A multi-stage fluidized bed device and method for producing aromatics by catalytic conversion of alcohol/ether

A catalytic conversion, fluidized bed technology, applied in chemical instruments and methods, hydrocarbon production from oxygen-containing organic compounds, chemical recovery, etc., can solve the problem of not ensuring rapid deactivation of catalysts, prolonging catalyst residence time, and increasing wastewater treatment costs, etc. problems, to achieve the effect of rich heat exchange area, low waste water treatment cost, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

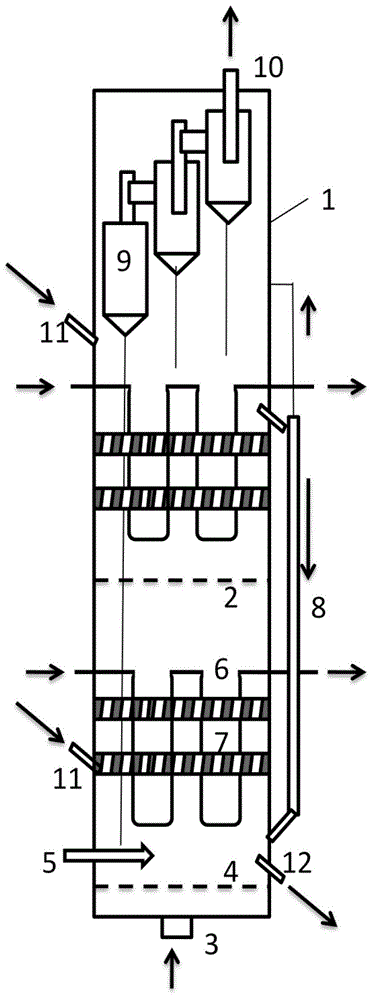

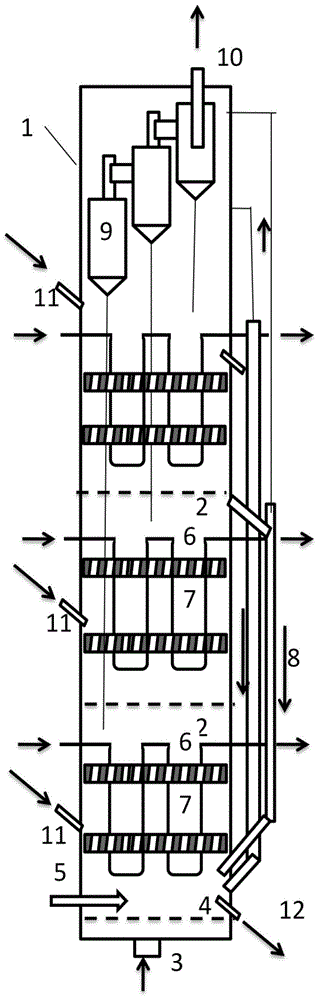

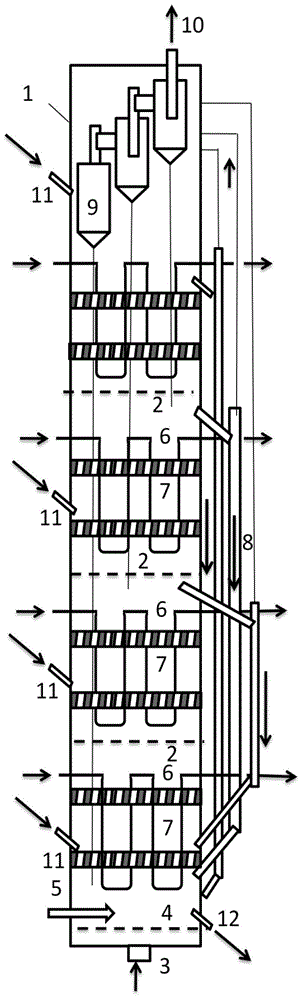

[0083] use figure 1 In the two-stage fluidized bed 1 shown, the distance between the gas distributor 4 and the liquid phase nozzle 5 is controlled to be 0.1 times the diameter of the two-stage fluidized bed 1 . A liquid phase nozzle 5 is extended into the two-stage fluidized bed 1 and fixed on the cylinder wall of the two-stage fluidized bed 1 . The distance between the outlet at the upper end of the outer overflow pipe 8 and the horizontal porous distribution plate 2 below is 0.1 times the diameter of the two-stage fluidized bed 1 . The position of the inlet at the lower end of the outer overflow pipe 8 is in the first catalyst filling section. The two catalyst inlets 11 lead into the two catalyst filling sections respectively, and the position of the uppermost catalyst inlet 11 is 1m higher than the upper outlet of the adjacent outer overflow pipe 8 . The gas contained in the catalyst entering from the outlet at the upper end of the outer overflow pipe 8 is led to the vici...

Embodiment 2

[0088] use figure 1 The two-stage fluidized bed 1 is shown. Control the distance between the gas distributor 4 and the liquid phase nozzle 5 to be 0.05 times the diameter of the fluidized bed. Four liquid phase nozzles 5 are fixed on the cylinder wall of the two-stage fluidized bed 1 and distributed symmetrically, and extend into the two-stage fluidized bed 1 . The distance between the outlet at the upper end of the outer overflow pipe 8 and the horizontal porous distribution plate 2 below is twice the diameter of the two-stage fluidized bed 1 . The position of the inlet at the lower end of the outer overflow pipe 8 is in the first catalyst filling section. The two catalyst inlets 11 lead into the two catalyst filling sections respectively, and the position of the uppermost catalyst inlet 11 is 2m higher than the upper outlet of the adjacent outer overflow pipe 8 . The gas contained in the catalyst entering from the upper outlet of the outer overflow pipe 8 is led to the vi...

Embodiment 3

[0093] use figure 1 The two-stage fluidized bed 1 is shown. Control the distance between the gas distributor 4 and the liquid phase nozzle 5 to be 0.2 times the diameter of the two-stage fluidized bed 1 . Twelve liquid phase nozzles 5 are fixed on the cylinder wall of the two-stage fluidized bed 1 and evenly distributed, and extend into the two-stage fluidized bed 1 . The distance between the outlet at the upper end of the outer overflow pipe 8 and the horizontal porous distribution plate 2 below is 4 times the diameter of the two-stage fluidized bed 1 . The position of the inlet at the lower end of the outer overflow pipe 8 is in the first catalyst filling section. The two catalyst inlets 11 lead into the two catalyst loading sections respectively, and the position of the uppermost catalyst inlet 11 is 1.5m higher than the upper outlet of the adjacent outer overflow pipe 8 . The gas contained in the catalyst entering from the upper outlet of the outer overflow pipe 8 is le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com