Intelligent preassembled transformer substation and control method therefor

A prefabricated substation and control method technology, applied in the substation/distribution device casing, substation/switch layout details, substation/switchgear cooling/ventilation, etc., can solve the problem of fire inside the substation box and uncontrollable fire degree , substation scrap and other issues, to achieve the effect of fast cooling, avoid further expansion of fire, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

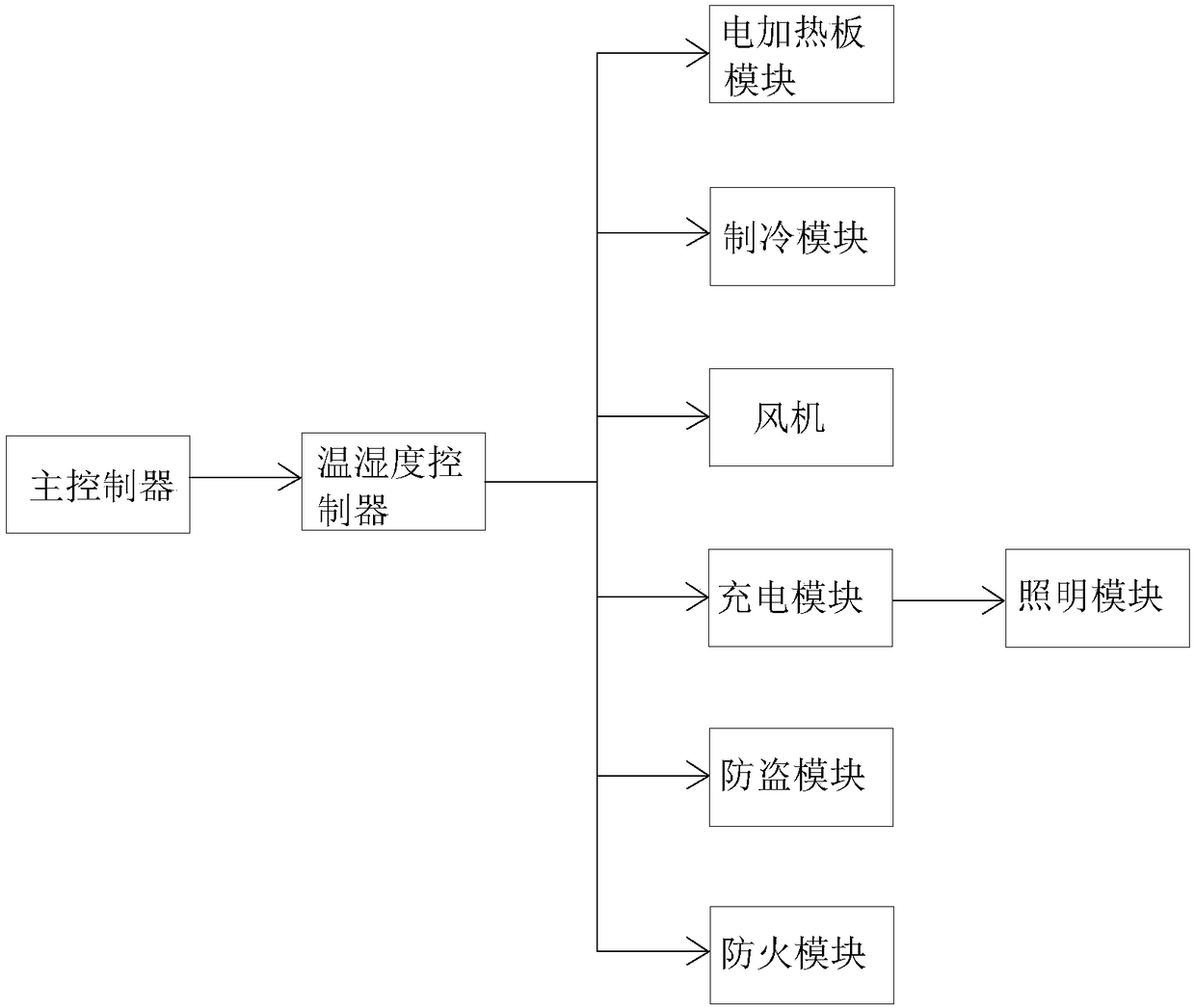

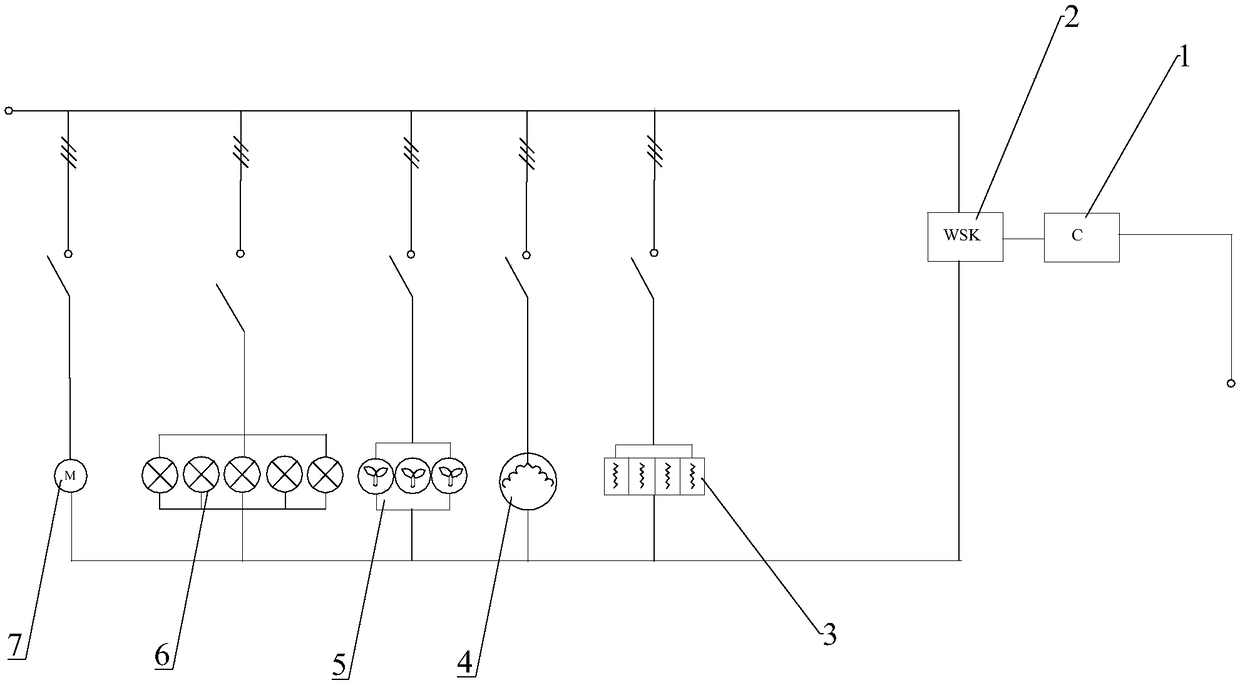

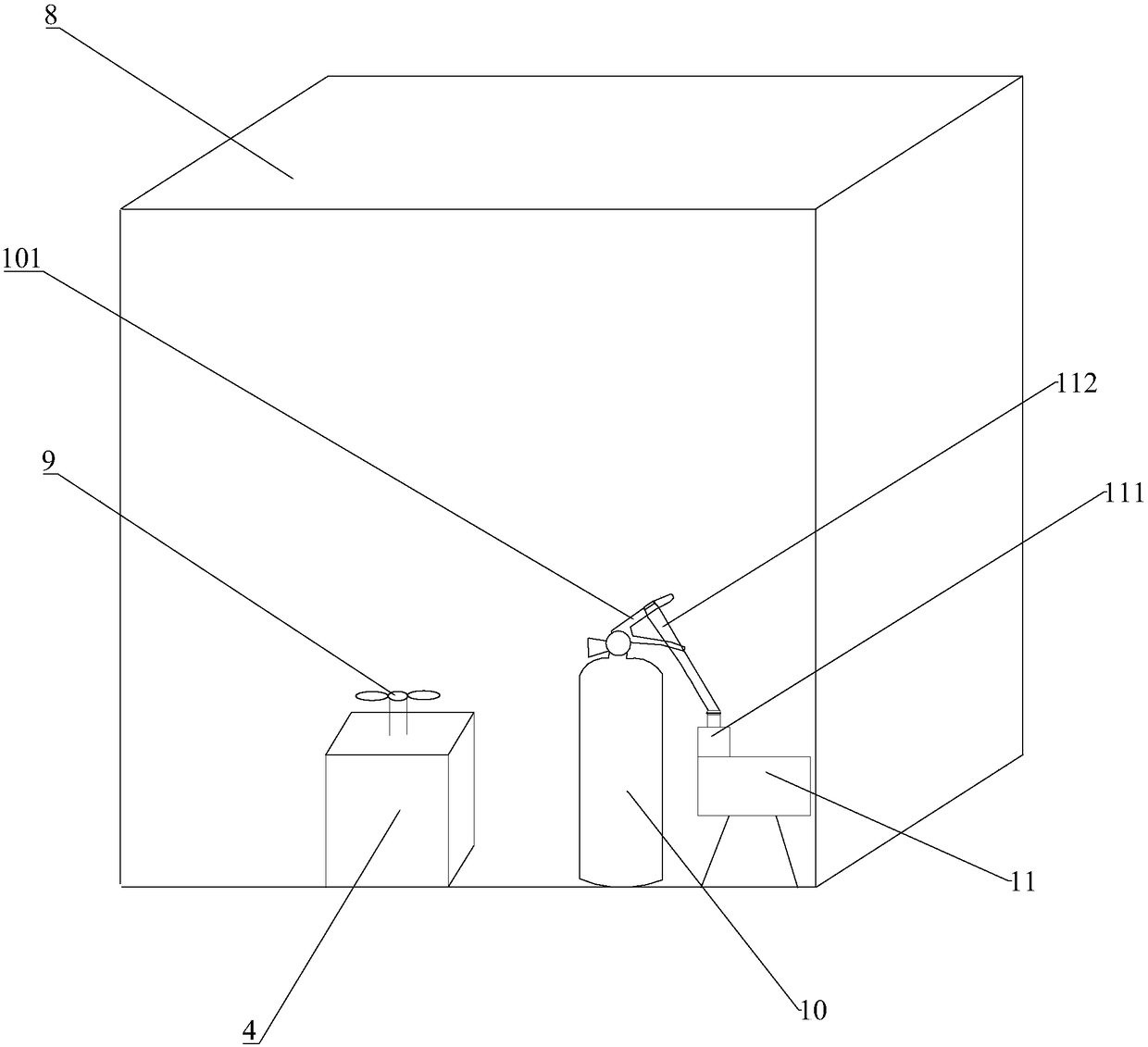

[0025] like Figure 1 to Figure 3 As shown, an intelligent prefabricated substation includes a main controller 1 installed inside the prefabricated substation box, the main controller 1 can be a PLC controller, and a temperature and humidity controller 2 connected to the main controller 1 1. The temperature and humidity controller can be a WSK temperature and humidity controller, and the electric heating plate module 3, the refrigeration module 4, the fan 5, the lighting module 6, the fire extinguishing module 7, and the anti-theft module are respectively connected to the temperature and humidity controller in turn; the electric heating plate module , Refrigeration module, fan, lighting module and fire extinguishing module are connected in parallel with each other; Refrigeration module 4 includes a compressor, an evaporator, an expansion valve and a condenser connected in sequence; Fire extinguishing module 7 includes a fire extinguisher 10 and a telescopic mechanism, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com