Seedbed for greenhouse strawberry planting

A strawberry and seedbed technology, applied in botany equipment and methods, horticulture, container cultivation, etc., can solve the problems of complex structure, high cost, high failure rate, etc., and achieve the effects of light and simple structure, increased planting amount, and increased quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

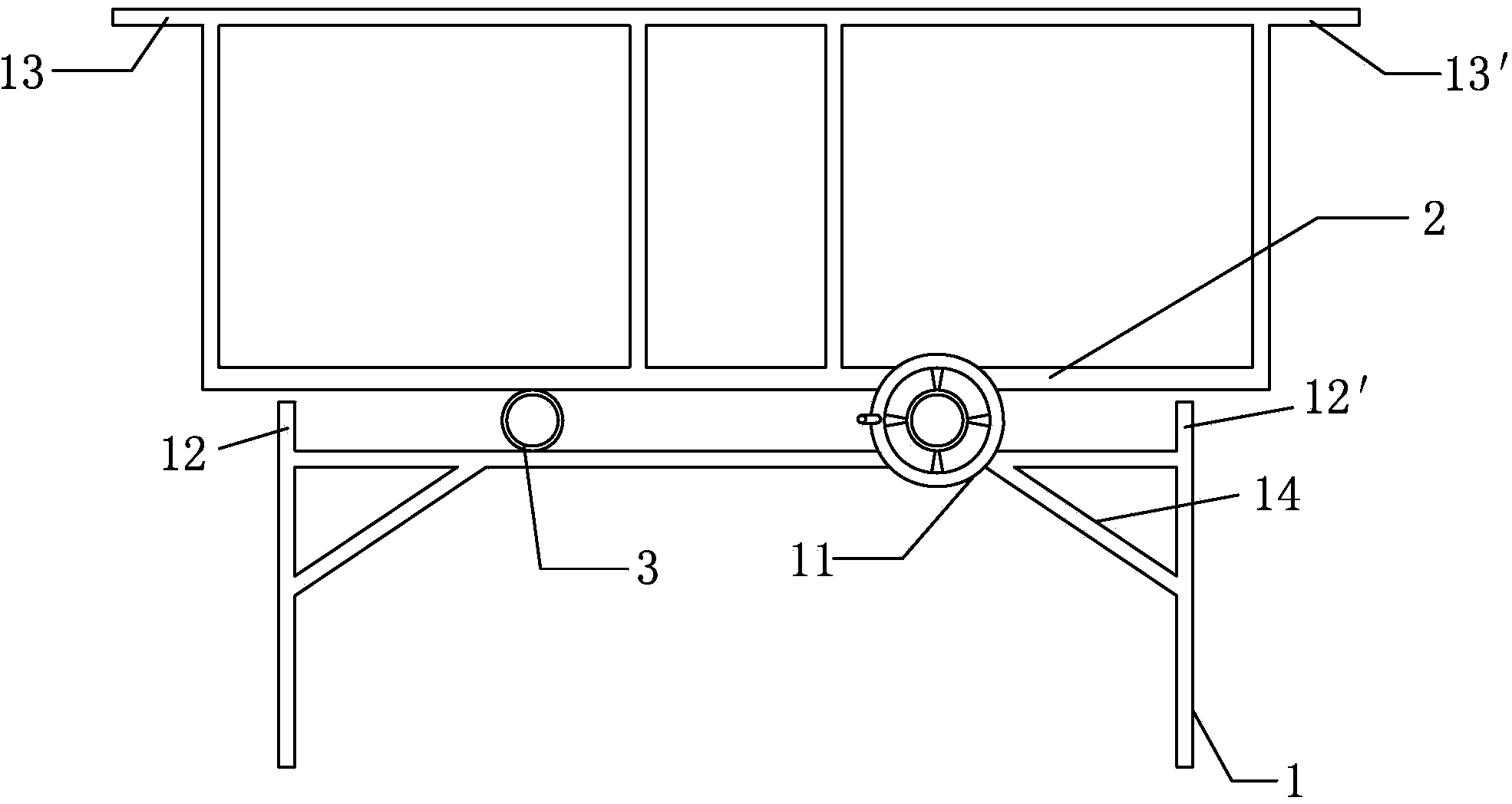

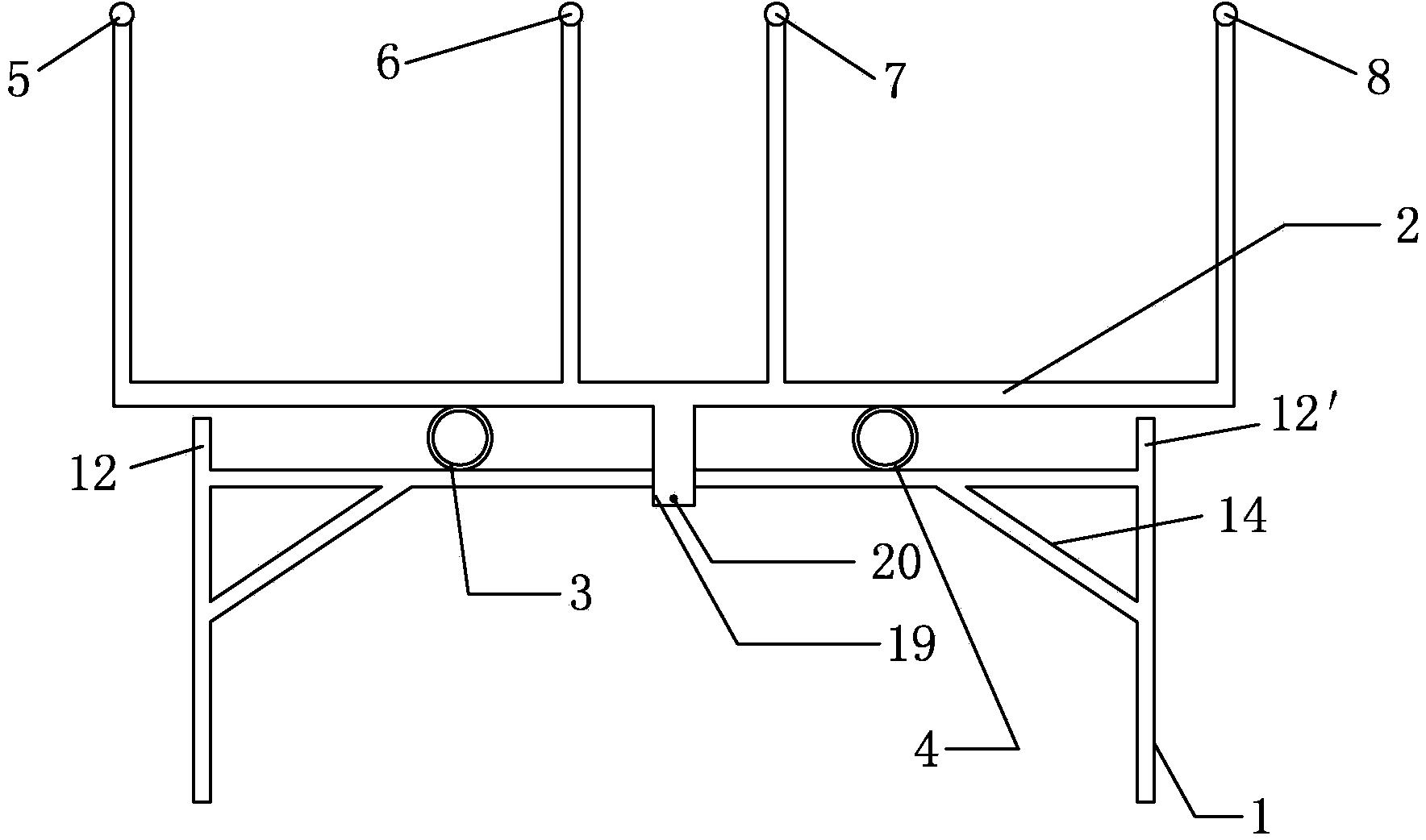

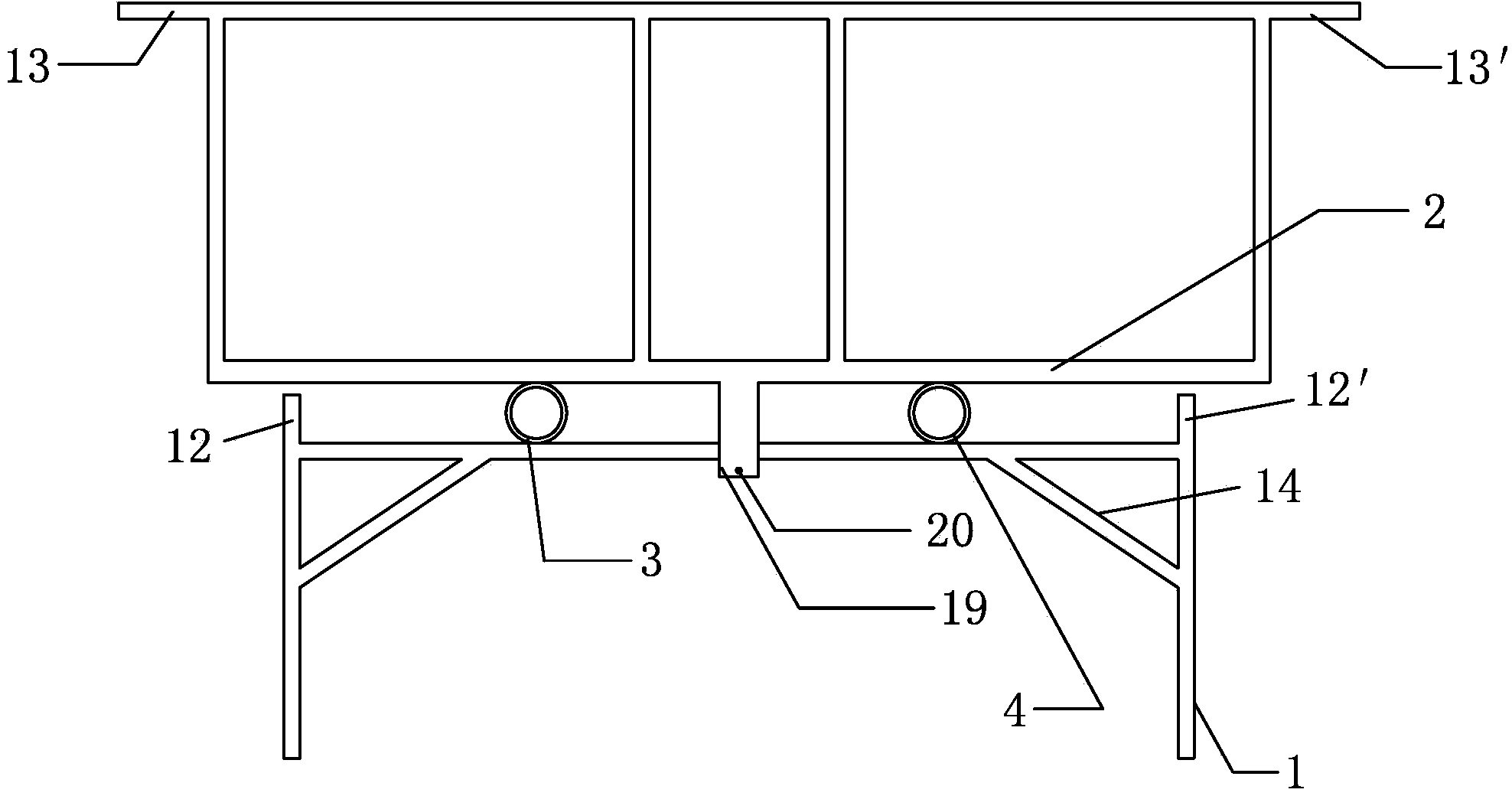

[0036] Example: see Figure 1~6 As shown, a seedbed for growing strawberries in a greenhouse includes a lower support frame 1, an upper bracket 2, and a first round bar 3 and a second round bar 4 with the same size; the lower support frame 1 is vertically positioned in the greenhouse On the inner ground, the top of the lower support frame 1 has a supporting horizontal plane extending longitudinally along the greenhouse, and the first round rod 3 and the second round rod 4 are placed on the support of the lower support frame 1 along the lengthwise direction of the greenhouse. level.

[0037] The upper bracket 2 is placed on the first round bar 3 and the second round bar 4. On the cross section along the greenhouse, the first round bar 3 and the second round bar 4 are centered on the vertical line of the center of gravity of the upper bracket 2. Symmetrical arrangement (the first round rod 3 and the second round rod 4 are preferably located at 1 / 3 of the upper bracket, because ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com