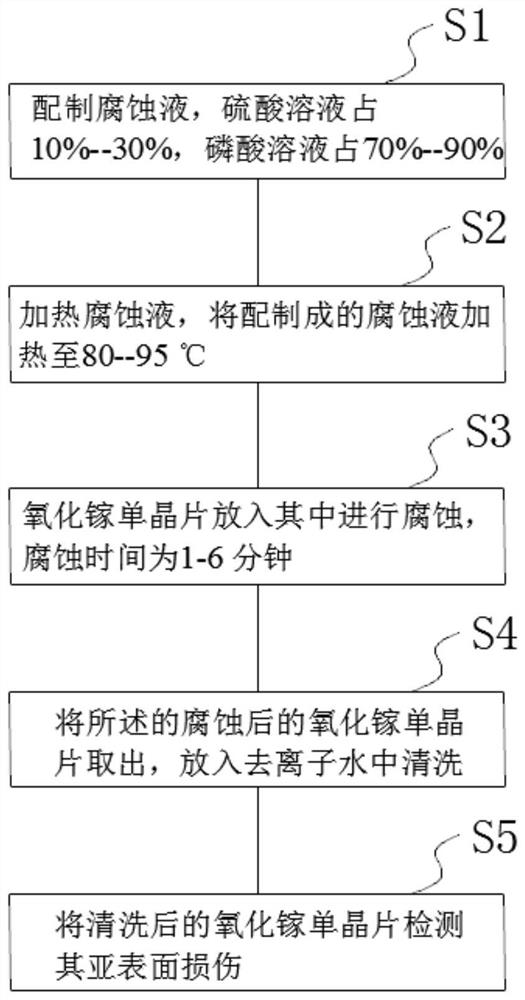

Corrosive liquid for detecting layer damage layer after gallium oxide single crystal processing and detection method

A technology for surface processing and detection methods, which is applied in the fields of weather resistance/light resistance/corrosion resistance, measuring devices, optical testing flaws/defects, etc., which can solve problems such as slow corrosion speed, high service temperature, and poor repeatability of corrosion results, and achieve corrosion resistance. The effect of low temperature and fast corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] An embodiment of the present invention provides an etching solution for detecting damage to the surface layer of gallium oxide single wafer processing, the raw materials of the etching solution include sulfuric acid solution and phosphoric acid solution;

[0031] Calculated by volume percentage, the corrosion solution is composed of 10-30% sulfuric acid solution and 70-90% phosphoric acid solution. less than 85%.

Embodiment 2

[0033] An embodiment of the present invention provides an etching solution for detecting damage to the surface layer of a gallium oxide single wafer, and the raw materials of the etching solution include sulfuric acid solution and phosphoric acid solution;

[0034] Calculated by volume percentage, the corrosion solution is composed of 15% sulfuric acid solution and 85% phosphoric acid solution, the concentration of sulfuric acid solution is not lower than 98%, and the concentration of phosphoric acid solution is not lower than 85%.

Embodiment 3

[0036] An embodiment of the present invention provides an etching solution for detecting damage to the surface layer of gallium oxide single wafer processing, the raw materials of the etching solution include sulfuric acid solution and phosphoric acid solution;

[0037] Calculated by volume percentage, the corrosion solution is composed of 20% sulfuric acid solution and 80% phosphoric acid solution, the concentration of sulfuric acid solution is not lower than 98%, and the concentration of phosphoric acid solution is not lower than 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com