Chain wheel tooth hole of COF product

A sprocket and product technology, applied in the field of COF product manufacturing, can solve the problems of reduced utilization rate of COF products, increased cost, tearing of substrates, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

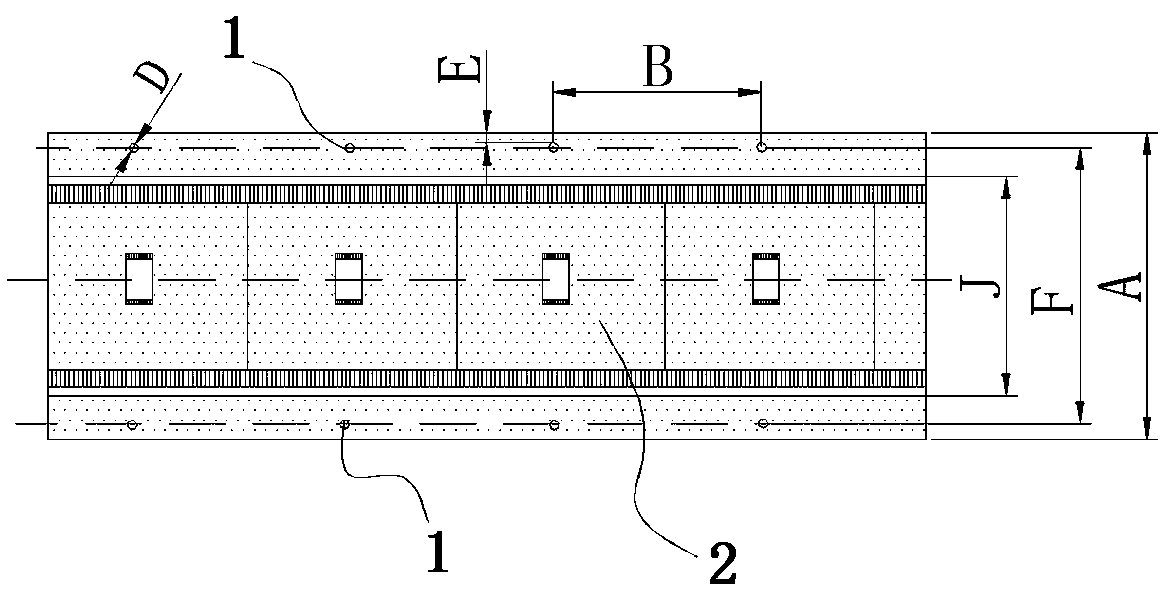

[0031] Such as figure 1 As shown, a sprocket tooth hole of a COF product is characterized in that:

[0032] The COF product is a strip-shaped coil, including an effective wiring pattern area 2 and symmetrically distributed sprocket holes 1 located on both sides of the effective wiring pattern area 2;

[0033] When the width A of the COF product is 35mm, the pitch B of the sprocket hole is 32mm-34mm; the distance E from the sprocket hole to the edge of the COF product is 0.5-1.0mm; the distance F between the sprocket holes is 32mm-34mm ; The distance J of the effective area of the wiring pattern is 28-30mm.

[0034] The distance E between the tooth hole of the sprocket and the edge of the COF product refers to the distance from the outer side of the tooth hole of the sprocket closest to the edge of the COF product.

[0035] The sprocket tooth hole is circular, that is, the diameter D of the sprocket tooth hole is 0.8-1.4mm.

[0036] The sprocket hole may be elliptical, tha...

Embodiment 2

[0038] When the width A of the COF product is 35mm, 48mm, and 70mm, the relevant parameters of the sprocket hole are shown in Table 3 below;

[0039] table 3

[0040] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com