Patents

Literature

50results about How to "Control corrosion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Absorbable magnesium alloy stent of anticorrosion and drug release composite coating and preparation method thereof

InactiveCN101721266AExtension of timeSolve the problem of excessive release concentrationStentsMedical devicesControlled releasePlasma electrolytic oxidation

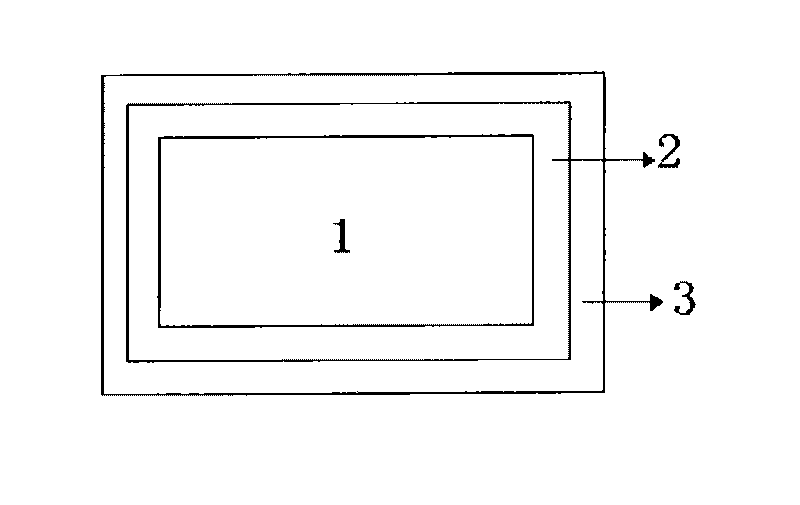

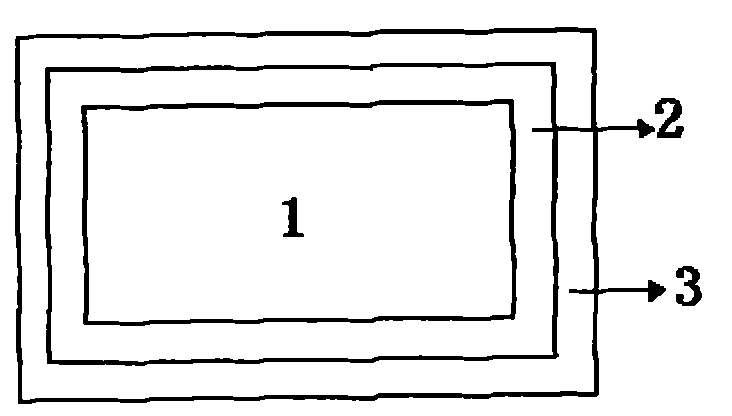

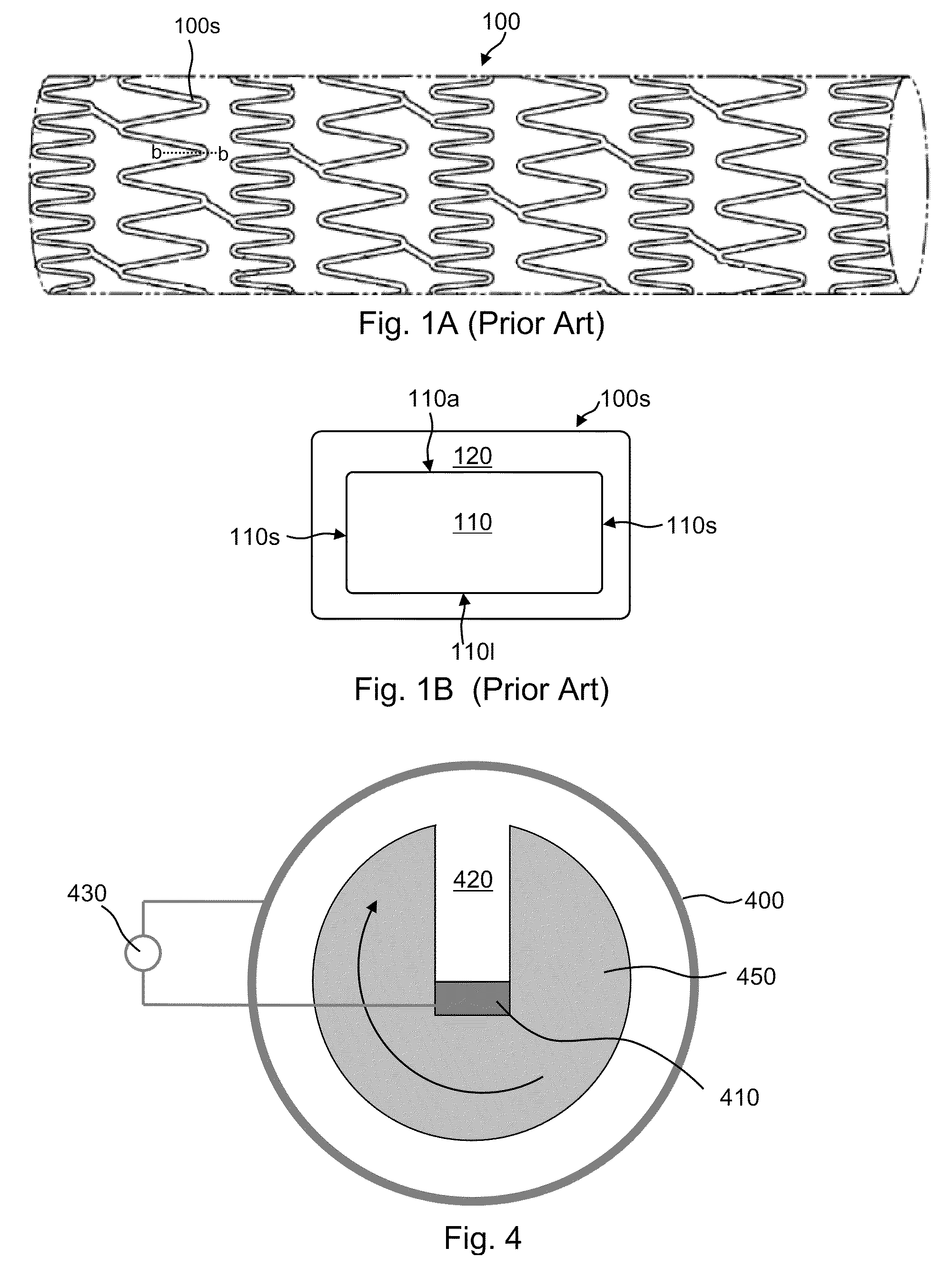

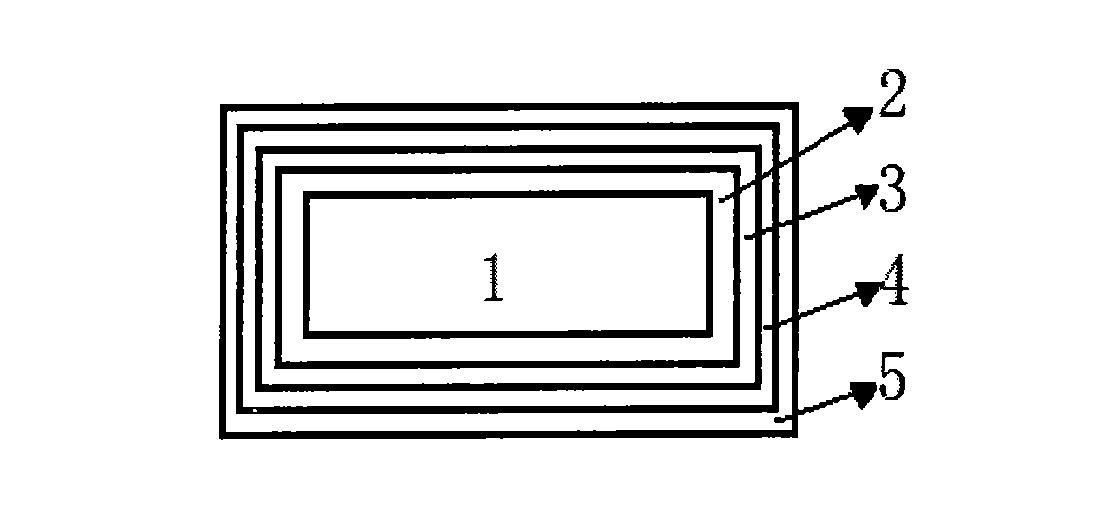

The invention relates to an absorbable magnesium alloy stent of anticorrosion and drug release composite coating and a preparation method thereof. The absorbable magnesium alloy stent comprises a magnesium alloy stent skeleton and composite coating, wherein the surface layer of the magnesium alloy stent skeleton is an inorganic anti-corrosion coating, the outside of the inorganic anti-corrosion coating is provided with organic sealing and drug release composite coating; and the inorganic anti-corrosion coating is dense coating with metallurgical structure composed of MgSiO3, MgO and SiO2 with zeolite structure. The inorganic anti-corrosion coating is prepared on the surface of a matrix through microarc oxidation, and the sealing and drug release composite coating composed of crosslinked gelatin / PLGA medicine-carried nanospheres blend film is prepared outside the anti-corrosion coating. The absorbable magnesium alloy stent of the invention effectively controls the corrosivity of the magnesium alloy stent, the organic coating has double functions, the use of the sealing inorganic coating increases the corrosion resistance, controls the drug to release, and reduces the burst effect of the drug to ensure that the drug is released in a certain concentration continuously and slowly. Meanwhile, each coating can be biodegraded and the degradation product is non-toxic, thus effectively improving the biocompatibility and blood compatibility of the magnesium alloy surface.

Owner:TIANJIN UNIV

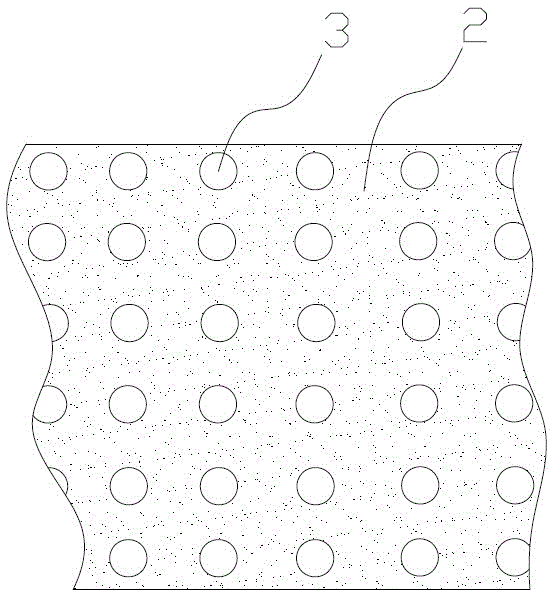

Absorbable magnesium alloy bracket of inorganic and organic antiseptic biocompatible composite coating and preparation method thereof

ActiveCN101721753AExtension of timeImprove corrosion resistanceAnodisationSurgerySide effectBiocompatibility Testing

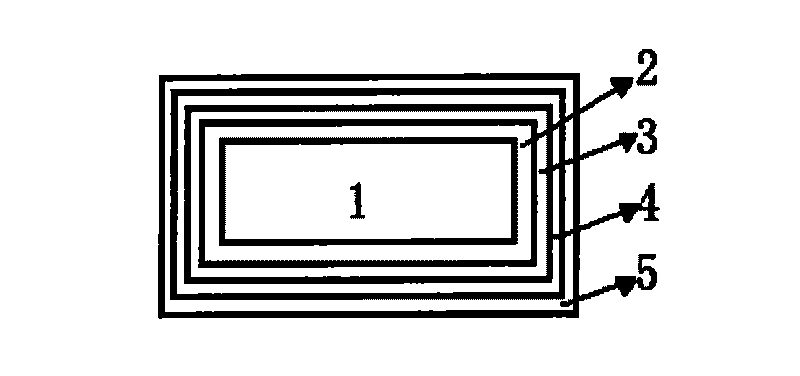

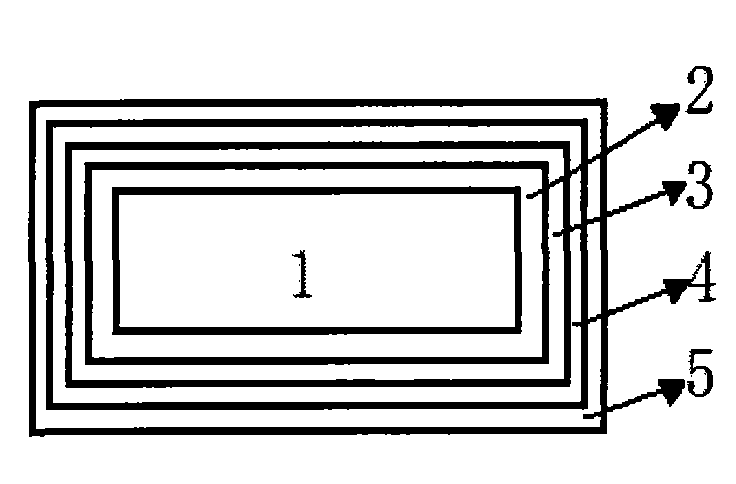

The invention relates to an absorbable magnesium alloy bracket of an inorganic and organic antiseptic biocompatible composite coating and a preparation method thereof. The absorbable magnesium alloy bracket of the inorganic and organic antiseptic biocompatible composite coating comprises a magnesium alloy bracket backbone and a composite coating. The composite coating consists of an inorganic antiseptic coating, a compact organic hole sealing coating, a drug releasing coating and a drug slow release coating; the surface layer of the absorbable magnesium alloy bracket backbone is an inorganic porous antiseptic coating, the compact organic hole sealing coating is arranged outside the inorganic antiseptic coating, the drug releasing coating is arranged outside the compact organic coating, and the drug slow release coating is arranged outside the drug releasing coating. The invention effectively improves the corrosion resistance of the magnesium alloy bracket backbone and controls releasing rate of magnesium ions; meanwhile, the organic membrane layer improves the surface biocompatibility; the degraded products have no side effect, can be absorbed by human bodies, and have good biocompatibility and blood compatibility; and the drug releasing coating can reduce burst release of drug and ensure sustained slow release of drug.

Owner:中知在线股份有限公司

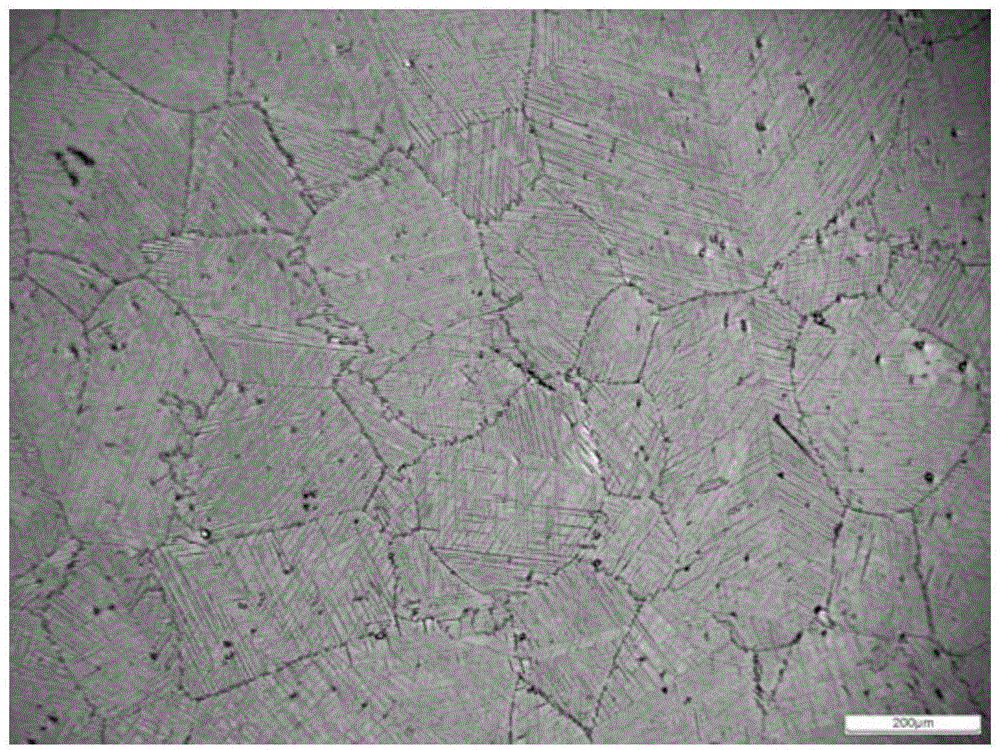

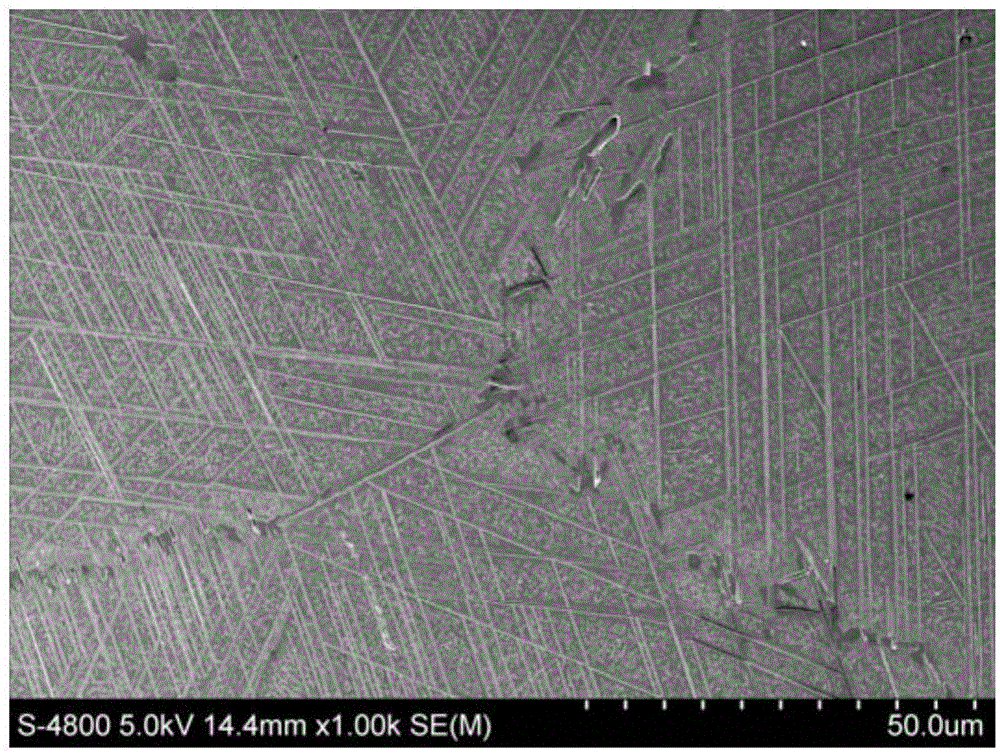

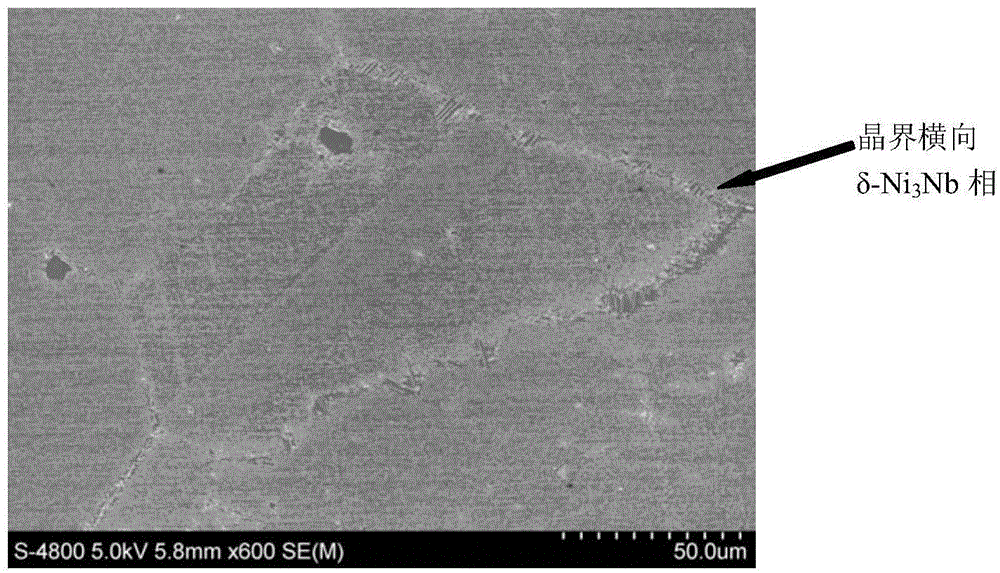

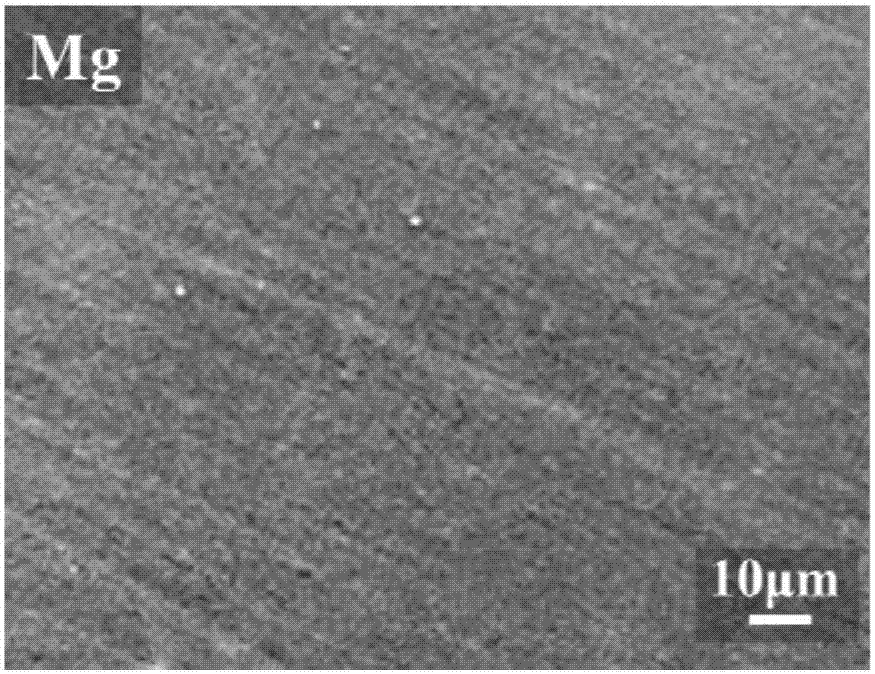

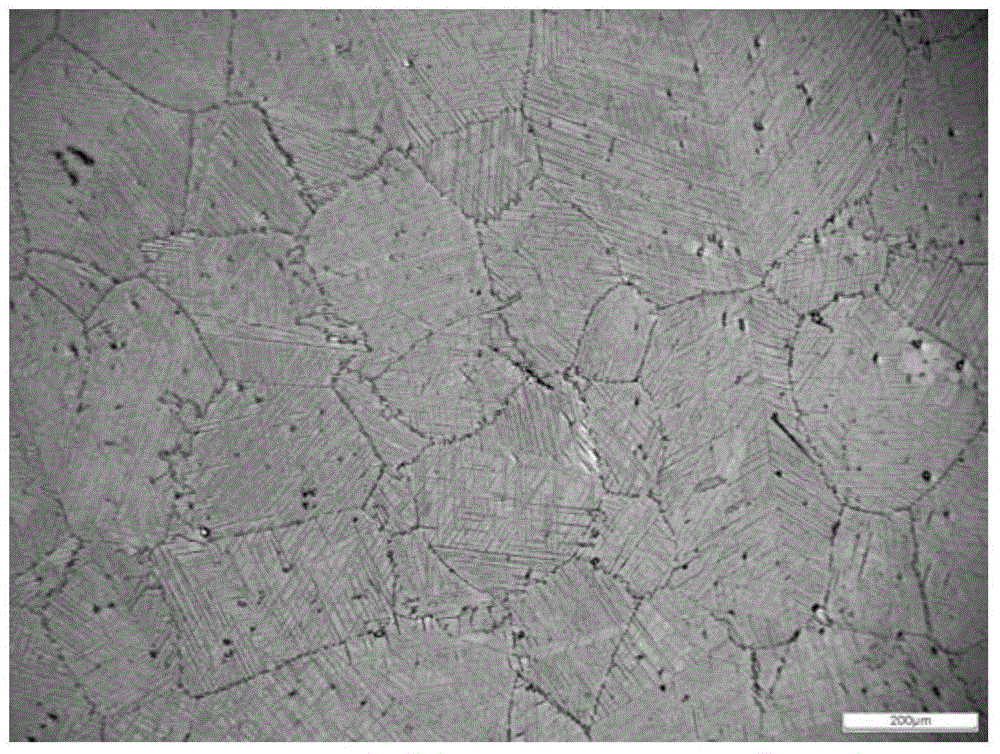

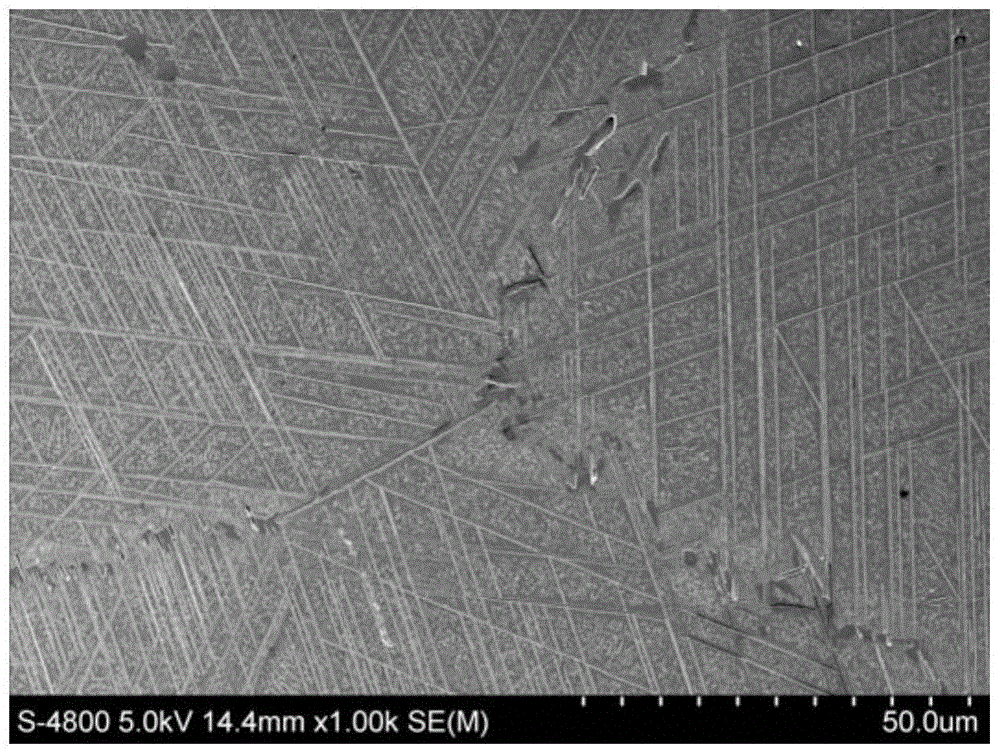

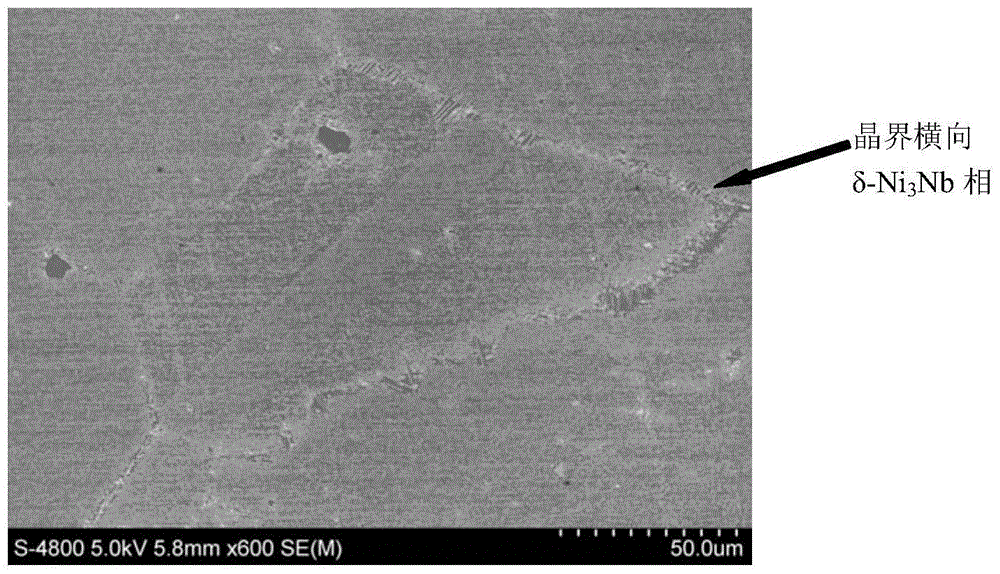

Metallographical corrosive for observing delta-Ni3Nb phase in ferronickel-based superalloy structure and using method of metallographical corrosive

ActiveCN104593775AGood chemical stabilityControl Corrosion RatePreparing sample for investigationSuperalloyCopper sulfate

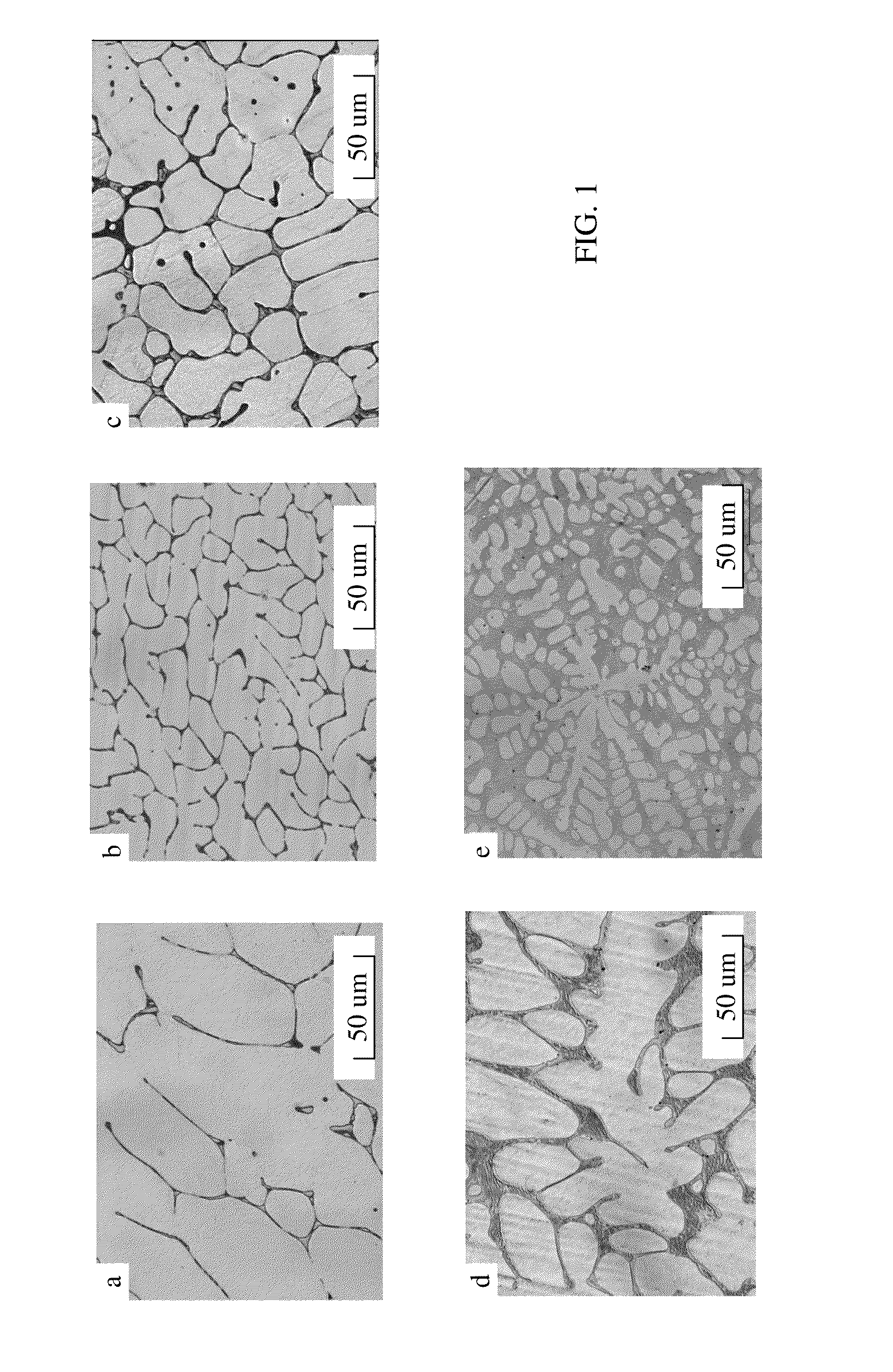

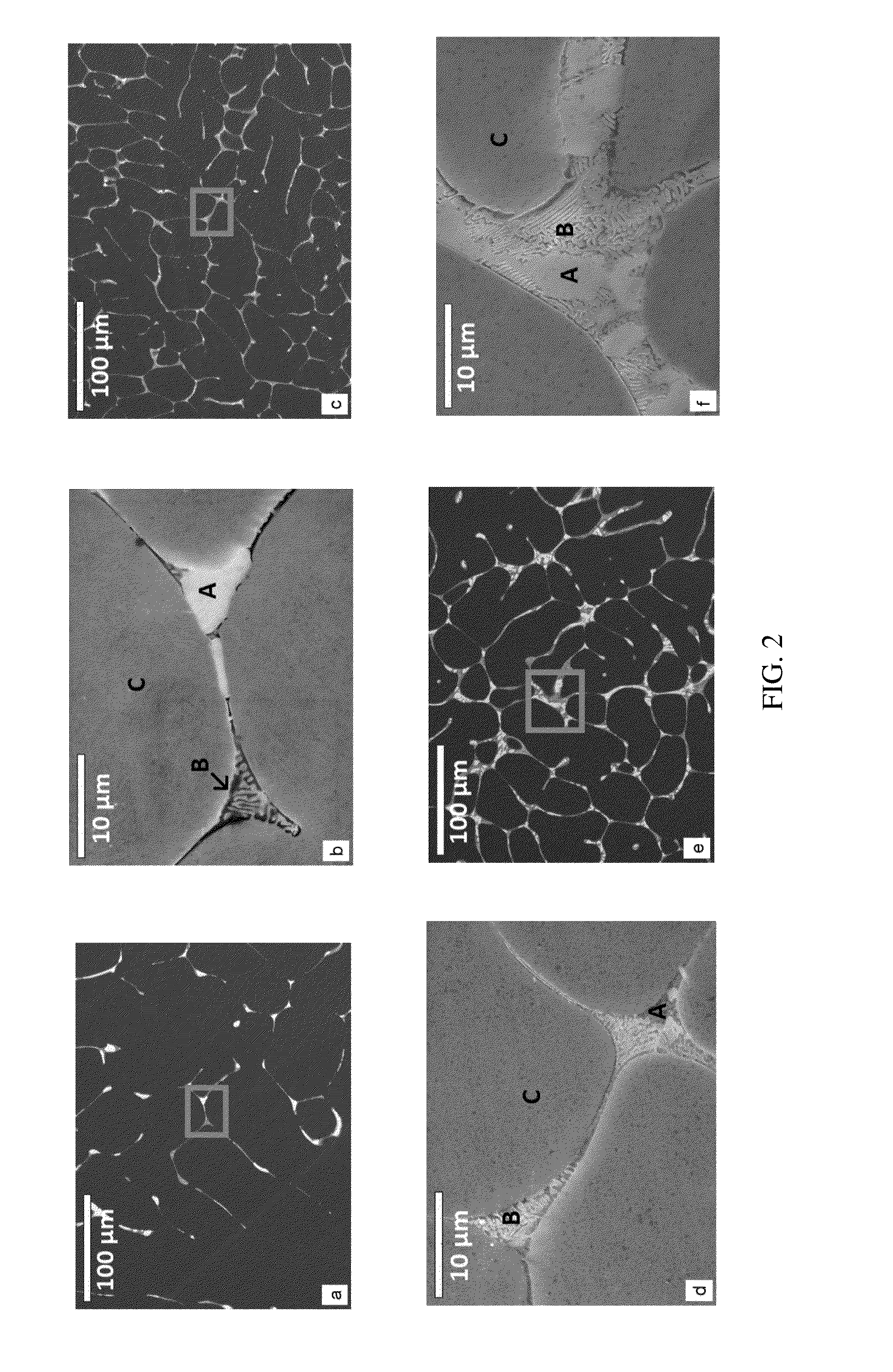

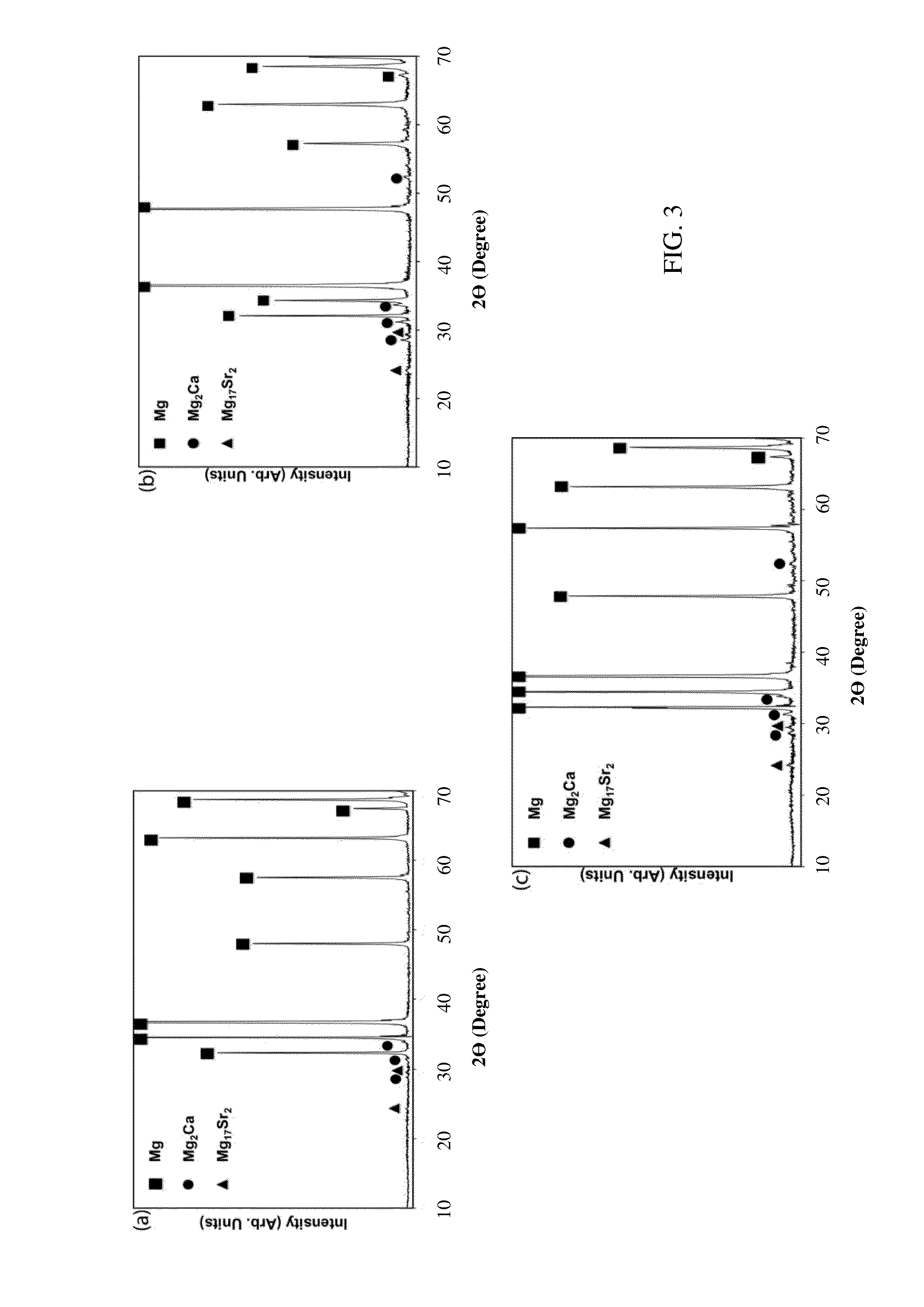

The invention discloses a metallographical corrosive for observing delta-Ni3Nb phase in a ferronickel-based superalloy structure and a using method of the metallographical corrosive. The metallographical corrosive comprises the following components by volume fraction: 26-33% of hydrochloric acid, 30-37% of nitric acid, 13-18% of hydrofluoric acid and 12-31% of ethyl alcohol; every 100 mL of the metallographical corrosive contains 2g of oxalic acid and 1g of copper sulfate; the mass percentage concentration of the hydrochloric acid is 36%; the mass percentage concentration of the nitric acid is 68%; the mass percentage concentration of the hydrofluoric acid is 40%; the copper sulfate is anhydrous copper sulfate; the ethyl alcohol is anhydrous ethyl alcohol; and the selected chemical reagents are analytical reagents. The using method comprises the following steps: coating the prepared metallographical corrosive on the metallographical surface of a ferronickel-based superalloy sample; chemically corroding for 5-8 seconds; washing and drying the metallographical corrosive on the metallographical surface by clear water and alcohol; and observing the delta-Ni3Nb phase in the microscopic structure through an optical microscope and a scanning electron microscope.

Owner:CHINA HUANENG GRP CO LTD +1

Coptis extract silicon slice texturing agent and preparation method thereof

InactiveCN105113017AControl corrosion rateImprove conversion efficiencyPolycrystalline material growthAfter-treatment detailsSodium CaseinateCoptis

The invention discloses a coptis extract silicon slice texturing agent. The coptis extract silicon slice texturing agent is characterized by being prepared from, by weight, 5-10 parts of coptis roots, 1.5-2.5 parts of sodium hydroxide, 3-5 parts of sodium tripolyphosphate, 0.3-0.5 part of lauryl sodium sulfate, 0.3-0.5 part of sodium lauroamphoacetate, 5-10 parts of texturing modifiers, 0.3-0.5 part of coconut oil, 0.5-1 part of sodium caseinate, 0.3-0.5 part of maltodextrin and 100-150 parts of water. By means of the silicon slice texturing agent, the texturing efficiency can be improved, the stability of the texturing technology can be improved, dosage of chemicals can be reduced, the silicon slice texturing agent is free of toxicity, harmless, green and environmentally friendly, the production cost is reduced, the transfer efficiency of a battery slice is effectively improved, good antibacterial and cleaning properties are achieved, and the product quality is stable.

Owner:安徽飞阳能源科技有限公司

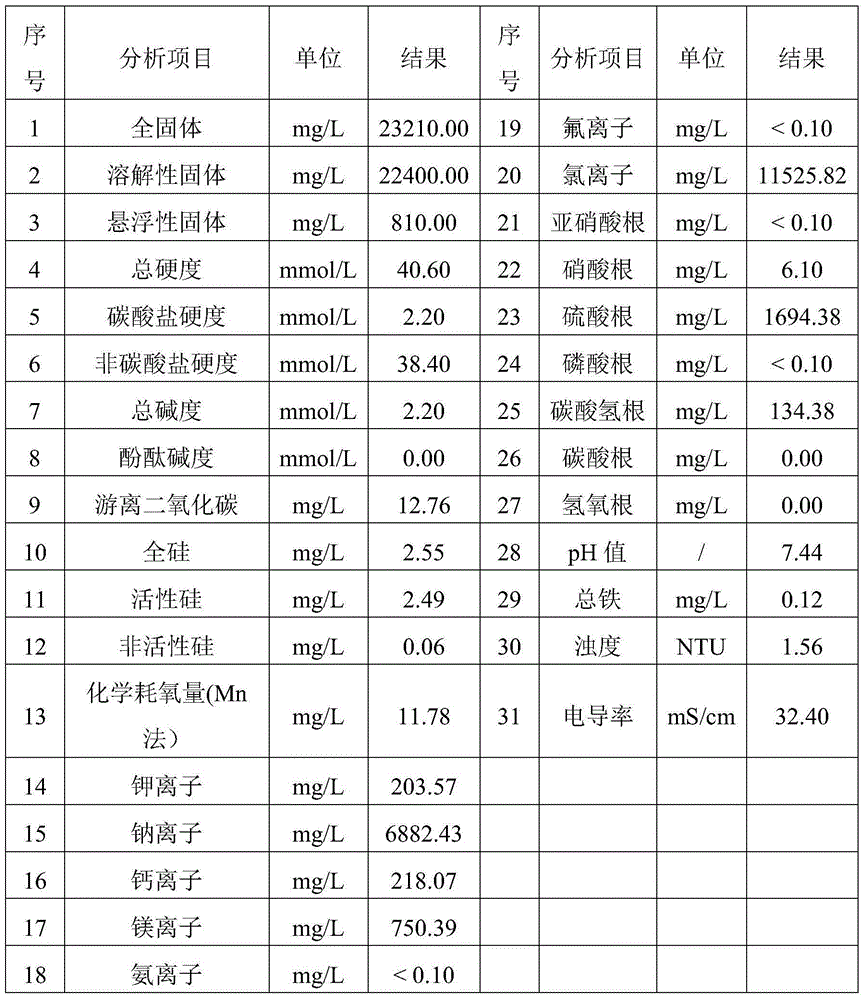

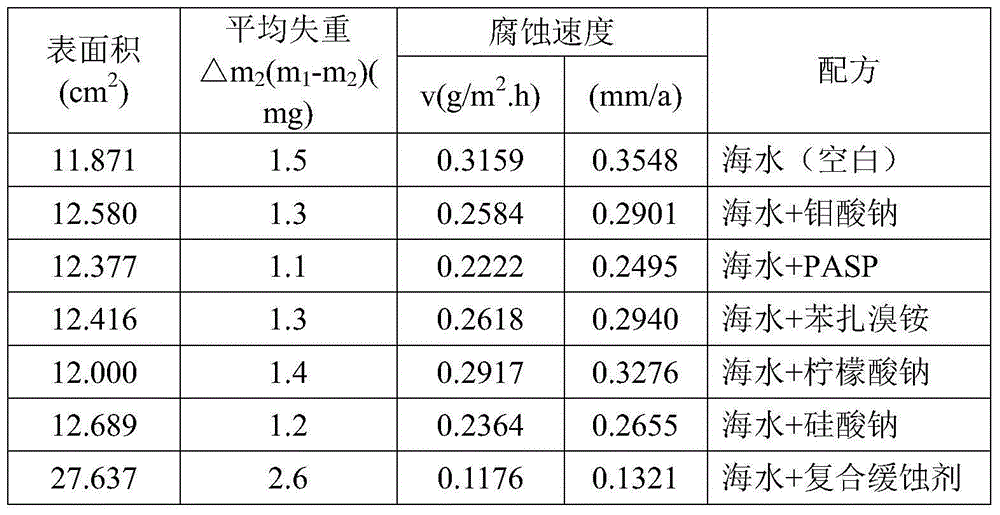

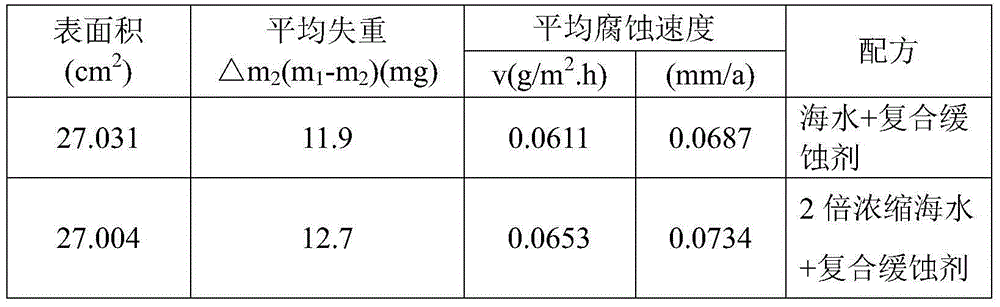

Composite corrosion inhibitor for seawater circulation cooling system carbon steel material anticorrosion

The invention discloses a composite corrosion inhibitor for seawater circulation cooling system carbon steel material anticorrosion. The composite corrosion inhibitor comprises sodium molybdate, polyaspartic acid (PASP), benzalkonium bromide, sodium citrate and sodium silicate according to a mass ratio of 0.8-1.2:1.5-2.5:3.5-4.5:3.5-4.5:7.5-8.5. The corrosion inhibitor does not contain phosphorus (phosphine), difficultly decomposed polymers or heavy metal salts, so the corrosion inhibitor is harmless to environment; the corrosion inhibitor can reach a corrosion inhibition effect under a small dosage, so the use cost is reduced; and the corrosion inhibitor can control the carbon steel corrosion speed in a national standard allowed range in seawater and 2 times concentrated seawater, so the application range of the corrosion inhibitor is wide.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

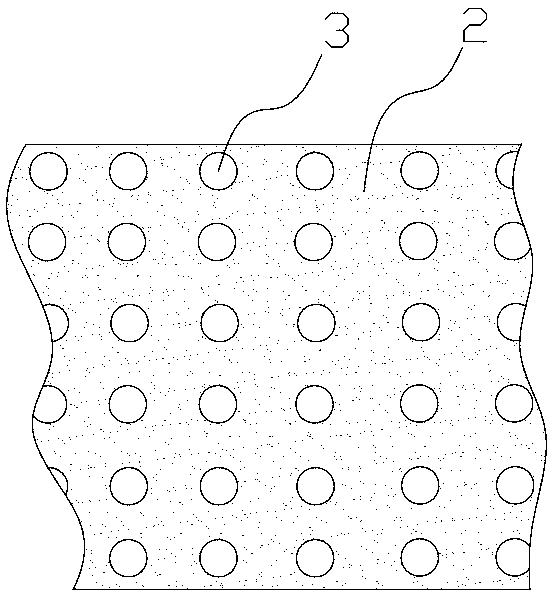

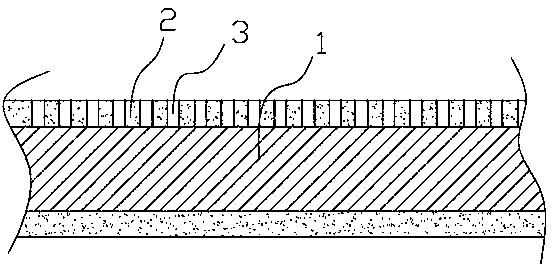

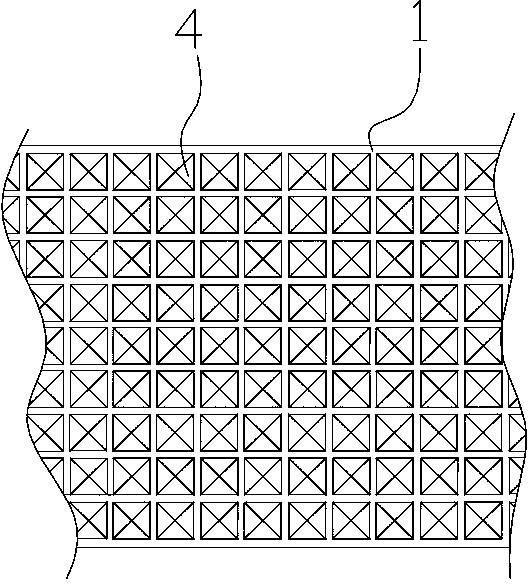

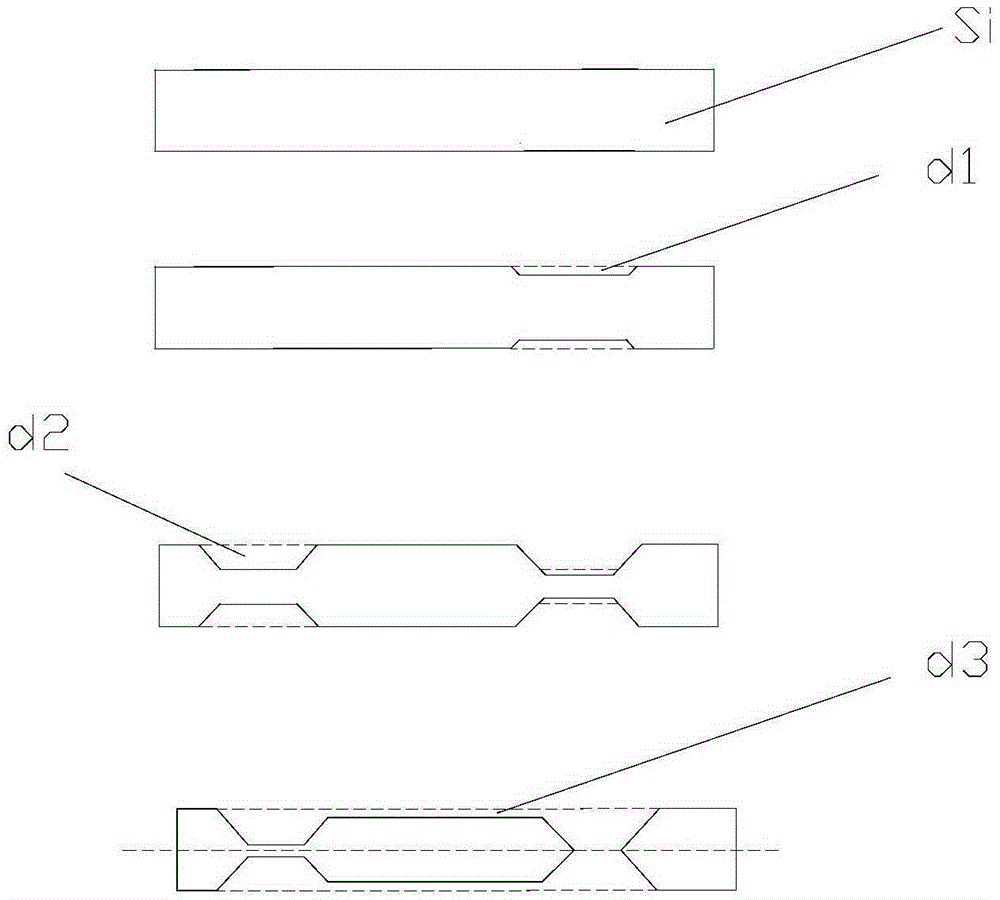

Alkaline type texturing process of monocrystalline silicon wafer

ActiveCN103572373ASize and arrangementSpread evenlyAfter-treatment detailsFinal product manufactureMonocrystalline siliconSingle crystal silicon wafer

The invention discloses an alkaline type texturing process of monocrystalline silicon wafer, which is used for solving the problems that secondary reflection cannot be completely formed very well and good contact with conductive slurry is difficult to form due to uneven diffusion as size and arrangement of a textured surface obtained by the alkaline type texturing process in the prior art are random. The alkaline type texturing process mainly comprises the following steps: (a) removing an affected layer; (b) preparing a mask; (c) windowing the mask; (d) texturing on a surface; and (e) removing the mask. The alkaline type texturing process disclosed by the invention is simple in step, suitable for industrial production and low in cost; the obtained monocrystalline silicon wafer textured structure is an inverted pyramid structure with regular size and arrangement, so that secondary reflection can be completely formed very well; and meanwhile, diffusion is guaranteed to be uniform and coating of conductive slurry is facilitated, so that thickness of the conductive slurry is controlled easier, contact with the conductive slurry is good, metal sintering is facilitated, and contact resistance is reduced.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Medical devices having electrodeposited conductive polymer coatings

Owner:BOSTON SCI SCIMED INC

Semiconductor silicon wafer corrosive liquid and corrosion method thereof

InactiveCN106024675AReduce damageEasy to controlSemiconductor/solid-state device manufacturingMicroelectronicsCorrosion

The invention relates to the technical field of microelectronic processing and especially to a semiconductor silicon wafer corrosive liquid. The semiconductor silicon wafer corrosive liquid is formed by mixing nitric acid, hydrofluoric acid, and glacial acetic acid according to a volume ratio of 4-14: 4-14: 6-18. A semiconductor silicon wafer is placed in a closed container containing the semiconductor silicon wafer corrosive liquid in order to be corroded on a low-temperature condition. Different corrosion demands are satisfied by regulating the ratio of the nitric acid to the hydrofluoric acid. The corrosion rate and the corrosion depth of the semiconductor silicon wafer, and the surface cleanliness of the corroded semiconductor silicon wafer can be controlled on the low-temperature condition. The corrosion rate at a low-temperature environment is less than that at a normal-temperature environment, so the corrosive uniformity of the semiconductor silicon wafer is easier to control. The semiconductor silicon wafer corrosive liquid is easy to form, attainable in raw material, low in cost, and very suitable for industrial production of semiconductor microelectronics.

Owner:江苏佑风微电子有限公司

Method for flowingly corroding complicated slender copper tube cores made of aluminum alloy castings

The invention discloses a method for flowingly corroding complicated slender copper tube cores made of aluminum alloy castings. Slots are formed on embedded copper tube cores in the prior art, and the copper tube cores are corroded by a method for soaking the copper tube cores in corrosive liquid and has shortcomings that the corrosion efficiency is low; the copper tube cores cannot be thoroughly corroded, and the quality of castings which are processed in follow-up procedures such as thermal treatment for the castings is affected; and matrixes of the aluminum alloy castings are corroded. In order to overcome the shortcomings, the method is used for dynamically corroding the complicated slender copper tube cores made of the aluminum alloy castings by means of enabling corrosive liquid to flow. The method has the advantages that the corrosive liquid flows in copper tubes by the aid of corrosion-resistant magnetic valves, and the corrosion efficiency is improved; the flow rate of the corrosive liquid can be adjusted, so that the corrosion speed is controlled; the multiple copper tubes or a plurality of castings can be corroded simultaneously by the aid of a multi-tube joint; the requirement on corroding parts with different apertures can be met by means of replacing different sleeves; and the corrosive liquid is basically prevented from being in contact with matrixes of the castings, and accordingly the matrixes are protected against being corroded.

Owner:NANCHANG HANGKONG UNIVERSITY

Antibacterial silicon wafer texturing agent and preparation method therefor

InactiveCN105133034AControl corrosion rateImprove cleanlinessAfter-treatment detailsFinal product manufactureSorbitolSilicon

The invention discloses an antibacterial silicon wafer texturing agent which is characterized by being prepared from the following raw materials in parts by weight: 1-2 parts of mycose, 1-2 parts of dipotassium glycyrrhizinate, 1.5-2.5 parts of sodium hydroxide, 0.5-1 part of lauramidopropylamine oxide, 0.3-0.5 part of polyoxyethylene sorbitol anhydride monooleate, 5-10 parts of a texturing adjustor, 0.3-0.5 part of mint oil, 0.2-0.4 part of ginger oil, 1-2 parts of sodium carboxymethylcellulose and 100-150 parts of water. The silicon wafer texturing agent disclosed by the invention not only can improve the texturing efficiency and the stability of a texturing process and reduce the use level of chemicals, but also has a good antibacterial function to prevent bacteria from breeding on the surface of the silicon wafer, so that the cleanness of the silicon wafer is improved, and the product is stable in quality, long in storage time and hard to deteriorate.

Owner:ANHUI KING AUTO ELECTRONICS TECH CO LTD

Low-reflectivity silicon wafer texturing agent and preparation method thereof

InactiveCN105088351AIncrease nucleation densityIncreased anisotropyAfter-treatment detailsChemistryDiethylenetriamine

The invention discloses a low-reflectivity silicon wafer texturing agent. The low-reflectivity silicon wafer texturing agent is characterized by being prepared by, by weight, 0.3-0.5 part of sodium pyrophosphate, 1.5-2.5 parts of sodium hydroxide, 0.5-1 part of disodium C-[2-[2-[2-(dodecyloxy)ethoxy]ethoxy]ethyl] sulphonatosuccinate, 0.3-0.5 part of trisodium N-iminodiacetate, 0.1-0.2 part of diethylenetriamine pentaacetic acid, 0.3-0.5 part of konjac glucomannan, 5-10 parts of texturing regulator, 0.2-0.4 part of tricaprylin and 100-150 parts of water. The low-reflectivity silicon wafer texturing agent can improve texturing efficiency and stability of texturing process and can make suede more uniform, lower reflectivity, effectively improve conversion efficiency of cells, improve performance of the cells and is stable in product quality.

Owner:安徽飞阳能源科技有限公司

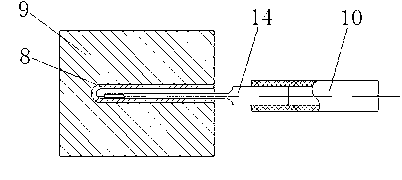

Etching solution for selectively etching gallium arsenide solar cell cap layer and preparation method thereof

InactiveCN104178172AImprove complexation abilityImprove chelation abilityFinal product manufactureSurface treatment compositionsSelective leachingSolar cell

The invention discloses an etching solution for selectively etching a gallium arsenide solar cell cap layer, which is composed of the following components in parts by mass: 5-150 parts of component A, 10-100 parts of component B, 1-20 parts of component C, 1-20 parts of component D and 100 parts of component E. The component A is solid citric acid; the component B is oxydol; the component C is amine compounds; the component D is amino acid compounds; and the component E is deionized water. Preferably, the purity of the component A is greater than 99.8%, and the mass concentration of the component B is 30%. The invention also discloses a preparation method of the etching solution. The etching solution can well control the etching rate, has higher etching uniformity, and thoroughly removes the residues, thereby obtaining the cell gate line structure with smooth side bench.

Owner:XIAMEN CHANGELIGHT CO LTD

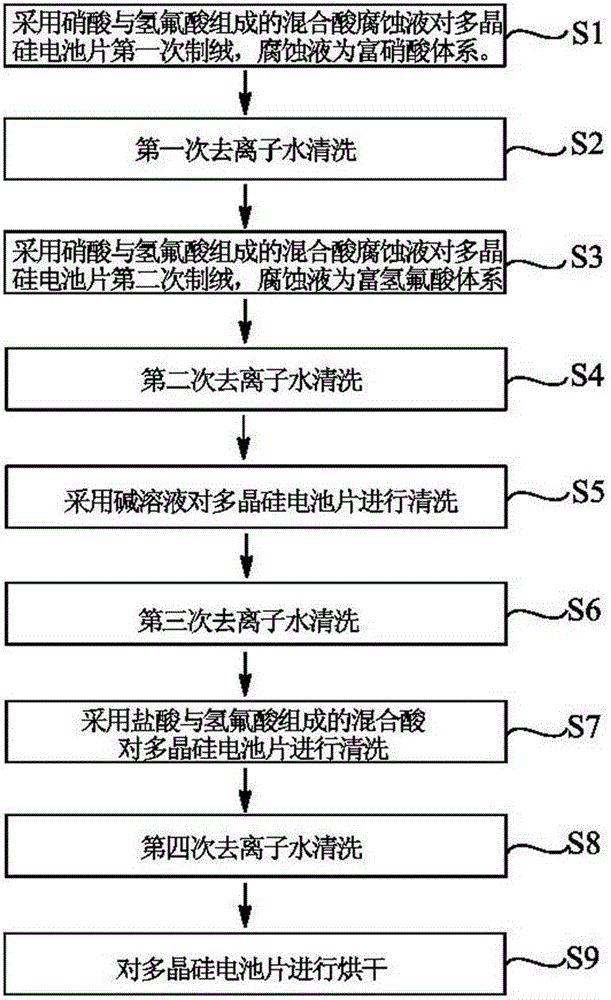

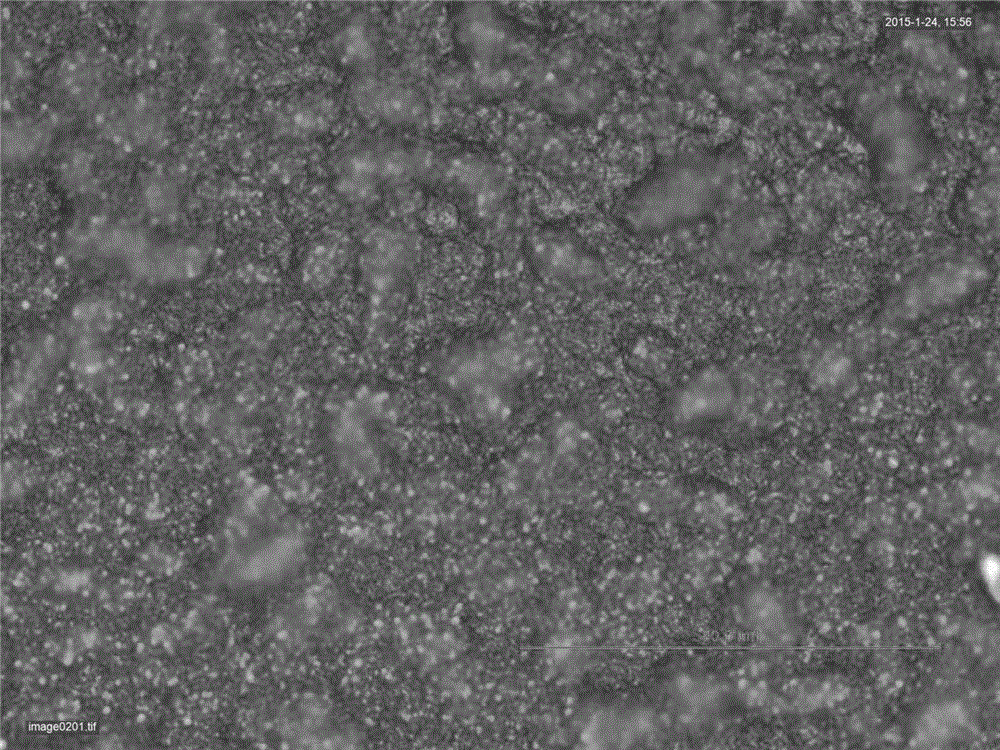

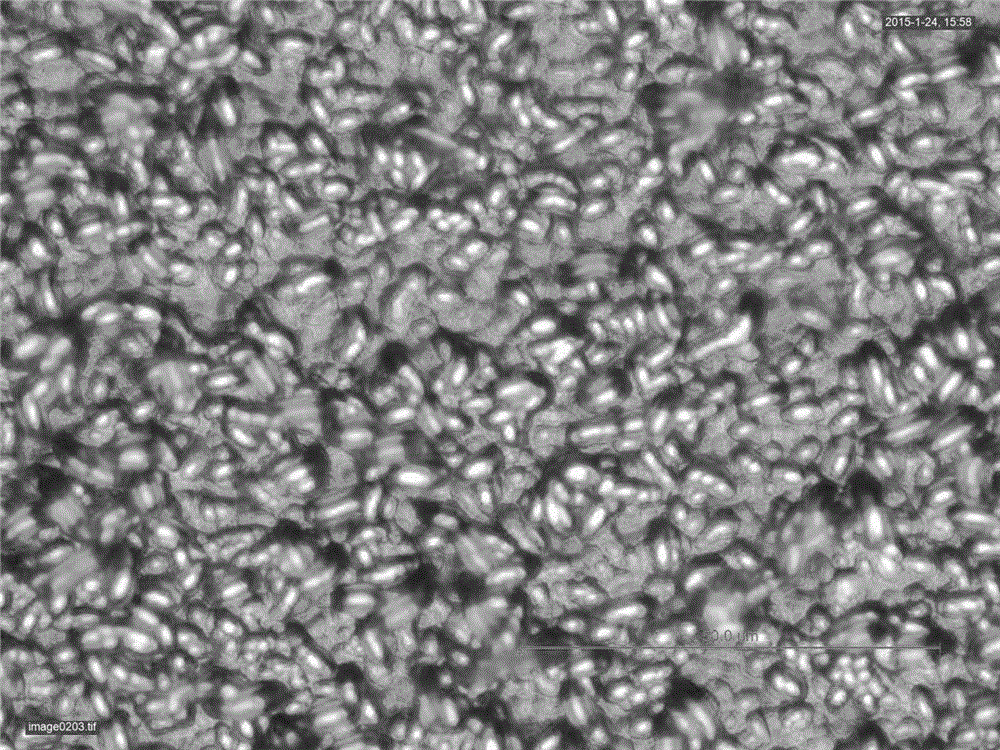

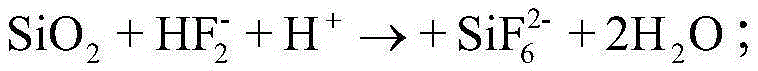

Texturing method of polysilicon solar cell

InactiveCN104835879AReduce oxidation densityImprove light trappingFinal product manufacturePhotovoltaic energy generationProduction lineHydrofluoric acid

The invention relates to a texturing method of a polysilicon solar cell. Twice texturing is included, and a combined acid corrosion solution is by formed mixing HNO3, HF and H2O. The texturing method comprises the following steps that A) first texturing is carried out on the polysilicon solar cell by using the mixed acid corrosion solution, in which the mass concentration of HNO3 is greater than that of HF, of the rich HNO3 system; B) the polysilicon solar cell after texturing in step A is cleaned by deionized water; and C) secondary texturing is carried out on the polysilicon solar cell by using the mixed acid corrosion solution, in which the mass concentration of HNO3 is greater than that of HF, of the rich HNO3 system. The solutions used in twice texturing need neither a texturing additive nor other chemicals, the texturing reflectivity of twice texturing is 9% or more lower than that of once texturing traditionally, the light tripping effect of the textured surface is improved, the short circuit current is improved by 200mA or more, and the efficiency is improved by 0.35%; and the texturing method can be combined with a present production line conveniently to reduce the cost and provide convenience for large-scale production.

Owner:REALFORCE POWER

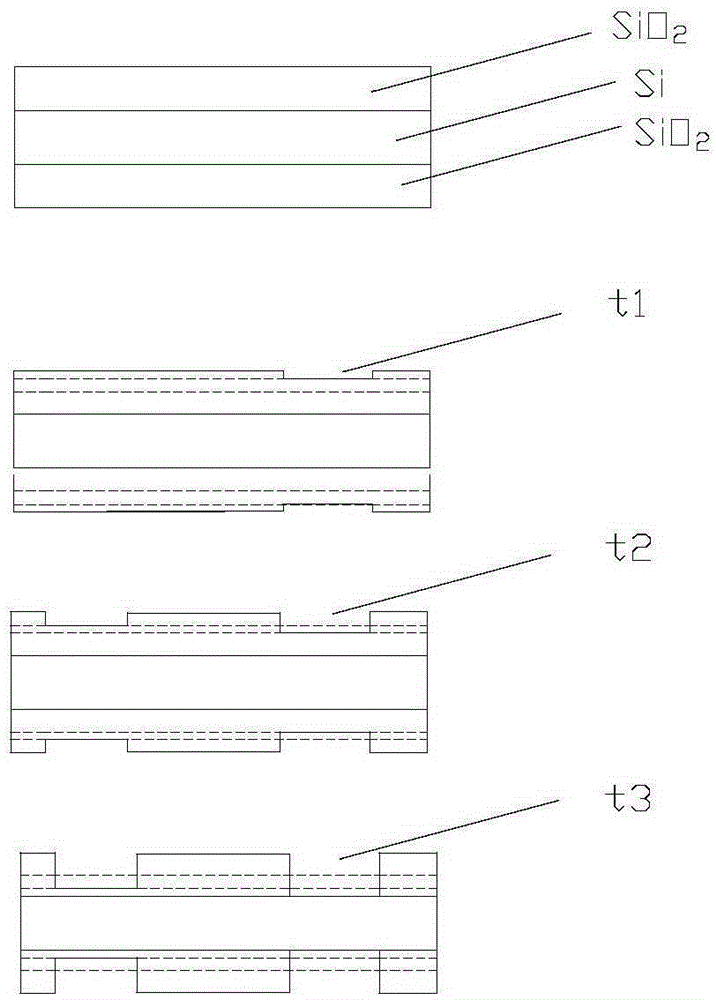

MEMS sandwich accelerometer sensitive chip wet etching processing method

InactiveCN105329848AAvoid Bottom ReflectionsImprove the quality of corrosion processingAcceleration measurement using interia forcesDecorative surface effectsSmooth surfaceOxide

The present invention discloses a MEMS sandwich accelerometer sensitive chip wet etching processing method, a single-layer oxide layer is grown on a silicon wafer, double-sided lithographic etching the single-layer oxide film layer is performed for 3 times, the depth of each tie of etching is precisely controlled, and the single-layer oxide film layer is divided into three layers of different structures of oxide film layers. At a temperature of 60-80 DEG C, the silicon wafer is wet-etched, the first silicon etching time is 20 to 30 minutes, the first layer oxide film layer is etched; the second silicon etching time is 150 to 160 minutes, the second layer oxide film layer is etched; the silicon wafer is wet-etched at a temperature of 30-40 DEG C in the third etching, the etching time is 30 to 40 minutes, and the third layer oxide film layer is etched. A sensitive chip with smooth surface and accurate dimension can be processed by the method, and by improvement of the method, the quality and rate of finished products of the sensitive chip can be greatly improved.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Fluorine surface etchant for semiconductor and preparation method thereof

The invention relates to a fluorine surface etching liquid for semiconductors and a preparation method thereof. The etching liquid formula: stabilizer 25-50, hydrofluoric acid 0.2-2, buffer 1-10, nitric acid 2-10, nonionic surfactant 0.0001 -0.001, appropriate amount of deionized water. Process steps: 1. Add buffering agent to hydrofluoric acid according to the proportion, stir for 30 minutes to obtain mixture I, 2. add stabilizer to nitric acid according to the proportion, and stir for 40 minutes to obtain mixture II. 2 Mix the obtained mixtures I and II with an appropriate amount of deionized water, stir for 30 minutes, and then add nonionic surfactant after standing still for 10 minutes, and stir evenly. The etchant prepared by the present invention controls its corrosion strength by adding hydrofluoric acid to the buffer; Adds the etching stability of nitric acid to control the nitric acid by the stabilizer; Reduces the surface tension of the etchant by adding nonionic surfactants, Improve the wetting effect of the etchant, which greatly improves the stability of the product, the smoothness and precision of etching, and improves the yield.

Owner:JIANGYIN RUNMA ELECTRONICS MATERIAL

Bottom electrode bottom-removing etching method of space three-junction gallium arsenide solar battery

InactiveCN101894878AIncrease surface appearanceGuaranteed firmnessFinal product manufactureSemiconductor devicesHydrofluoric acidOrganic solvent

The invention relates to a bottom electrode bottom-removing etching method of a space three-junction gallium arsenide solar battery, comprising the following steps of: (1) spreading rubber and drying; (2) configuring main etching liquid and 201 etching liquid; (3) etching and washing wafers, wherein the etching time of the wafers which are put into the main etching liquid is 30-40s; (4) cleaning an organic solvent, wherein in the step (2), the peroxide, the hydrofluoric acid and the deionized water in the main etching liquid are in the volume proportion: of 1:1:8; washing the wafers 4-6 times by using the deionized water, then, putting the wafers into the 201 etching liquid to etch for 10-20s; and finally, taking the wafers out of the etching liquid and washing the wafers 6-10 times by using the deionized water. The invention has simple technology and scientific design, adopts a bottom electrode etching technology to increase the yield of bulk batteries, bottom electrode firmness of batteries and battery performance, and promotes the wide application of three-junction solar batteries in the field of new environment-friendly energy resources.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Long-acting silicon wafer texture-etchant and preparation method therefor

InactiveCN105133030AControl corrosion rateImprove conversion efficiencyAfter-treatment detailsInstabilitySodium hydroxide

The invention discloses a long-acting silicon wafer texture-etchant which is characterized by being prepared from the following raw materials in parts by weight: 0.1-0.2 part of dodecyl benzyl dimethyl ammonium chloride, 2-4 parts of triethanolamine, 1.5-2.5 parts of sodium hydroxide, 1-2 parts of glycerine ethoxylate, 1-2 parts of sodium perborate, 2-4 parts of ethylenediamine tetraacetic acid disodium, 0.2-0.4 part of barium petroleum sulfonate, 1-2 parts of hydroxyethyl cellulose, 5-10 parts of a texture-etching adjuster and 100-150 parts of water. The silicon wafer texture-etchant disclosed by the invention not only can improve the texture-etching efficiency and the stability of a texture-etching process and effectively improve the conversion efficiency of a battery sheet, but also can effectively solve the problem of instability of the texture-etchant in a using process, so that the service life of a solution is prolonged, the production cost is lowered and the product is stable in quality.

Owner:CHINALAND SOLAR ENERGY

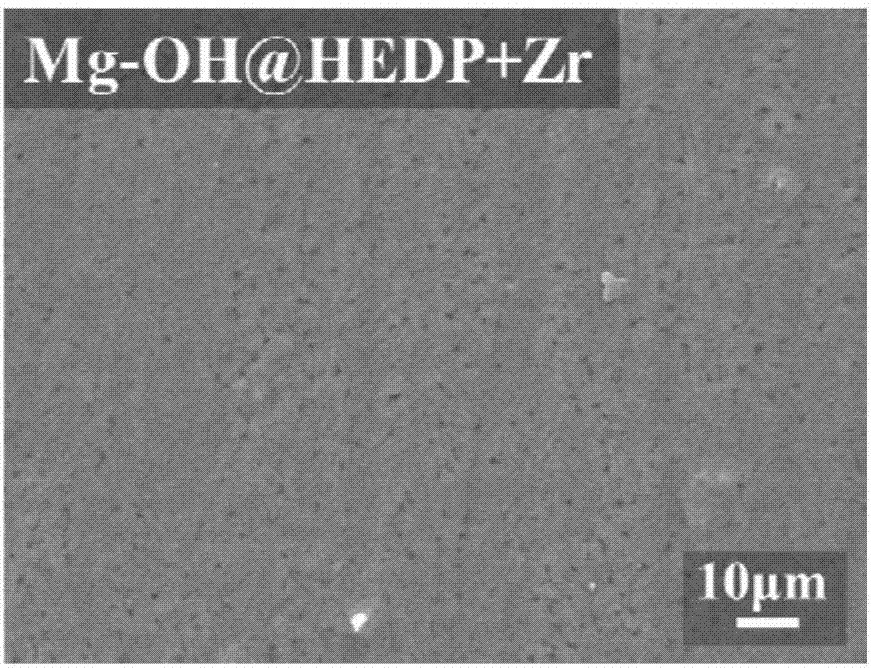

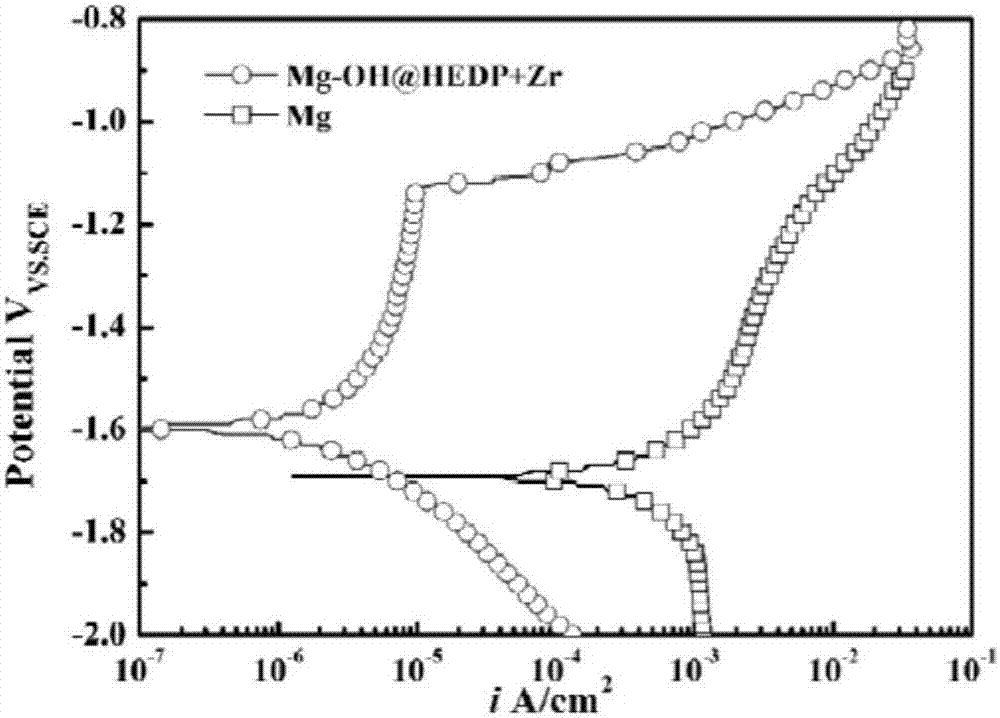

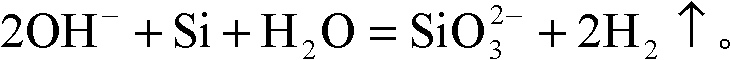

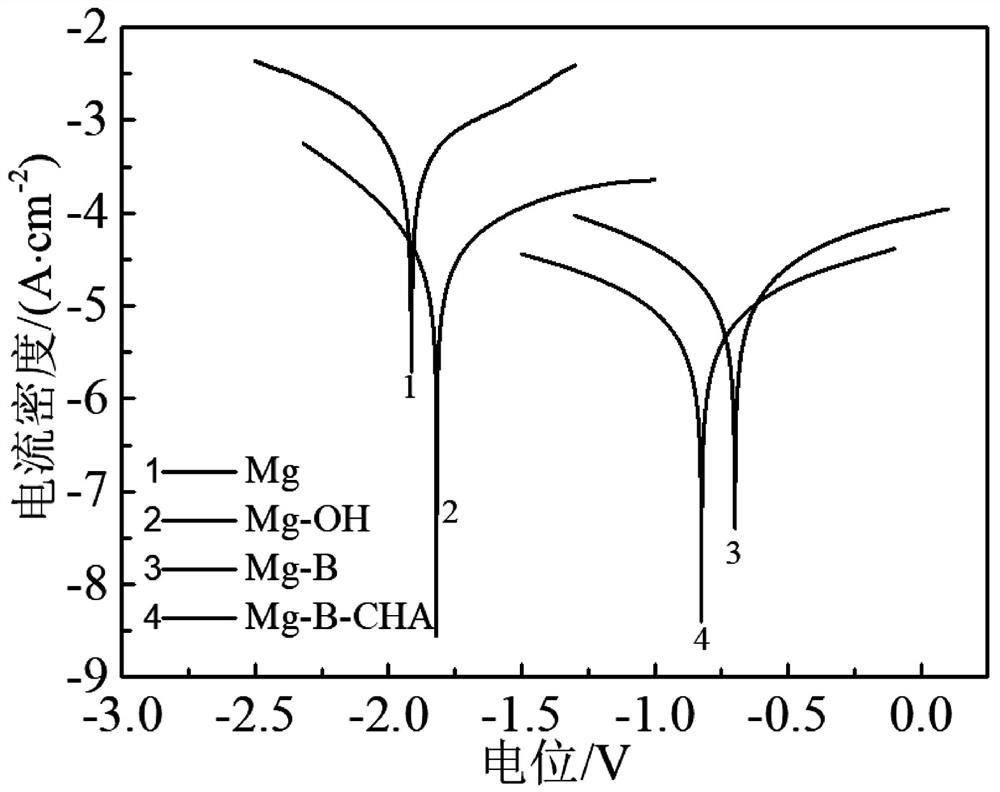

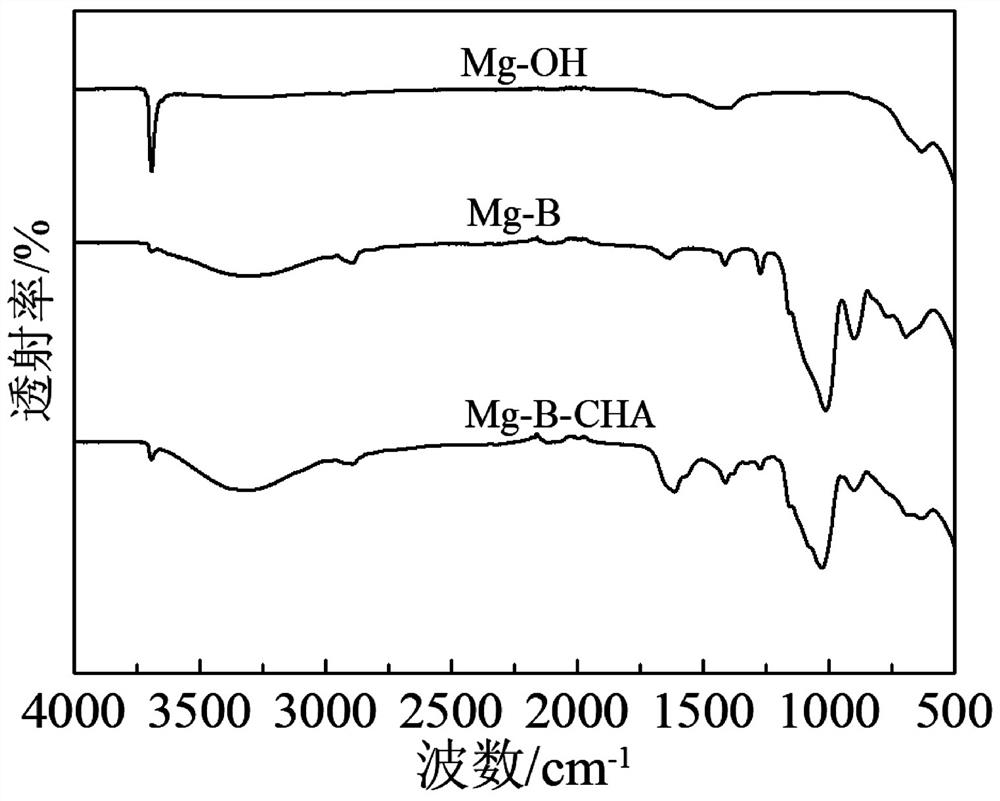

Method for establishing metal-organic framework composite coating on surface of magnesium metal

ActiveCN107267973AGuaranteed biocompatibilityPromote value-addedMetallic material coating processesMetal-organic frameworkPhosphoric acid

The invention discloses a method for establishing a metal-organic framework composite coating on the surface of magnesium metal. The method includes the main steps that A, a magnesium metal sheet is ground and polished, then ultrasonic cleaning is conducted and afterwards vacuum drying is performed; B, the magnesium sheet is put into a 2-4mol / L NaOH solution of 55-65 DEG C to be soaked for 10-14h, and accordingly an alkali-activated magnesium metal sheet is obtained; C, an HEDP solution with the concentration being 0.4-0.6g / L is prepared, and then the pH is adjusted to 7-8; D, deionized water and absolute ethyl alcohol are prepared into mixed solvent according to the volume ratio of 0.8-1.2:1, and then zirconium ions are dissolved into the mixed solvent to obtain a zirconium ion solution with the concentration being 0.8-1.2mmol / L; E, the magnesium sheet obtained in the step B is put into the HEDP solution obtained in the step C, and soaking is conducted for 8-12h under the temperature condition of 55-65 DEG C; F, the magnesium sheet is deposited in the zirconium ion solution for 10-30s; G, the magnesium sheet is deposited in the HEDP solution for 3-5min; and H, operation in the steps F and G is repeated for 4-6 times and accordingly the metal-organic framework composite coating can be obtained. The metal-organic framework composite coating prepared through the method is good in coating / substrate binding force, the coating is thin and compact, the corrosion rate of magnesium can be well controlled and the bone compatibility is good.

Owner:SOUTHWEST JIAOTONG UNIV

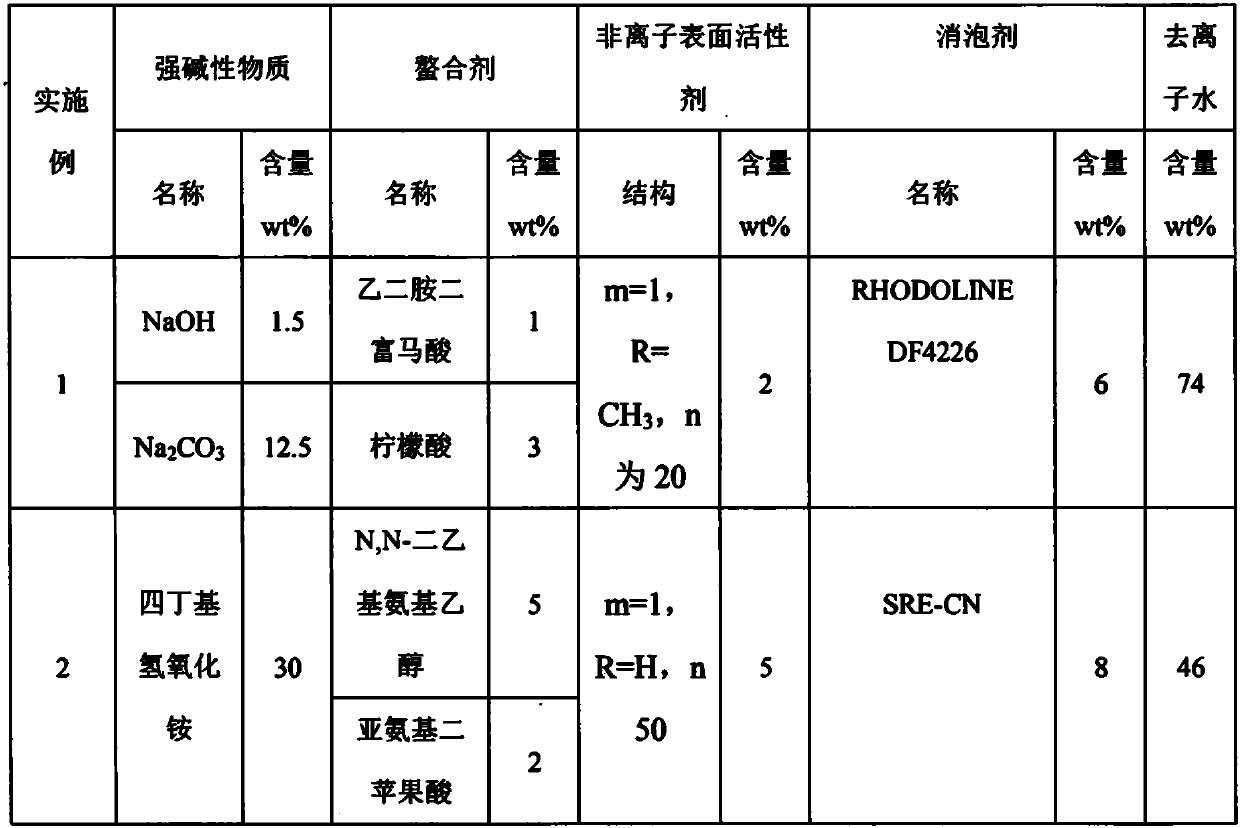

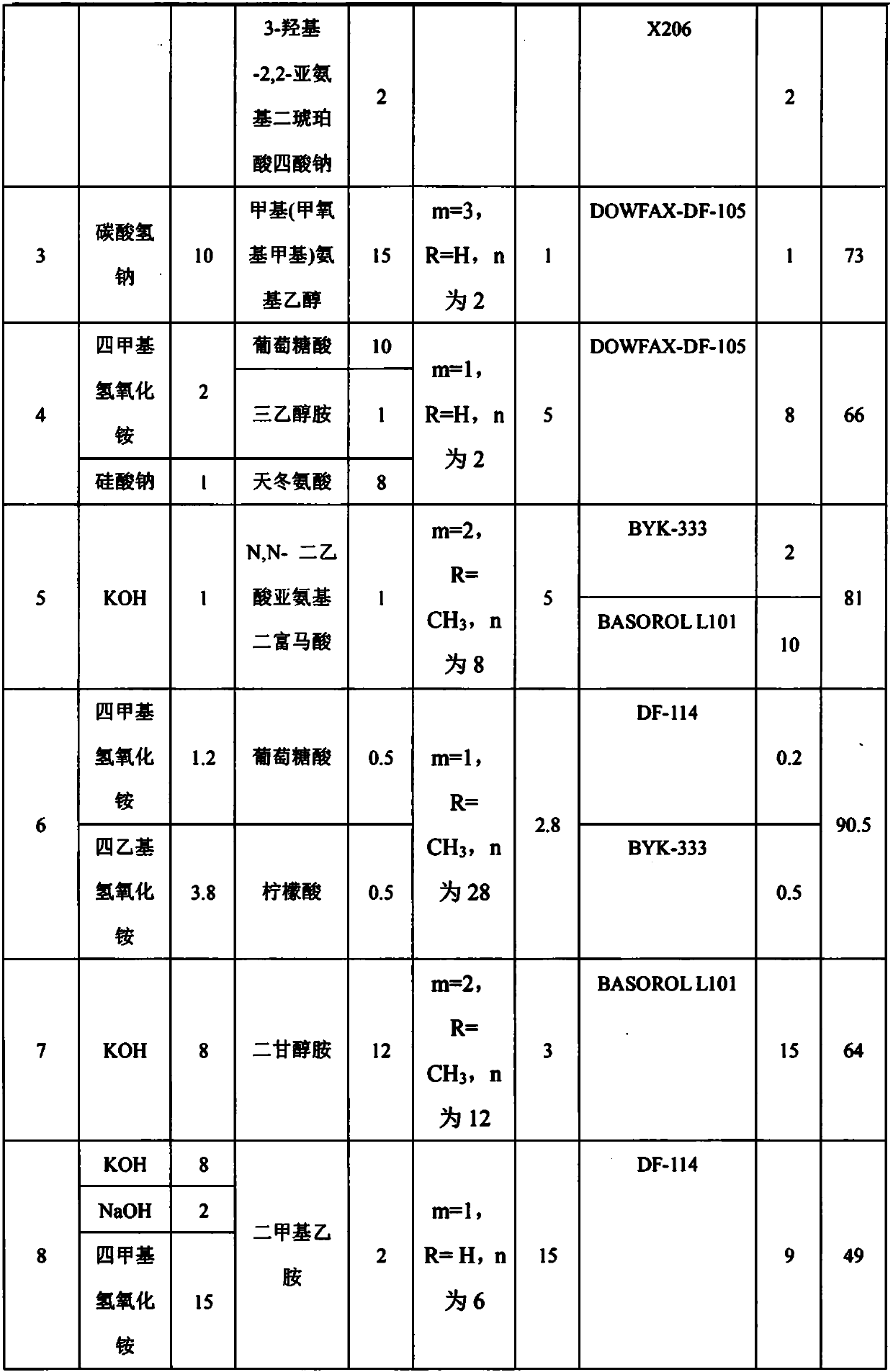

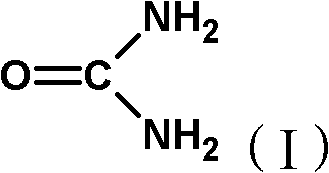

Low-foam glass substrate cleaning solution

InactiveCN110819468ANot corrosiveNon-toxic and non-corrosiveInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsActive agentPhysical chemistry

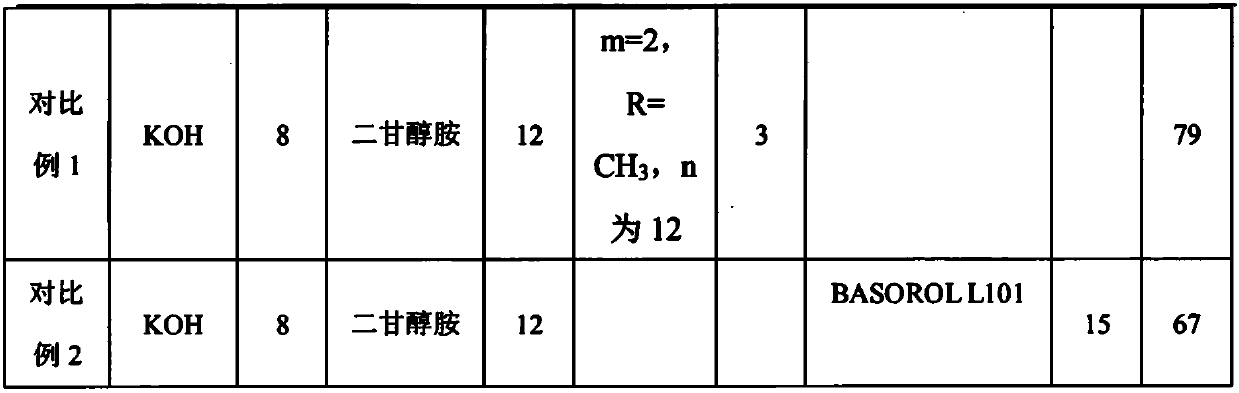

The invention relates to a low-foam glass substrate cleaning solution, and belongs to the field of microelectronic materials. The low-foam glass substrate cleaning solution comprises the following components in percentage by weight: 1 to 45 percent (preferably 3 to 30 percent ) of strong alkali substance, 0.1 to 50 percent (preferably 0.5 to 20 percent ) of chelating agent, 0.1 to 15 percent (preferably 0.2 to 10 percent ) of defoaming agent, 30 to 99.3 percent (preferably 40 to 98 percent ) of deionized water, and 0.1 to 25 percent (preferably 0.2 to 20 percent ) of non-ionic surface active agent with a structure as shown in a formula I, wherein m is 1 to 3, R is H or CH3, and n is 2 to 50. The cleaning solution provided by the invention is non-toxic and non-corrosiveness, free of low-boiling-point organic volatile matters, non-pollute to the environment, and capable of effectively removing residues on the surface of a surface substrate without corroding a glass substrate at the sametime.

Owner:华璞微电子科技(宁波)有限公司

Bamboo extraction solution silicon wafer texture-etchant and preparation method therefor

The invention discloses a bamboo extraction solution silicon wafer texture-etchant which is characterized by being prepared from the following raw materials in parts by weight: 10-15 parts of fresh bamboo leaves, 3-5 parts of sodium tripolyphosphate, 0.3-0.5 part of sodium carbonate, 1.5-2.5 parts of sodium hydroxide, 0.5-1 part of octadecyl diethoxy glycine betaine, 5-10 parts of a texture-etching adjuster, 0.2-0.4 part of cottonseed oil, 1-2 parts of polyethylene glycol, 0.3-0.5 part of xanthan gum and 100-150 parts of water. The silicon wafer texture-etchant disclosed by the invention not only can improve the texture-etching efficiency and the stability of a texture-etching process and effectively improve the conversion efficiency of a battery sheet, but also can reduce the texture-etching corrosion amount, reduce the wrapping degree of the silicon wafer, and reduce fragments. The silicon wafer texture-etchant is non-toxic and harmless, and safe and environmental-friendly, and the product is stable in quality.

Owner:CHINALAND SOLAR ENERGY

Environment-friendly high-efficient silicon chip texturing agent and preparation method thereof

InactiveCN105177719AControl corrosion rateImprove conversion efficiencyAfter-treatment detailsSodium hydroxideHydroxyethylidene Diphosphonic Acid

The invention discloses an environment-friendly high-efficient silicon chip texturing agent, which is characterized by being prepared from the following raw materials in parts by weight: 1.5 to 2.5 parts of sodium hydroxide, 0.5 to 1 part of sodium cocoyl methyl taurate, 0.3 to 0.5 part of castor oil-polyoxyethylene ether, 0.2 to 0.4 part of hydroxyethylidene diphosphonic acid, 1 to 2 parts of sodium polyacrylate, 0.3 to 0.5 part of sodium oleate, 0.3 to 0.5 part of sodium silicate, 5 to 10 parts of texturing conditioning agent, and 100 to 150 parts of water. The provided silicon chip texturing agent can improve the texturing efficiency and stability of texturing technology, effectively improves the conversion efficiency of battery chips, reduces the texturing time, improves the production efficiency, reduces the using amount of chemical products, has a good degradable property, is pollution-free to the environment, reduces the production cost and wastewater treatment cost, and generates good economic benefits and environment benefits.

Owner:安徽飞阳能源科技有限公司

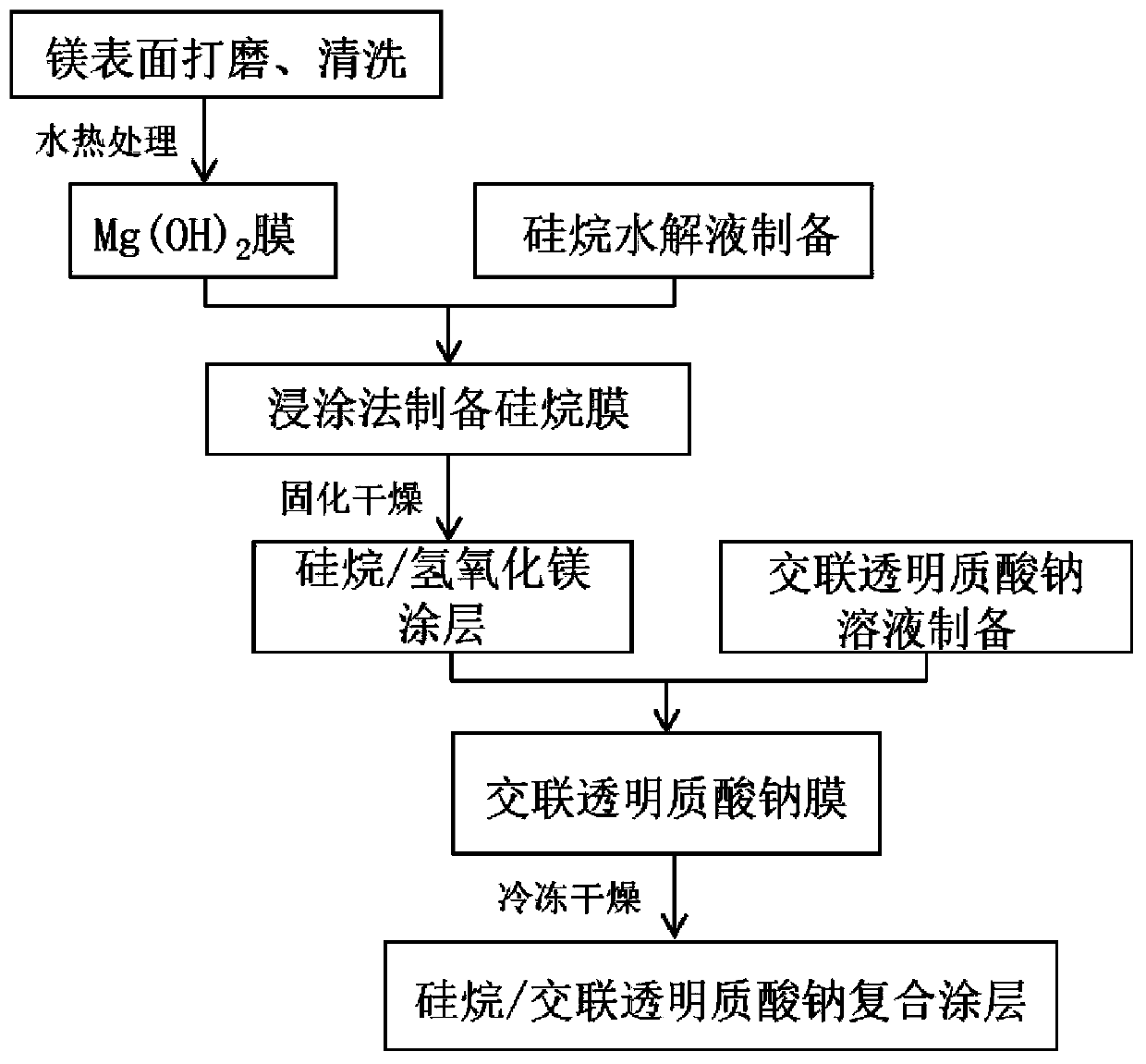

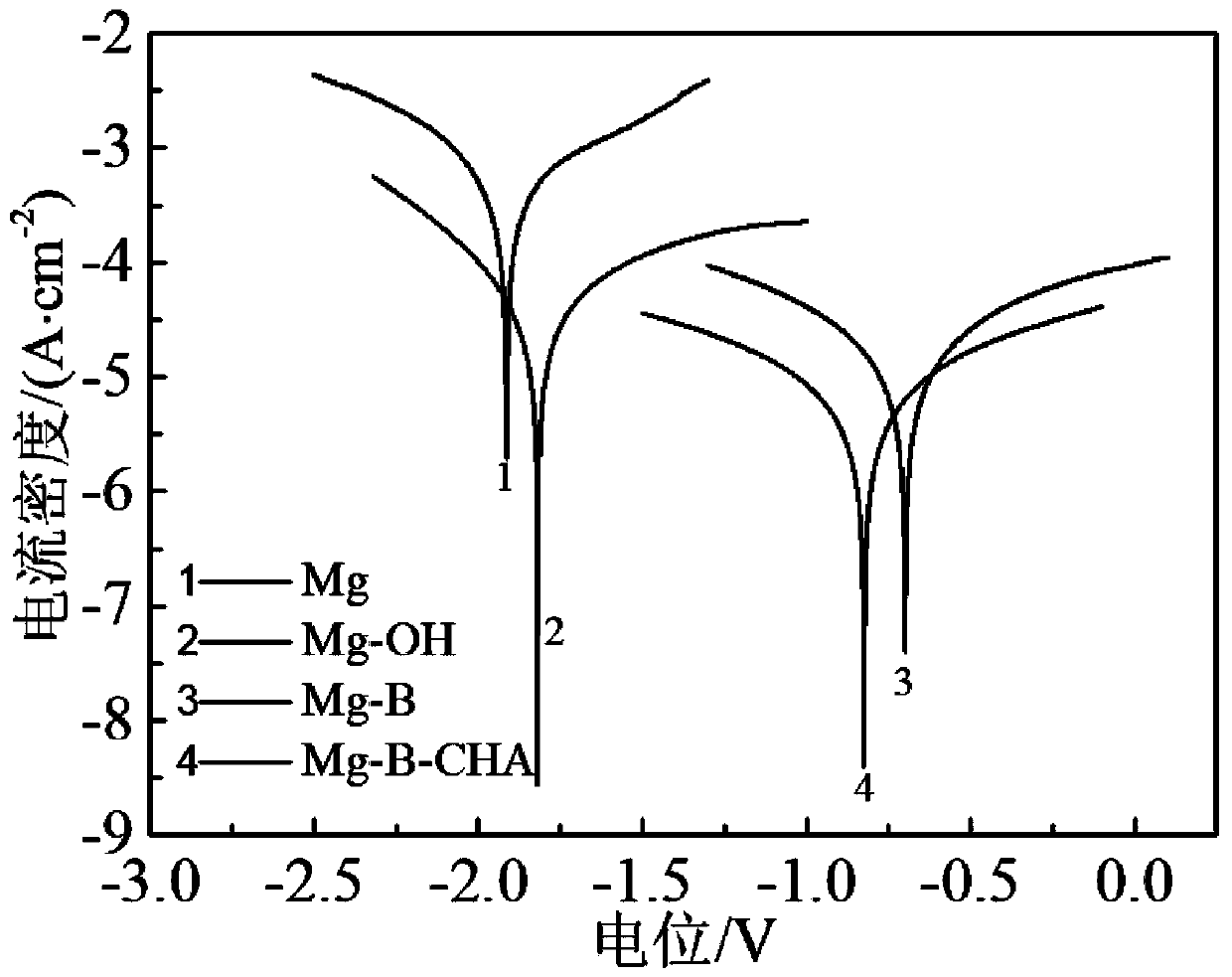

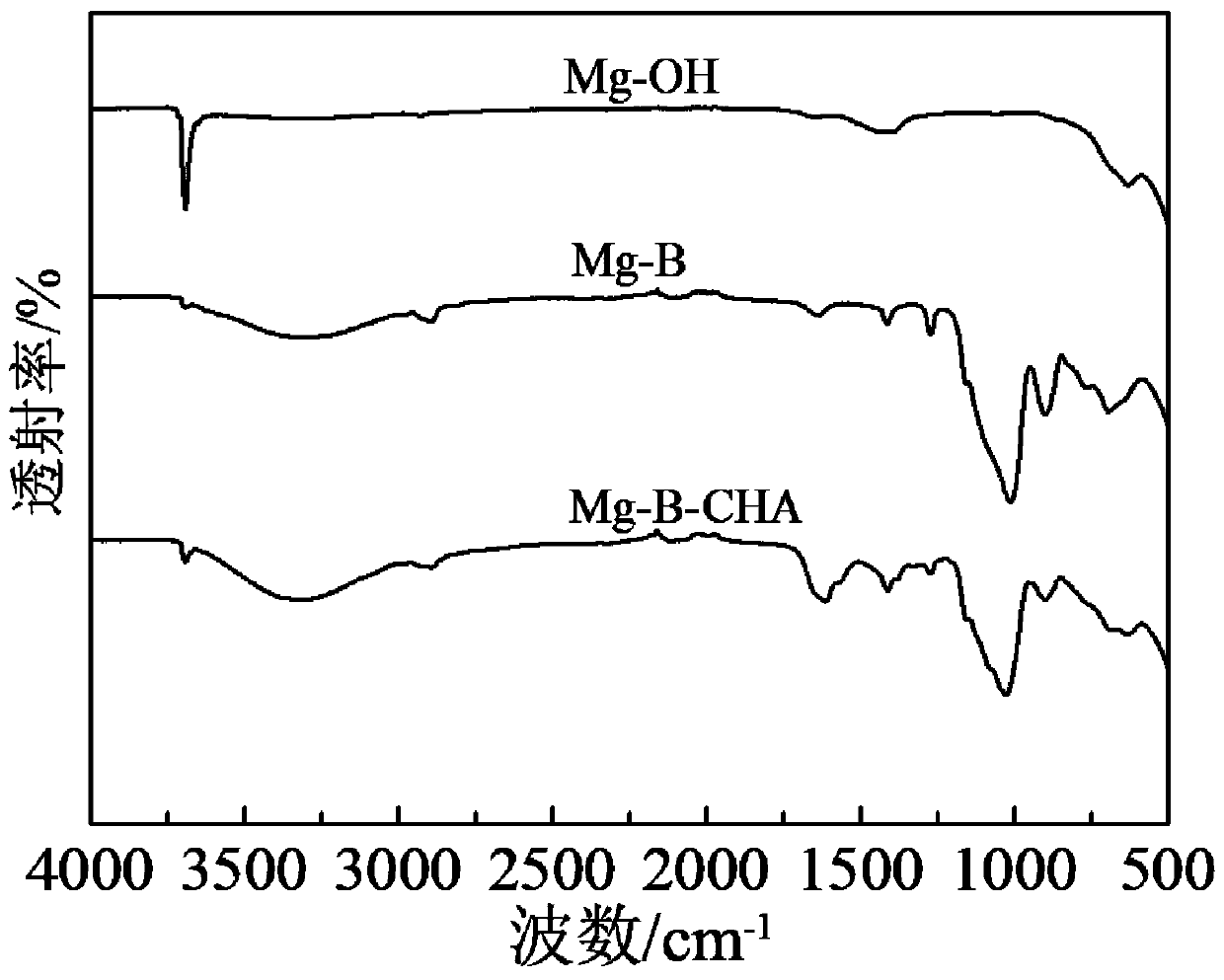

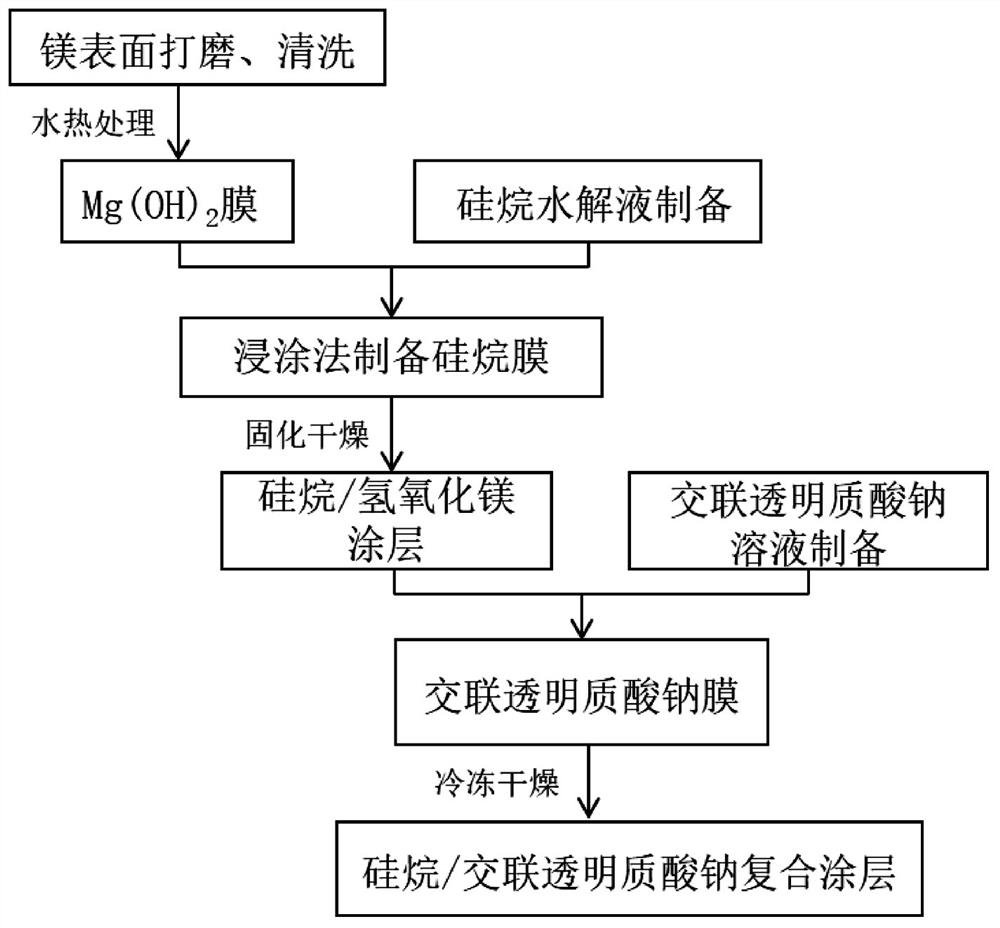

Preparing method for magnesium and magnesium alloy with surface provided with silane/sodium hyaluronate composite coating

ActiveCN109825835AReduce material costsReduce processing costsMetallic material coating processesSilanesBiocompatibility Testing

The invention discloses a preparing method for the magnesium and magnesium alloy with the surface provided with a silane / sodium hyaluronate composite coating. According to the method, the magnesium and magnesium alloy are subjected to hydro-thermal treatment in an alkaline solution, and a magnesium hydrate film with active hydroxyl is obtained to serve as a substrate with a protection function anda pretreatment layer improving bonding force with silane; then, silane molecules are assembled to the magnesium and magnesium alloy through molecular bonds; and finally, a dipping method is used forobtaining a covalent bond grafted EDC / NHS crosslinking modified sodium hyaluronate coating on the surface of a silanization sample, and the composite coating is obtained after drying. Through the method, the corrosion speed of the magnesium and magnesium alloy can be effectively controlled, the corrosion rate is reduced, introduction of harmful impurities is avoided, and good biocompatibility anddegradability are achieved; a positive role is played for ophthalmic disease treatment through slowly-released magnesium ions, and the success ratio of operation is guaranteed; and the product cost islow, the patient expense is reduced, the method is expected to become a new ophthalmology intervention therapy method, and a new thought is brought for ophthalmic disease treatment.

Owner:CHONGQING UNIV

Absorbable magnesium alloy bracket of inorganic and organic antiseptic biocompatible composite coating and preparation method thereof

ActiveCN101721753BExtension of timeImprove corrosion resistanceAnodisationSurgeryControlled releaseSide effect

The invention relates to an absorbable magnesium alloy bracket of an inorganic and organic antiseptic biocompatible composite coating and a preparation method thereof. The absorbable magnesium alloy bracket of the inorganic and organic antiseptic biocompatible composite coating comprises a magnesium alloy bracket backbone and a composite coating. The composite coating consists of an inorganic antiseptic coating, a compact organic hole sealing coating, a drug releasing coating and a drug slow release coating; the surface layer of the absorbable magnesium alloy bracket backbone is an inorganic porous antiseptic coating, the compact organic hole sealing coating is arranged outside the inorganic antiseptic coating, the drug releasing coating is arranged outside the compact organic coating, and the drug slow release coating is arranged outside the drug releasing coating. The invention effectively improves the corrosion resistance of the magnesium alloy bracket backbone and controls releasing rate of magnesium ions; meanwhile, the organic membrane layer improves the surface biocompatibility; the degraded products have no side effect, can be absorbed by human bodies, and have good biocompatibility and blood compatibility; and the drug releasing coating can reduce burst release of drug and ensure sustained slow release of drug.

Owner:中知在线股份有限公司

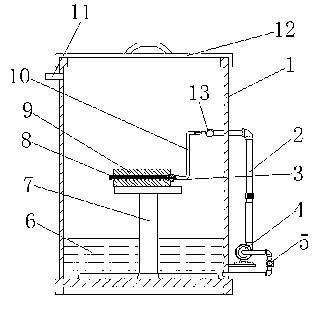

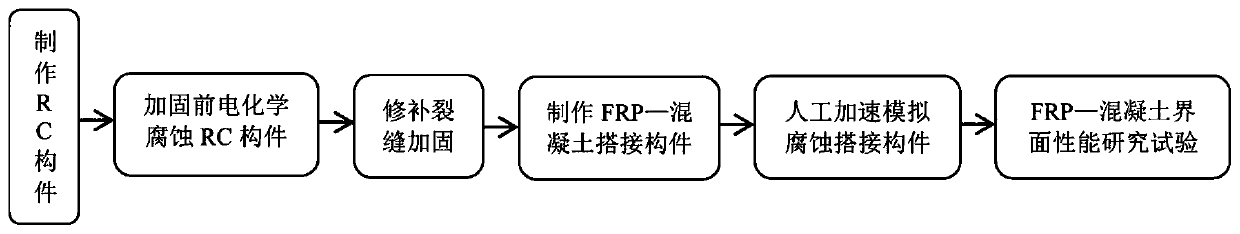

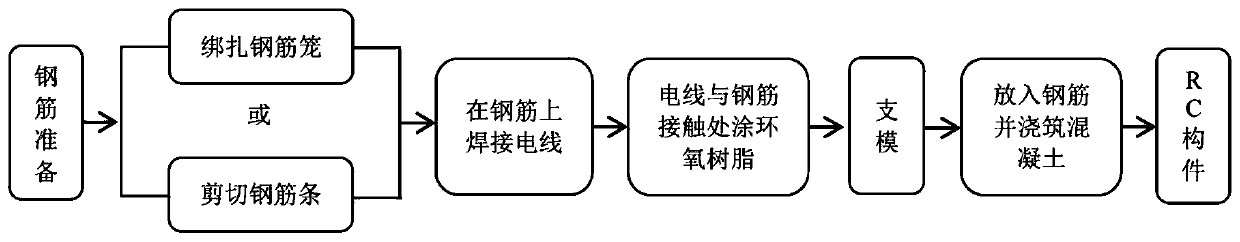

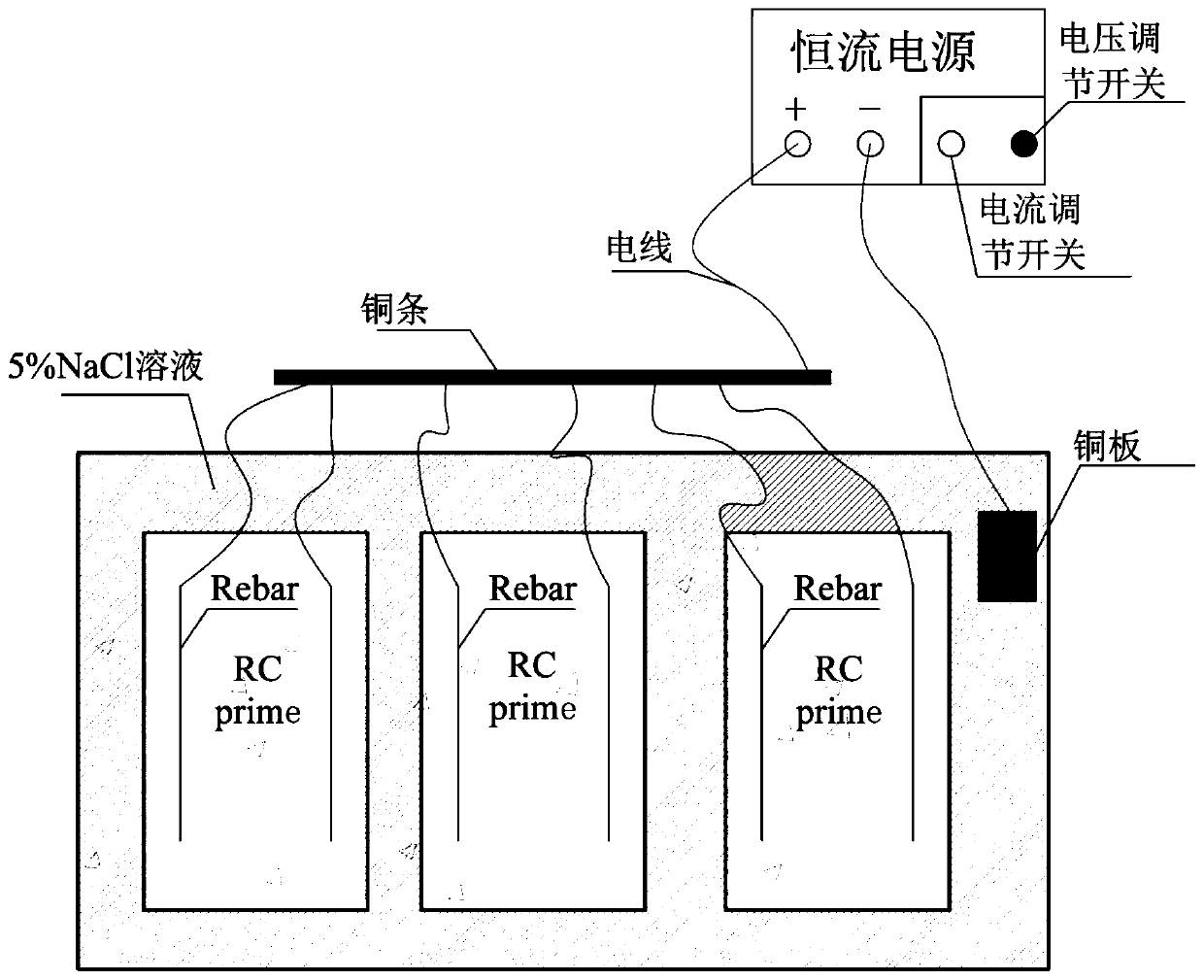

Accelerated corrosion method and device for FRP reinforced damaged RC component in simulated marine environment

PendingCN111189772AThe degree of rust is controllableEasy to operateWeather/light/corrosion resistanceWet bondingLap joint

The invention relates to the technical field of reinforced concrete structures. More specifically, the present invention relates to a method for manufacturing, the invention relates to an acceleratedcorrosion method and device for FRP reinforced damaged RC components in a simulated marine environment. The method comprises manufacturing an RC component, manually accelerating electrochemical corrosion of the reinforcing steel bars in an electrolyte solution to obtain a damaged RC component with cracks, using crack pouring glue for pouring glue and repairing cracks, using bonding glue for FRP wet bonding method reinforcement to obtain the FRP reinforced damaged RC component, soaking the FRP reinforced damaged RC component in a constant-temperature salt solution for secondary accelerated corrosion, obtaining a test lap joint component, and researching and testing the FRP-concrete interface durability of the lap joint member. The sodium chloride solution is adopted to simulate the marine environment, the steel bars in the RC component are electrified in the sodium chloride solution to accelerate corrosion of the steel bars, the corrosion degree of the steel bars is controllable, and operability is high; and the FRP reinforced RC component is soaked in the sodium chloride solution for artificial secondary accelerated corrosion, so that the time can be saved and the cost can be reduced on the premise of ensuring that the test purpose is achieved.

Owner:GUANGDONG UNIV OF TECH

A kind of monocrystalline silicon texturizing agent and the preparation method of textured monocrystalline silicon

ActiveCN103184523BImprove decontamination abilityIncrease buoyancyAfter-treatment detailsFinal product manufactureSodium lactateAmmonia

Owner:JETION SOLAR HLDG

Silicon wafer texturing agent containing kelp extraction liquid and preparation method for silicon wafer texturing agent

InactiveCN105133036AControl corrosion rateImprove stabilityAfter-treatment detailsSodium benzoateSilicon

The invention discloses a silicon wafer texturing agent containing a kelp extraction liquid. The silicon wafer texturing agent is characterized by being prepared from the following raw materials in parts by weight: 5-10 parts of kelp powder, 3-5 parts of sodium tripolyphosphate, 1.5-2.5 parts of sodium hydroxide, 0.5-1 part of diisooctyl sodium sulfosuccinate, 0.3-0.5 part of sorbide monooleate, 0.1-0.2 part of amino trimethylene phosphonic acid, 5-10 parts of a texturing adjustor, 0.5-1 part of sodium benzoate and 100-150 parts of water. The silicon wafer texturing agent disclosed by the invention not only can improve the texturing efficiency and the stability of a texturing process, but also can reduce the use level of chemicals, and is non-toxic and harmless, and the cost is lowered, so that the conversion efficiency of a battery piece is effectively improved, and the product quality is stable.

Owner:ANHUI KING AUTO ELECTRONICS TECH CO LTD

Preparation method of magnesium and magnesium alloy with silane/sodium hyaluronate composite coating on surface

ActiveCN109825835BReduce material costsReduce processing costsMetallic material coating processesMg alloysBiocompatibility

Owner:CHONGQING UNIV

Used to observe the δ-Ni in the nickel-iron-based superalloy structure 3 Metallographic etchant for Nb phase and method of use thereof

ActiveCN104593775BGood chemical stabilityControl corrosion ratePreparing sample for investigationOXALIC ACID DIHYDRATESuperalloy

Owner:CHINA HUANENG GRP CO LTD +1

Alkaline texturing process for monocrystalline silicon wafers

ActiveCN103572373BImprove secondary reflectionsPromote sinteringAfter-treatment detailsFinal product manufactureElectrical resistance and conductanceInverted pyramid

The invention discloses an alkaline type texturing process of monocrystalline silicon wafer, which is used for solving the problems that secondary reflection cannot be completely formed very well and good contact with conductive slurry is difficult to form due to uneven diffusion as size and arrangement of a textured surface obtained by the alkaline type texturing process in the prior art are random. The alkaline type texturing process mainly comprises the following steps: (a) removing an affected layer; (b) preparing a mask; (c) windowing the mask; (d) texturing on a surface; and (e) removing the mask. The alkaline type texturing process disclosed by the invention is simple in step, suitable for industrial production and low in cost; the obtained monocrystalline silicon wafer textured structure is an inverted pyramid structure with regular size and arrangement, so that secondary reflection can be completely formed very well; and meanwhile, diffusion is guaranteed to be uniform and coating of conductive slurry is facilitated, so that thickness of the conductive slurry is controlled easier, contact with the conductive slurry is good, metal sintering is facilitated, and contact resistance is reduced.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com