A kind of etchant and corrosion method for displaying aluminum-magnesium alloy metallographic structure

A metallographic structure and aluminum-magnesium alloy technology, which is applied in the field of corrosion showing the metallographic structure of aluminum-magnesium alloys, can solve the problems of excessive corrosion, difficulty in metallographic observation, and incomplete grains, and achieves clearly visible morphology and composition. Simple, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

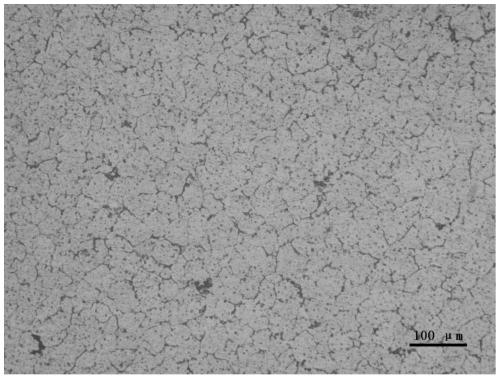

Embodiment 1

[0038] Step 1. Polish the sample with a size of 10mm×10mm×10mm first, then rinse it with alcohol for 2 minutes and dry it with a hair dryer with cold air;

[0039] Step 2, electrolytic corrosion: Pour 220ml of water, 580ml of sulfuric acid solution with a concentration of 18.4mol / L and 200ml of glycerin into a clean container in sequence at room temperature, and stir until the glycerin is uniform to obtain an electrolytic corrosion agent; mix 80ml of water and 20ml of Pour phosphoric acid with a mass concentration of 85% into a beaker at room temperature and stir evenly to obtain a phosphoric acid solution with a volume fraction of 20%, which is a chemical etchant. Connect the cleaned sample to the positive electrode of the DC power supply, and the stainless steel rod to the negative electrode. Connect, then put the positive and negative electrodes into the electrolytic etchant, turn on the DC power supply to start corrosion, keep the voltage of the DC power supply at 10V, and ...

Embodiment 2

[0042] Step 1. Polish the sample with a size of 10mm×10mm×10mm first, then rinse it with alcohol for 2 minutes and dry it with a hair dryer with cold air;

[0043] Step 2, electrolytic corrosion: Pour 220ml of water, 500ml of sulfuric acid solution with a concentration of 18.4mol / L and 200ml of glycerin into a clean container in turn at room temperature, and stir until the glycerin is uniform to obtain an electrolytic corrosion agent; mix 80ml of water and 20ml of Pour phosphoric acid with a mass concentration of 85% into a beaker at room temperature and stir evenly to obtain a phosphoric acid solution with a volume fraction of 20%, which is a chemical etchant. Connect the cleaned sample to the positive electrode of the DC power supply, and the stainless steel rod to the negative electrode. Connect, then put the positive and negative electrodes into the electrolytic etchant, turn on the DC power supply to start corrosion, keep the voltage of the DC power supply at 15V, and keep...

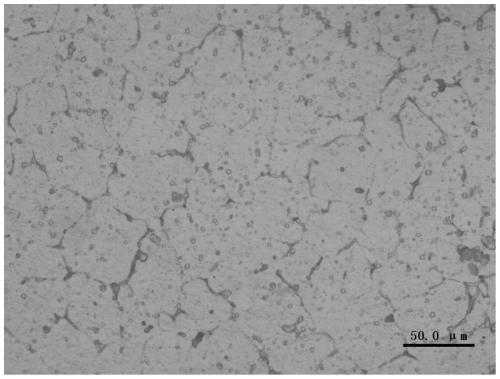

Embodiment 3

[0046] Step 1. Polish the sample with a size of 10mm×10mm×10mm first, then rinse it with alcohol for 2 minutes and dry it with a hair dryer with cold air;

[0047]Step 2. Electrolytic corrosion: Pour 220ml of water, 520ml of sulfuric acid solution with a concentration of 18.4mol / L and 300ml of glycerin into a clean container at room temperature, and stir until the glycerin is uniform to obtain an electrolytic corrosion agent; mix 80ml of water and 20ml of Pour phosphoric acid with a mass concentration of 85% into a beaker at room temperature and stir evenly to obtain a phosphoric acid solution with a volume fraction of 20%, which is a chemical etchant. Connect the cleaned sample to the positive electrode of the DC power supply, and the stainless steel rod to the negative electrode. Connect, then put the positive and negative electrodes into the electrolytic etchant, turn on the DC power supply to start corrosion, keep the voltage of the DC power supply at 12V, and keep the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com