3cr oil well pipe and its production method

A production method and oil well pipe technology, applied in the field of metallurgy, can solve the problems of unsatisfactory mechanical properties and high cost of 3Cr seamless steel pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

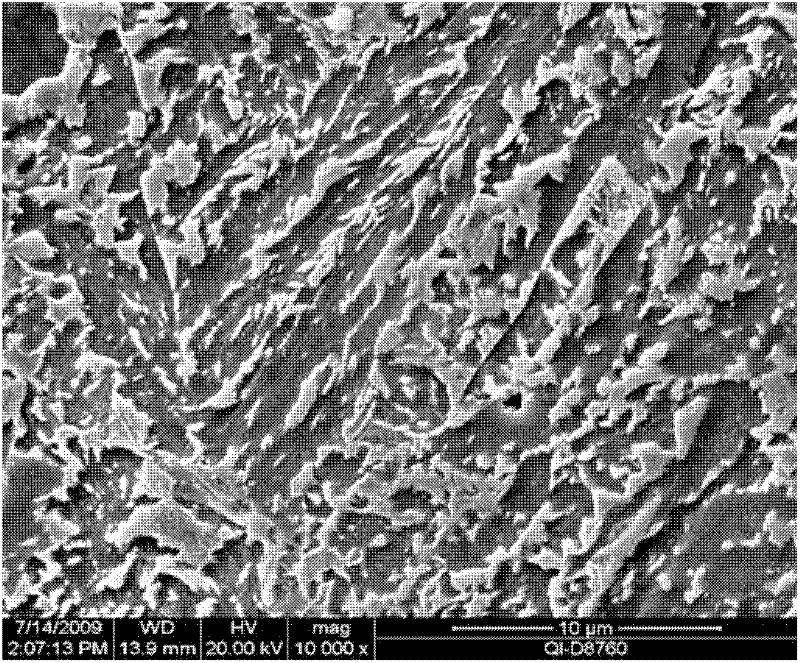

Image

Examples

Embodiment 1

[0028] According to the API 5CT standard P110 steel grade, the production specification is 139.7×9.17mm 3Cr seamless steel pipe. The steel material is 2Cr3Mo. The chemical composition is shown in Table 1. The balance is Fe and unavoidable impurities in terms of weight percentage.

[0029] Table 1-1 2Cr3Mo chemical composition

[0030] C

[0031] The rare earth element is 0.2%, among which europium: 0.08%, bismuth: 0.08%, cobalt: 0.04%.

[0032] Production process: selection of raw materials, smelting (including refining outside the furnace), continuous casting, continuous rolling, reheating, tension sizing and quenching and tempering heat treatment.

[0033] Reheating and tension sizing: hot rolling at 850°C, sizing by a micro-tension reducer, so that the change in the outer diameter of the billet is 30%, and a second sizing at 500°C after heat treatment, so that the change in the outer diameter is 5%, and warm straightening at 500°C.

[0034] Quenching and tempe...

Embodiment 2

[0044] According to the API 5CT standard P110 steel grade production specification is 224.5×7.92mm3Cr seamless steel pipe, the steel material is 2Cr3Mo, the chemical composition is shown in Table 1, by weight percentage, and the balance is Fe.

[0045] Table 2-1 2Cr3Mo chemical composition

[0046] C

[0047] The rare earth element is 0.1%, among which europium: 0.05%, bismuth: 0.01%, cobalt: 0.04%.

[0048] Production process: raw material selection, smelting, continuous casting, continuous rolling, reheating, tension sizing and quenching and tempering heat treatment. The quenching and tempering heat treatment adopts the quenching + high temperature tempering heat treatment process, the quenching temperature is 850 ℃ ~ 870 ℃, the quenching medium is water, the holding time is 40 minutes, the tempering temperature is 600 ~ 660 ℃, and the holding time is 100 minutes.

[0049] Take three groups of 3Cr oil well pipe samples and test the mechanical performance data, t...

Embodiment 3

[0056] According to the API 5CT standard P110 steel grade production specification is 224.5×7.92mm3Cr seamless steel pipe, the steel material is 2Cr3Mo, the chemical composition is shown in Table 1, by weight percentage, the balance is Fe and unavoidable impurities.

[0057] Table 2-1 2Cr3Mo chemical composition

[0058] C

Si

mn

S

P

Cr

V

Mo

Al

B

0.187

0.221

0.691

0.001

0.002

2.67

0.003

0.122

0.005

0.007

[0059] It also contains 0.005% of rare earth elements; of which europium: 0.002%, bismuth: 0.001%, cobalt: 0.002%.

[0060] Production process: raw material selection, smelting, continuous casting, continuous rolling, reheating, tension sizing and quenching and tempering heat treatment.

[0061] Reheating and tension sizing: hot rolling at 800°C, sizing by a micro-tension reducer, so that the change in the outer diameter of the billet is 10%, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com