Wire sawing device

A technology of wire sawing and sawing, which is applied in the field of wire saws, can solve the problems of scrapped workpieces, and achieve the effects of saving space, reducing costs, reducing investment costs and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

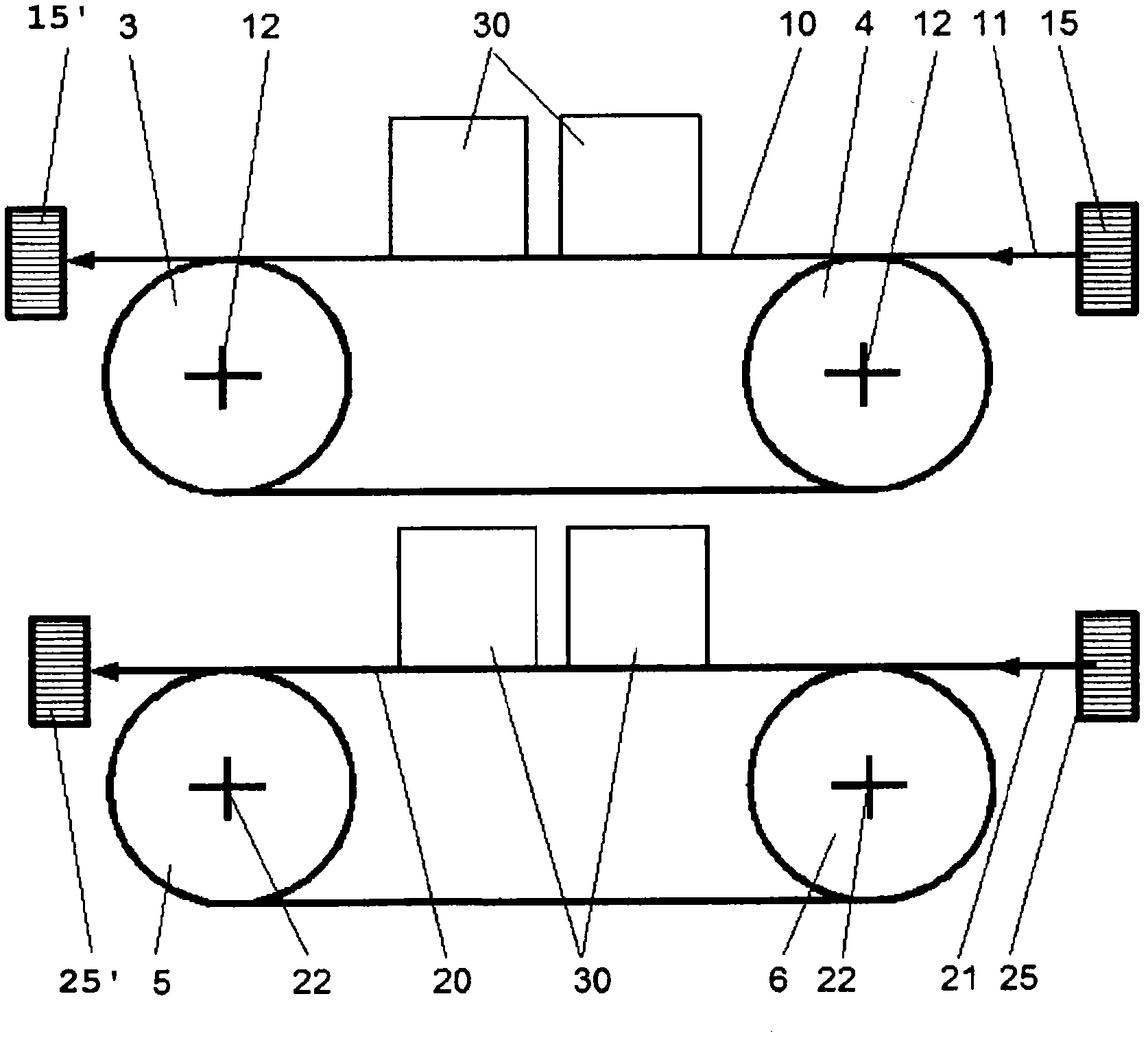

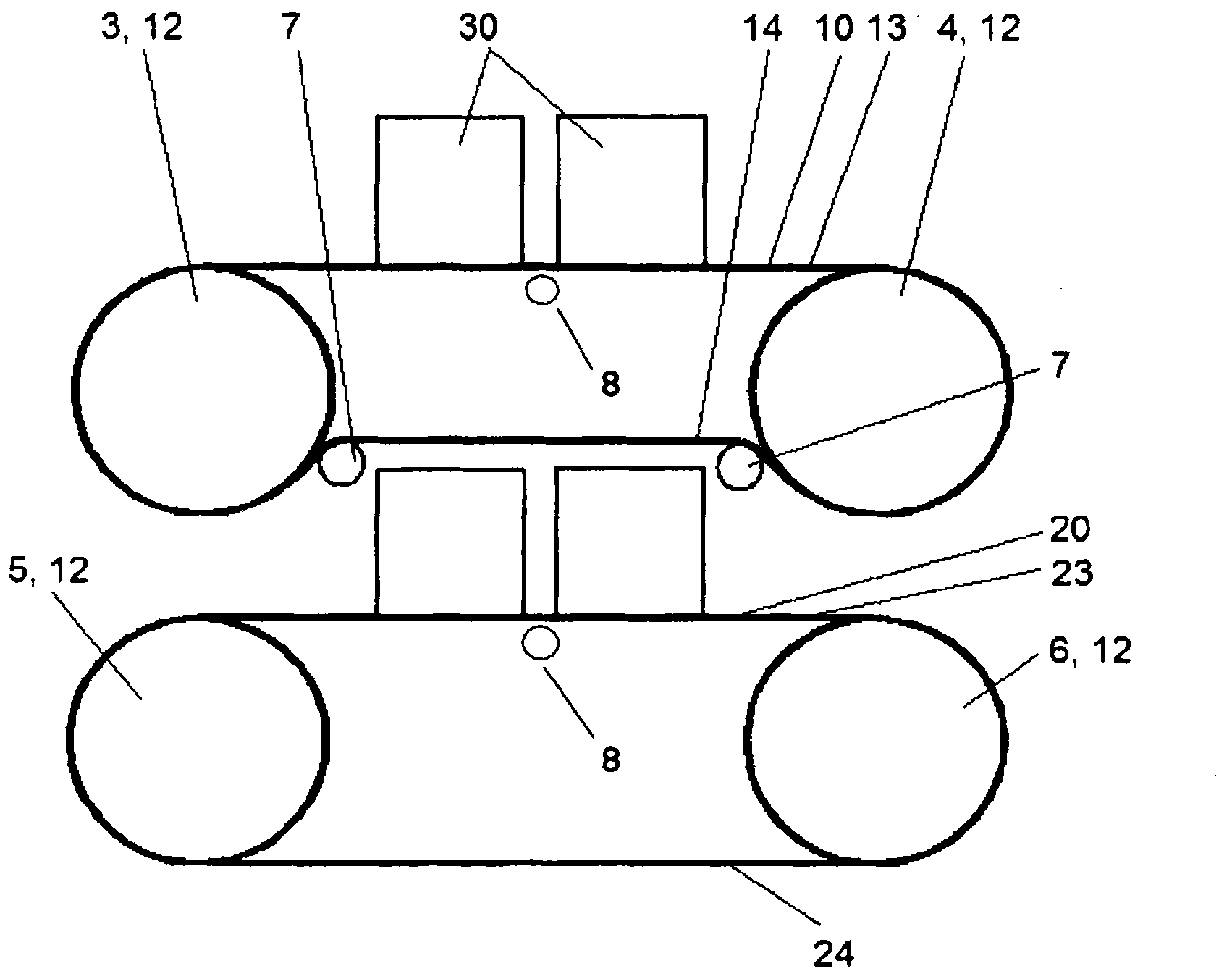

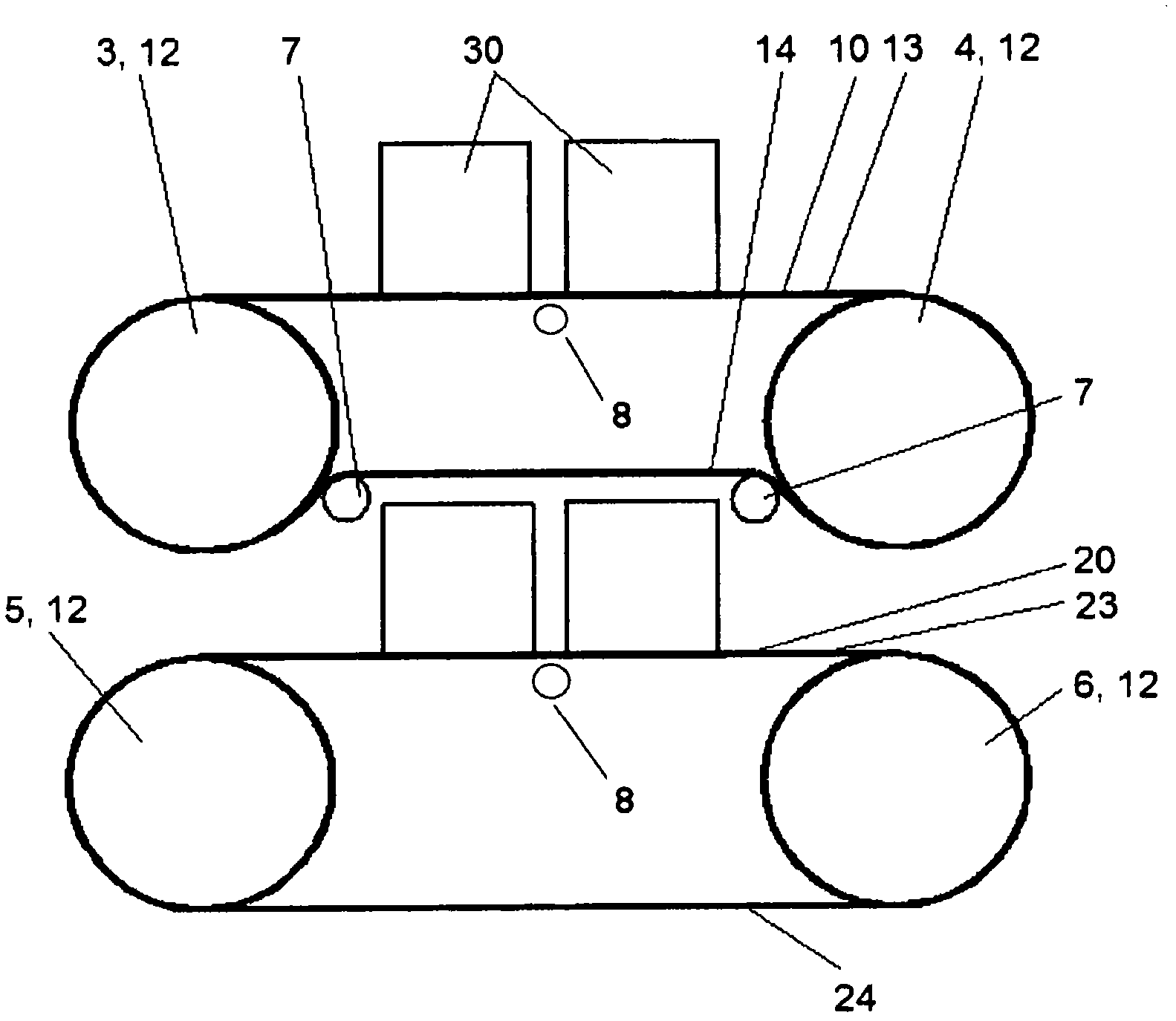

[0019] Such as figure 1 with 2 As shown, the sawing device according to the first embodiment includes a first sawing zone 10 and a second sawing zone 20, which respectively surround a pair of wire guide rollers 3, 4, and 5 as wire guide mechanisms. 6 stretched into. The drum has grooves, which determine the sawing pitch. The wire guide mechanism or the axis of the drum is arranged in parallel and, for example, is assembled in a machine frame not shown. Of course, the device can also have more than four wire guide rollers. The wire guide rollers 3, 4, 5, 6 define the parallel planes of the sawing areas 10, 20 through their upper envelope. By figure 1 The wire storage 15 or 15', 25 or 25' shown in the provide separate sawing wires 11, 21, where the wire storage here is composed of an unwinding coil and a winding coil, respectively, and the movement of the wire is indicated by arrows direction. Of course, the direction of line movement can be reversed.

[0020] The wire drives ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com