Splicing combined universal material basket

A combined type and material basket technology, which is applied to multi-axis trolleys, trolleys, motor vehicles, etc., can solve problems such as difficult installation and manufacturing, damage to the surface of materials, and inconvenient insertion and removal of materials, so as to facilitate insertion and removal. The effect of taking out, maneuvering and flexible arrangement, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

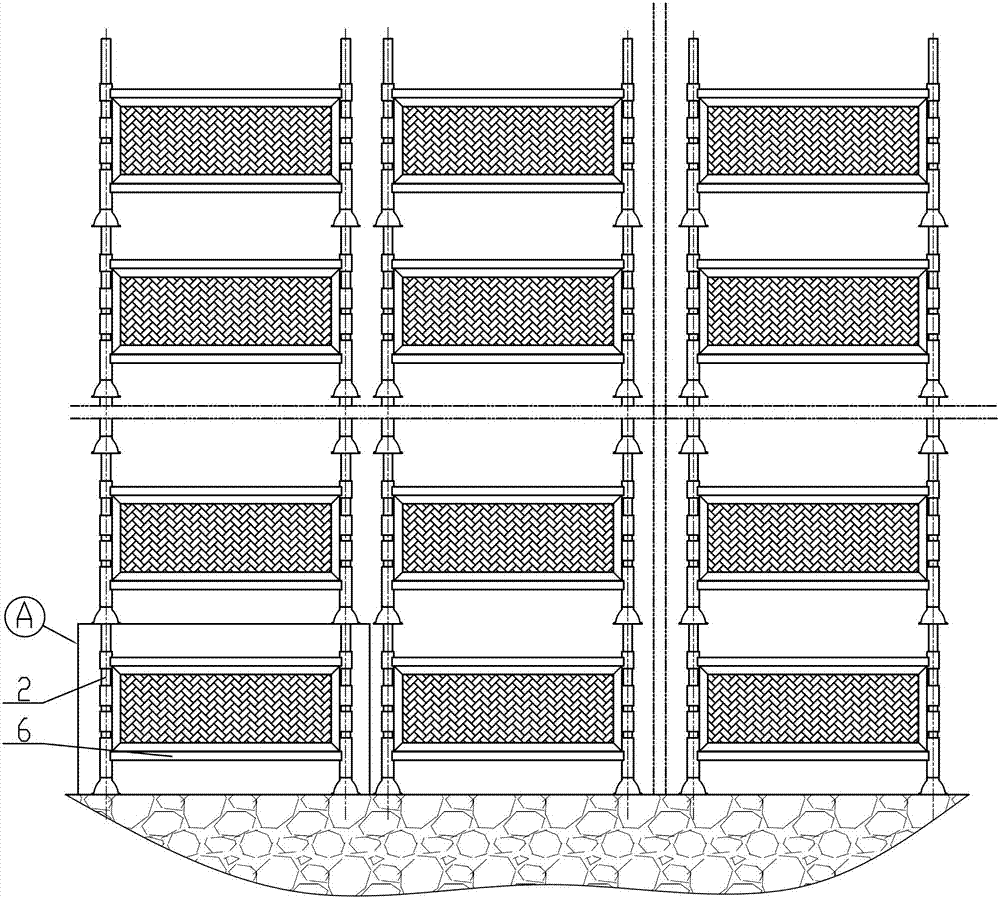

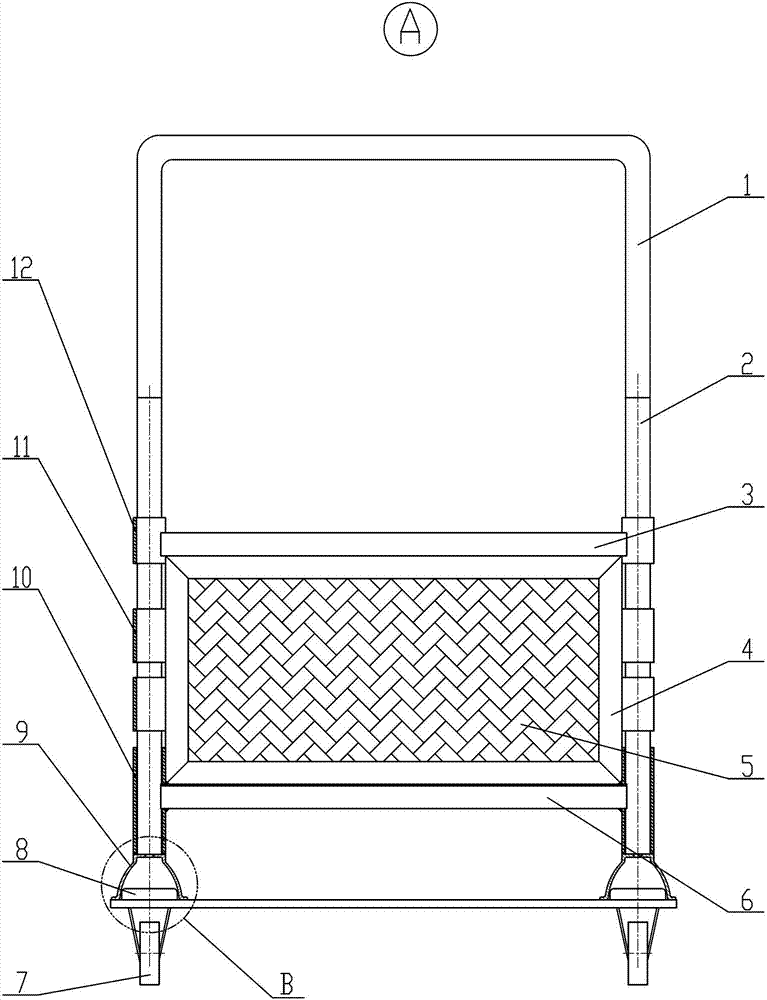

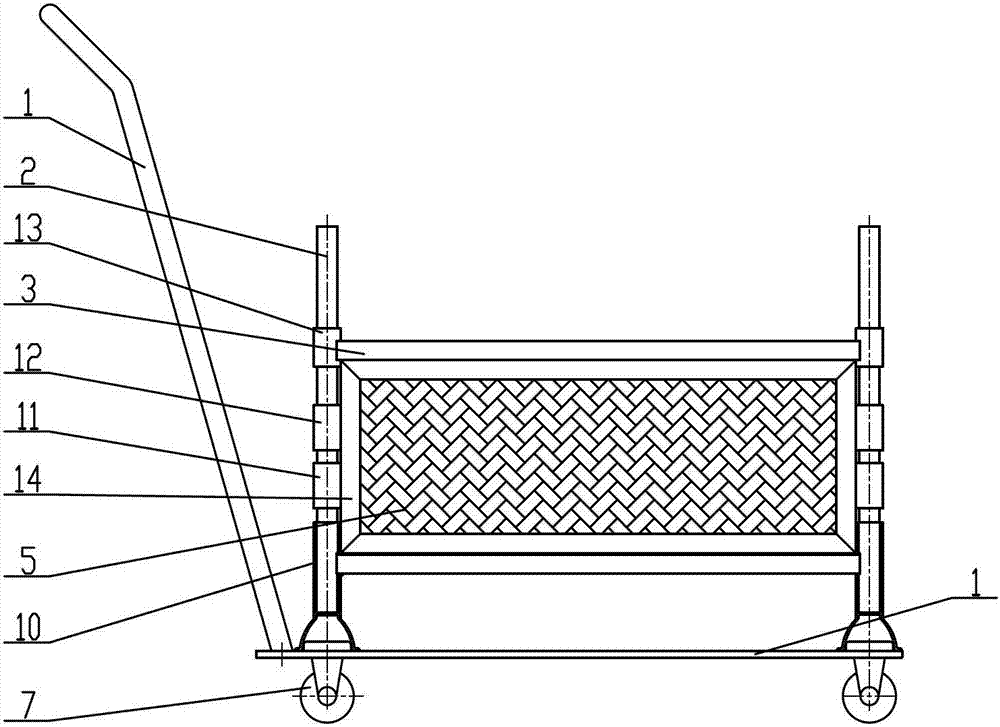

[0019] figure 1 , 2 Shown in , 3, 4 is the specific embodiment of the present invention, and it is the general material basket of splicing combination type that distribution is installed in the semi-finished product storehouse of certain machine factory, it is characterized in that: dolly 1 in the mechanical workshop of processing parts On the top surface of the car body, 8 spliced and combined general-purpose baskets are stacked on the top surface of the car body; each general-purpose basket is composed of a basket bottom plate 6, a column cover 10, a column 2, two long The side wall 14, two wide side walls 4, the top frame 3 and stacked components are composed of four mutually perpendicular column sleeves 10 symmetrically connected to the outer sides of the four corners of the basket bottom plate 6, and the four column sleeves 10 are respectively Load four galvanized tube uprights 2 of the same size; the upper sections of the four uprights 2 are exposed outside the four u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com