Method for improving thickness uniformity of single crystal piezoelectric film

A piezoelectric film with uniform thickness, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

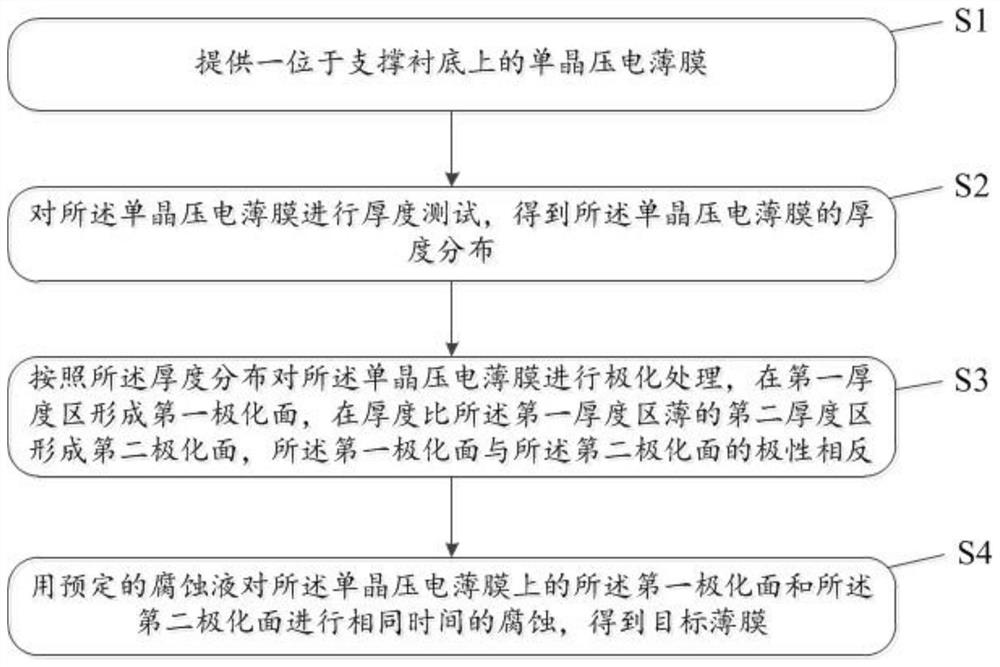

[0039] This embodiment provides a method for improving the uniformity of the thickness of a single crystal piezoelectric film, see figure 1 , the method for improving the uniformity of the thickness of the single crystal piezoelectric thin film of the present embodiment comprises the following steps:

[0040] Step S1, providing a single crystal piezoelectric thin film on a supporting substrate.

[0041] In this embodiment, ion implantation is performed on the piezoelectric single crystal substrate by ion beam stripping technology, and the implanted material is bound to the supporting substrate material by bonding technology, and the aggregation of ions in the material is realized by means of heating The purpose of transferring the target single crystal piezoelectric film is achieved. High-quality single-crystal thin films can be integrated on amorphous, polycrystalline, and even flexible substrates by ion beam exfoliation, providing a simple and efficient means for realizing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com