Test method for accelerating reproduction of salt spray corrosion pulverization effect of binding post of electric energy meter

A technology of salt spray corrosion and test method, applied in the direction of weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0032] A test method for accelerating the reproduction of the powdering effect of salt spray corrosion on the terminals of electric energy meters, the innovation of which is that it includes the following steps:

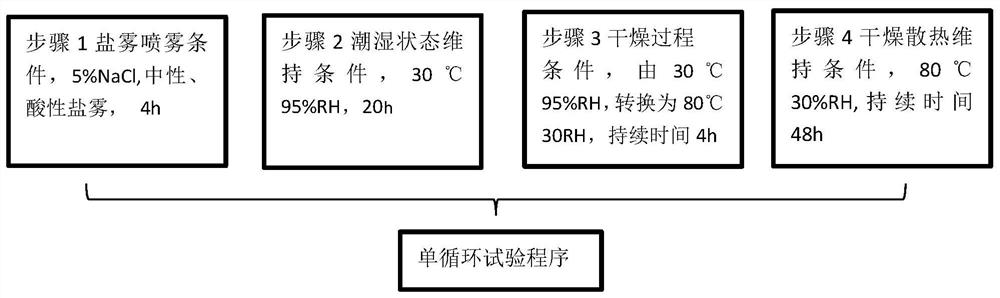

[0033] Step 1: In the standard neutral salt spray test chamber, spray salt spray to the terminal post of the electric energy meter. The pH value of the salt spray is 6.5-7.2, the temperature is 15-35°C, and the spray is continued for 4 hours;

[0034] Step 2: After the spraying is over, transfer the terminal of the electric energy meter into the damp heat test chamber, set the temperature in the damp heat test chamber to 30-40°C, and the relative humidity to 90%-95%, and the duration is 20h;

[0035] Step 3: Keep the terminal of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com