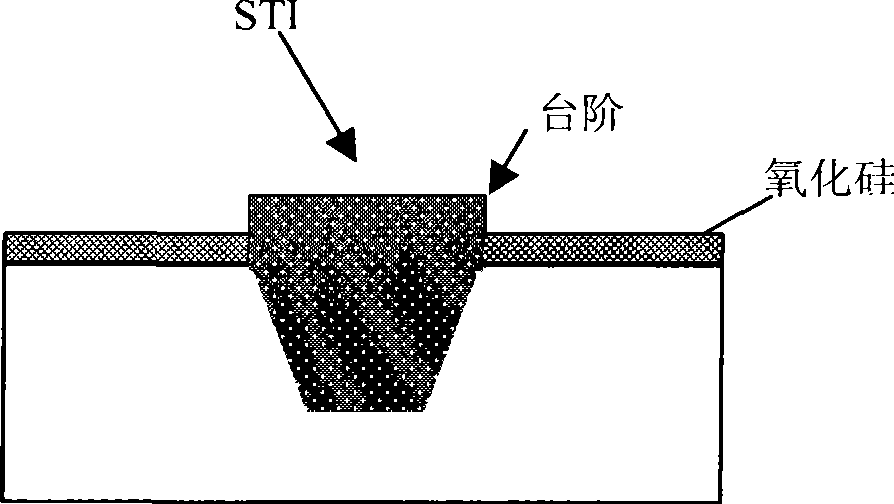

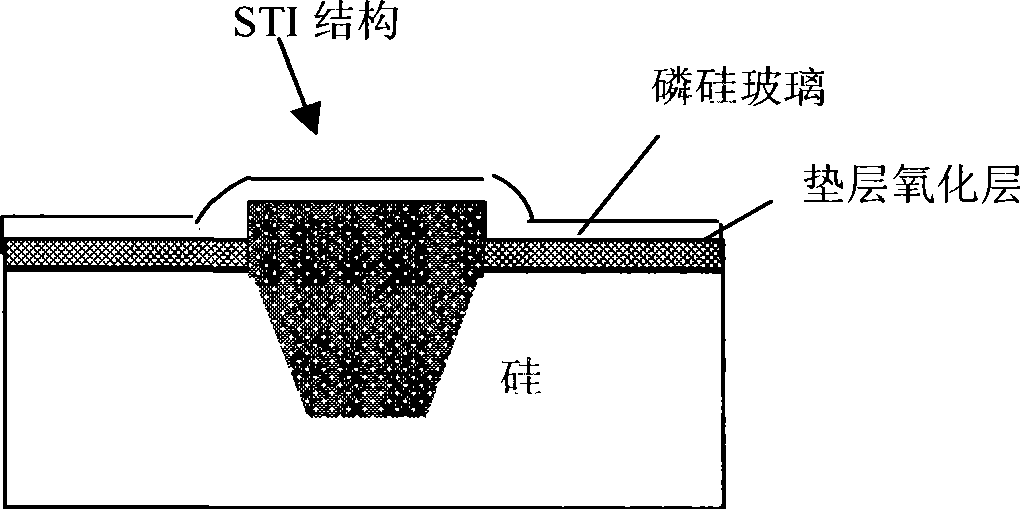

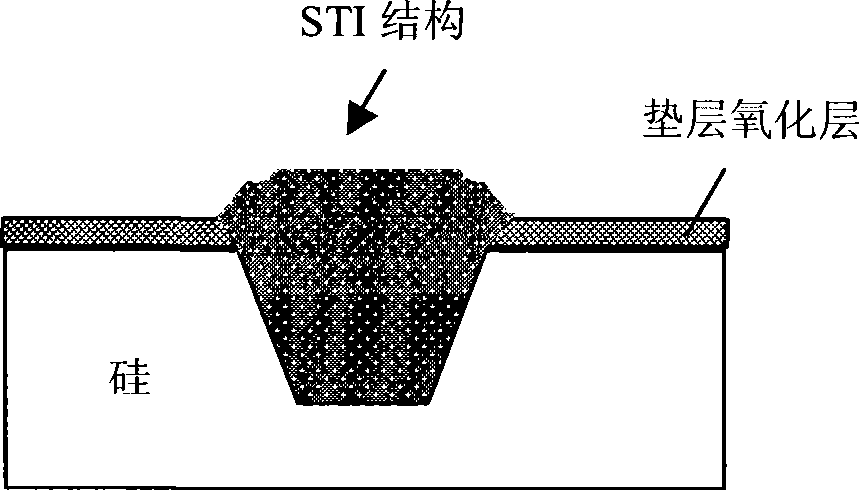

[0012] STI structure preparation method flow process of the present invention is:

[0013] (1) A pad oxide layer is grown on the substrate silicon, and then a hard mask layer (usually silicon nitride) is deposited. The function of the hard mask layer is to protect the silicon that does not need to be etched in the subsequent etching process. part;

[0014] (2) Photoresist coating and exposure development to define the position of the shallow groove;

[0015] (3) Hard mask layer etching and photoresist removal, the exposed hard mask layer is partially etched away, and a dry etching process can be used, and then the photoresist is removed;

[0016] (4) dry etching silicon, forming shallow grooves on the substrate silicon, and the etching process can be plasma etching;

[0017] (5) Thermally grow an oxide layer inside the groove, the purpose of which is to repair the surface of the groove damaged during the etching process, and the thickness of the oxide layer is the same as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com