A kind of monocrystalline silicon texturizing agent and the preparation method of textured monocrystalline silicon

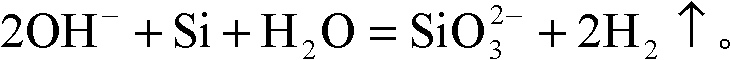

A monocrystalline silicon texturing agent and crystal silicon texturing agent technology, which is applied in chemical instruments and methods, crystal growth, final product manufacturing, etc., can solve the problem of uneven pyramid-shaped textured surface and low pass rate of monocrystalline silicon textured surface and other issues, to achieve the effect of improving short-circuit current and conversion efficiency, improving pass rate, and reducing bright spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

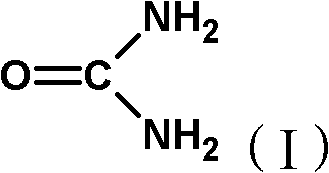

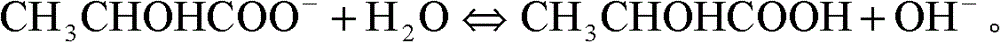

[0042]The preparation method of the corrosive agent is not particularly limited in the present invention. The urea aqueous solution described in the above technical solution may be prepared first, and then sodium lactate is added to the urea aqueous solution to obtain the corrosive agent.

[0043] The preparation method of the corrosive agent can also first prepare the sodium lactate aqueous solution described in the above technical solution, and then add urea to the sodium lactate aqueous solution to obtain the corrosive agent.

[0044] The preparation method of the corrosive agent can also firstly mix urea and sodium lactate to obtain a mixture of urea and sodium lactate; then add water to the mixture of urea and sodium lactate to obtain the corrosive agent described in the above technical solution.

[0045] After obtaining the corrosive agent, the present invention preferably mixes the basic compound in the above technical scheme with the corrosive agent to obtain a mixture ...

Embodiment 1

[0062] 200mL of water was added to 22.2g of urea to obtain a urea solution with a mass concentration of 10%, and then 6.87g of sodium lactate was added thereto to obtain a corrosive agent, wherein the mass concentration of sodium lactate was 3%. Take 4.5g of sodium hydroxide and 26.7mL of the above corrosive agent, add 200mL of water to it to obtain a texturing agent, wherein the mass concentration of sodium hydroxide is 2%, and the total mass concentration of urea and sodium lactate in the corrosive agent is 1.5%.

Embodiment 2

[0066] 200 mL of water was added to 10.5 g of sodium lactate to obtain a sodium lactate solution with a mass concentration of 5%, and then 28.7 g of urea was added thereto to obtain a corrosive agent, wherein the mass concentration of urea was 12%. Take 5.85g of sodium hydroxide and 24.38mL of the above-mentioned corrosive agent, and add 200mL of water to it to obtain a texturing agent, wherein the mass concentration of sodium hydroxide is 2.5%, and the total mass concentration of urea and sodium lactate in the corrosive agent is 1.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com