Patents

Literature

37results about How to "Fully utilize the area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

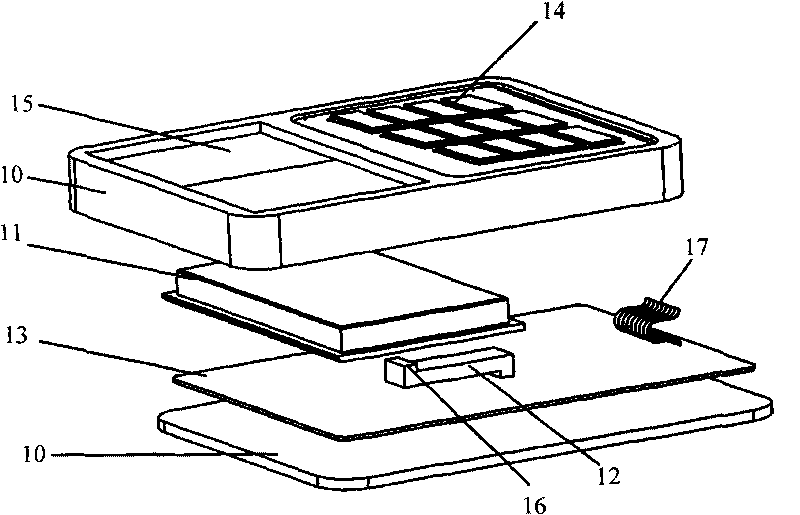

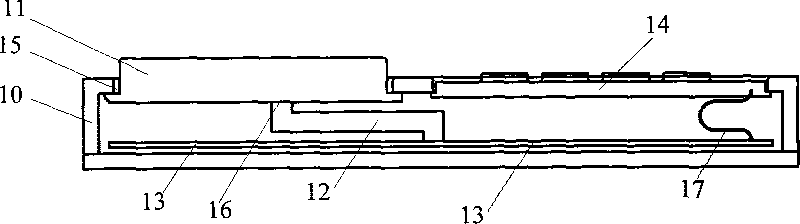

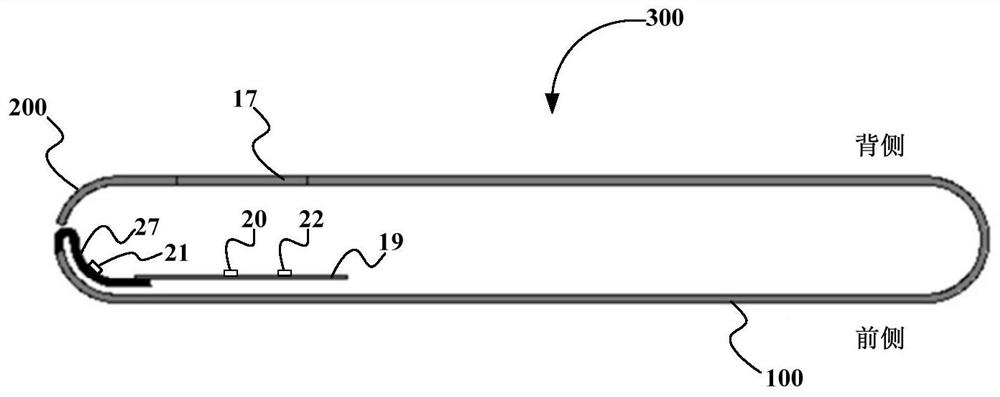

Portable electronic device capable of weighing

InactiveCN101692680ARealize functionFunction does not affectTelephone set constructionsSpecial purpose weighing apparatusDisplay deviceLoad cell

Owner:理康互联科技(北京)有限公司

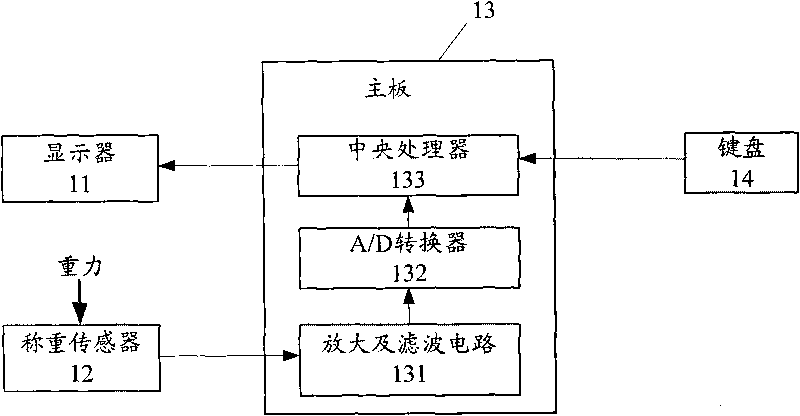

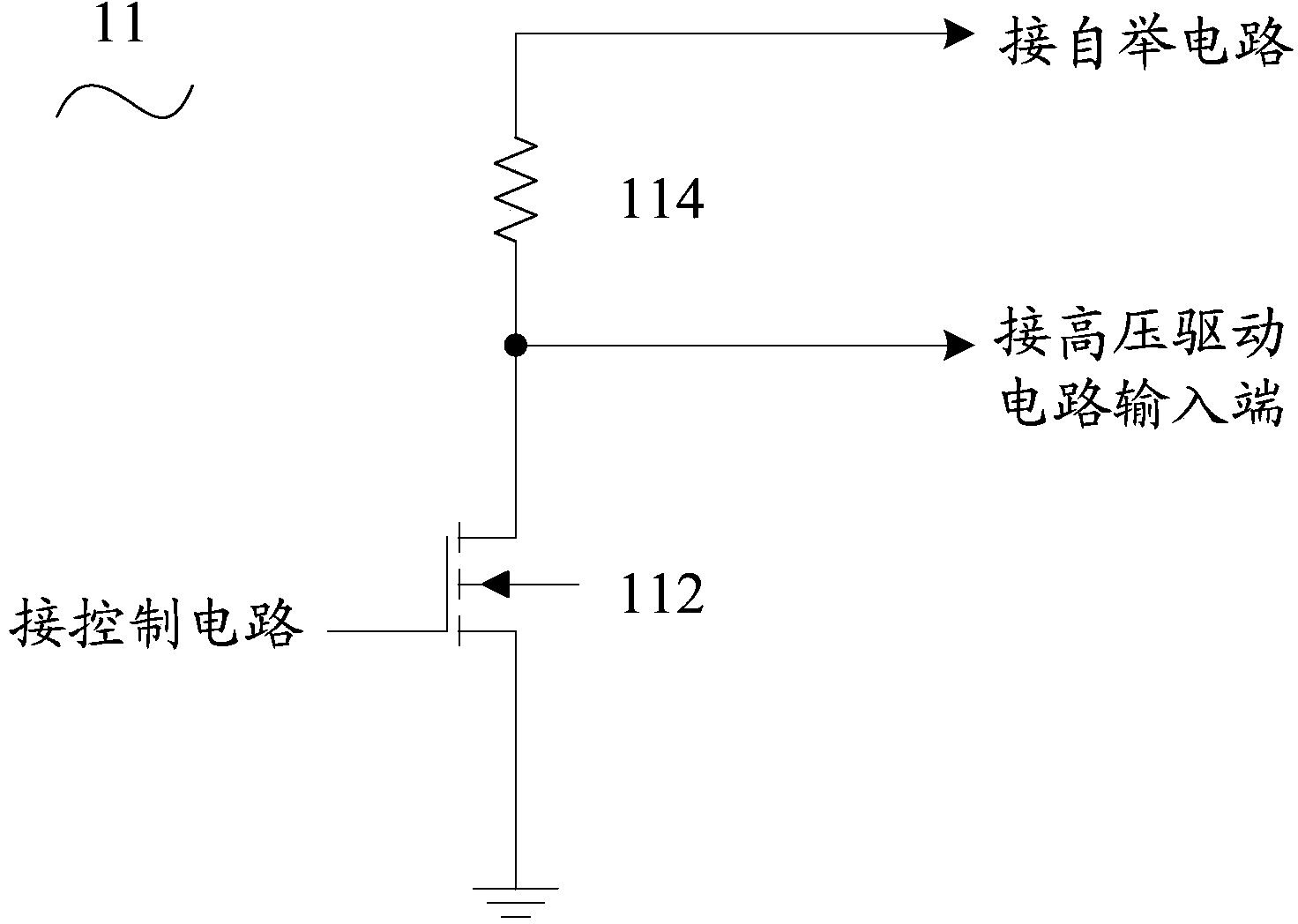

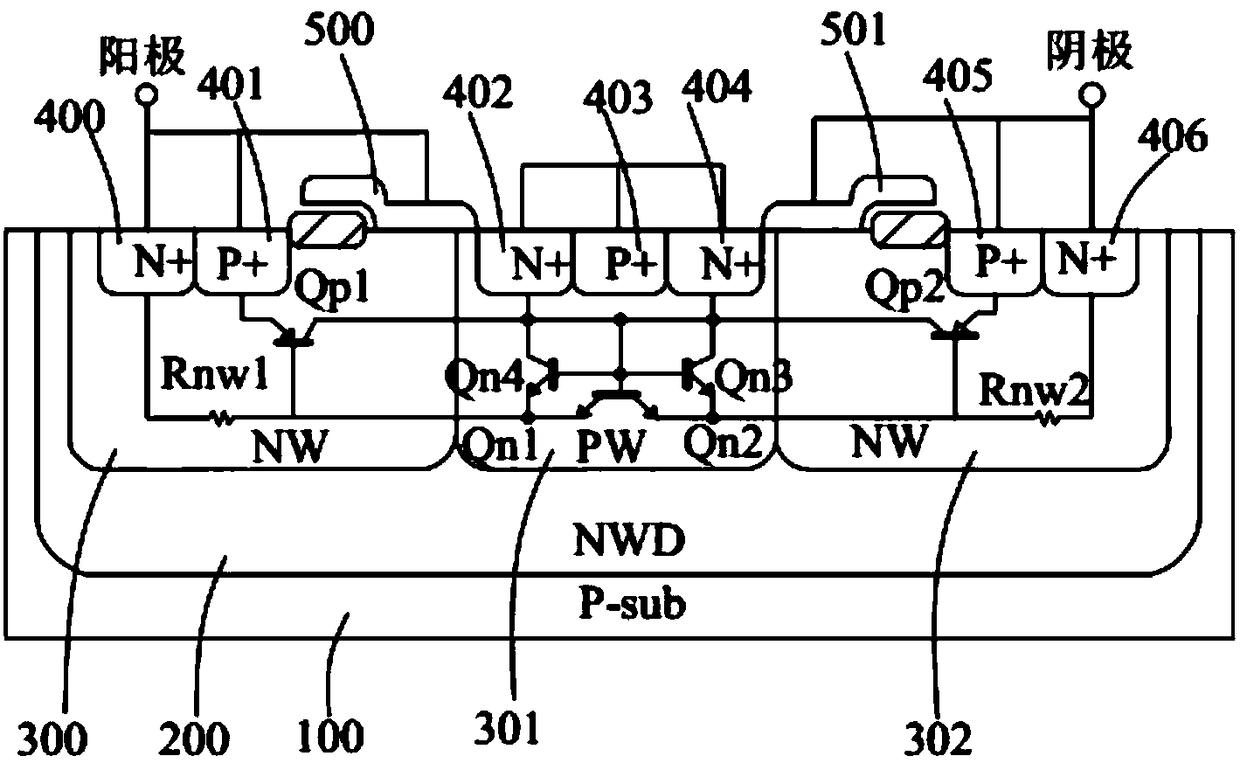

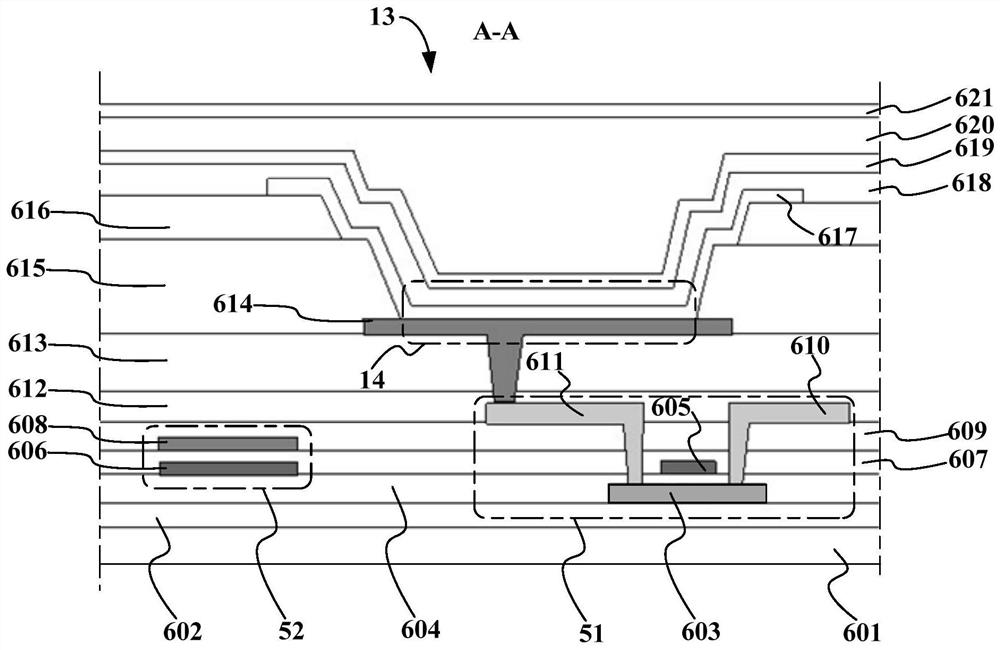

Integrated circuit chip with level shift LDMOS embedded in junction terminal and manufacturing method thereof

ActiveCN104022110AFully utilize the areaReduce areaSolid-state devicesSemiconductor/solid-state device manufacturingVoltageEngineering

The invention relates to an integrated circuit chip with a level shift LDMOS embedded in a junction terminal. The integrated circuit chip comprises the junction terminal located on the periphery of the chip, a high basin region surrounded by the junction terminal and a bootstrap level region arranged between the junction terminal and the high basin region. The level shift LDMOS is embedded in the junction terminal. The integrated circuit chip further comprises an isolating ring and a metal interconnection line. The level shift LDMOS and the junction terminal are isolated by the isolating ring. The metal interconnection line starts from the drain electrode of the level shift LDMOS, goes across a part of the junction terminal, the isolating ring and the high basin region and then is connected to the bootstrap level region. The invention further relates to a manufacturing method of the integrated circuit chip with the level shift LDMOS embedded in the junction terminal. According to the integrated circuit chip, since the voltage on the metal interconnection line is small, the influence on the region which the metal interconnection line goes across is small, and the influence on a withstand voltage is also small. Besides, due to the fact that the level shift LDMOS is embedded in the high-voltage junction terminal, the area of the high-voltage junction terminal is fully utilized, and the area of the chip can be saved.

Owner:CSMC TECH FAB2 CO LTD

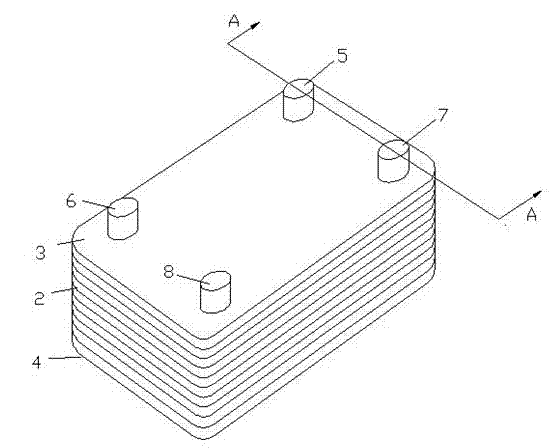

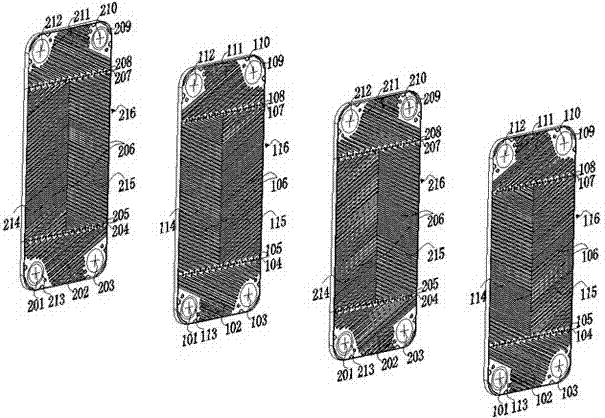

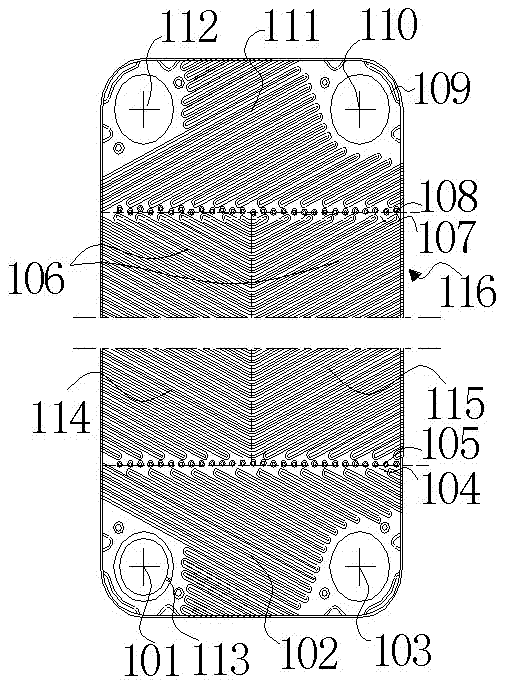

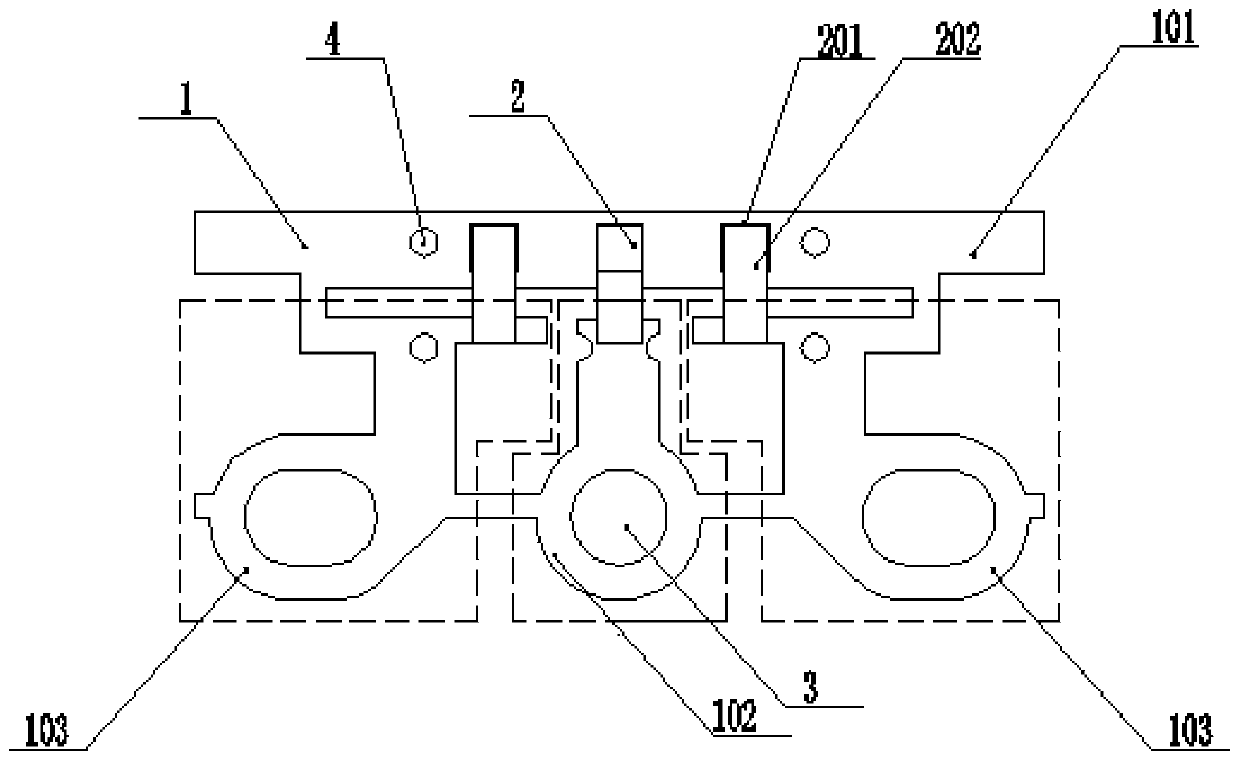

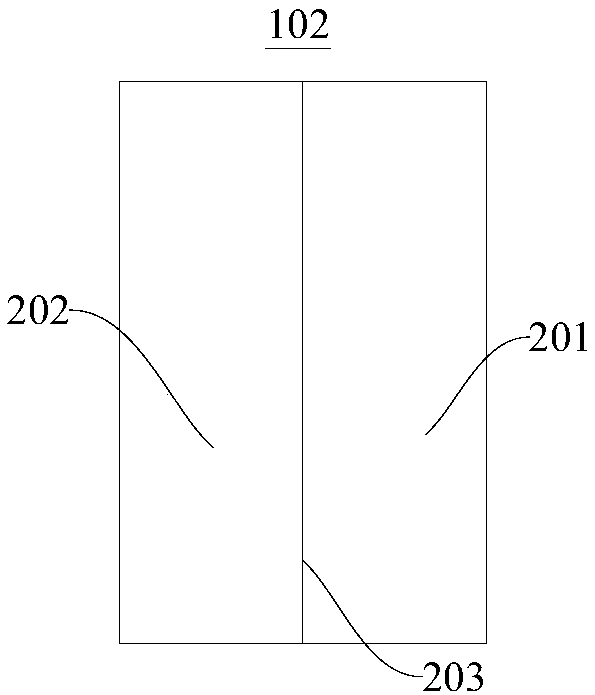

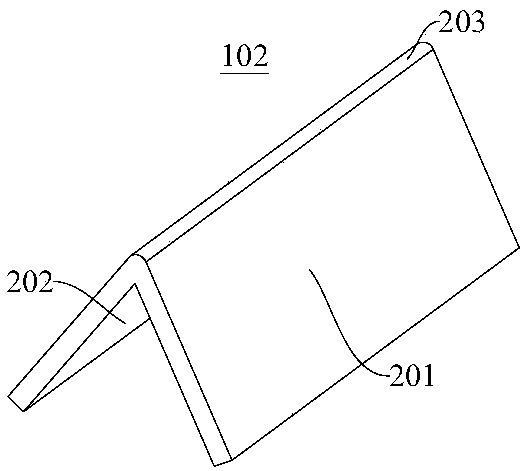

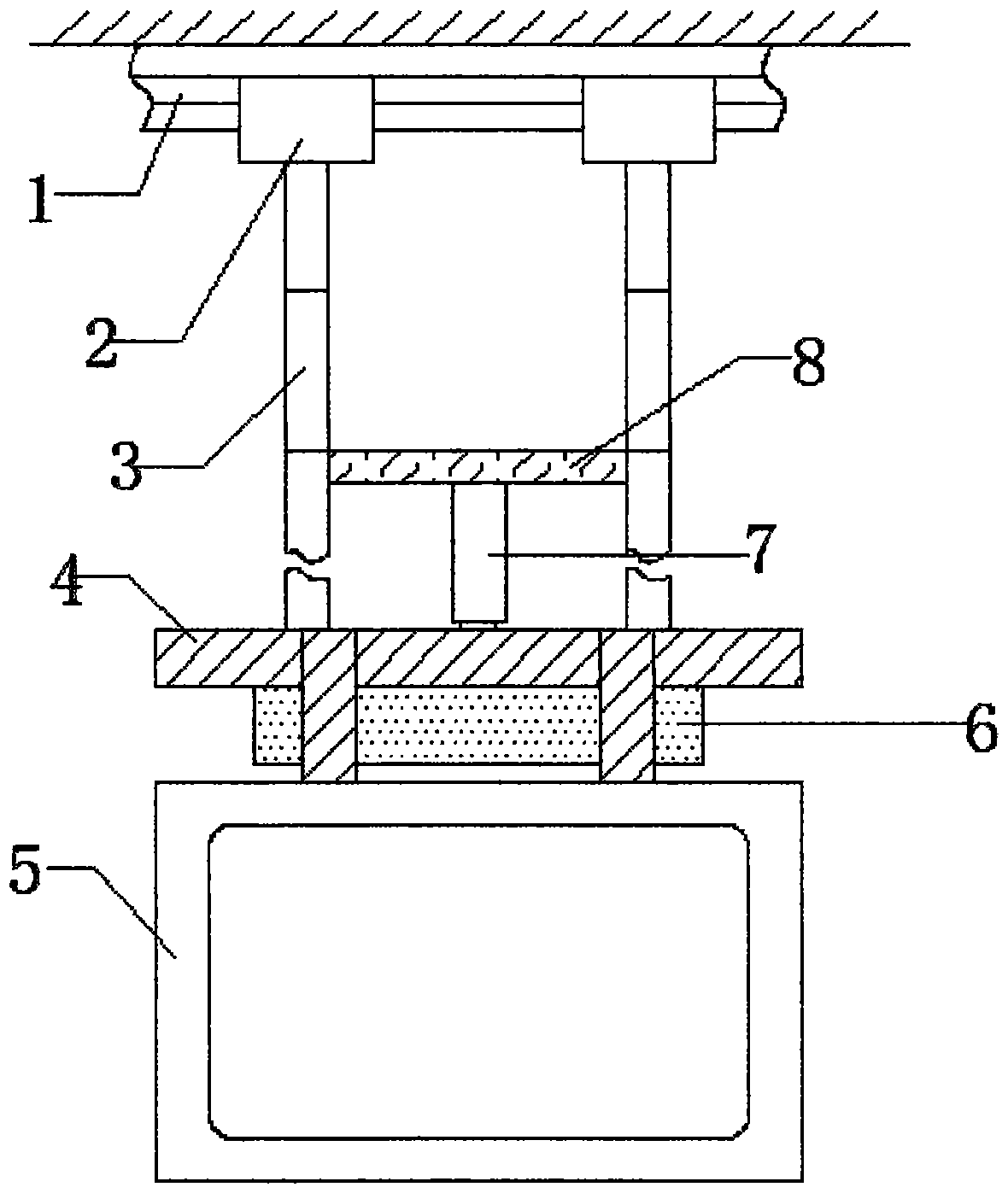

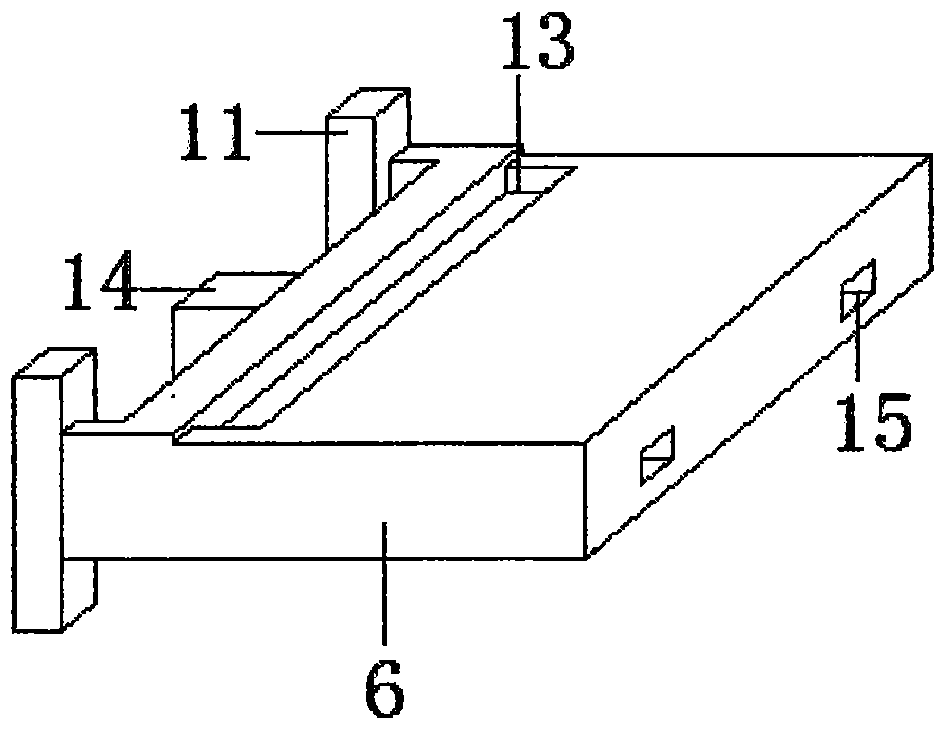

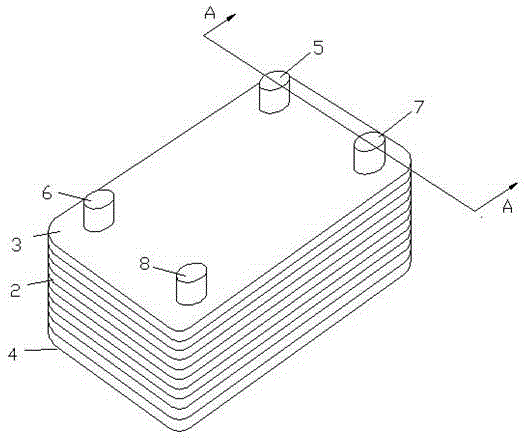

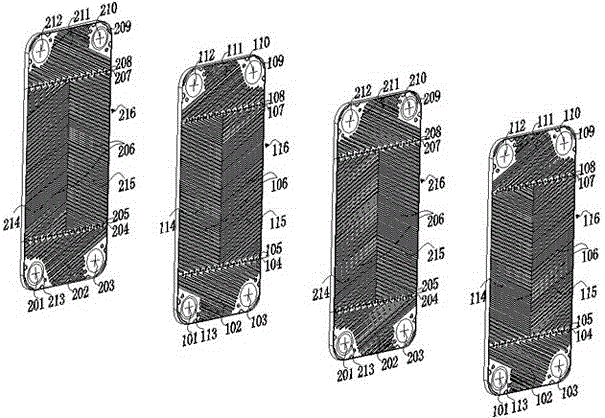

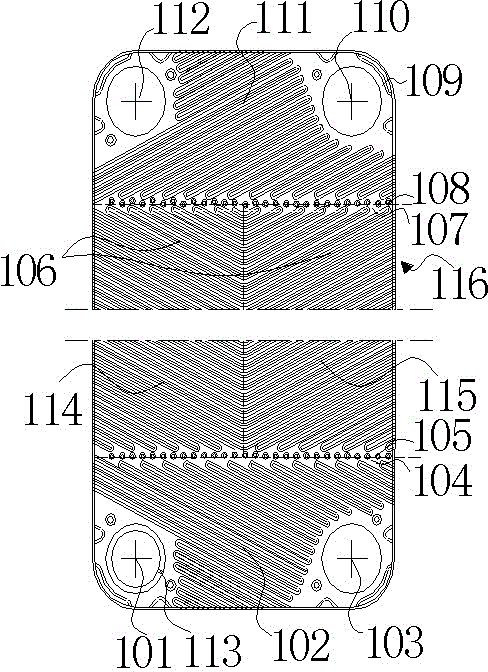

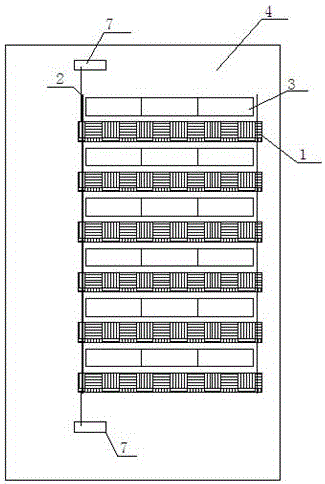

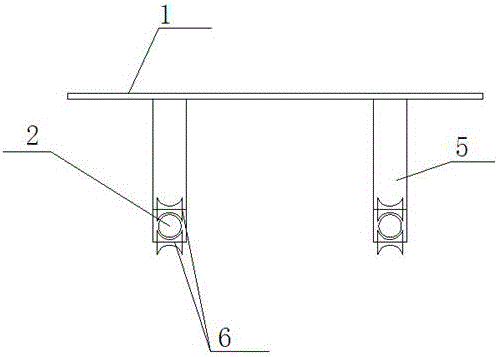

Plate-type heat exchanger with secondary throttling function

ActiveCN102809311AIncrease resistanceReduce resistanceHeat exchange apparatusStationary plate conduit assembliesRefrigerantMechanical engineering

The invention discloses a plate-type heat exchanger with a secondary throttling function. The plate-type heat exchanger comprises a front end plate and a rear end plate; fluid interface channels are arranged symmetrically on the front end plate and the rear end plate; heat-exchanging plate units are arranged between the front end plate and the rear end plate and are overlapped in sequence; each heat-exchanging plate unit consists of a first heat-exchanging plate and a second heat-exchanging plate; one distributing zone is arranged between a heat-exchanging zone and a first flow guiding zone; one distributing zone is arranged between the heat-exchanging zone and a second flow guiding zone; one distributing zone is arranged between the other heat-exchanging zone and the other first flow guiding zone; and one distributing zone is arranged between the other heat-exchanging zone and the other second flow guiding zone. By using the plate-type heat exchanger with the secondary throttling function, provided by the invention, the resistance of the refrigerant flowing through a channel between the heat-exchanging zones on the corner hole sides of an inlet and an outlet is increased, the resistance of the refrigerant flowing through the channel between the heat-exchanging zones is decreased, and the refrigerant is uniformly distributed on the whole surface of the heat-exchanging zone, in this way, the areas of the heat-exchanging plates are used sufficiently.

Owner:JIANGSU BAODE HEAT EXCHANGER EQUIP

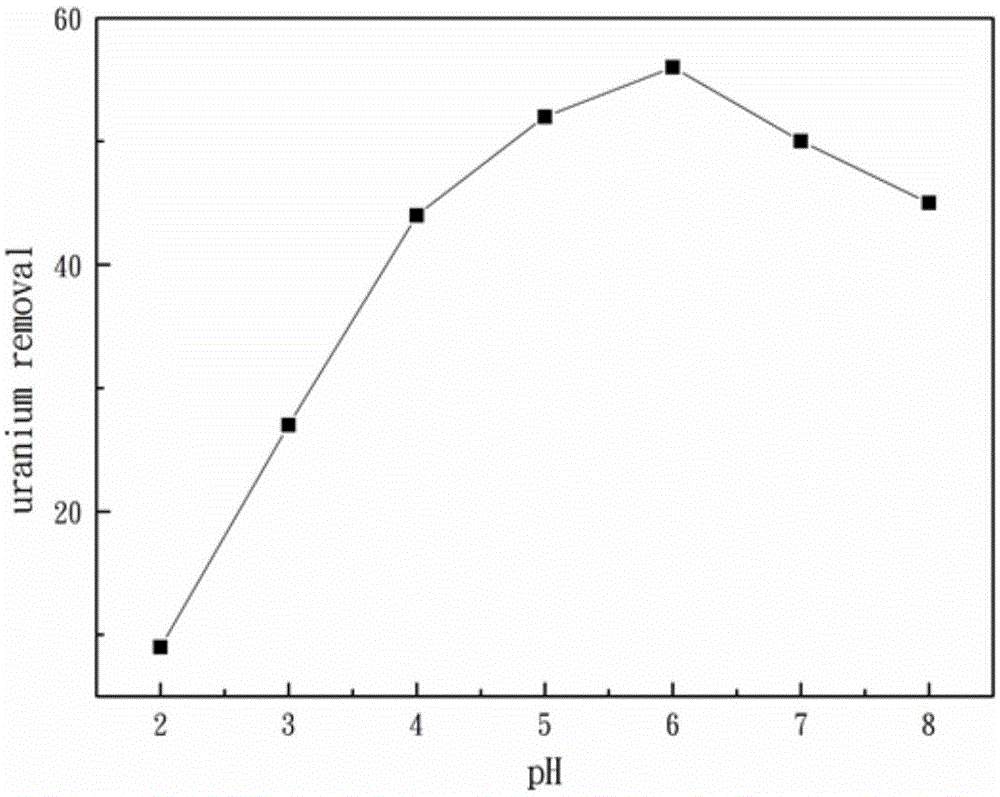

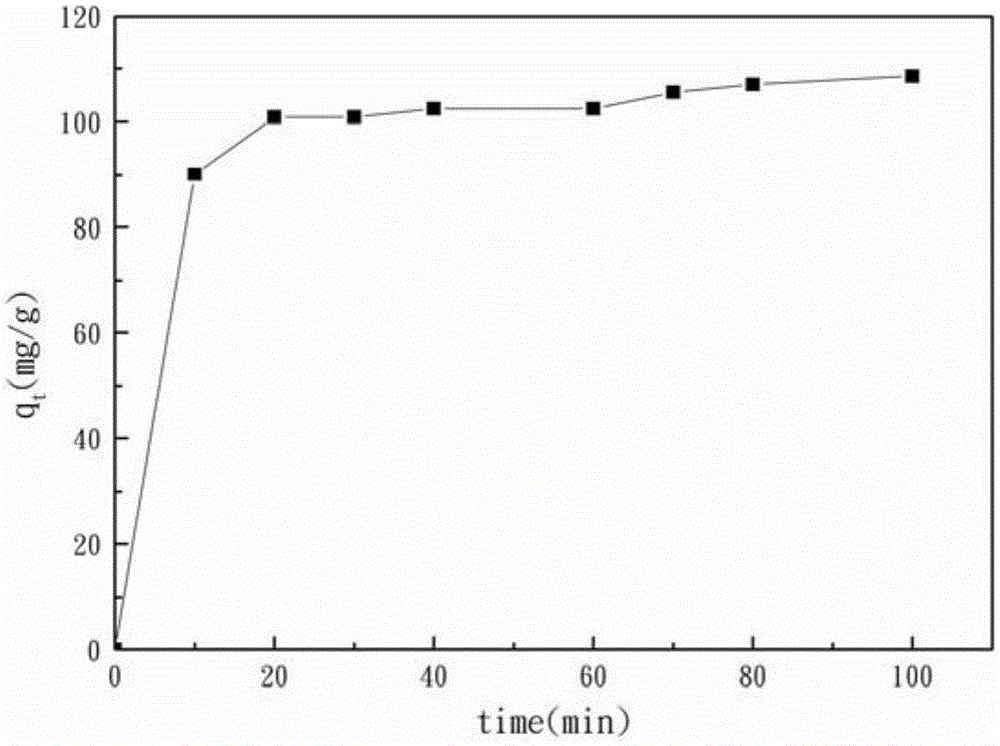

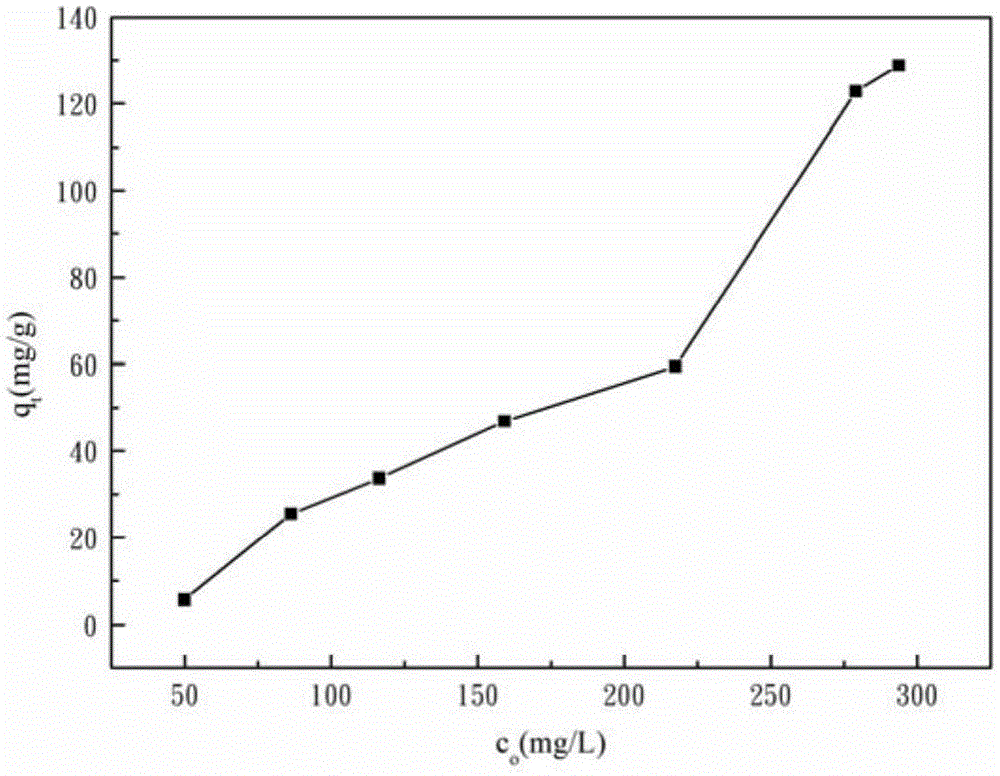

Application of porous orderly silicon dioxide foam material to processing of radionuclide uranium in waste water

InactiveCN105139910AFully utilize the areaMake full use of the pore volumeRadioactive decontaminationWastewaterRadioactive waste

The invention discloses application of a porous orderly silicon dioxide foam material to processing of radionuclide uranium in waste water. The addition amount of the porous orderly silicon dioxide foam material in the waste water is not less than 0.02 mg / ml, and the pH value of the waste water is 2 to 8. The effect of the porous orderly silicon dioxide foam material for removing radionuclide uranium in the waste water is good, the removal rate can reach 99%, the porous orderly silicon dioxide foam material has good capacity for removing uranium ions in the waste water, and damage of the radioactive waste water to the environment can be reduced.

Owner:NANJING UNIV OF SCI & TECH

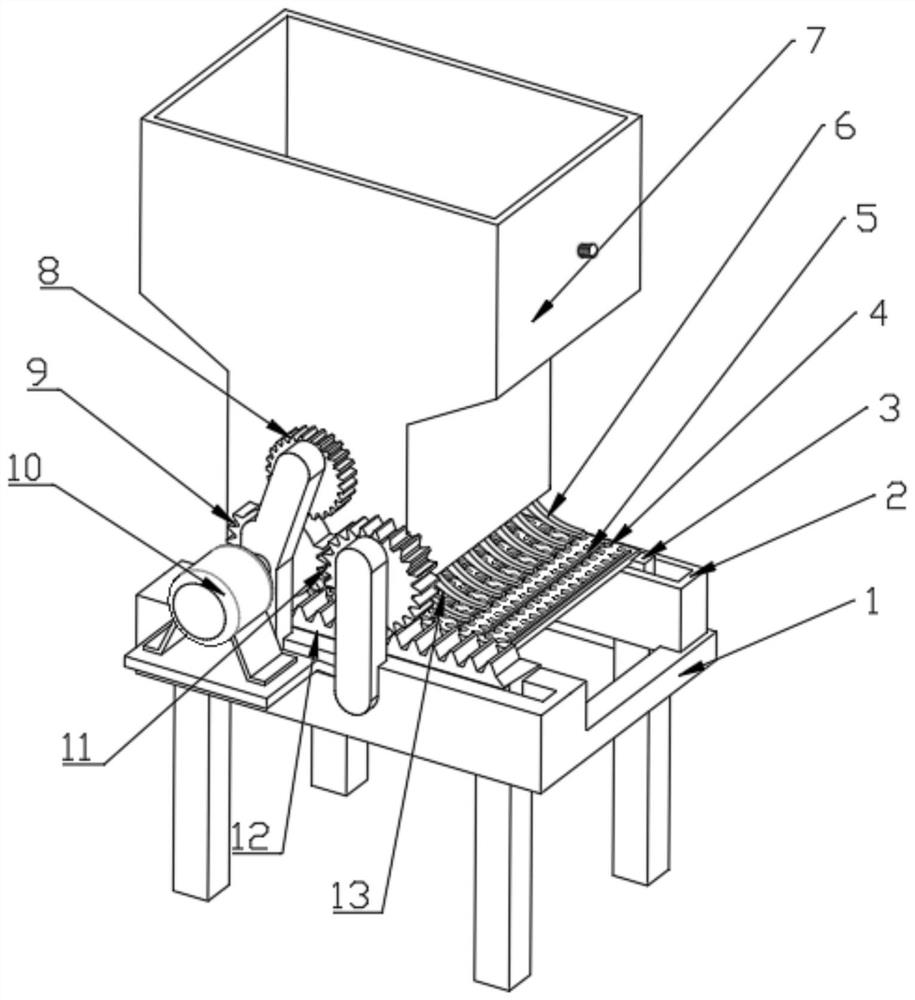

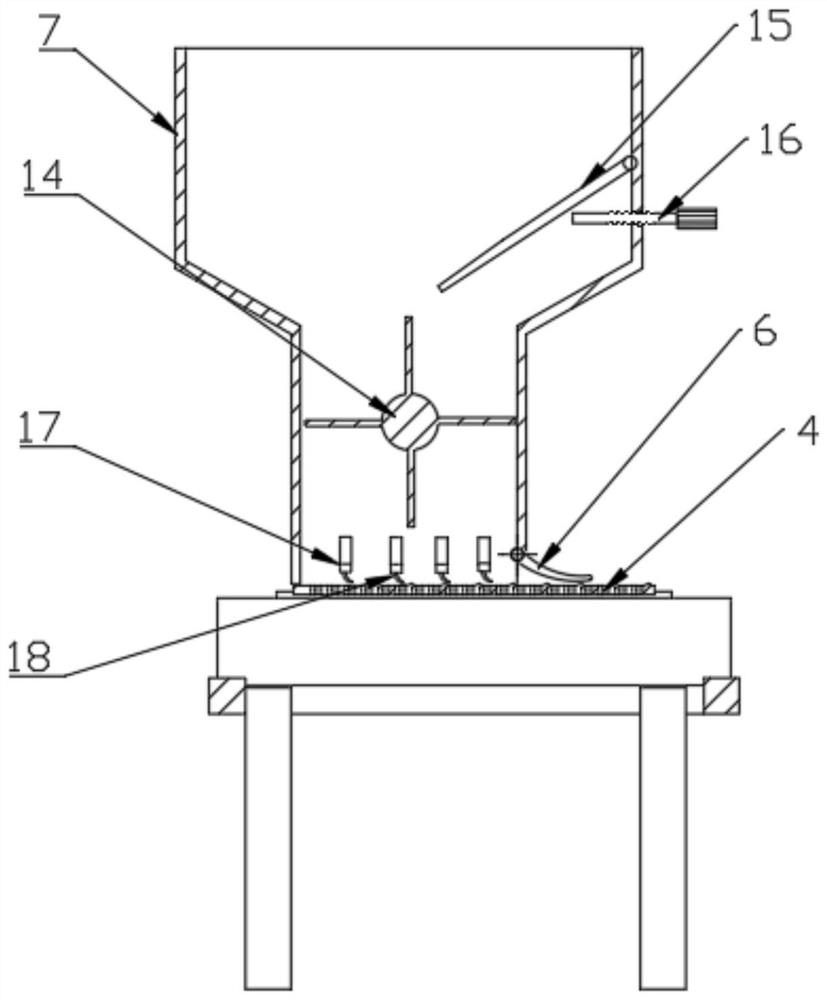

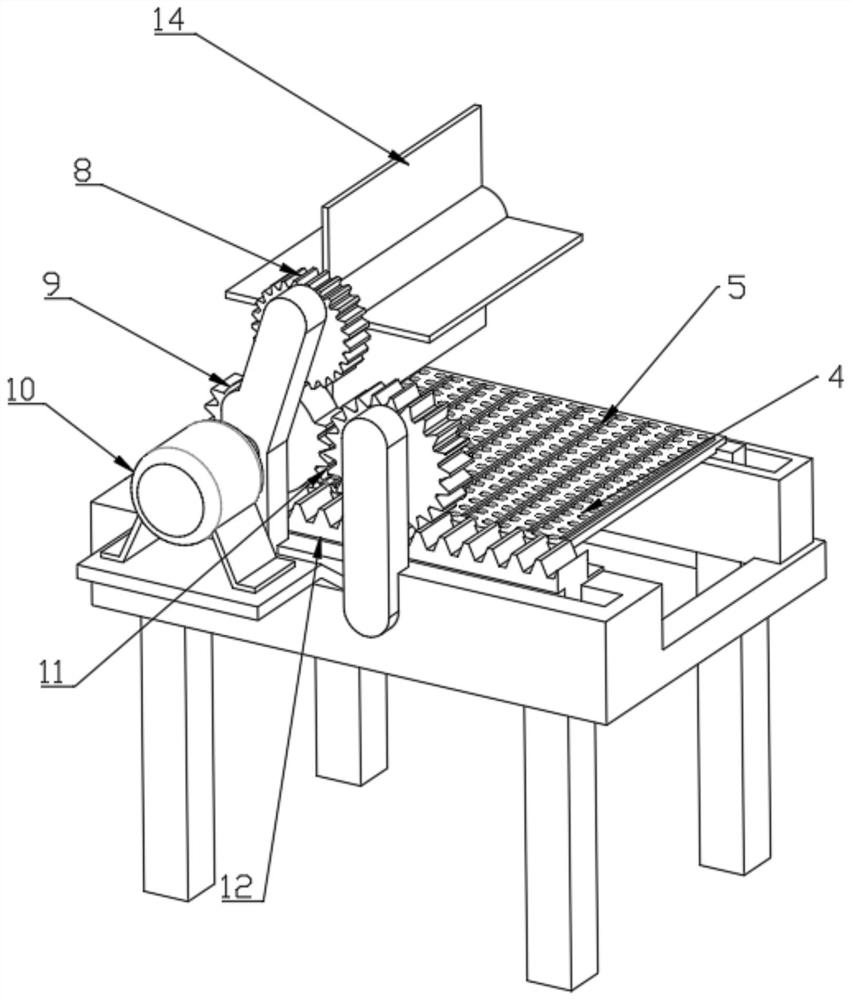

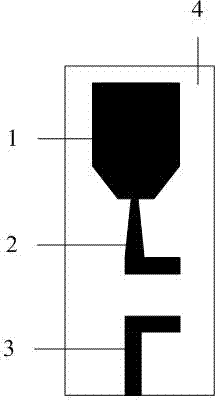

Concrete raw material screening device

The invention is applicable to the technical field of concrete, and provides a concrete raw material screening device. The screening device comprises a machine frame used for supporting and mounting,a hopper fixedly installed on the machine frame and used for containing concrete raw materials, a sieve plate slidably arranged on the machine frame below the hopper and used for sieving the concreteraw materials, a feeding roller rotationally arranged in the hopper and used for controlling feeding of the concrete raw materials, and a driving part connected with the feeding roller and the sieve plate through transmission parts and used for driving the feeding roller to rotate for feeding and driving the sieve plate to slide for screening, wherein the transmission parts comprise a first gear,an intermittent gear, a second gear and a rack, the rack is at least fixed to one end of the non-sliding side of the sieve plate, the first gear, the intermittent gear and the second gear are rotationally connected to the machine frame, and the second gear is meshed with the rack. The screening device has the advantages of simple structure, convenient operation, energy conservation, good synchronism, high screening efficiency and convenience in popularization and implementation.

Owner:李淑敏

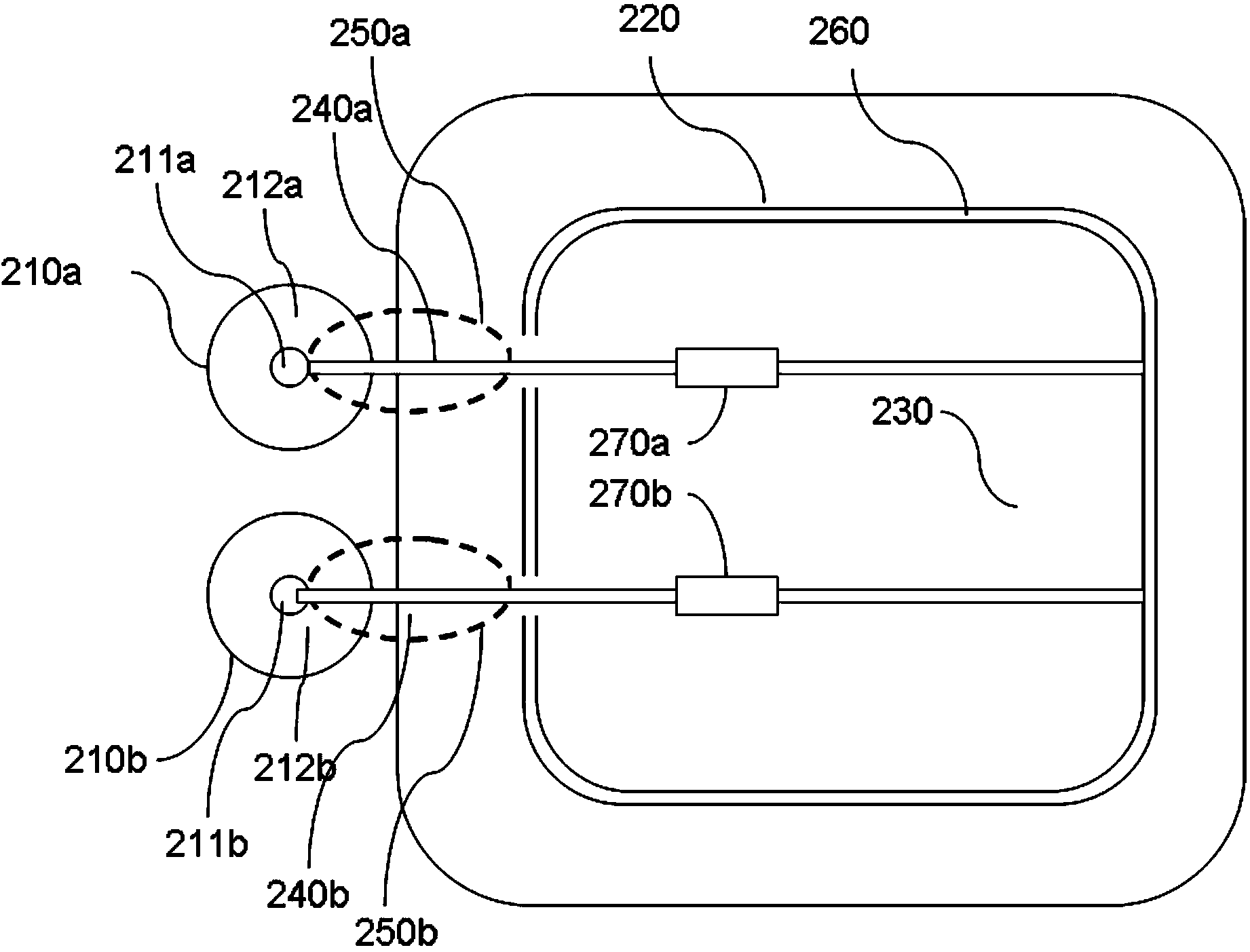

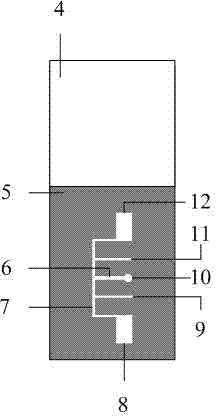

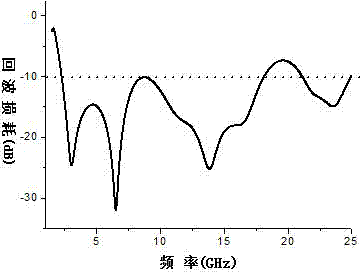

Integrated ultra wide band antenna of fusion slot line ultra wide band filter unit

InactiveCN103943950ASmall sizeGood ultra-wideband characteristicsRadiating elements structural formsAntenna earthingsUltra wideband antennasOut of band rejection

The invention discloses an integrated ultra wide band antenna of a fusion slot line ultra wide band filter unit. The integrated ultra wide band antenna of the fusion slot line ultra wide band filter unit is composed of a branch loading slot line resonant cell and a hexagonal paster radiation unit in a cascading mode. The hexagonal paster radiation unit is composed of a main hexagonal paster radiation unit and a gradual micro-strip line, wherein the main hexagonal paster radiation unit is composed of a trapezoid and a rectangle; the branch loading slot line resonant cell is composed of a U-shaped slot line resonant cell and three loaded slot line branches, wherein two ends of the U-shaped slot line resonant cell are connected with a stepped impedance cell, the three branches are uniformly distributed in a resonator, and the end of the middle branch is connected with a circular slot line paster. Compared with a traditional ultra wide band filter, the integrated ultra wide band antenna of the fusion slot line ultra wide band filter unit greatly improves the out-of-band rejection characteristic of the ultra wide band antenna based on guaranteeing the circuit volume, effectively reduces the reflection and consumption of the antenna in cascading, and enables the whole performance to be improved. The integrated ultra wide band antenna of the fusion slot line ultra wide band filter unit achieves the frequency selectivity of the ultra wide band without changing a feeder structure.

Owner:EAST CHINA JIAOTONG UNIVERSITY

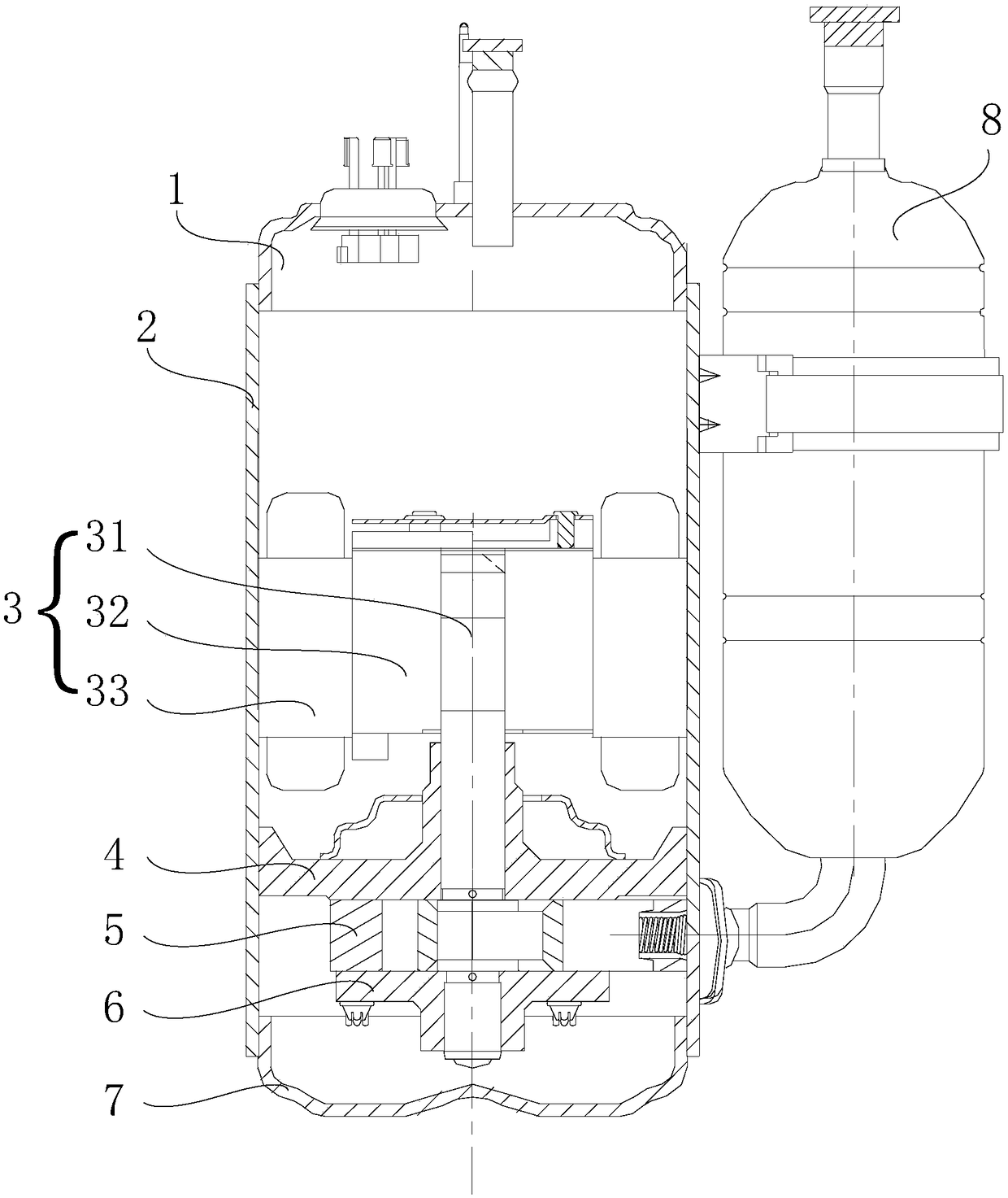

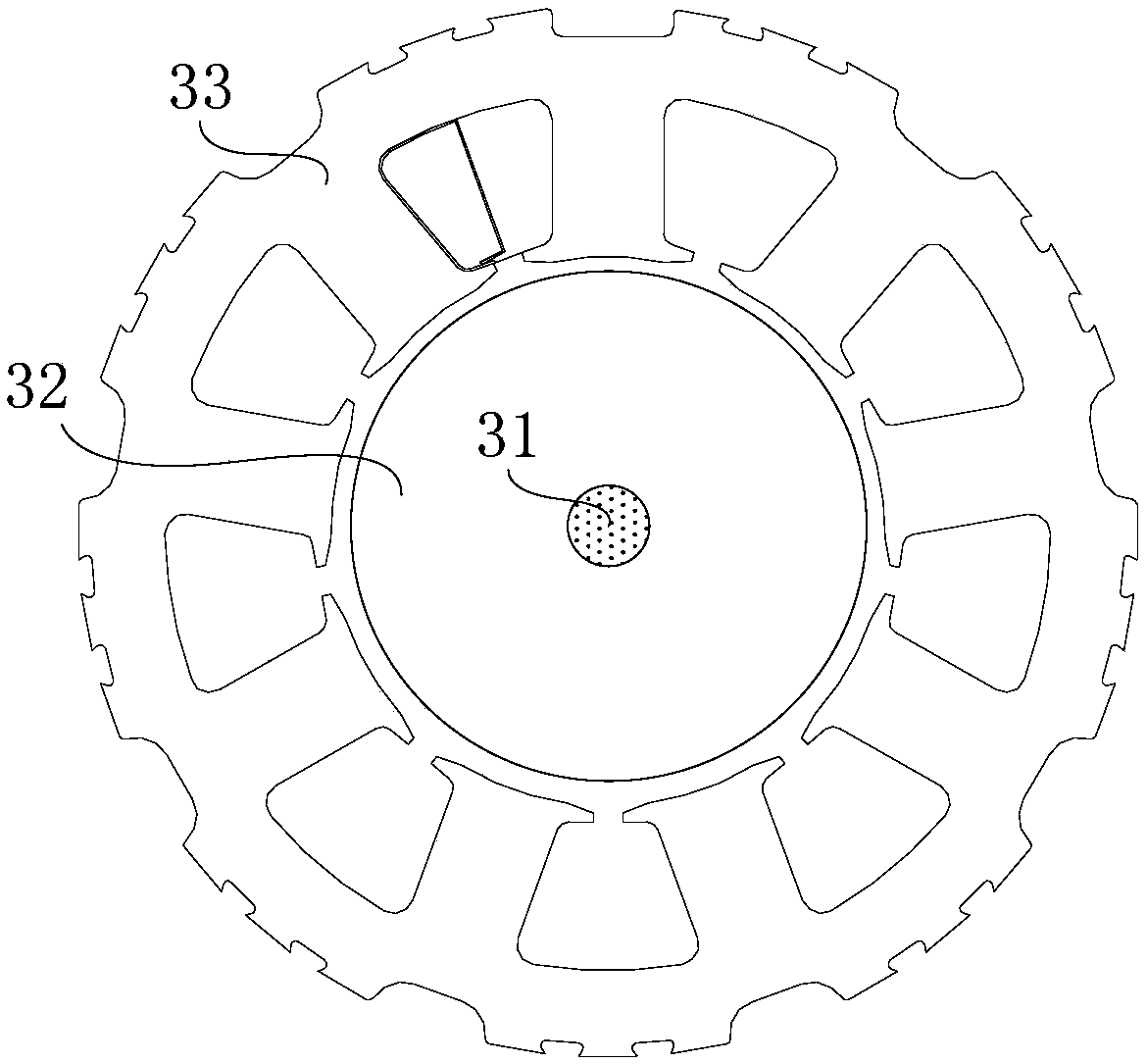

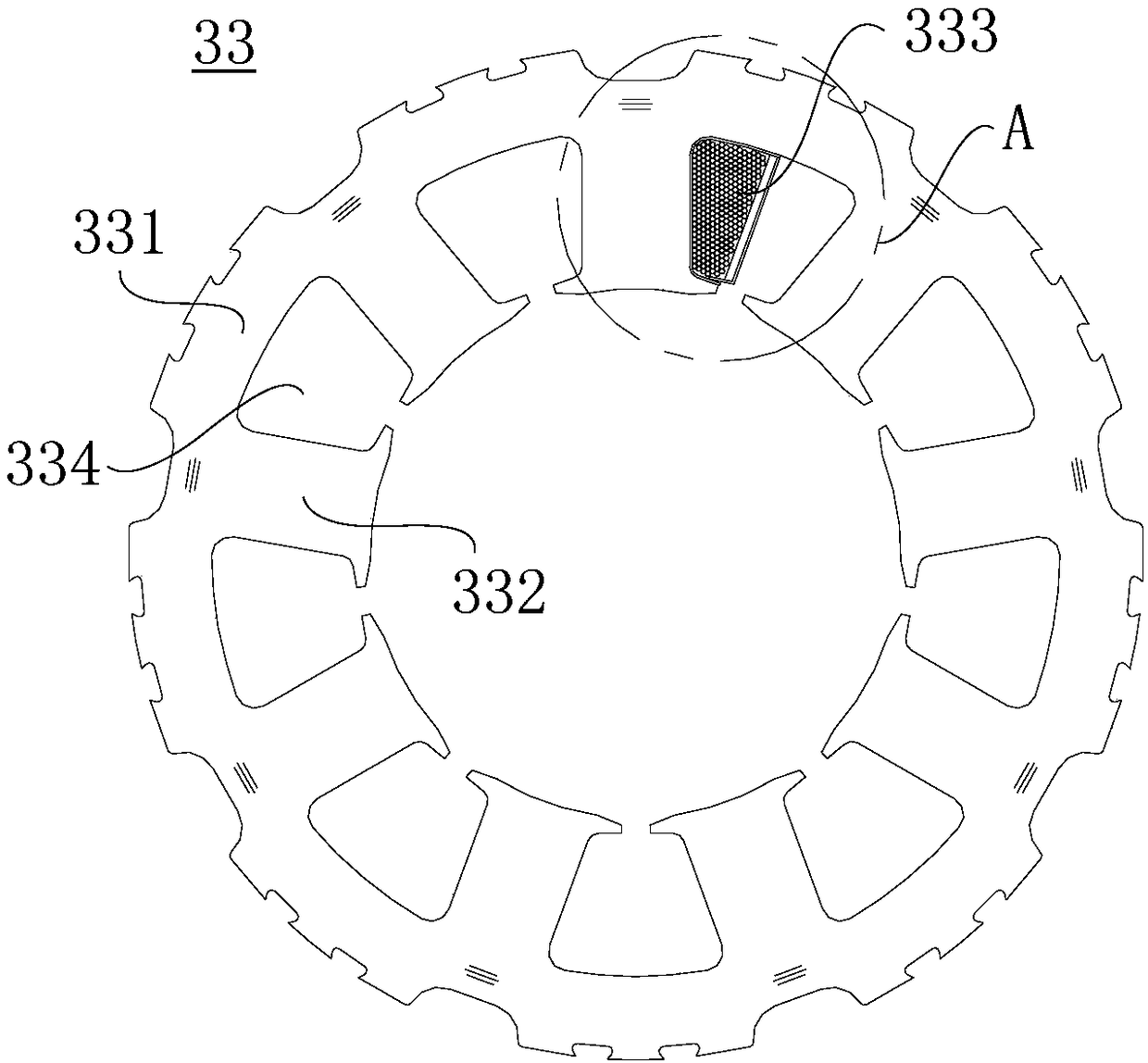

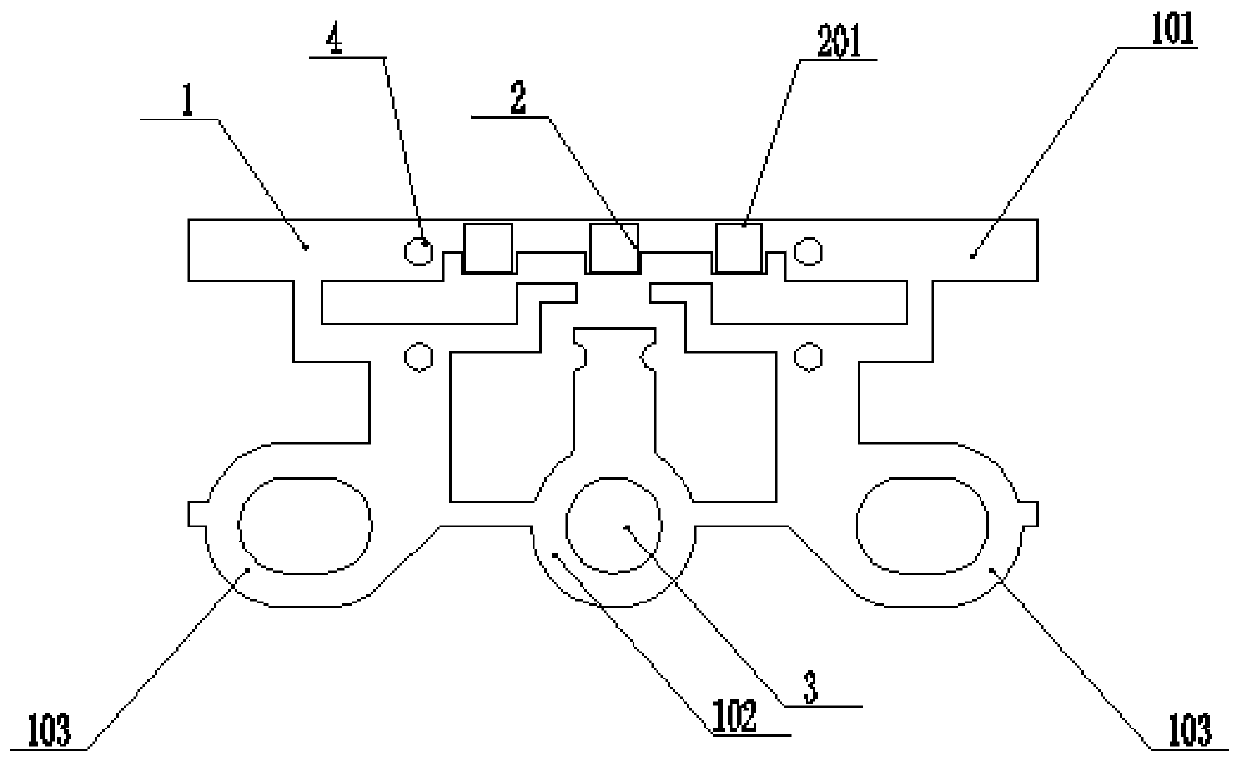

Compressor stator, compressor and manufacturing method thereof

PendingCN109494896AReduce gapAvoid occupyingMagnetic circuit stationary partsManufacturing stator/rotor bodiesFilling rateEngineering

The invention provides a compressor stator, a compressor and a manufacturing method thereof. The compressor stator comprises multiple T-like iron cores which are mutually combined annularly; each T-like iron core is wound by a winding; each T-like iron core comprises a tooth part and a pair of connecting arms integrally extending from two sides of the first end of the tooth part respectively; thewinding corresponding to each T-like iron core performs winding along the tooth part of the T-like iron core; the winding passes through two included angle areas formed by two sides of the tooth partand the two connecting arms; the end part of the connecting arm is provided with at least one connecting tenon and / or at least one connecting slot; and two adjacent T-like iron cores are connected through the connecting tenons and / or the connecting slots. Through blocked individual winding, a winding pin can be prevented from occupying a stator slot, and in comparison with the traditional centralized winding motor, the motor slot filling rate Spf can be greatly improved, and optimization of the motor performance is further achieved.

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

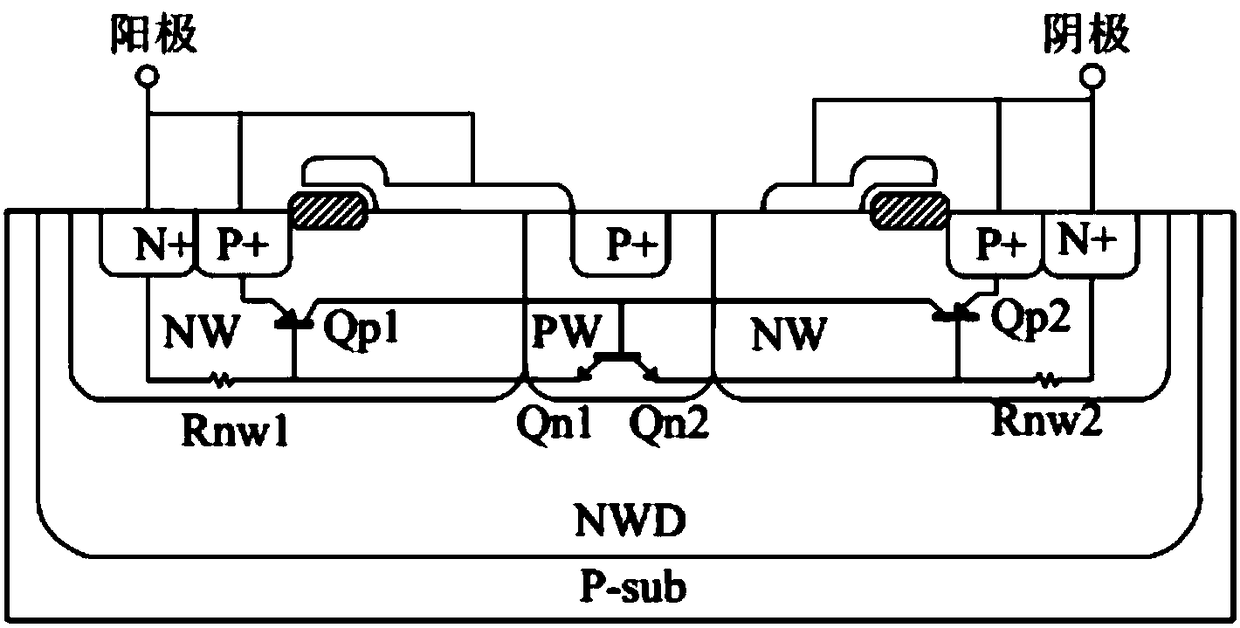

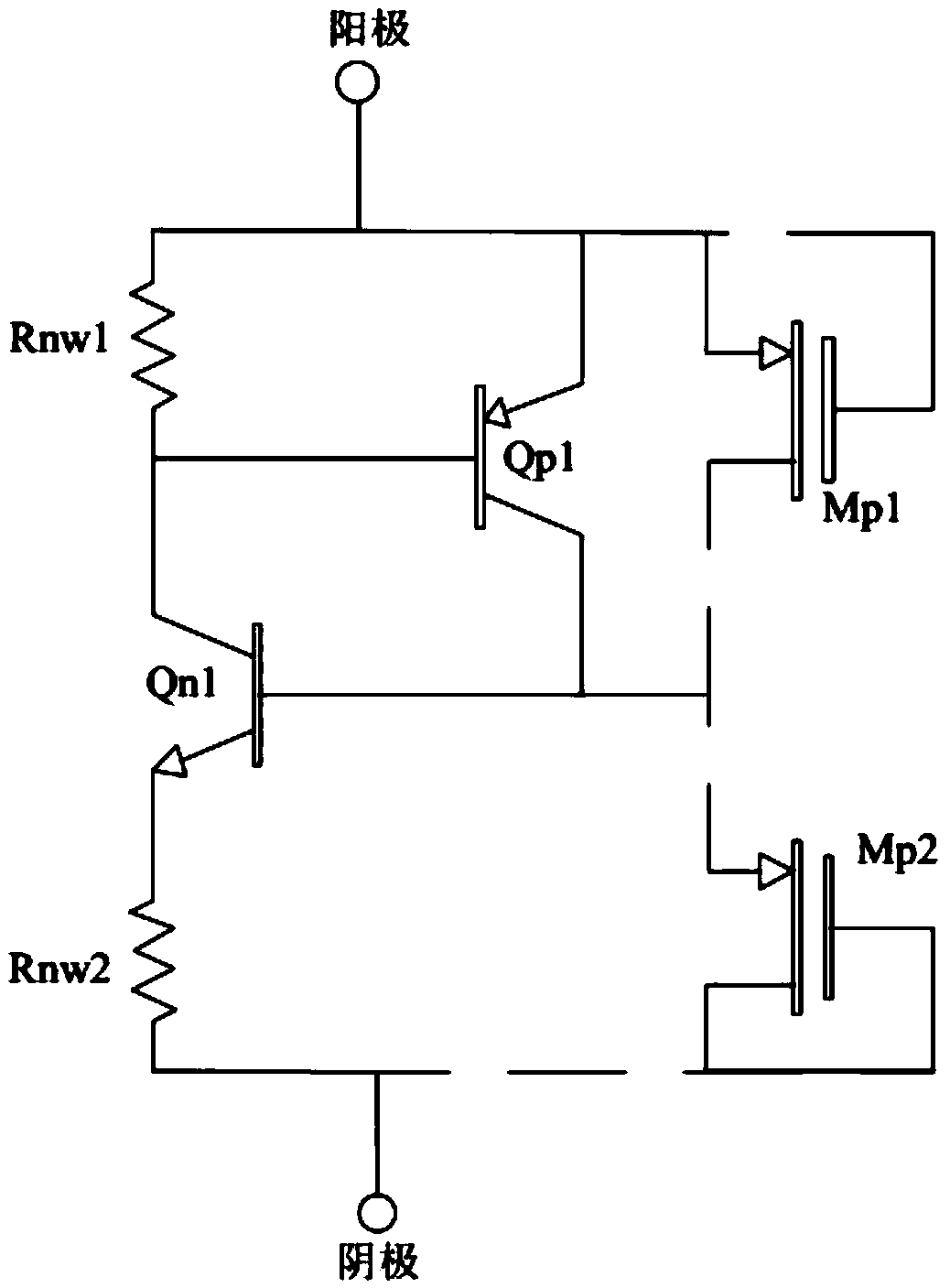

Electrostatic protection device

ActiveCN108807370AIncrease holding voltageFully utilize the areaTransistorSolid-state devicesEngineeringVoltage

The invention provides an electrostatic protection device. The electrostatic protection device comprises a substrate, wherein a deep N well is arranged in the substrate, a first N well, a first P welland a second N well are sequentially arranged in the deep N well from left to right, a first N+ injection region and a first P+ injection region are sequentially arranged in the first N well from left to right, a second N+ injection region, a second P+ injection region and a third N+ injection region are sequentially arranged in the first P well, a third P+ injection region and a fourth N+ injection region are sequentially arranged in the second N well, the first N+ injection region and the first P+ injection region both are connected with a positive electrode, the third P+ injection region and the fourth N+ injection region both are connected with a negative electrode, and the shape of the electrostatic protection device is axisymmetric octagon. With the electrostatic protection device proposed by the invention, the maintenance voltage can be increased, and the ESD robustness is improved.

Owner:HUNAN UNIV

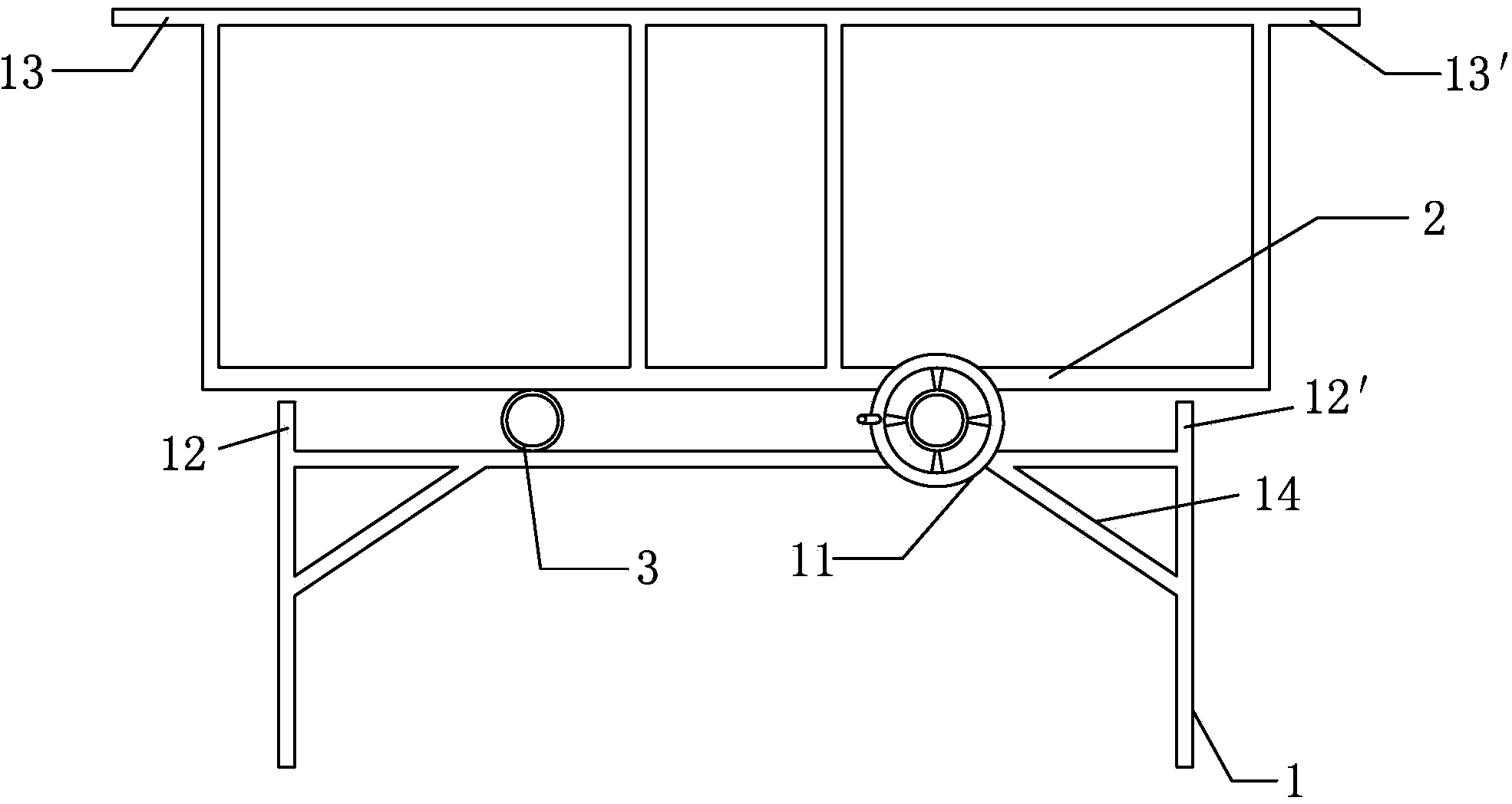

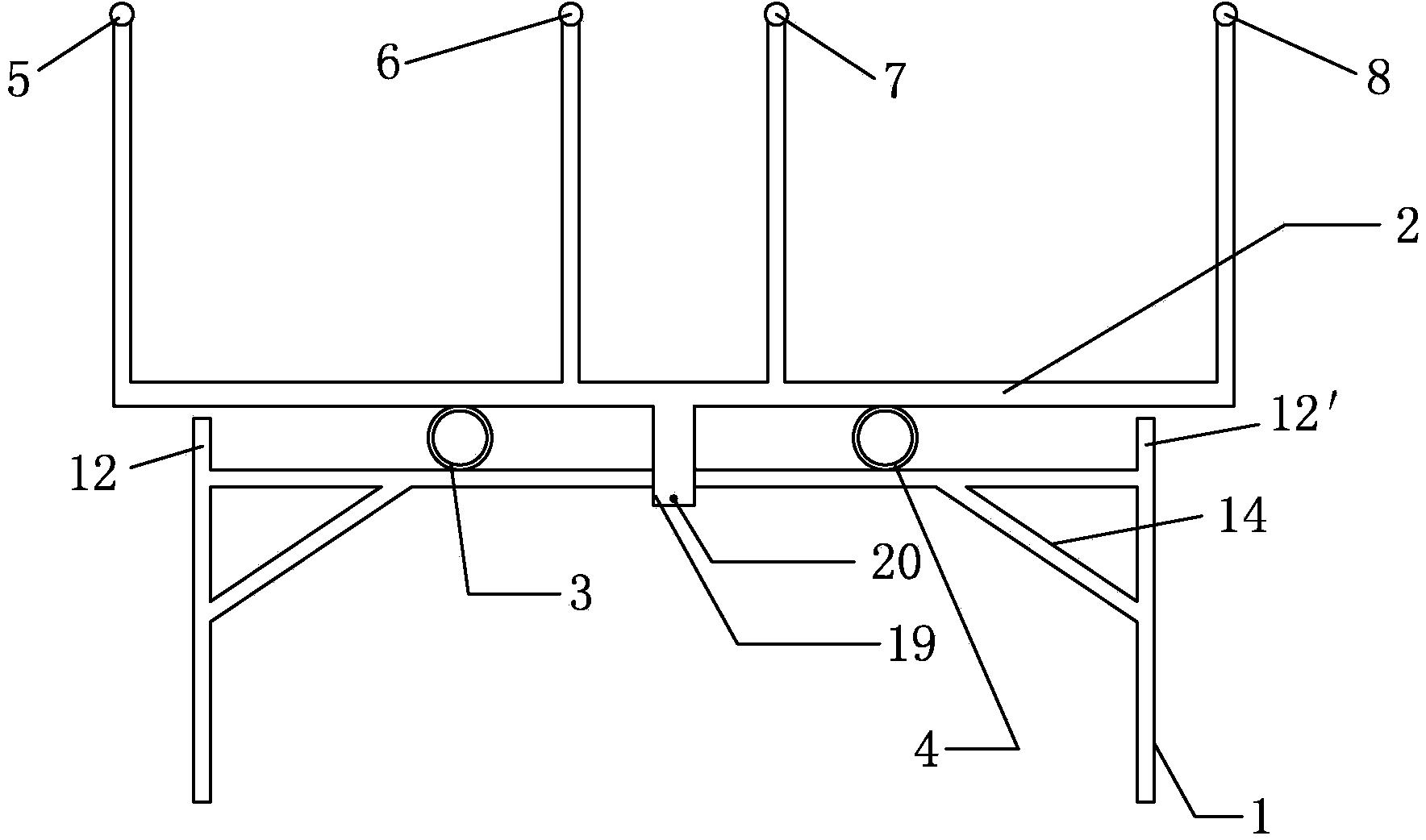

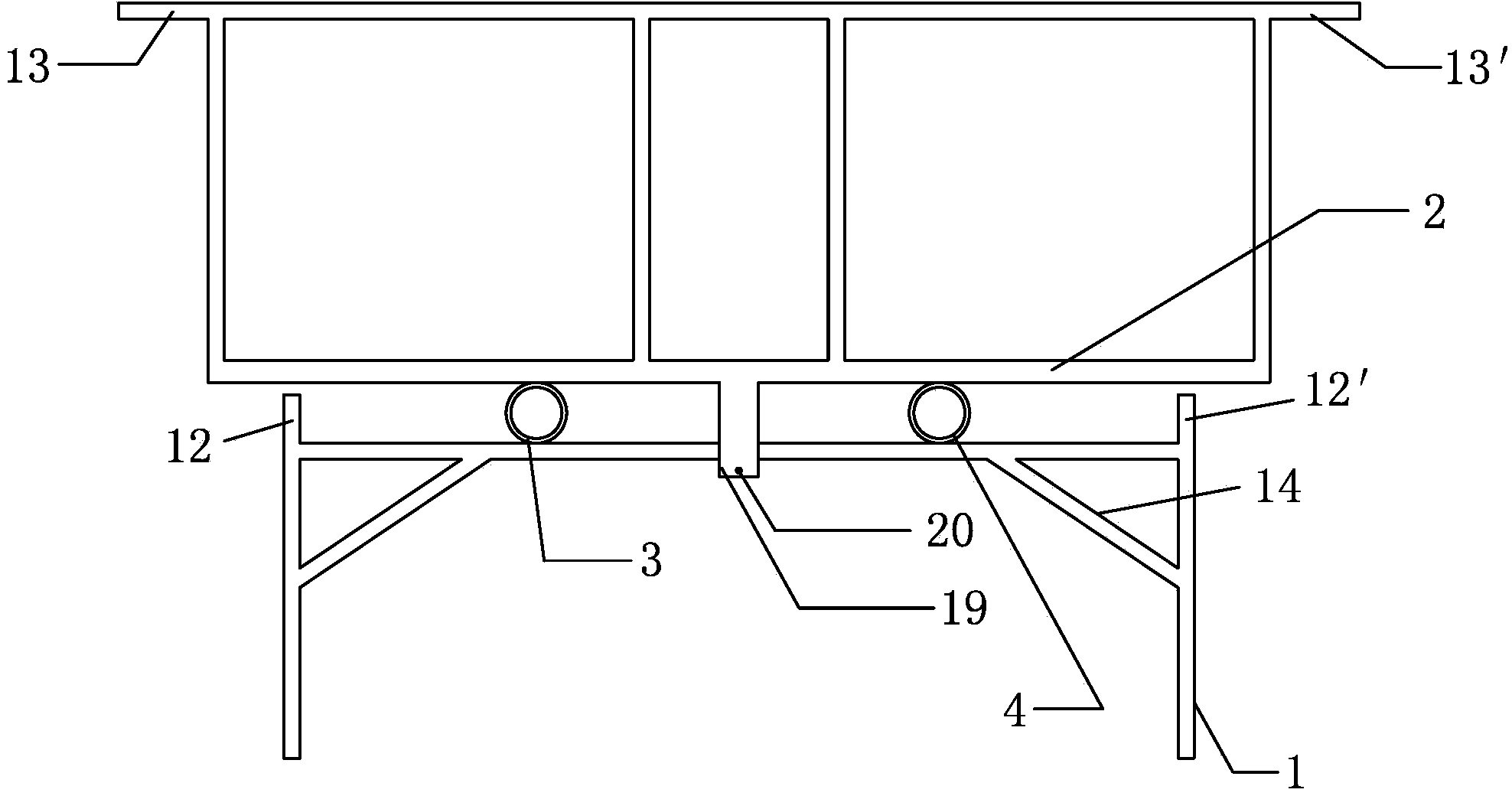

Wire sawing device

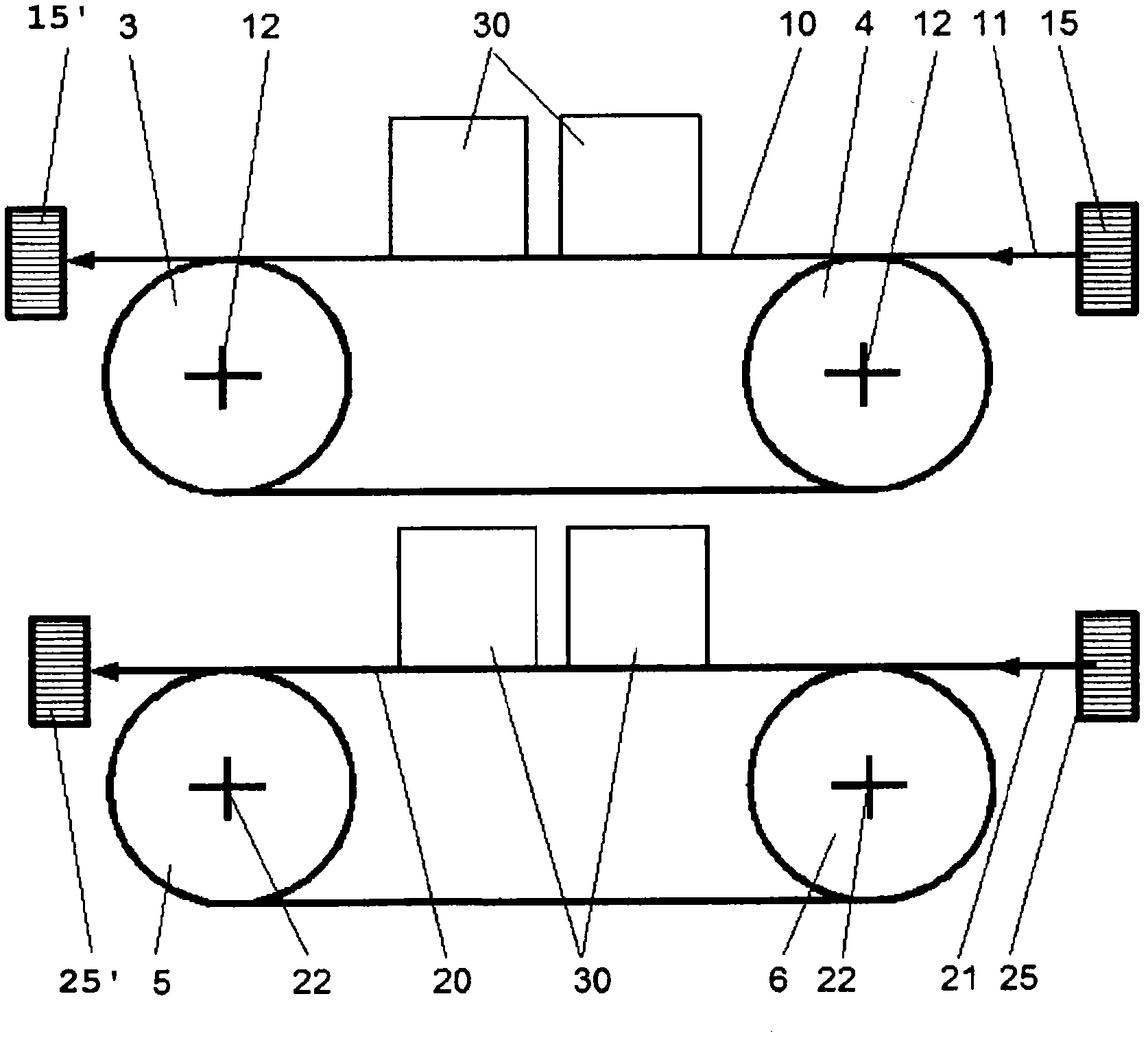

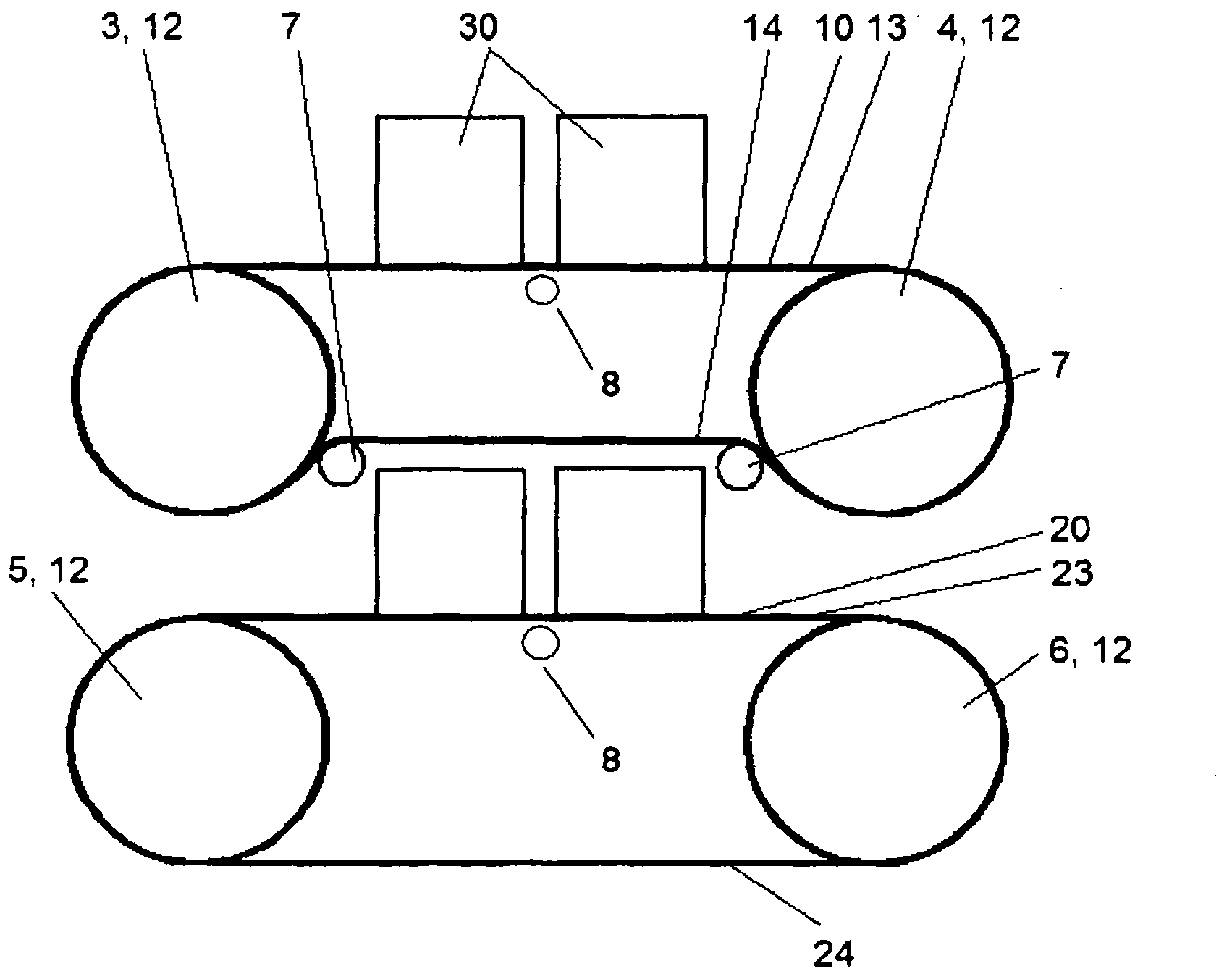

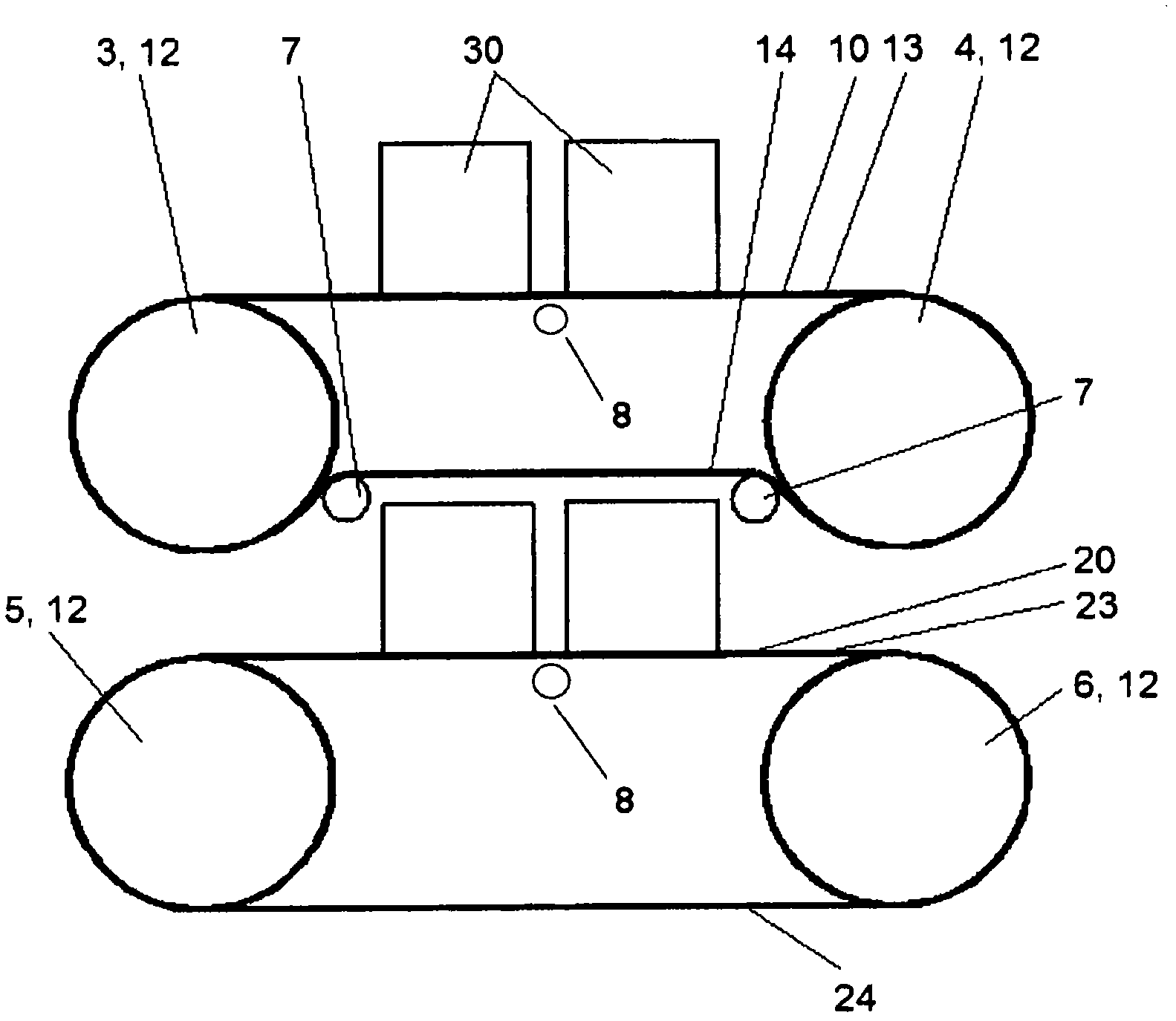

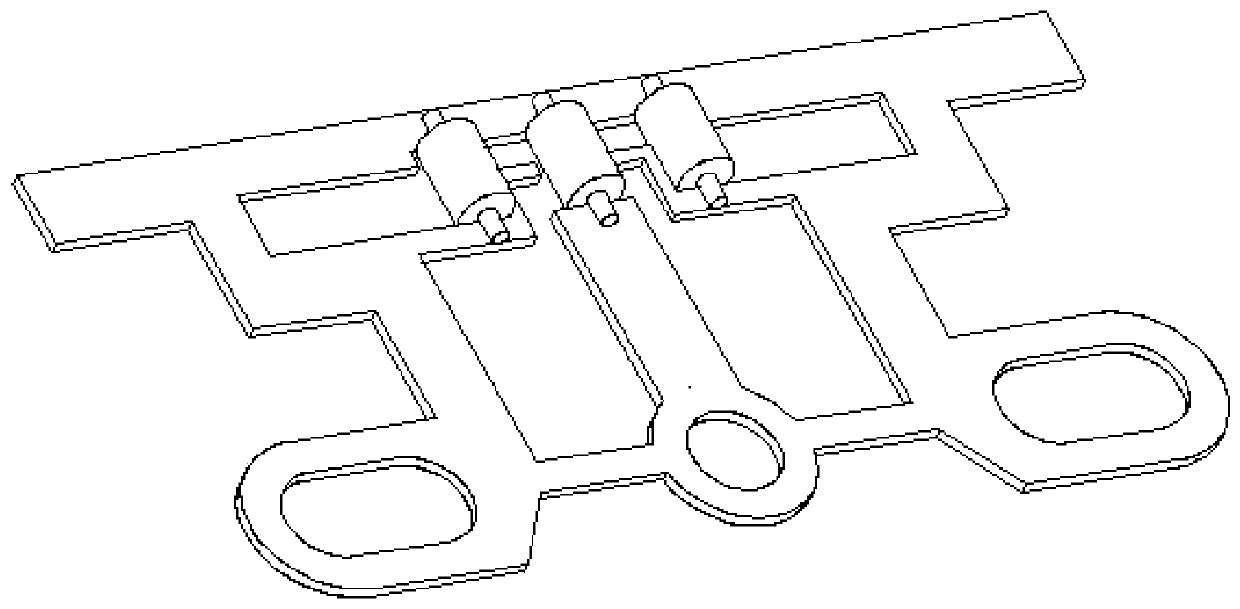

InactiveCN102099143AReduce the height of the structureLow costMetal sawing devicesEngineeringWire saw

The invention describes a wire saw which, in order to saw at least one workpiece (30), has one or more saw wires that are clamped between wire guiding means (3, 4, 5, 6) and form a field of saw wires arranged equidistantly next to one another. The wire saw comprises at least two saw fields (10, 20), each saw field having an independent wire drive (12, 22). The saw fields are preferably arranged one above another. Each saw field (10, 20) usually has an independent wire accumulator (15, 20) which can be used to continuously feed respectively separate saw wires (11, 21).

Owner:SCHOTT SOLAR AG (DE)

Vehicle generator excitation module

InactiveCN111245162AIncrease the maximum areaIncrease cooling areaSynchronous generatorsCooling/ventillation arrangementChip sizeStructural engineering

The invention discloses a vehicle generator excitation module. The vehicle generator excitation module comprises a frame and at least one semiconductor unit welded on the frame. The semiconductor unitcomprises at least one chip and at least one jumper wire. One pole of the chip is welded on the frame. The jumper wire is welded on the other pole of the chip. The tail end of the jumper wire is welded on the frame. According to the invention, the technical problems of limited chip size, poor heat dissipation and low manufacturing efficiency in the prior art are solved.

Owner:JIANGSU YINGDAFU ELECTRONICS TECH CO LTD

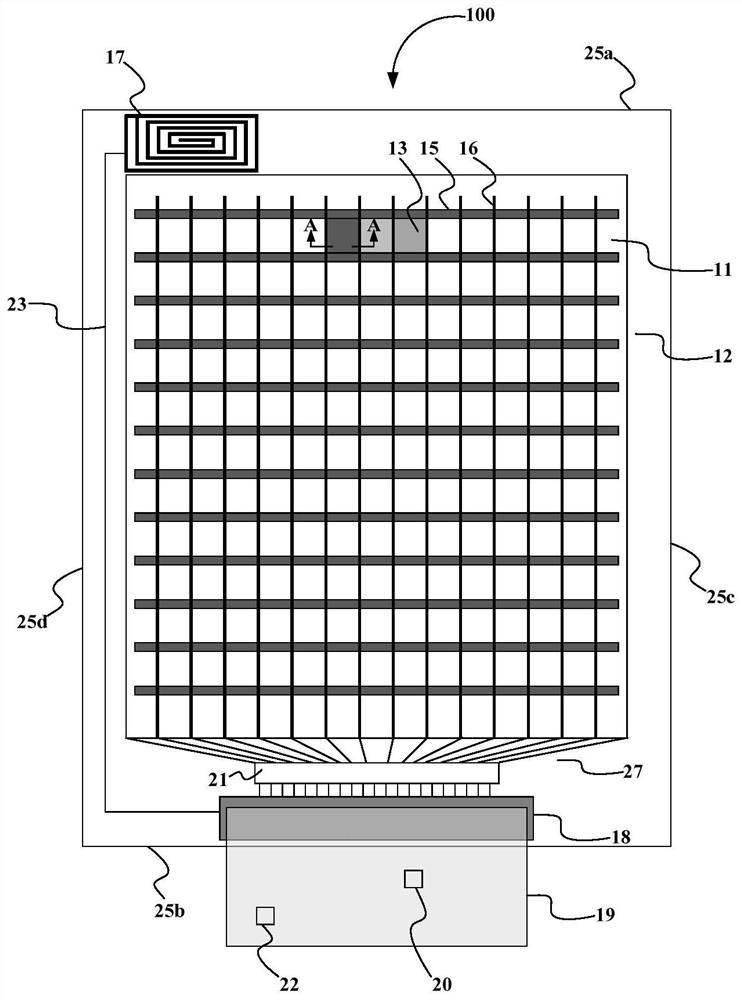

Display screen and display terminal

ActiveCN112863350AReduce difficultyLow production costAntenna supports/mountingsSolid-state devicesElectrical and Electronics engineeringOptics

The embodiment of the invention provides a display screen and a display terminal. The display screen comprises a display area and a non-display area surrounding the display area, the display area comprises a plurality of sub-pixels, at least one of the sub-pixels comprises a pixel circuit and a light-emitting element, the pixel circuit is configured to drive the light-emitting element, and the pixel circuit comprises at least one metal layer; and the non-display area comprises at least one antenna, and the at least one antenna and one metal layer in the at least one metal layer are manufactured on the same layer.

Owner:BOE TECH GRP CO LTD +1

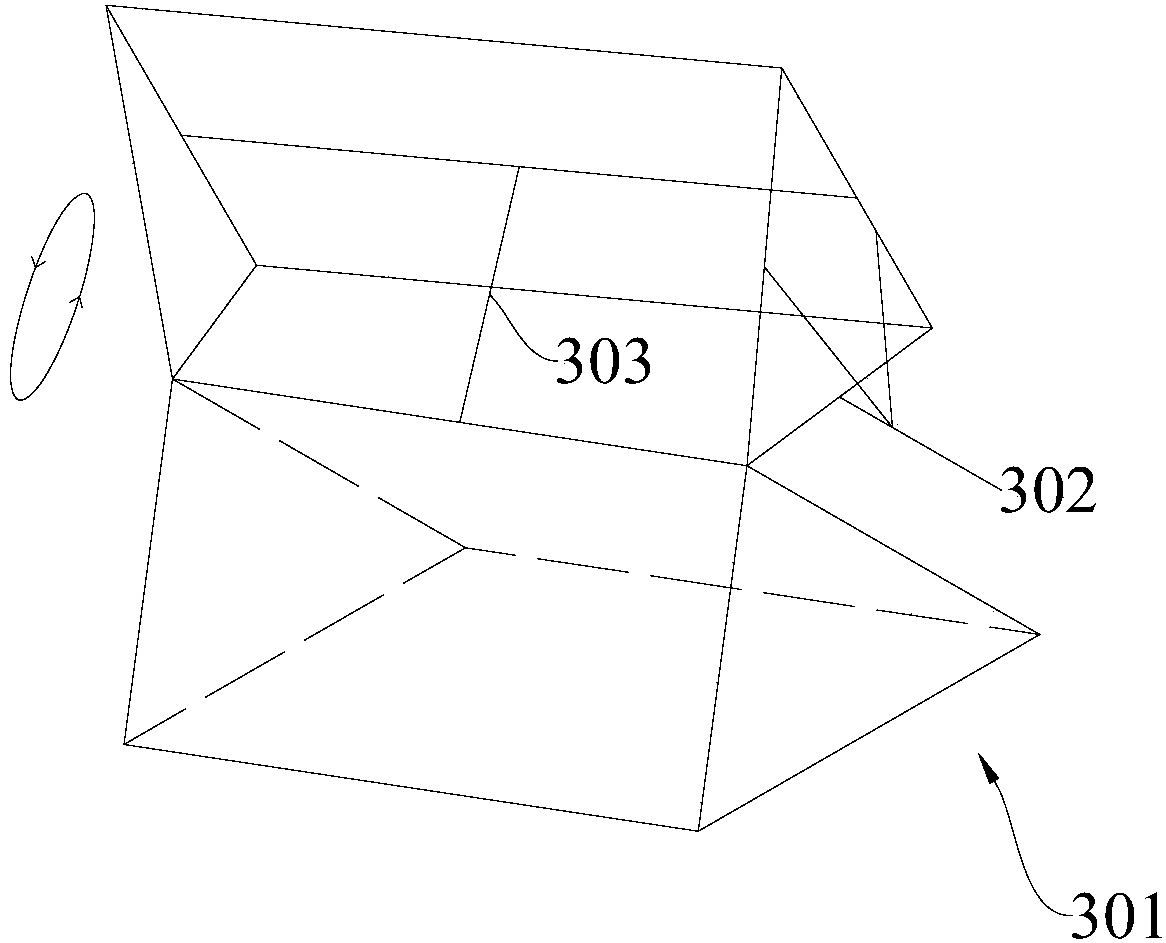

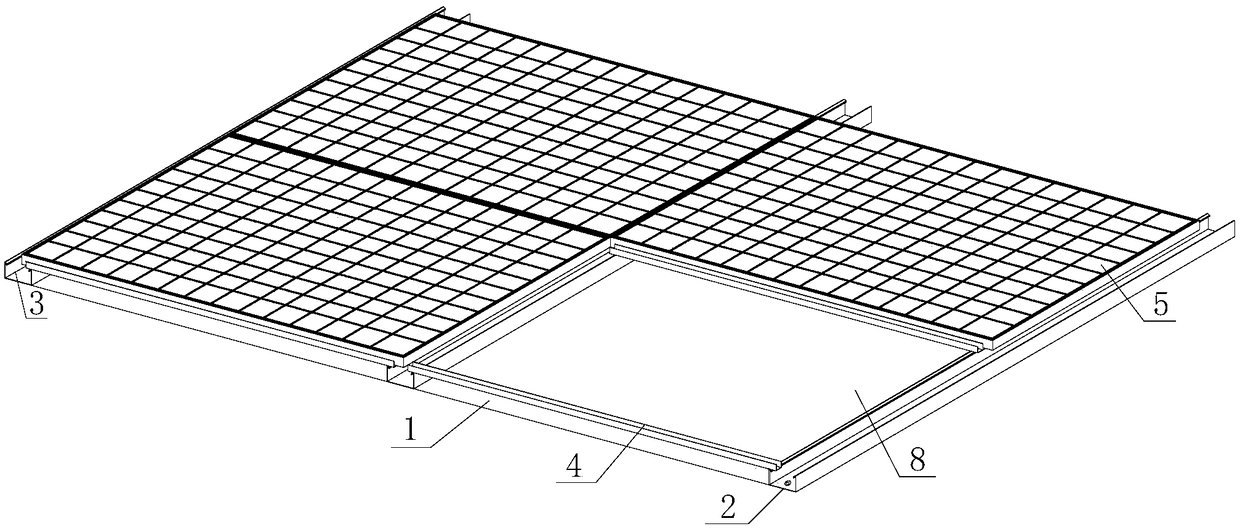

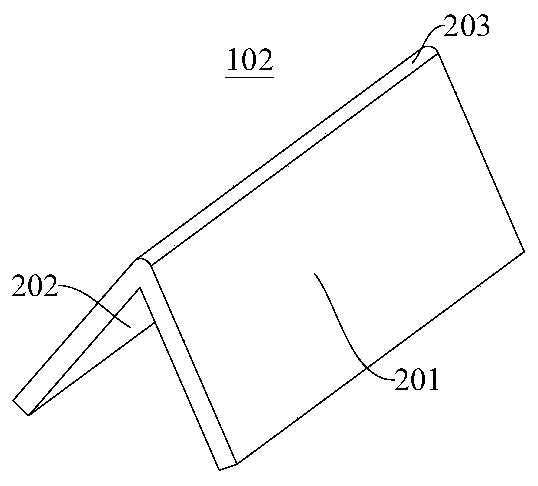

Photovoltaic power generation device and power supply system

ActiveCN108462460AMeet lighting needsFully utilize the areaPhotovoltaic supportsEnergy storageElectrical batteryLight energy

The invention discloses a photovoltaic power generation device and a power supply system, which belong to the field of batteries. The photovoltaic power generation device comprises a mounting frame, asliding mechanism, a battery pack and a pointing adjuster. The mounting frame is configured to be fixed to a building. The sliding mechanism is mounted on the mounting frame. The battery pack comprises a battery frame and a foldable battery panel, which are matched with each other. The battery rack is movably arranged on the sliding mechanism, and the foldable battery panel is rotatably connectedto the battery rack. The pointing adjuster is configured to independently adjust one or both of the battery frame and the foldable battery panel according to the lighting condition so that the foldable battery panel can track the sun movement. According to the photovoltaic power generation device, the external space of a building can be better utilized, and light energy can be effectively utilized.

Owner:HENAN POLYTECHNIC UNIV

Seedbed for greenhouse strawberry planting

InactiveCN103960078AIncrease usable areaIncrease the number ofReceptacle cultivationEngineeringGreenhouse

The invention provides a seedbed for greenhouse strawberry planting. The seedbed is characterized by comprising a lower supporting frame, an upper bracket, a first round bar and a second round bar, wherein the first round bar and the second round bar have the same size. The first round bar and the second round bar are both arranged on the bearing horizontal plane of the lower supporting frame in the longitudinal direction of a greenhouse according to the bar length direction of the first round bar and the bar length direction of the second round bar; the upper bracket is arranged on the first round bar and the second round bar. Along the cross section of the greenhouse, the width of the upper bracket is larger than that of the lower supporting frame. A first longitudinal bar, a second longitudinal bar, a third longitudinal bar and a fourth longitudinal bar are sequentially arranged on the upper portion of the upper bracket from left to right. The first longitudinal bar and the second longitudinal bar are correspondingly and fixedly provided with a plurality of first matrix bearing cloth pieces through snap rings, and the third longitudinal bar and the fourth longitudinal bar are correspondingly and fixedly provided with a plurality of second matrix bearing cloth pieces through snap rings. A hand wheel is fixedly arranged on the first round bar or the second round bar, and an anti-turning hook is arranged on the lower supporting frame or the center of the bottom of the upper bracket. By the adoption of the scheme, the planting area in the greenhouse can be fully utilized, the strawberry yield can be increased, and the seedbed is simple in structure, low in cost and convenient to maintain.

Owner:SUZHOU ACADEMY OF AGRI SCI

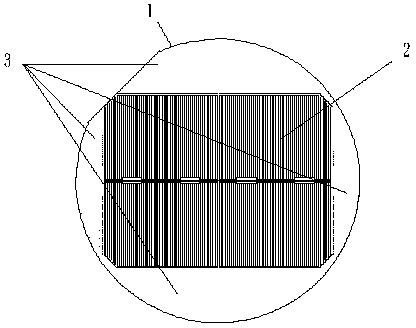

Solar battery manufacturing method

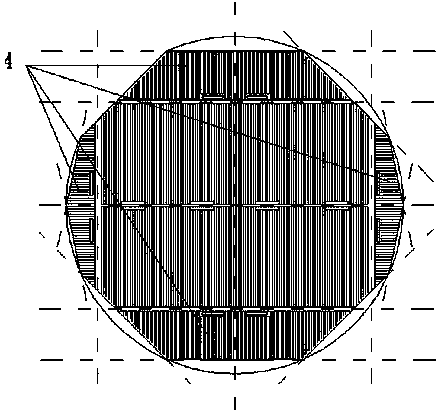

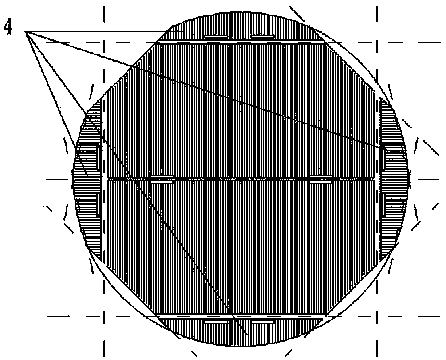

InactiveCN103928572AIncrease profitFully utilize the areaFinal product manufacturePhotovoltaic energy generationSolar batteryEngineering physics

The invention provides a solar battery manufacturing method. The method comprises the steps of providing an epitaxial wafer comprising a main solar battery area and a corner area located outside the main solar battery area, and forming an auxiliary solar battery area on the corner area. According to the method, processes of electrode evaporating, film coating, scribing and the like are simultaneously or sequentially carried out on the corner area of the solar battery epitaxial wafer so that solar batteries of different specifications can be manufactured, the epitaxial wafer can be utilized efficiently, the manufacturing process flow and the capacity of the solar batteries are not influenced, and the solar batteries formed on the corner area of the epitaxial wafer has the similar electrical property to that of the solar batteries formed on the main solar area.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

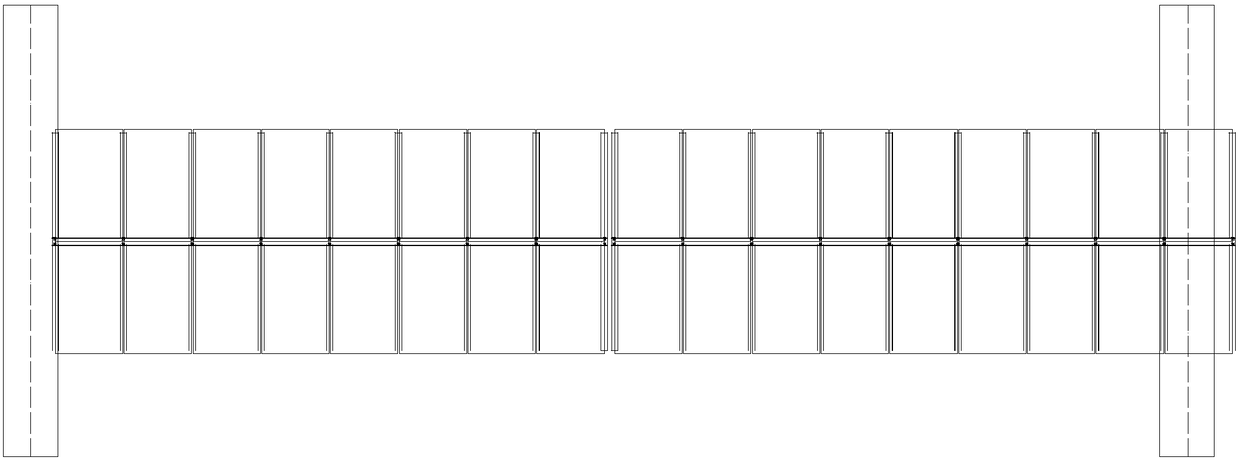

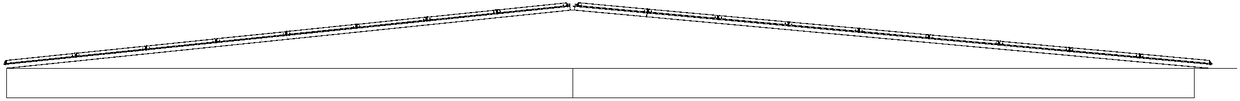

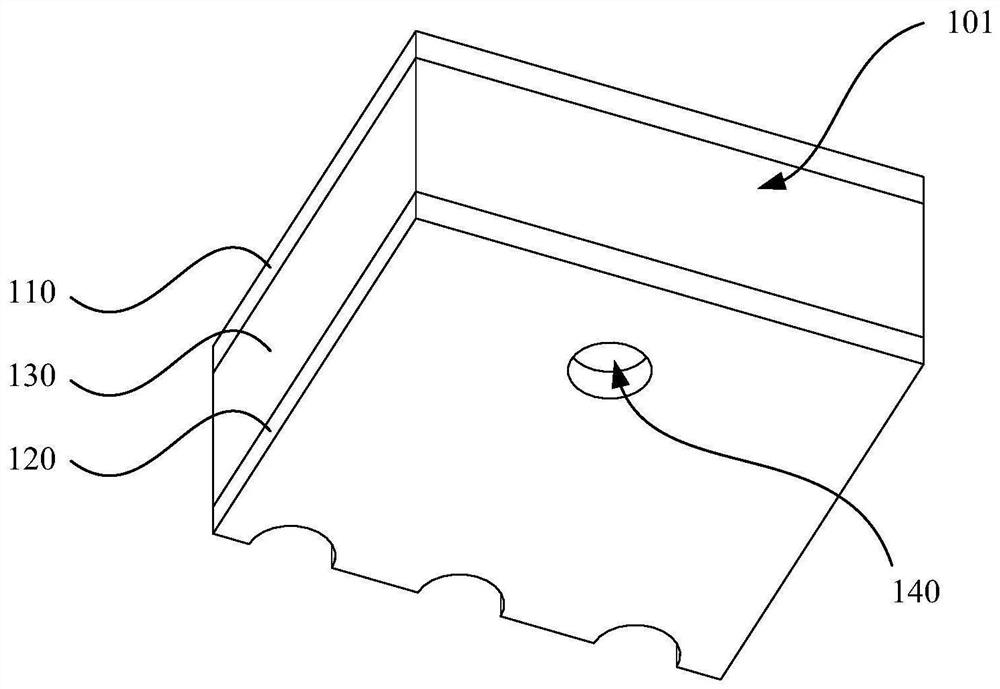

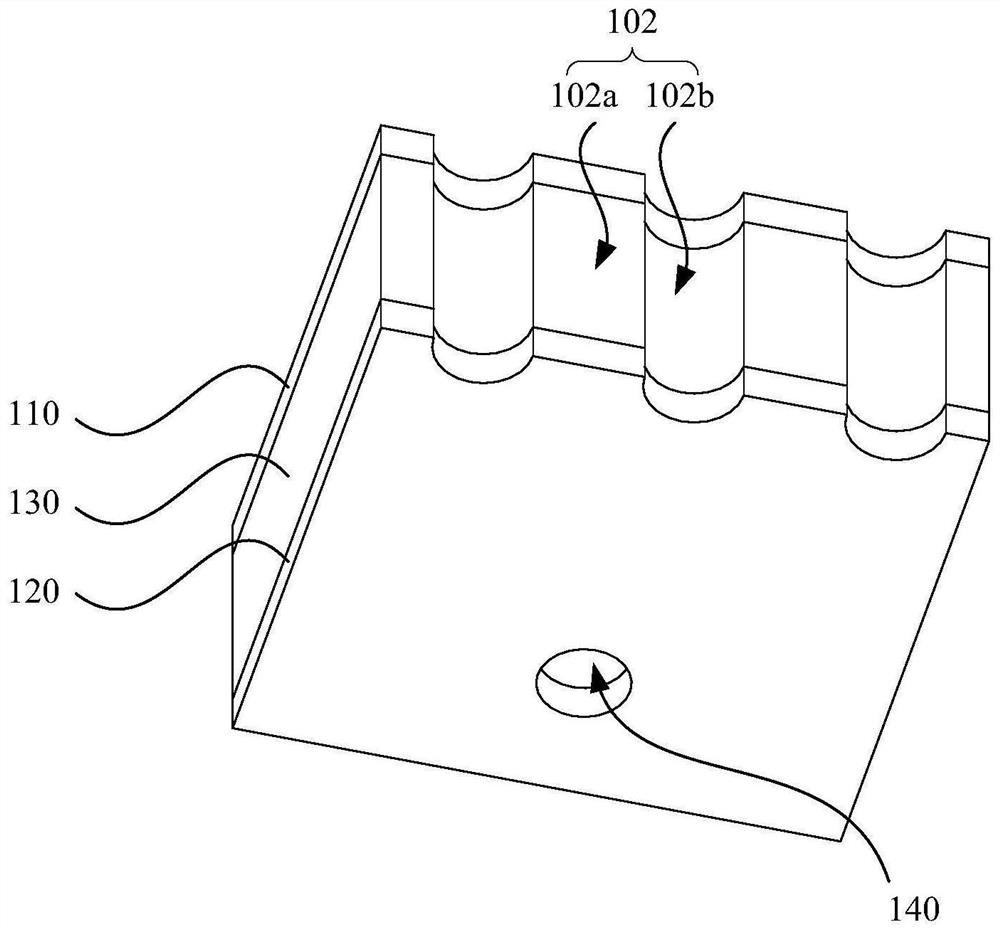

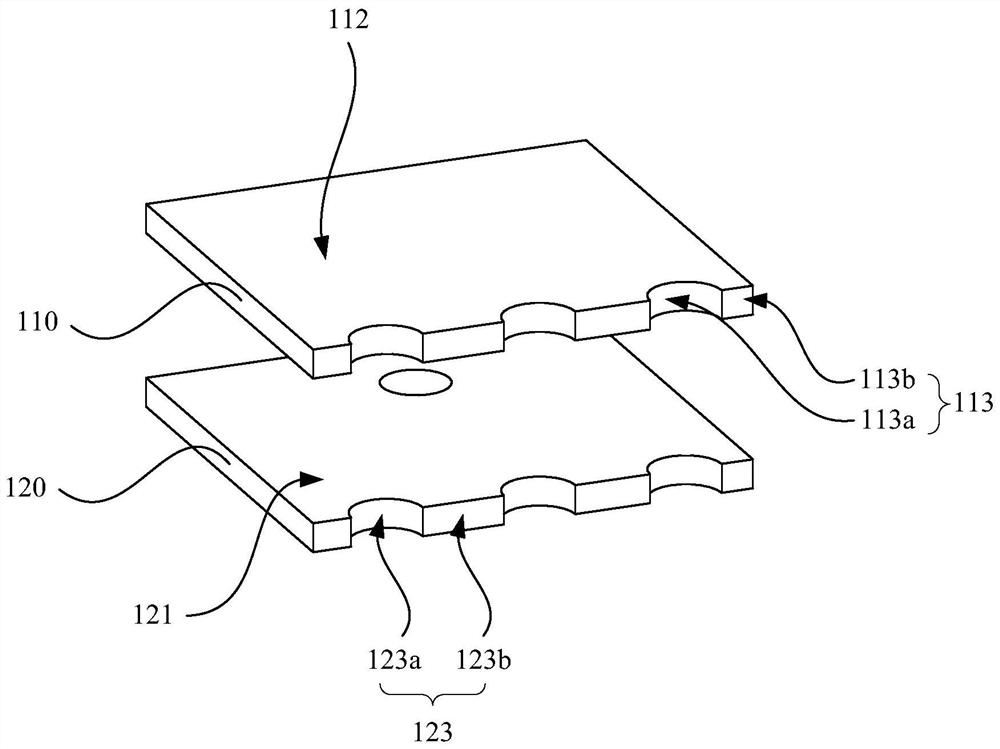

Integrated roof of photovoltaic building

PendingCN108532855AFully utilize the areaReduce construction costsPhotovoltaic supportsRoof covering using slabs/sheetsWater leakageElectrical and Electronics engineering

The invention provides an integrated roof of a photovoltaic building. The integrated roof comprises a roof surface, a plurality of purlines, vertical water grooves, transverse water grooves, photovoltaic assemblies, first clamping pieces and second clamping pieces. The multiple purlines are arranged in the vertical direction of the roof surface. The vertical water grooves are fixedly formed in thepurlines through a plurality of bolts. A plurality of pressing plates are arranged between the two adjacent vertical water grooves. The first clamping pieces are arranged on the two sides of the vertical water grooves. The second clamping pieces are arranged on the upper left portions of the first clamping pieces. The upper ends of the second clamping pieces are mutually in clamp fit with the upper ends of the pressing plates located at the outermost end. Pressing plate clamping grooves are formed in the two inner sides of the pressing plates. The two sides of the photovoltaic assemblies aremutually in clamp connection with the pressing plate clamping grooves. The transverse water grooves are formed between the adjacent pressing plates. Third clamping pieces are welded to the two ends ofthe transverse water grooves. The third clamping pieces are mutually in clamp connection with the pressing plates. According to the integrated roof of the photovoltaic building, the roof area is fully utilized, the water leakage problem of the roof is solved, and the building cost of the roof is saved.

Owner:浙江岐达科技股份有限公司

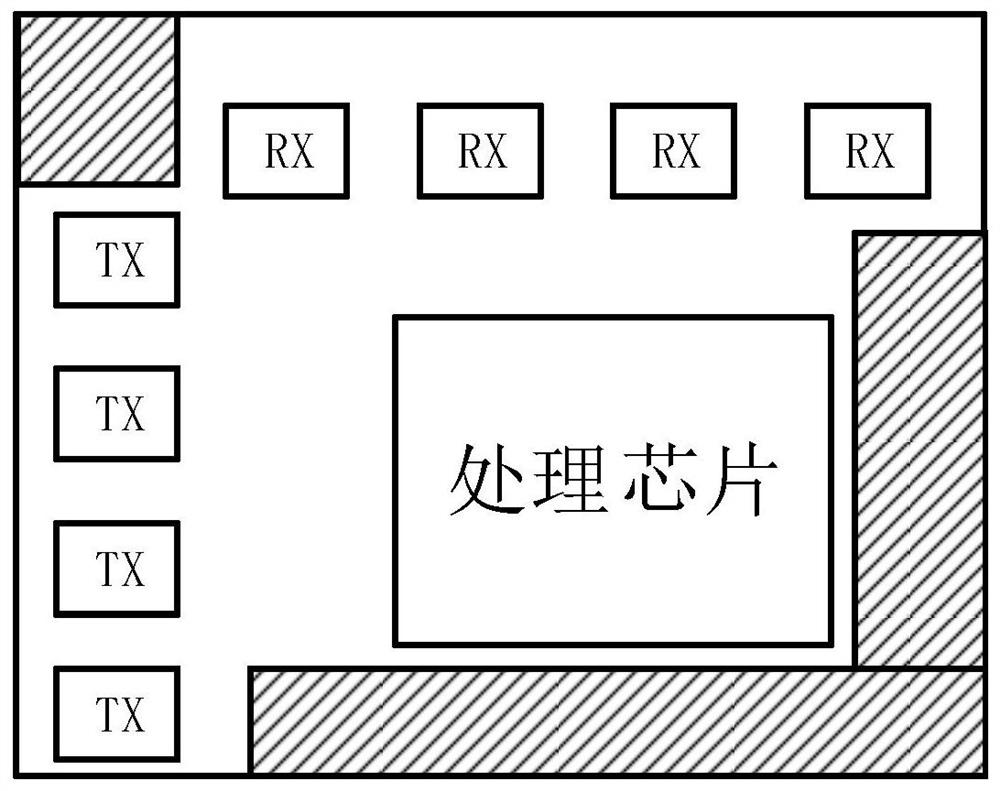

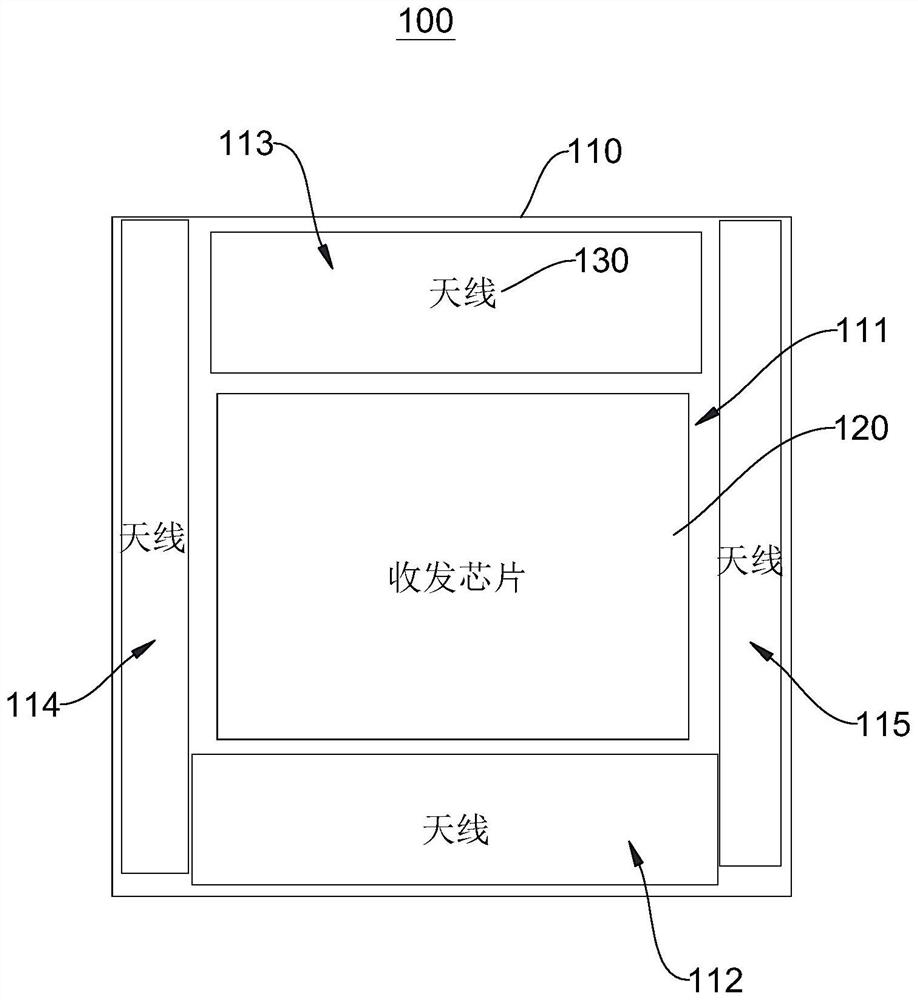

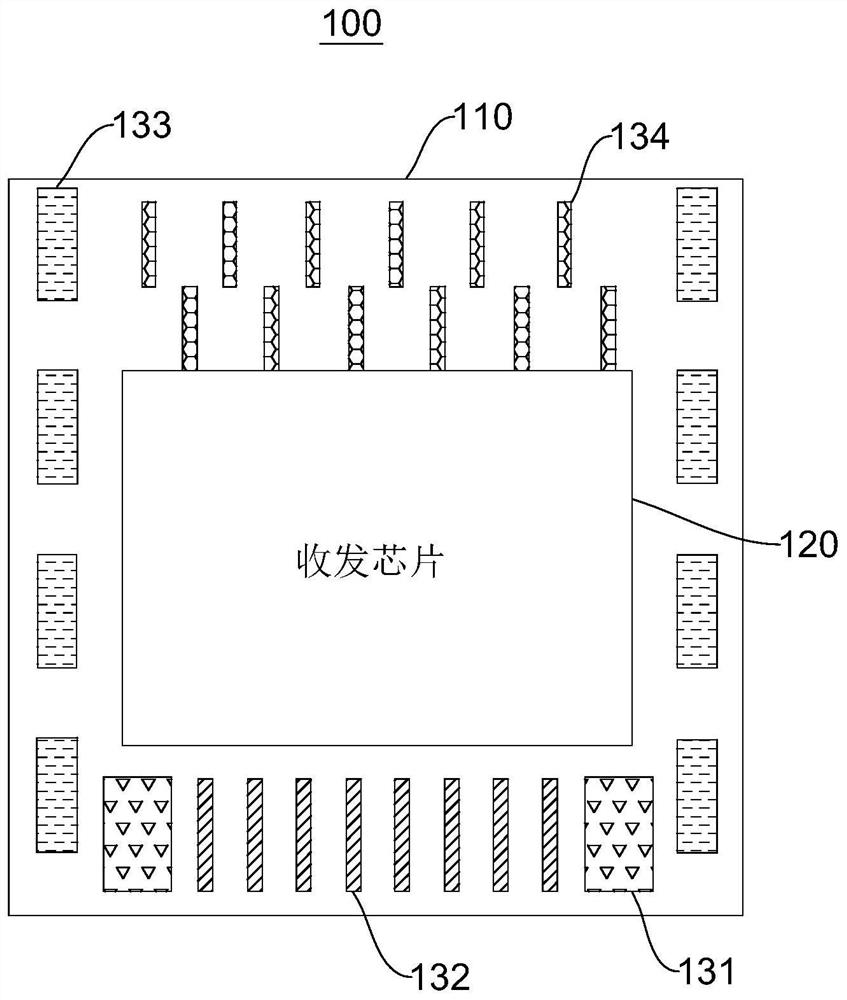

Radar and movable platform

The invention provides a radar and a movable platform, and relates to the technical field of radars. The radar comprises a substrate, and the substrate comprises a chip placement area located at the center position and an antenna arrangement area surrounding the chip placement area; the radar further comprises a transceiving chip installed in the chip placing area and an antenna installed in the antenna arranging area, and the antenna is electrically connected with the transceiving chip. The radar and the movable platform provided by the invention have the advantages that the integration level is higher, and the area waste of the circuit board cannot be caused.

Owner:GUANGZHOU XAIRCRAFT TECH CO LTD

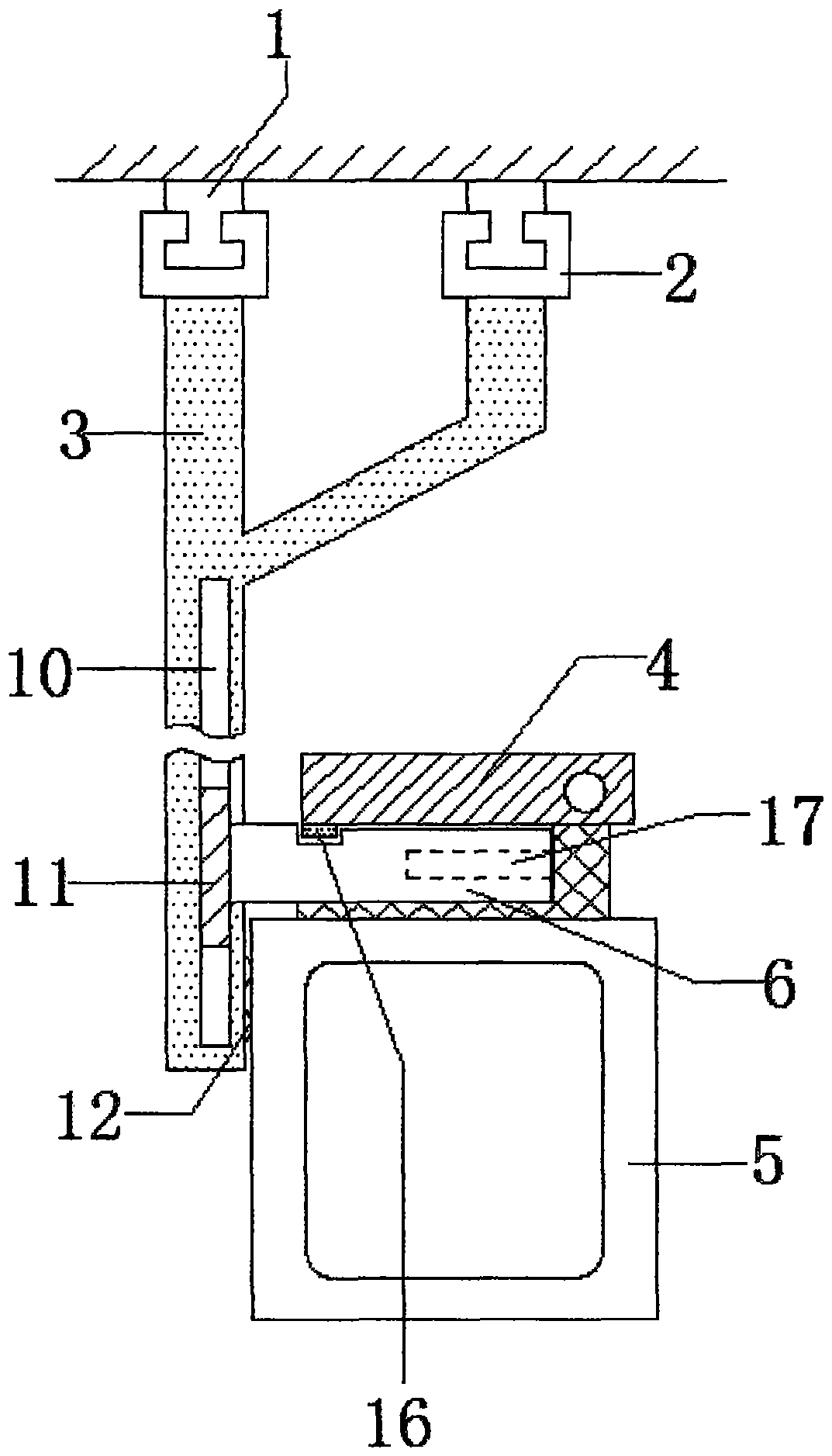

Dish-washing machine mounting structure and lifting type dish-washing machine

PendingCN111227756AEasy to adjustFully utilize the areaTableware washing/rinsing machine detailsControl engineeringSlide plate

The invention discloses a dish-washing machine mounting structure and a lifting type dish-washing machine. The structure comprises sliding rails. First sliding blocks are arranged at the lower end ofthe sliding rails. A connecting frame is fixed to the lower end of the first sliding block. Sliding blocks II are arranged on two sides of the connecting frame; a sliding plate is fixed to the right end of the second sliding block. A connecting part is clamped on the sliding plate; a dish-washing machine body is fixed at the lower end of the connector; the number of the sliding rails is two. The number of the first sliding blocks is four. The connecting frame is of a triangular structure. The number of the connecting frames is two; a limiting groove is formed in the upper end of the sliding plate; fixing blocks are fixed to the inner sides of the sliding plates. A connecting rod is fixed between the connecting frames; the dish washing machine can move transversely and longitudinally, the moving range is large, the position is convenient to adjust, use is convenient, the area of a kitchen is fully utilized, the space utilization rate is increased. Meanwhile, when the dish washing machine body ascends, misuse of children is avoided, and the safety performance is improved.

Owner:金诺言

Plate-type heat exchanger with secondary throttling function

ActiveCN102809311BIncrease resistanceReduce resistanceHeat exchange apparatusStationary plate conduit assembliesPlate heat exchangerFluid interface

The invention discloses a plate-type heat exchanger with a secondary throttling function. The plate-type heat exchanger comprises a front end plate and a rear end plate; fluid interface channels are arranged symmetrically on the front end plate and the rear end plate; heat-exchanging plate units are arranged between the front end plate and the rear end plate and are overlapped in sequence; each heat-exchanging plate unit consists of a first heat-exchanging plate and a second heat-exchanging plate; one distributing zone is arranged between a heat-exchanging zone and a first flow guiding zone; one distributing zone is arranged between the heat-exchanging zone and a second flow guiding zone; one distributing zone is arranged between the other heat-exchanging zone and the other first flow guiding zone; and one distributing zone is arranged between the other heat-exchanging zone and the other second flow guiding zone. By using the plate-type heat exchanger with the secondary throttling function, provided by the invention, the resistance of the refrigerant flowing through a channel between the heat-exchanging zones on the corner hole sides of an inlet and an outlet is increased, the resistance of the refrigerant flowing through the channel between the heat-exchanging zones is decreased, and the refrigerant is uniformly distributed on the whole surface of the heat-exchanging zone, in this way, the areas of the heat-exchanging plates are used sufficiently.

Owner:JIANGSU BAODE HEAT EXCHANGER EQUIP

Efficient manufacturing method of wood carving film pressing door plate

PendingCN112008824AEfficient preparation methodReduce idle wait timeDecorative surface effectsLaminationNumerical controlFilm-coated tablet

The invention discloses an efficient manufacturing method of a wood carving film pressing door plate. The efficient manufacturing method comprises the following steps that a numerical control carvingmachine is used for carving the front face and the back face of a door plate base material; surface burr grinding is conducted on the door plate base material with the front face and the back face being carved, and surface burrs are removed; the surface glue spraying operation is conducted on the ground door plate base material, and the placing and airing are conducted; before a plurality of doorplate base materials to be subjected to high-temperature film coating are placed on a film coating workbench of a high-temperature film coating machine, the placing positions of the plurality of aireddoor plate base materials to be subjected to high-temperature film coating on a film coating station are reasonably planned and arranged in advance; according to a pre-planned layout, the door platebase materials to be subjected to high-temperature film coating are placed at designated positions of the film coating workbench; the surfaces of the plurality of door plate base materials are coveredwith a PVC film on the film coating workbench; and the film coating workbench drives the door plate base materials to enter the high-temperature film coating station for PVC high-temperature film coating. According to the efficient manufacturing method, the labor cost can be reduced, and the manufacturing efficiency can be improved.

Owner:上海速居科技集团有限公司

MEMS sensor and packaging structure thereof

PendingCN113003530AEasy wiringImprove reliabilityTelevision system detailsImpedence networksMems sensorsPhysics

The invention discloses an MEMS sensor and a packaging structure thereof, and the packaging structure comprises: a shell which is provided with a first substrate, a second substrate and a connecting plate for connecting the first substrate and the second substrate, wherein the inner surface of the first substrate, the inner surface of the second substrate and the inner surface of the connecting plate form a cavity, the first substrate and the second substrate respectively extend from the top surface of the shell to the bottom surface of the shell, and the inner surface of the first substrate and / or the inner surface of the second substrate are / is provided with a conductive region; at least one electrode which is located outside the cavity and arranged on the bottom surface of the shell, wherein the bottom surface of the shell at least comprises one outer surface of the connecting plate; and at least one conductive structure which is used for electrically connecting the electrodes to the corresponding conductive regions through the first substrate and / or the second substrate respectively. According to the packaging structure, the wiring of the MEMS sensor is simplified, the reliability of the MEMS sensor is further improved, the complexity of the technological process is reduced, and the cost is reduced.

Owner:MEMSENSING MICROSYST SUZHOU CHINA

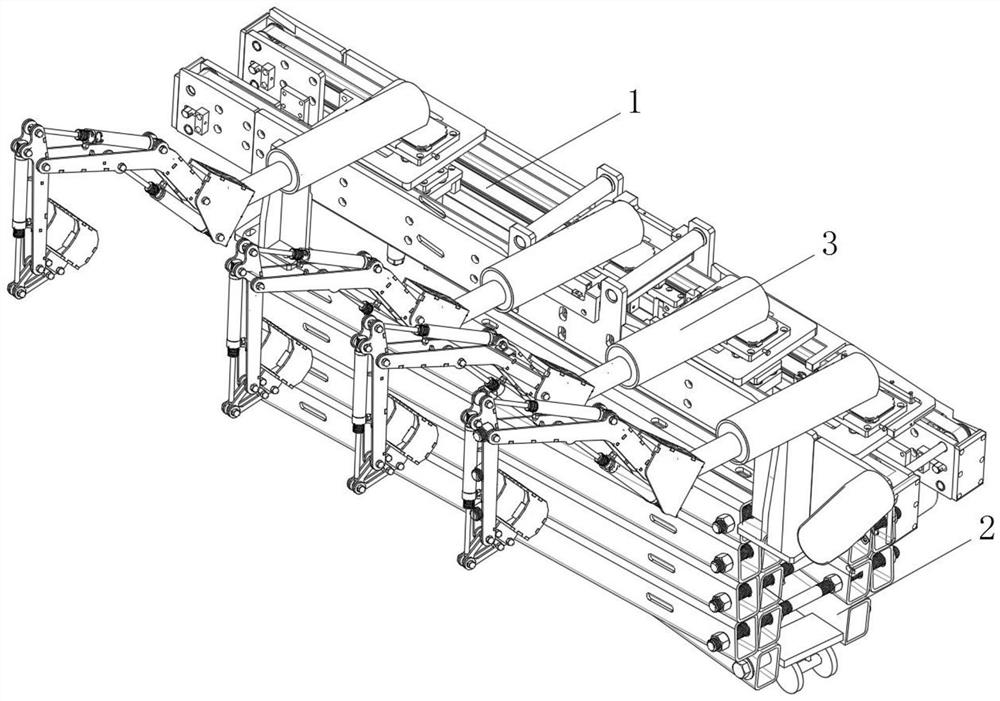

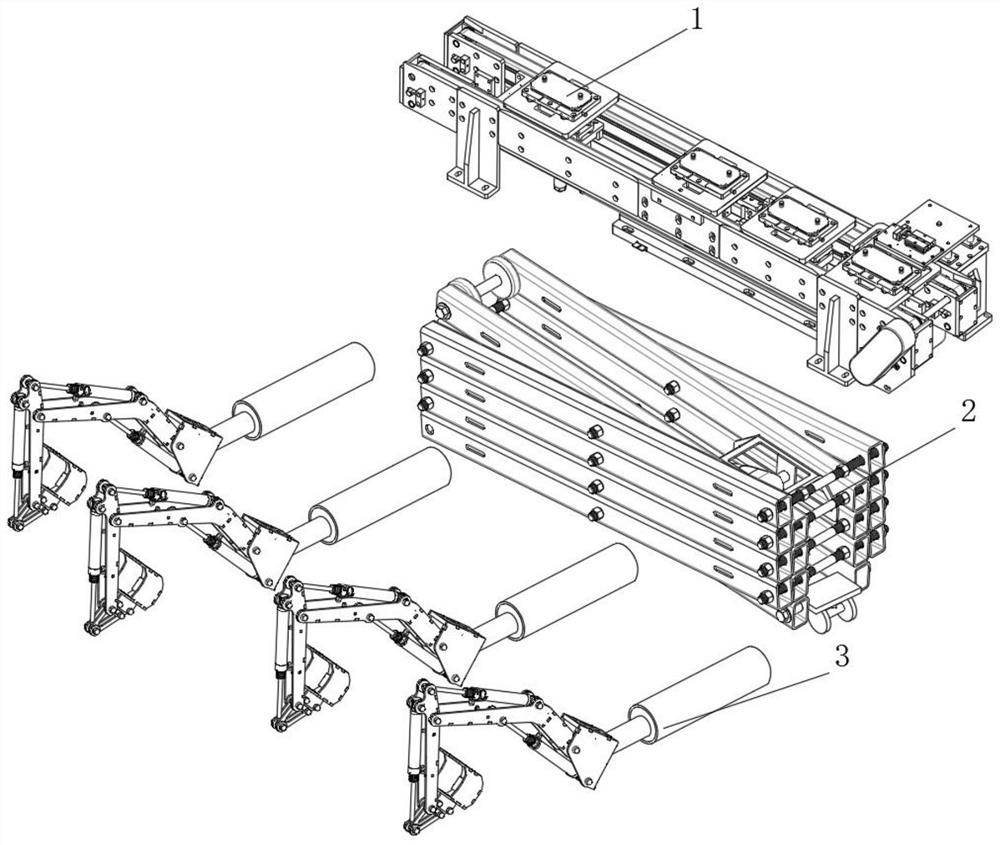

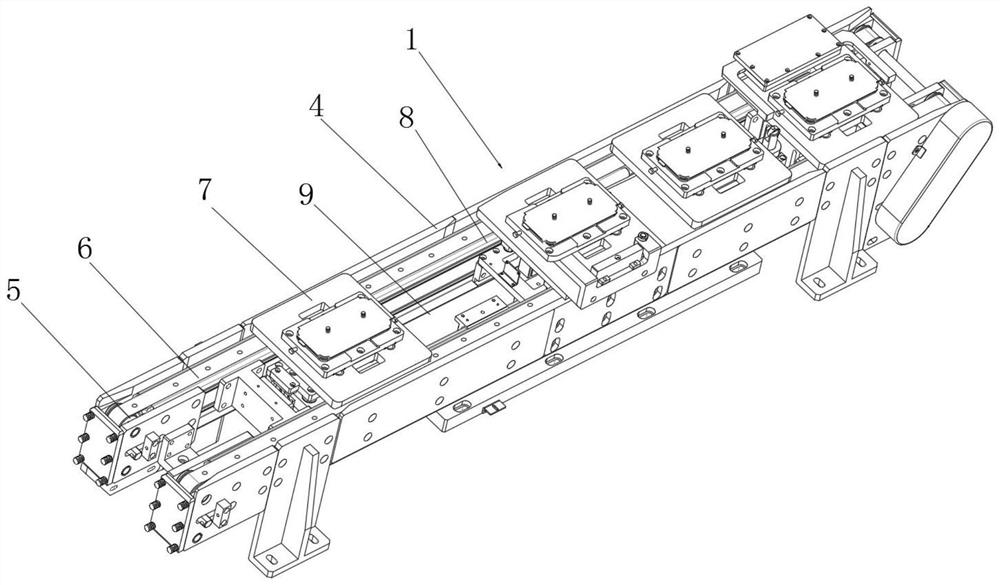

A kind of pit digging equipment and pit digging method for forestry planting

ActiveCN110447346BEasy plantingHigh degree of automationPlantingFurrow making/coveringForest industryAgricultural engineering

The invention discloses a pit digging equipment for forestry planting and a pit digging method, comprising a loading table, a lower tray and a rotary digging seat, the loading table is arranged above the lower tray; Both inner ends of the two pallets are provided with a motor one, and a drive crawler is set on a rotating sleeve on the motor one. The four rotary digging bases synchronously dig holes on the ground at different positions, and after the equipment completes digging around the area, the guide base immediately drives the equipment to move to the undigged area to continue digging. The equipment has a higher degree of automation and is more time-saving and labor-saving. On the other hand, it ensures that the equipment is more efficient in digging holes, and the motor 3 on the two guide seats can flexibly adjust the roller 2 through the rotating shaft to drive the equipment to move. direction, to ensure that the area covered by the equipment for digging in the planting area is more comprehensive.

Owner:SHANDONG FOREST GERMPLASM RESOURCES CENT

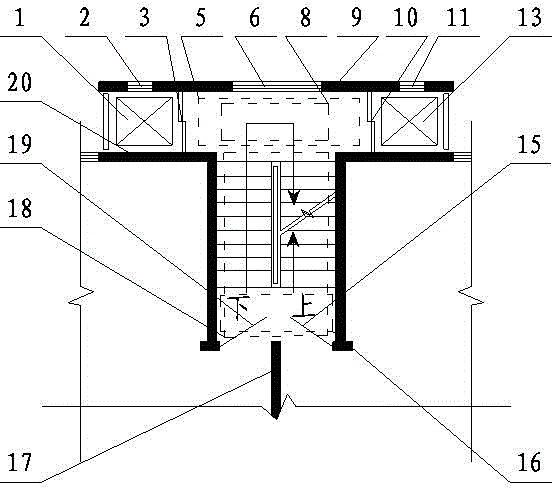

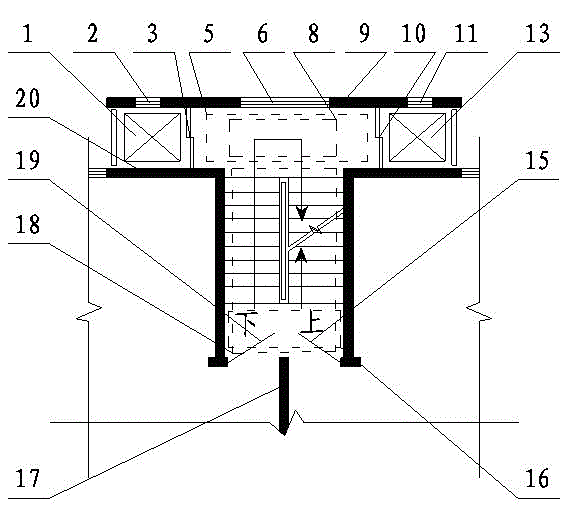

Residential building traffic junction with T-shaped plane

InactiveCN105569379AFully utilize the areaReduce the frequency of start and stopDwelling buildingSimulationEngineering

The invention discloses a residential building traffic junction with a T-shaped plane and belongs to the technical field of residential building design. The residential building traffic junction with the T-shaped plane is characterized in that the plane of the residential building traffic junction is T-shaped. The beneficial effects of the residential building traffic junction with the T-shaped plane are that equally shared area can be reduced; noise can be insulated and reduced; elevator operation cost can be reduced; and elevator riding comfortableness can be improved.

Owner:SHANDONG UNIV OF SCI & TECH

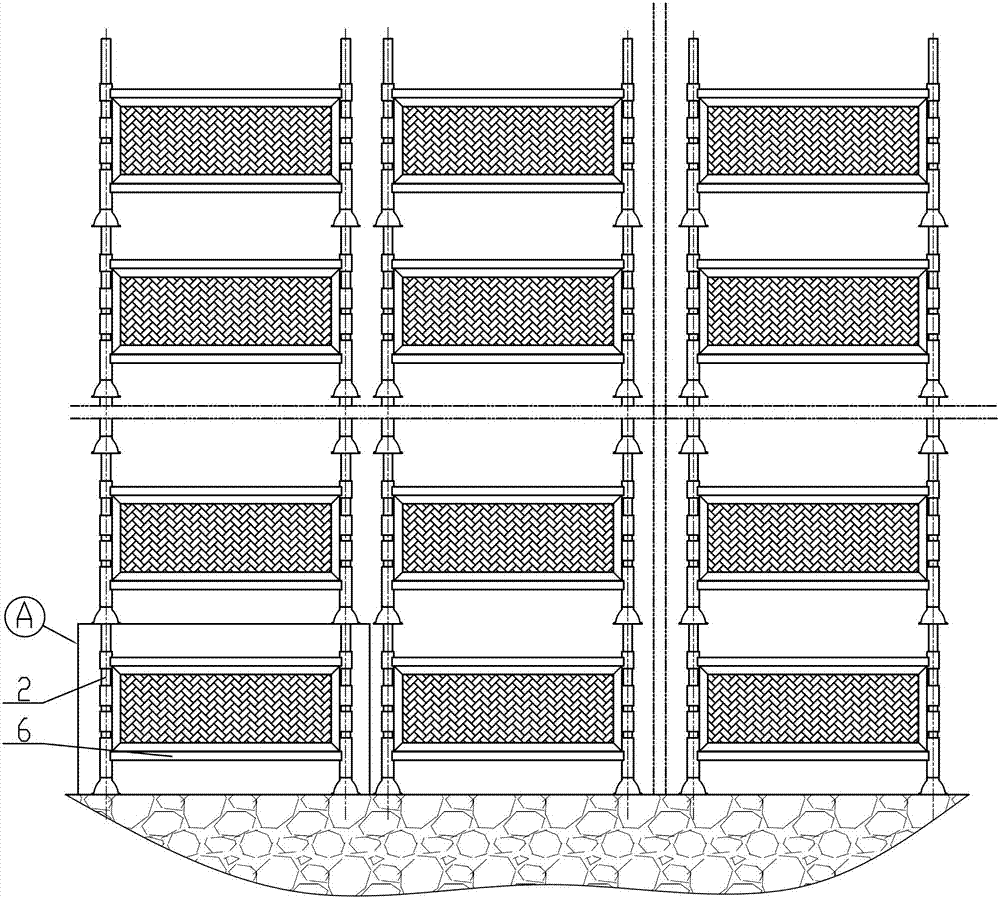

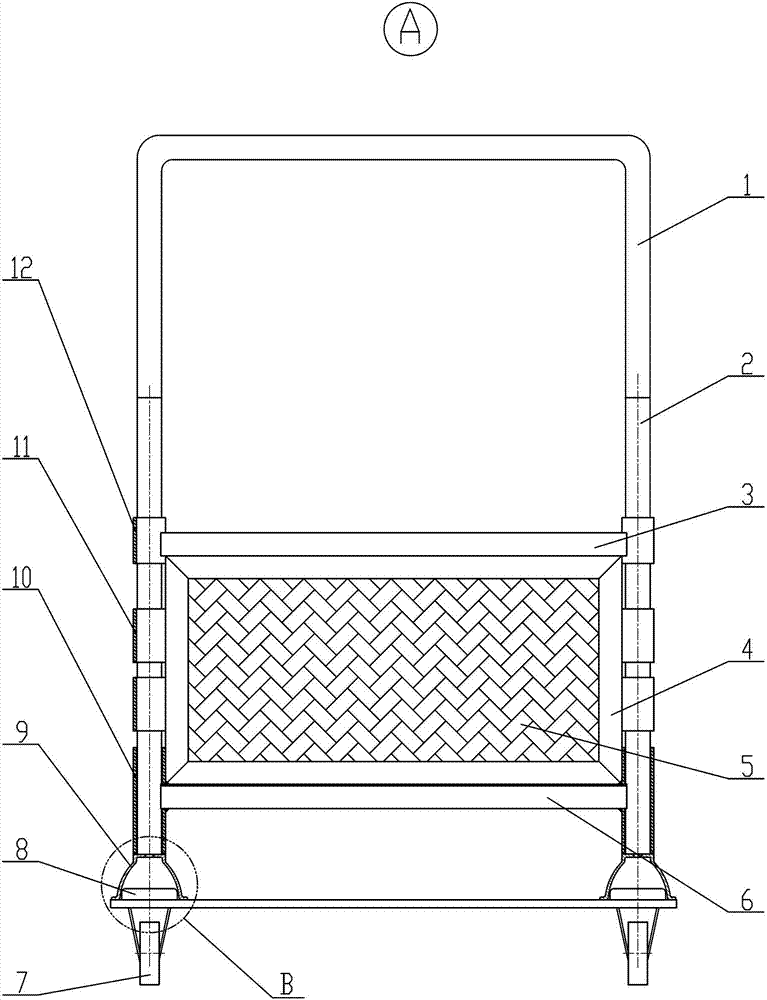

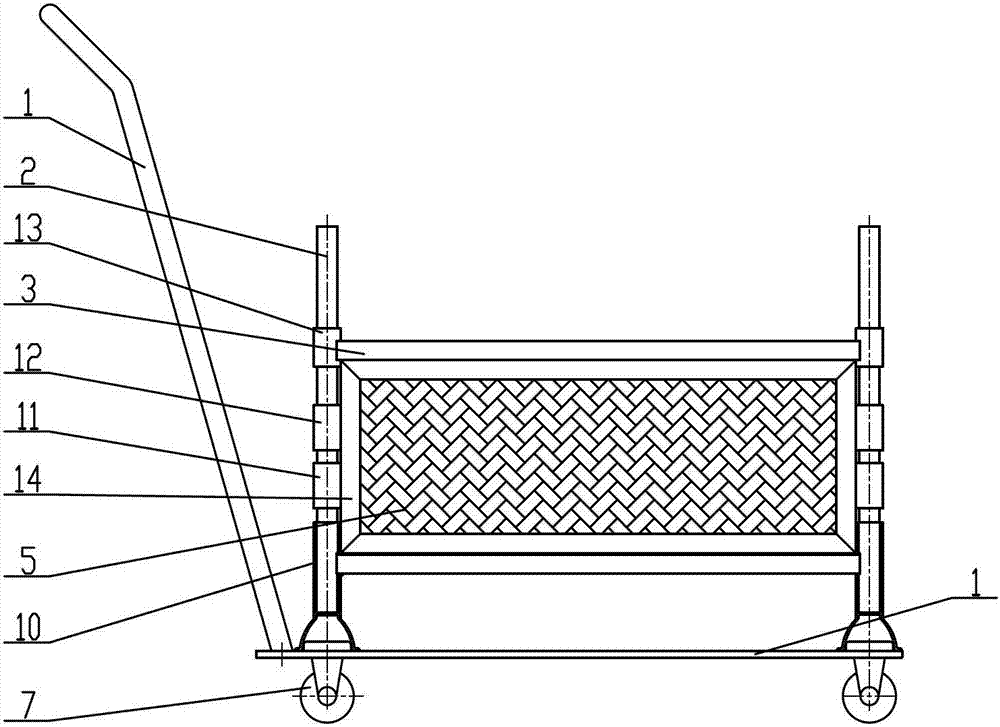

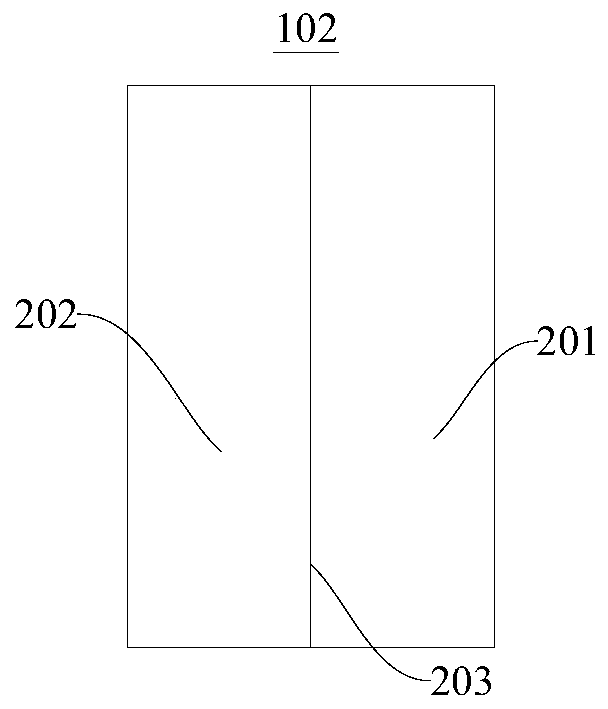

Splicing combined universal material basket

InactiveCN102975753BEasy to assembleEasy to storeHand carts with multiple axesGeneral purposeEngineering

The invention relates to a splicing-combined general-purpose material basket. The splicing-combined general-purpose material basket is characterized in that at least one splicing-combined general-purpose material basket is piled on a trolley; each general-purpose material basket consists of a basket bottom plate, four upright column sleeves, four upright columns, two long sidewalls, two wide sidewalls, a top frame and a piling component, wherein the four upright column sleeves are symmetrically connected to four corners of the basket bottom plate, and the four upright columns of the same size are mounted in the four upright column sleeves; the upper sections of the four upright columns extend out of the four upright column sleeves; the long sidewalls, the wide sidewalls and the top frame are connected to the extending sections of the four upright columns through slide sleeves; and the general-purpose material basket with a closed bottom and an open top is formed through splicing combination. According to the splicing-combined general-purpose material basket, the design is reasonable, simple and practical, the machining of parts is easy, the splicing assembly of the material basket is convenient, the storage of same components and parts is convenient, the loading and unloading of material pieces are favored, the labor intensity is low, storehouse racks can be movably and flexibly arranged, and then, the area of a storehouse is fully utilized. The splicing-combined general-purpose material basket has the characteristics of modern warehouse storage function management, and the like.

Owner:DALIAN SAGE GROUP

A photovoltaic power generation device and power supply system

ActiveCN108462460BMeet lighting needsFully utilize the areaPhotovoltaic supportsEnergy storageElectrical batteryLight energy

The invention discloses a photovoltaic power generation device and a power supply system, which belong to the field of batteries. The photovoltaic power generation device comprises a mounting frame, asliding mechanism, a battery pack and a pointing adjuster. The mounting frame is configured to be fixed to a building. The sliding mechanism is mounted on the mounting frame. The battery pack comprises a battery frame and a foldable battery panel, which are matched with each other. The battery rack is movably arranged on the sliding mechanism, and the foldable battery panel is rotatably connectedto the battery rack. The pointing adjuster is configured to independently adjust one or both of the battery frame and the foldable battery panel according to the lighting condition so that the foldable battery panel can track the sun movement. According to the photovoltaic power generation device, the external space of a building can be better utilized, and light energy can be effectively utilized.

Owner:HENAN POLYTECHNIC UNIV

T-shaped residential transportation junction

The invention discloses a T-shaped residential transportation junction, and belongs to a residential design technology. The T-shaped residential transportation junction is mainly characterized in that (1) the transportation junction is provided with an eastern elevator room and a western elevator room which are positioned out of an eave wall of a tower, the eave wall of the tower serves as an interior wall of the elevator rooms, and an elevator waiting hall is arranged between the two elevator rooms; (2) a public stair step section is a doglegged stair arranged in the south-north direction, and a public stair turning platform extends out of the eave wall of the tower, and is a portion of the elevator waiting hall; and (3) elevator passageways are distributed alternately. The T-shaped residential transportation junction has the advantages that residential pool area is reduced, effects of sound insulation and noise reduction are achieved, running cost of elevators is reduced, and riding comfort of the elevators is improved.

Owner:SHANDONG UNIV OF SCI & TECH

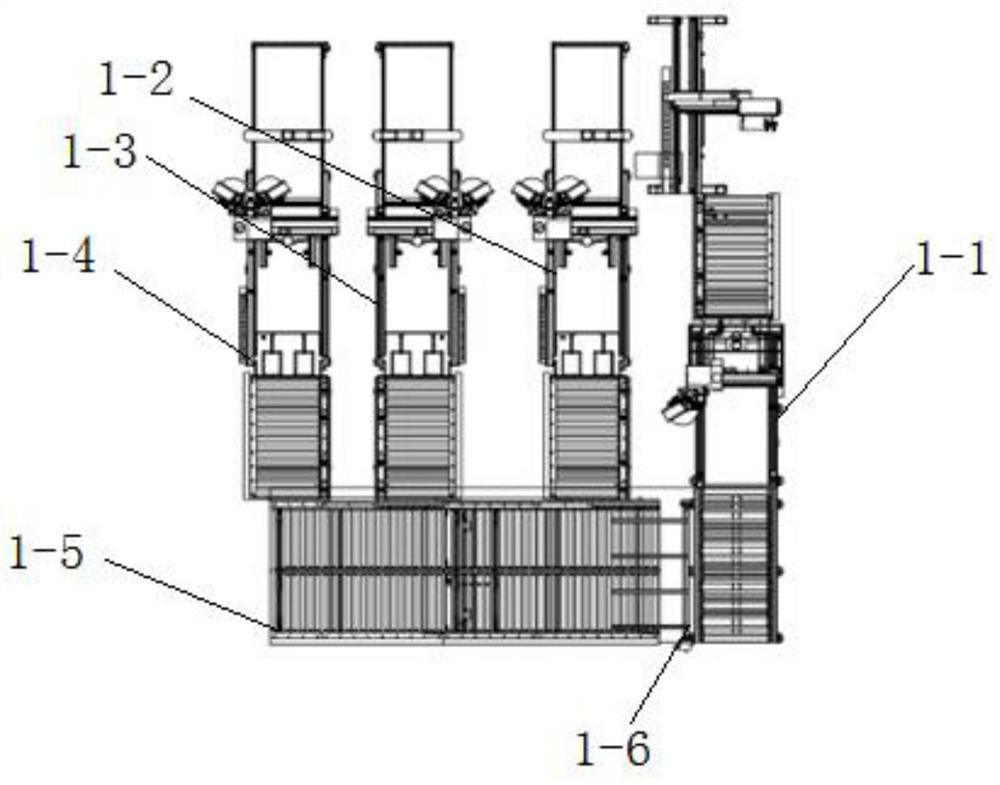

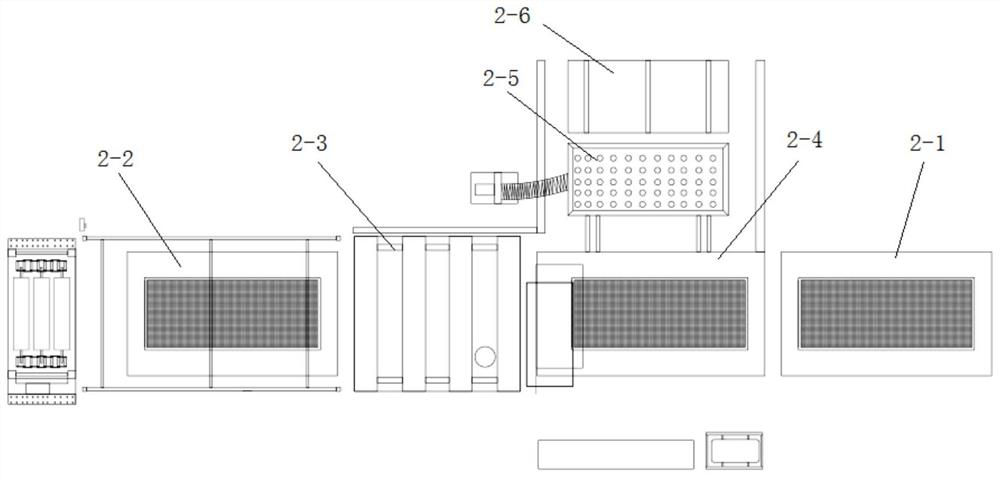

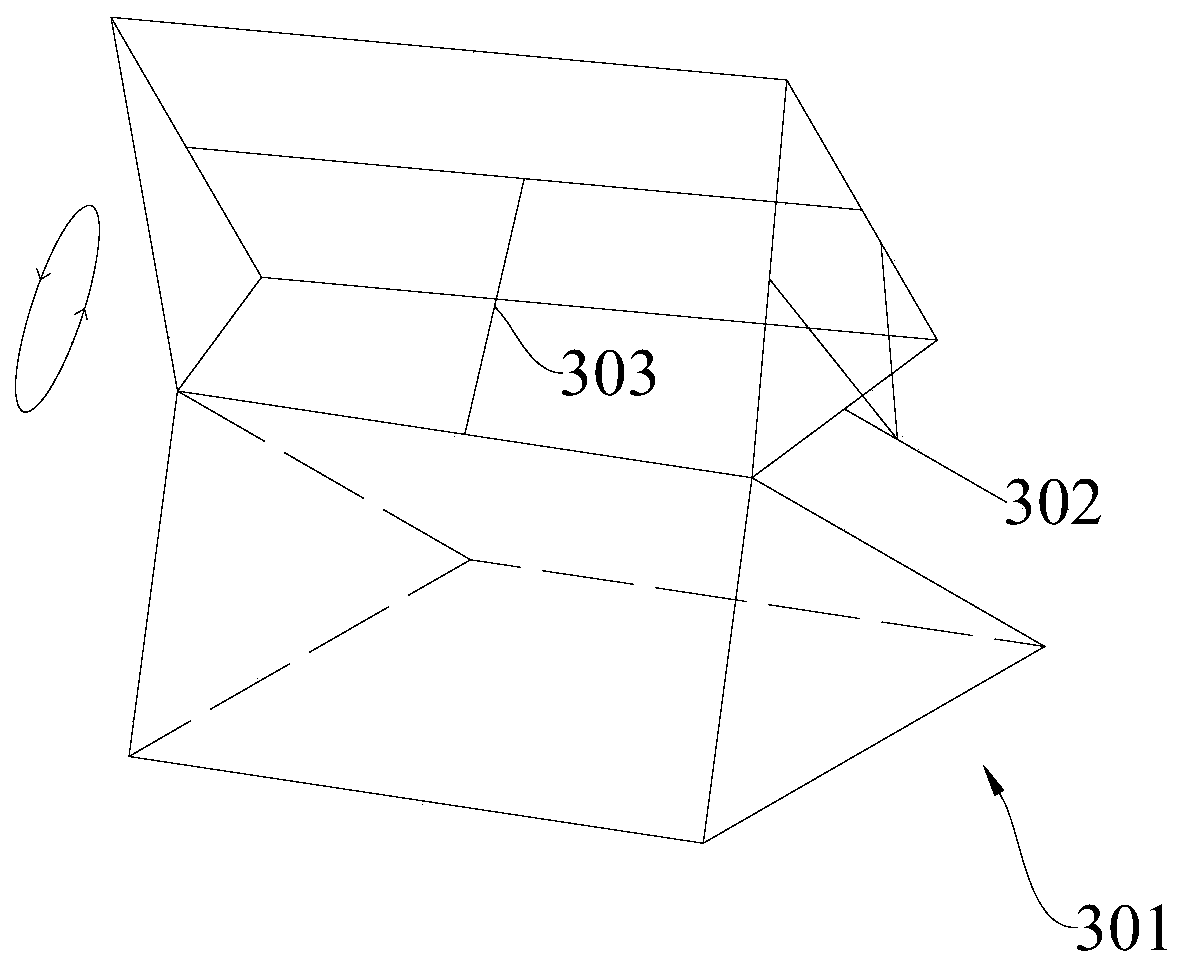

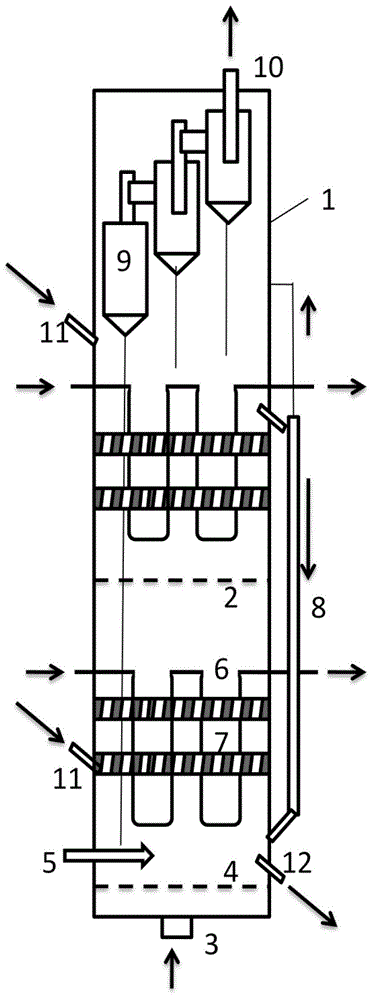

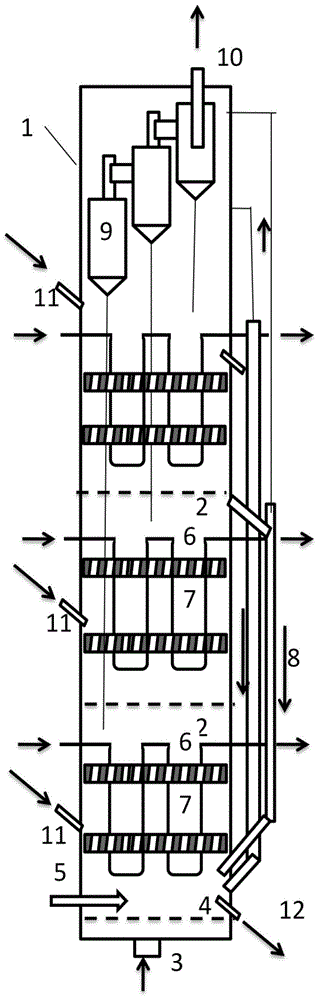

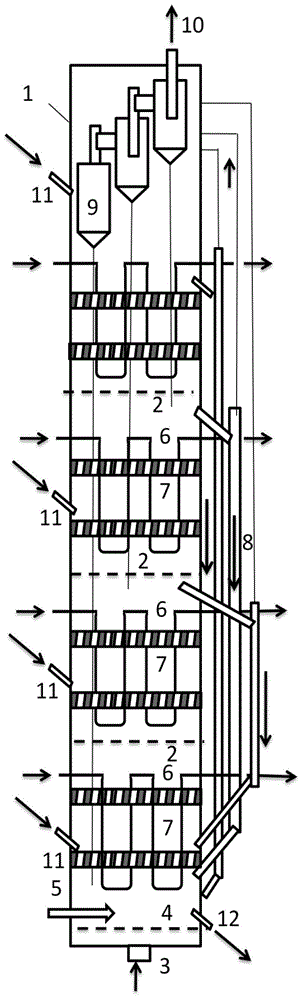

A multi-stage fluidized bed device and method for producing aromatics by catalytic conversion of alcohol/ether

ActiveCN103394312BEffective temperature controlUniform temperatureHydrocarbon from oxygen organic compoundsChemical recyclingHigh activityOperation safety

The invention belongs to the technical field of chemical preparation, and in particular relates to a multi-stage fluidized bed device and method for preparing aromatic hydrocarbon by alcohol / ether catalytic conversion. According to the method, a fluidized bed is divided into a plurality of catalyst filling sections through a transverse porous distribution plate, the operation of the fluidized bed can be stabilized by utilizing an overflow pipe, and a reacting raw material can be completely converted through the plurality of catalyst filling sections; the remained raw material can be contacted with a high-activity catalyst by adjusting the flow-rate of the regenerated catalysts at catalyst feed ports in different positions, so that complete conversion can be performed; a low-temperature liquid phase raw material is sprayed through a liquid phase nozzle and is directly vaporized to absorb heat; a low-temperature medium is introduced into a heat exchanger, so that the effects of controlling temperatures of different catalyst filling sections and controlling the coking amount of the catalyst can be played, and raw material preheating or side product steam can be completed. The multi-stage fluidized bed device has the advantages of high operation safety, high production strength of a reactor, high operation elasticity, continuous process, little investment and low energy consumption, is convenient to control temperature, and is suitable for large-scale operation.

Owner:TSINGHUA UNIV +1

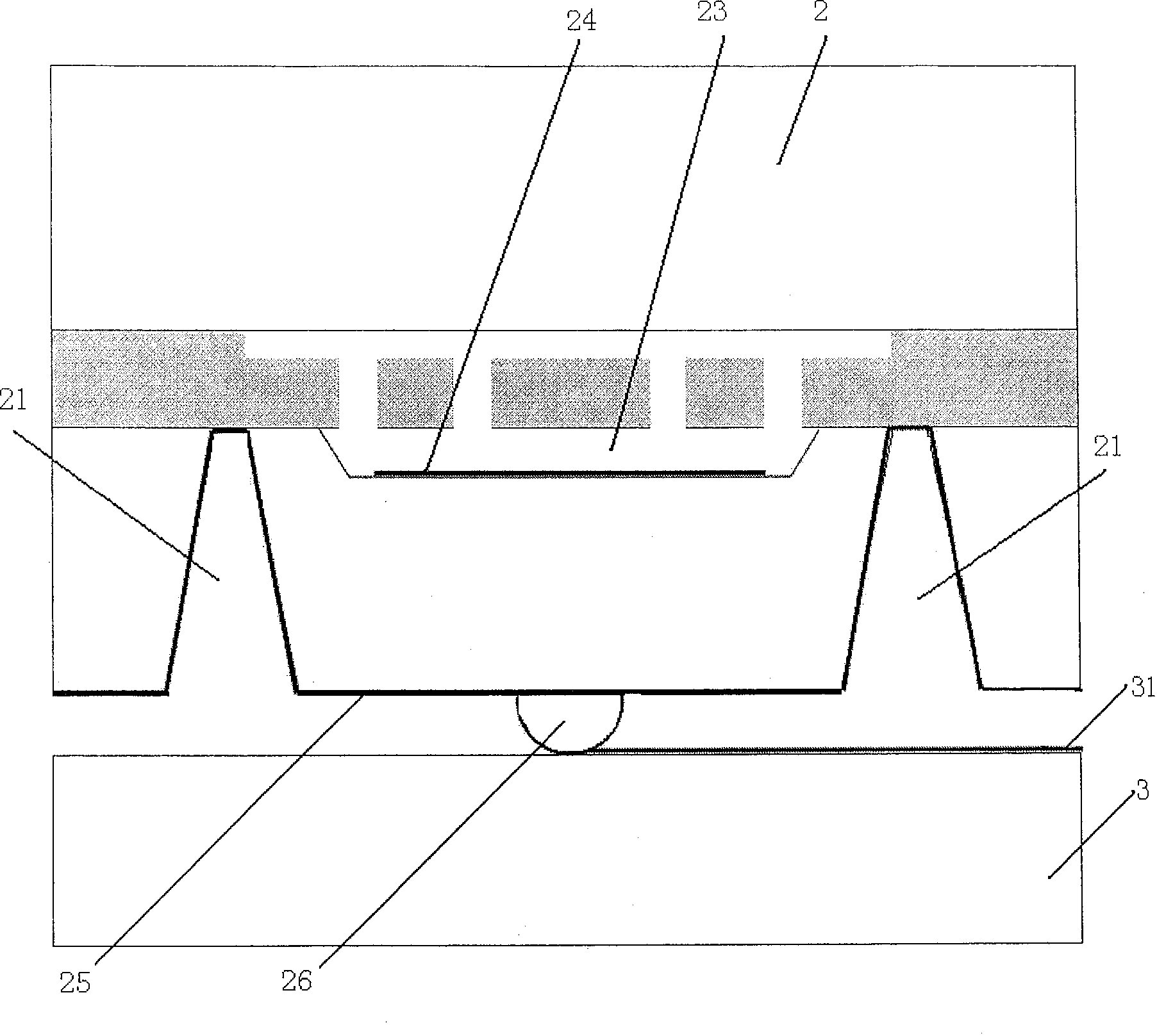

Wafer level vacuum encapsulation of microelectron mechanical system and upside-down mounting soldering method thereof

InactiveCN100513299CProtective structureHigh precisionSemi-permeable membranesPrecision positioning equipmentPass rateMicroelectromechanical systems

The invention relates to the wafer level vacuum package and the flip chip method of the microelectromechanical system, which comprises the following steps: nut cap glass sheets are perforated without getting through; tungsten alloy or chrome alloy is spattered on one side without perforating pin holes on the nut cap glass sheets and photoetching and corrosion are performed to form masks; the hydrofluoric acid is used to erode the glass cavity and erode through the pin holes without puncturing through; getter is spattered in the glass cavity; MEMS static electricity device structure wafers and the nut cap glass sheets are bonded by static electricity under the high temperature and the low pressure; metal electrodes are fabricated on the nut cap glass sheets and metal bumps are fabricated on the metal electrodes; single MEMS device chip after cutting is packaged with processing circuits by flip chip. The method package of the invention can be used in batch production, protect the MEMS device chips from outer pollution and damage and increase the pass-rate of production. The invention can be widely applied in the MEMS system.

Owner:PEKING UNIV

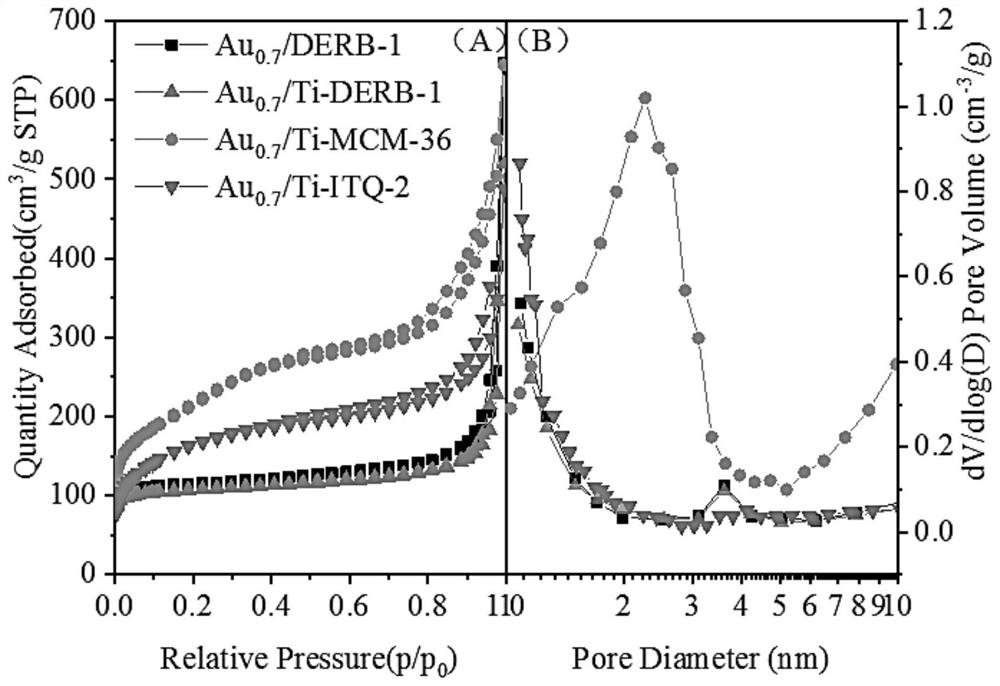

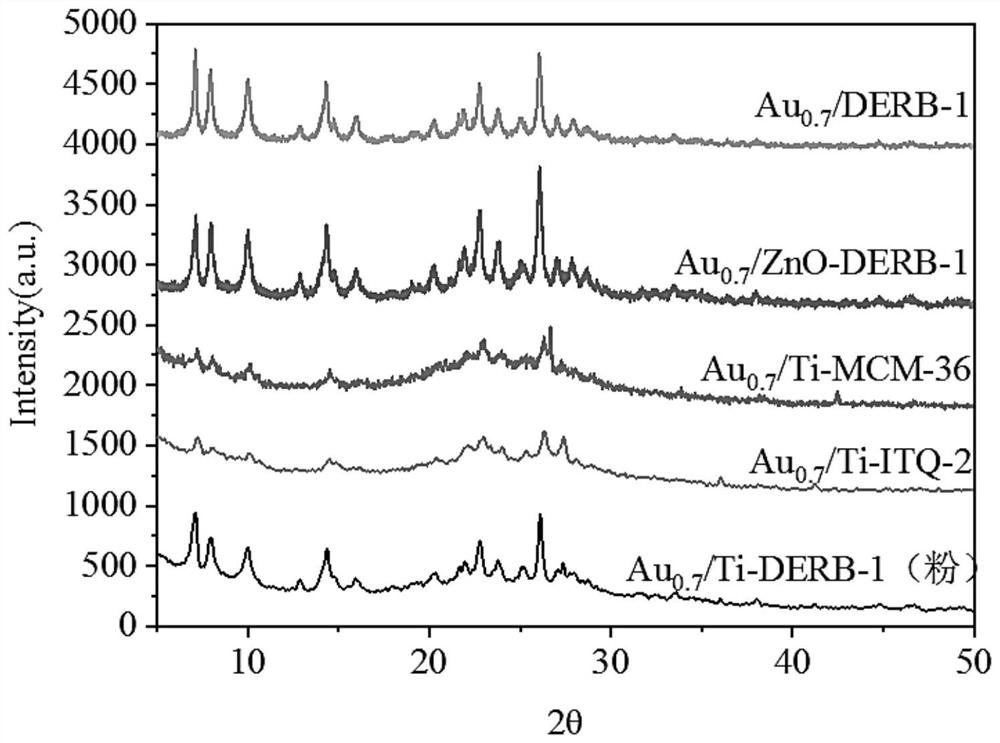

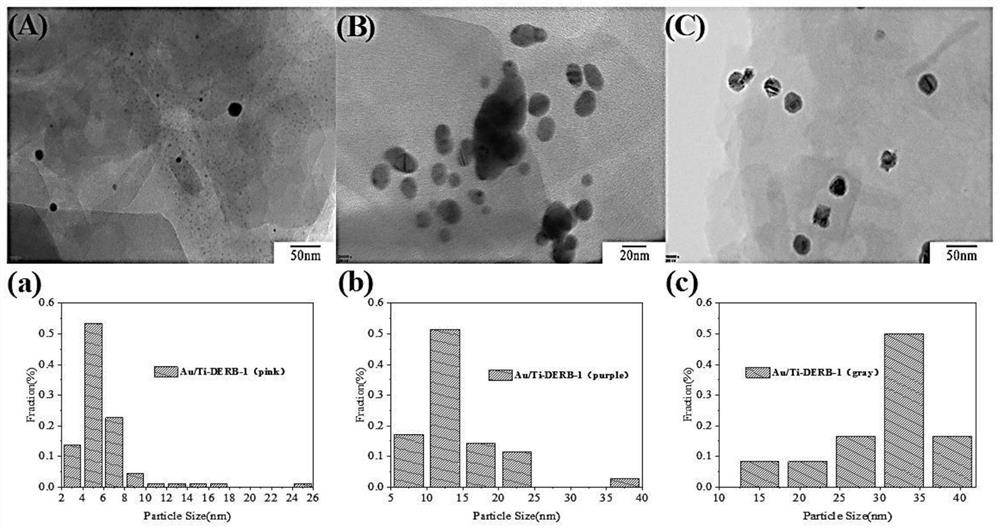

Catalyst for catalyzing alkane dehydrogenation to synthesize olefin as well as preparation method and application of catalyst

PendingCN114797959AEasy to removeReduce sizeMolecular sieve catalystsMolecular sieve catalystAlkaneMolecular sieve

The invention belongs to the technical field of catalysts, and particularly relates to a catalyst for catalyzing alkane dehydrogenation to synthesize olefin as well as a preparation method and application thereof. According to the hair style, the MWW molecular sieve is used as a carrier, and a hydroxyl structure is increased by regulating and controlling the layered structure; then fixing Ti by using hydroxyl groups on the surface through an atom in-situ transplantation method; the preparation method comprises the following steps: fixing Au nanoparticles on Ti of a molecular sieve through a deposition-precipitation method, and preparing the supported Au catalyst of which the MWW structure supports Au particles with the size of 1-2nm by utilizing the pore structure of the MWW molecular sieve, especially the size of the Au particles limited by 2nm mesopores in an MCM-36 structure.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Factory building roof solar photovoltaic panel sun-shading system

InactiveCN106130448AReduce energy consumptionImprove developmentPhotovoltaic supportsSunshadesElectricityEngineering

The invention relates to a factory building roof solar photovoltaic panel sun-shading system comprising a solar photovoltaic panel, a slide rail, a support rack, a clamping device-equipped semisphere-shaped pulley wheel and winches, wherein the support rack is arranged on a lower part of the solar photovoltaic panel, the clamping device-equipped semisphere-shaped pulley wheel is arranged a bottom part of the support rack, the clamping device-equipped semisphere-shaped pulley wheel is placed on the sliding rail, winches are arranged at both sides of the sliding rail, and the system is arranged beside a light gathering band on a roof; the factory building solar energy sun-shading system can be used for shading the light gathering band on the roof in summer, sunlight can be prevented from being directly emitted into a factory building, and demand for cooling loads in the factory building can be reduced; the sun-shading system can be moved away in winter, the sunlight is enabled to be directly emitted into the factory building, indoor temperature can be raised, thermal requirements of the factory building can be reduced, energy can be saved in summer and in winter, photovoltaic power generation can be realized via the system so as to satisfy part of demand for electricity consumption of the factory building, and a utilization rate of the roof of the factory building can be increased.

Owner:爱科住工(青岛)被动房屋有限公司

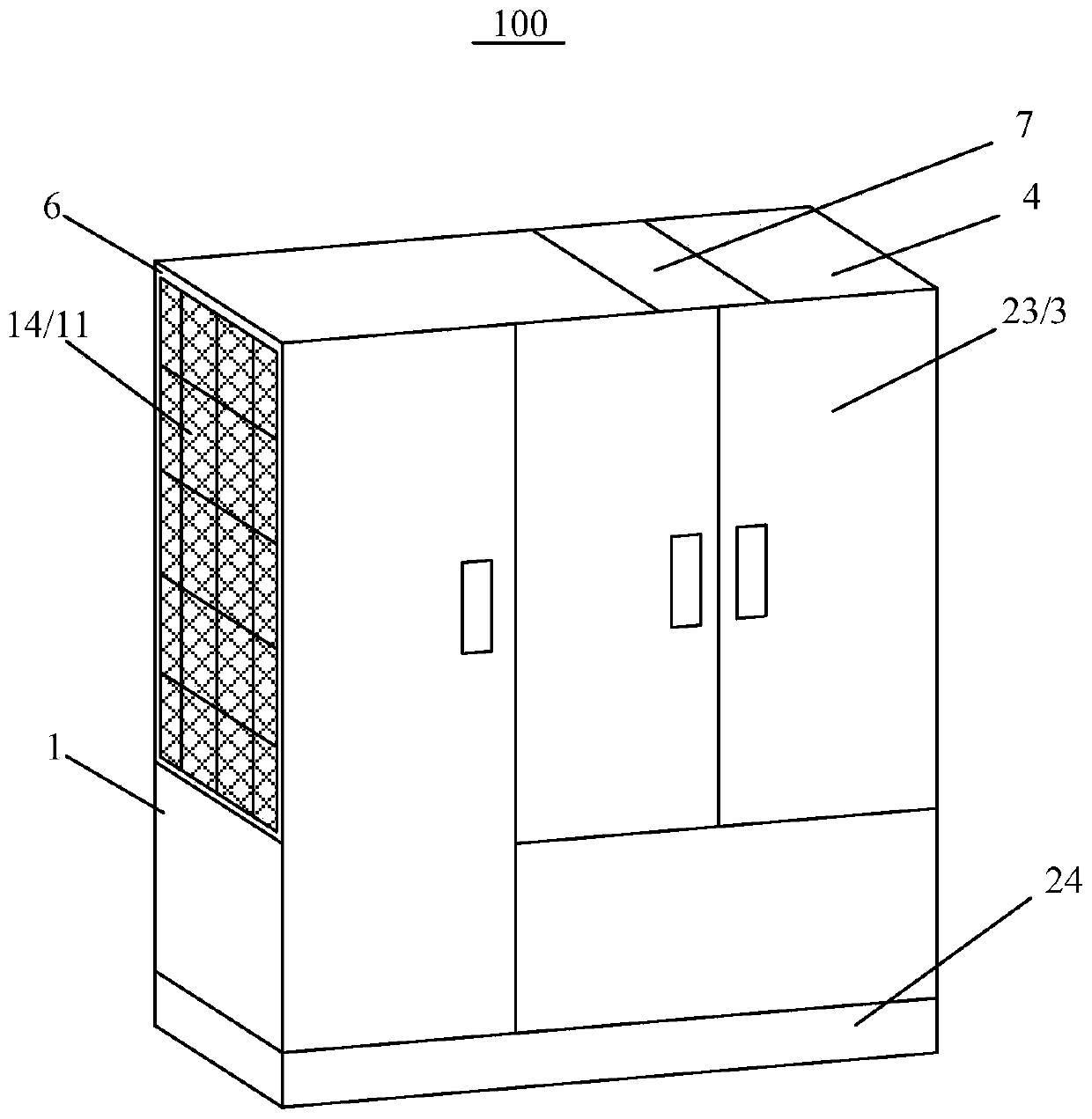

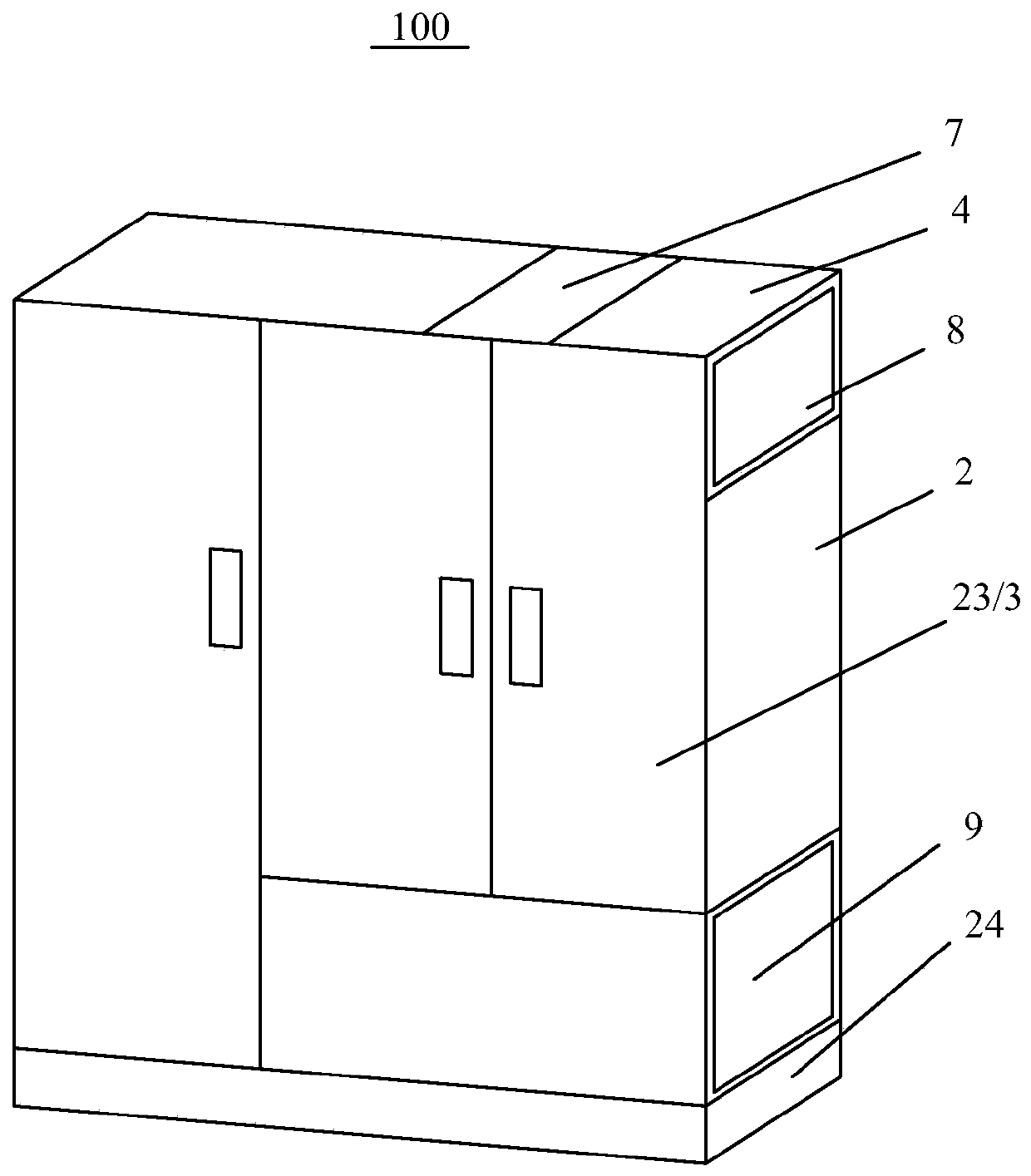

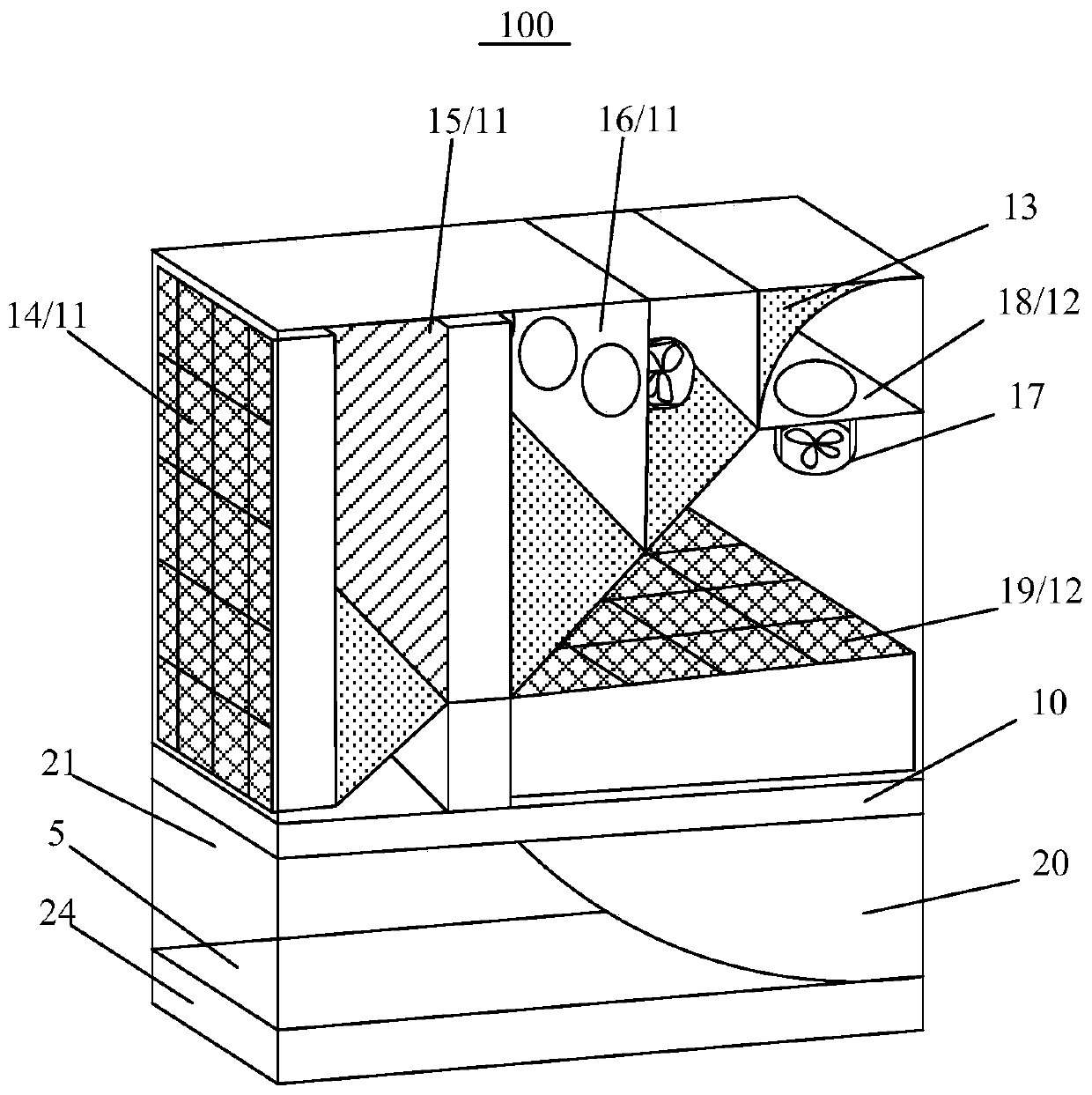

Machine room air conditioner integrated machine

InactiveCN110715377AFlexible arrangementFully utilize the areaMechanical apparatusLighting and heating apparatusEngineeringRefrigeration

The invention discloses a machine room air conditioner integrated machine. The machine room air conditioner integrated machine comprises a machine cabinet; the machine cabinet comprises a first side plate, a second side plate, a third side plate, a fourth side plate, a top plate and a bottom plate; a first air inlet is formed at one end, near the top plate, of the first side plate; a first air outlet is formed on the top plate; a second air inlet is formed at one end, near the top plate, of the third side plate; a second air outlet is formed at one end, near the bottom plate, of the third sideplate; the machine cabinet is internally provided with an upper branched part and a lower branched part; the upper branched part comprises an outer circulation branched part and a first inner circulation branched part; a first air inlet part, an auxiliary refrigeration part and a first air outlet part are arranged in the outer circulation branched part; the first air outlet part is provided witha plurality of fans; a second air inlet part and a filtering part are arranged in the first inner circulation branched part; the second air inlet part is provided with a plurality of fans; and the lower branched part comprises a second air outlet part and an equipment chamber. Complex functions and parts in a common machine room are concentrated into one machine cabinet, so that the arrangement mode of the machine room air conditioner is more flexible.

Owner:上海蓝色帛缔智能工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com