Wafer level vacuum encapsulation of microelectron mechanical system and upside-down mounting soldering method thereof

A micro-electronic machinery and vacuum packaging technology, applied in opto-mechanical equipment, microstructure devices, chemical instruments and methods, etc., can solve the problems of rare reports on the application of MEMS devices, and achieve the improvement of overall performance and yield, high packaging density, The effect of improving accuracy and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

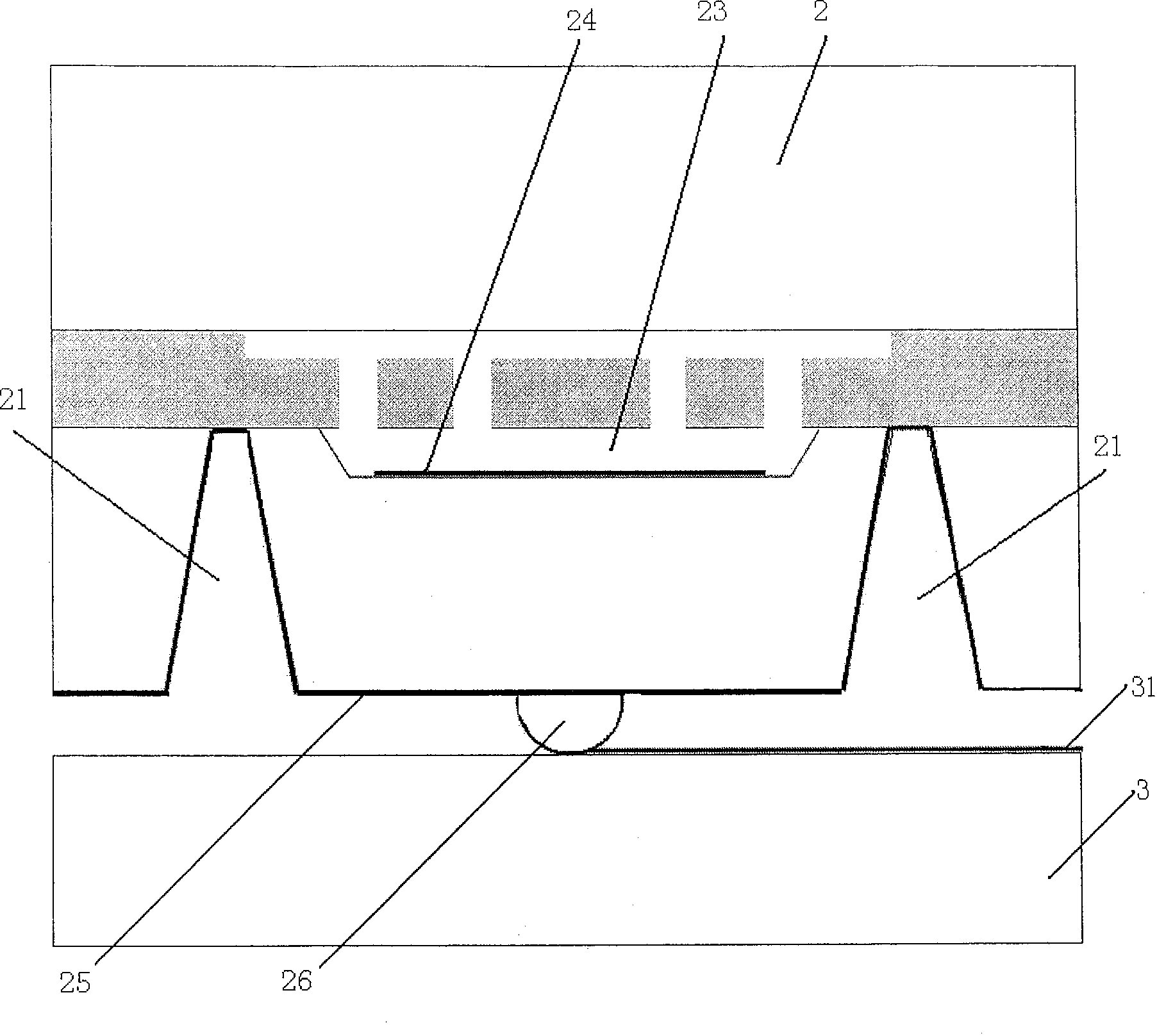

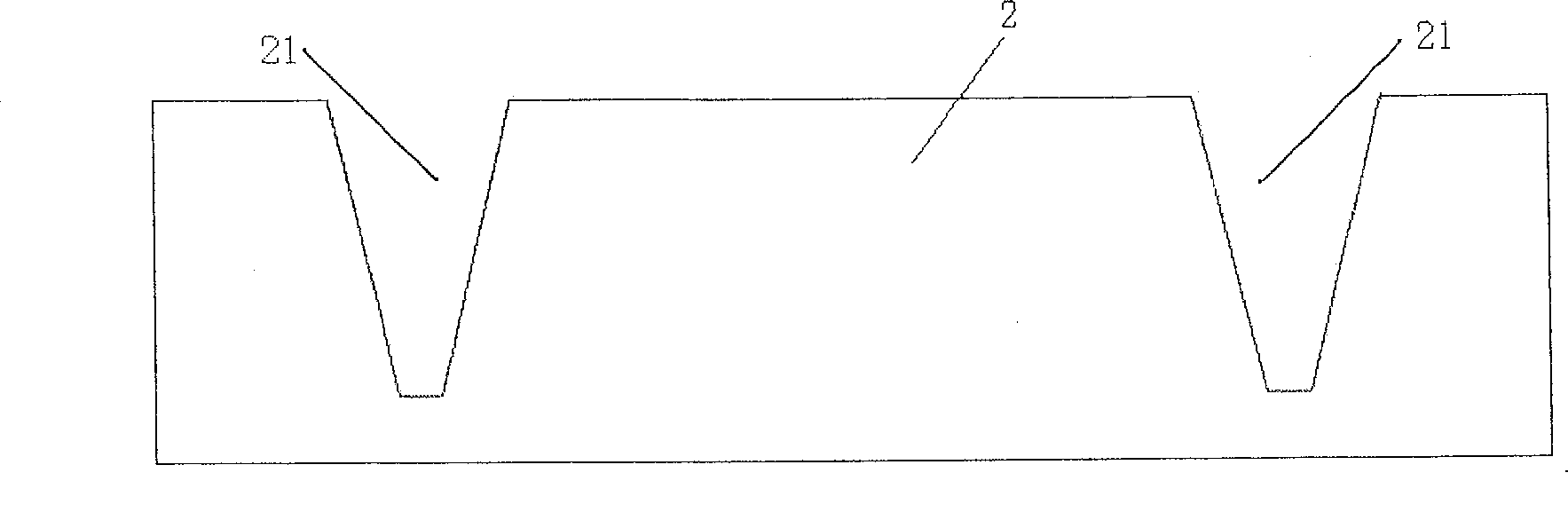

[0022] Such as figure 1 As shown, the present invention is mainly composed of a MEMS device structure wafer 1 , a cap glass wafer 2 and a peripheral processing circuit 3 . A MEMS device structure wafer 1 is composed of several hundred (determined by the size of the MEMS device chip) independent MEMS device chips. There are hundreds of vertical lead holes 21 on the cap glass sheet 2, and the number of lead holes 21 is equal to the product of the number of MEMS device chips on the MEMS device structure wafer 1 and the number of electrodes of the MEMS device chips. 2, process hundreds of glass cavities 23 (the number of the glass cavities corresponds to the number of MEMS chips), to protect the structure of the MEMS device chip, the glass cavities 23 are sputtered or coated with a getter 24 , the electrode leads 25 are placed in the lead holes 21, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com