Silicon slice thinning method based on metal nano particle catalysis

A technology of metal nanoparticles and silicon wafers, which is applied in the field of microelectronics to achieve the effect of smooth silicon surface, simple operation and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

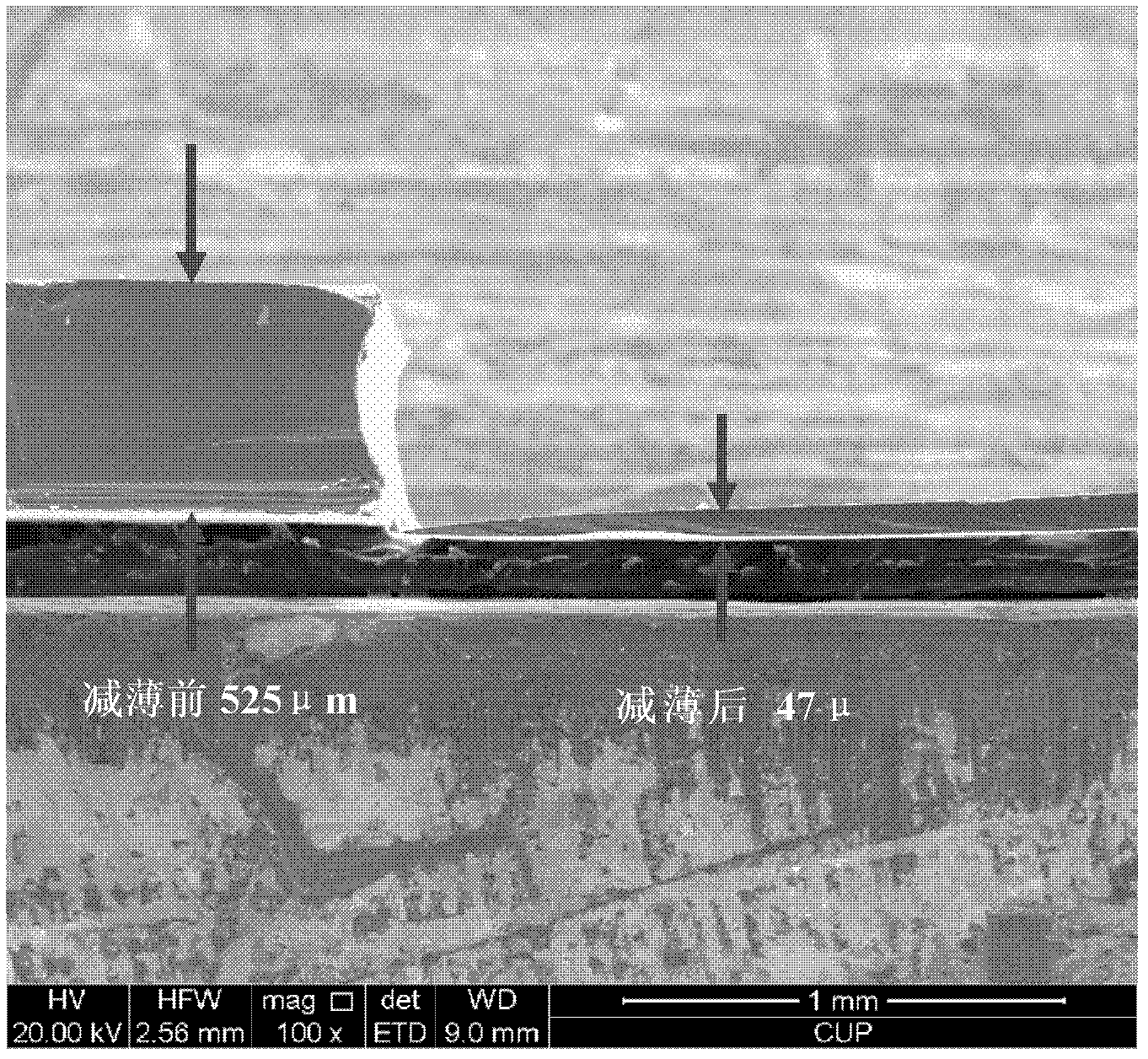

[0035] 1. Use a (100) monocrystalline silicon wafer with a resistivity of 7-13Ω·cm, with a thickness of 525 μm, ultrasonically clean it in acetone for 10 minutes; rinse it twice with deionized water, and then wash it in CP-4A solution Soak at room temperature for 5 minutes; then soak in hydrofluoric acid with a concentration of 7.3mol / L for 5 minutes at room temperature; rinse with deionized water for 2 minutes, and dry in vacuum; the resistivity of the deionized water is above 16MΩ·cm.

[0036]Described CP-4A solution is made of HF solution (mass fraction is 40%), HNO 3 solution, absolute ethanol, H 2 O is formulated at a volume ratio of 3:5:3:22, where HNO 3 The mass fraction of the solution is 68%, so as to ensure the polishing and etching of the silicon surface and the improvement of the surface quality.

[0037] 2. Use 40% (wt) HF solution, 30% (wt) hydrogen peroxide, deionized water (resistivity above 16MΩ·cm) and silver nitrate crystals to prepare a mixed solution wit...

Embodiment 2

[0044] Use a single crystal silicon wafer with a resistivity of 8-13Ω·cm and an orientation of (111), ultrasonically clean it in acetone for 10 minutes; rinse it twice with deionized water, and then soak it in CP-4A solution at room temperature for 5 minutes; Soak in 7.3mol / L hydrofluoric acid at room temperature for 5 minutes; rinse with deionized water for 2 minutes, and dry in vacuum;

[0045] Described CP-4A solution is made of HF solution (mass fraction is 40%), HNO 3 solution, absolute ethanol, H 2 O is formulated at a volume ratio of 3:5:3:22, where HNO 3 The mass fraction of the solution is 65%, so as to ensure the polishing and etching of the silicon surface and the improvement of the surface quality.

[0046] 2. Use 40% (wt) HF solution, 30% (wt) hydrogen peroxide, deionized water and silver nitrate crystals to prepare a mixed solution with the following concentration characteristics as the thinning solution: the concentration of silver nitrate is 0.01mol / L, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com