Patents

Literature

32results about How to "Smooth overflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

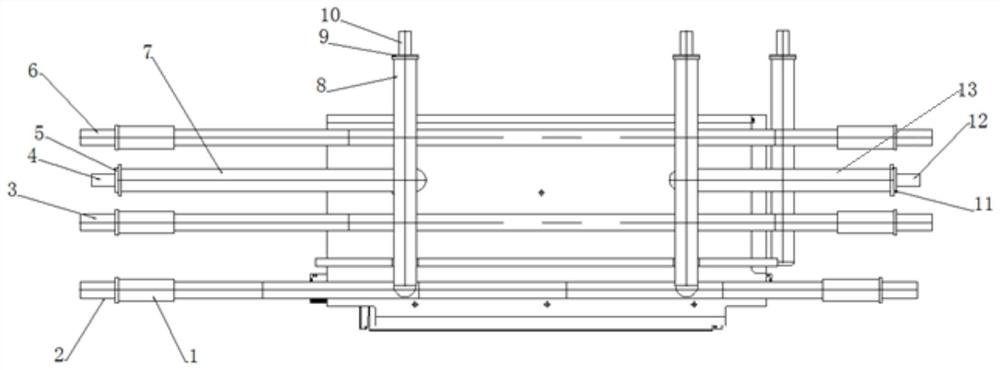

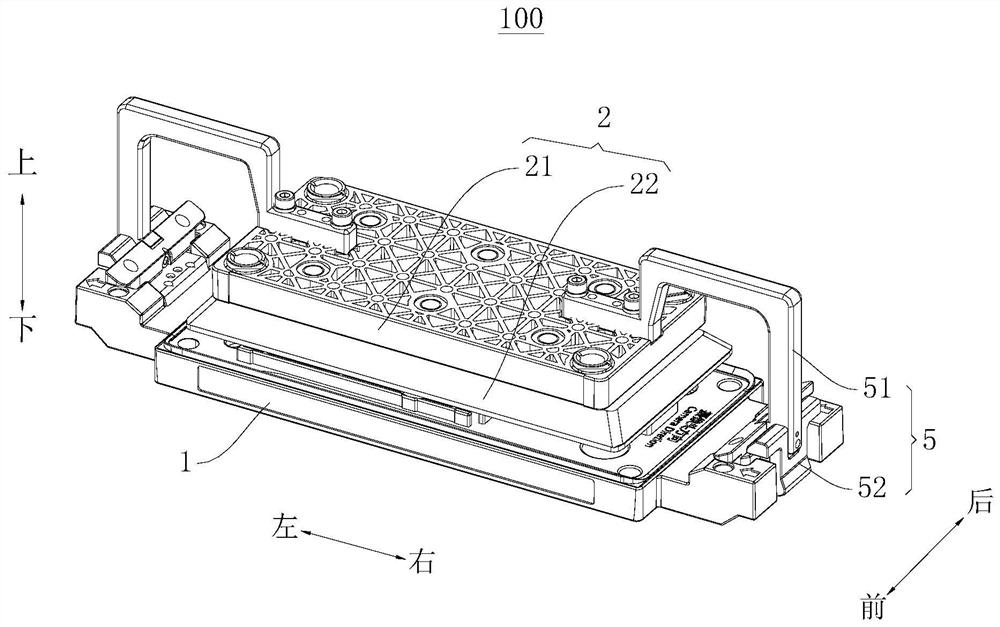

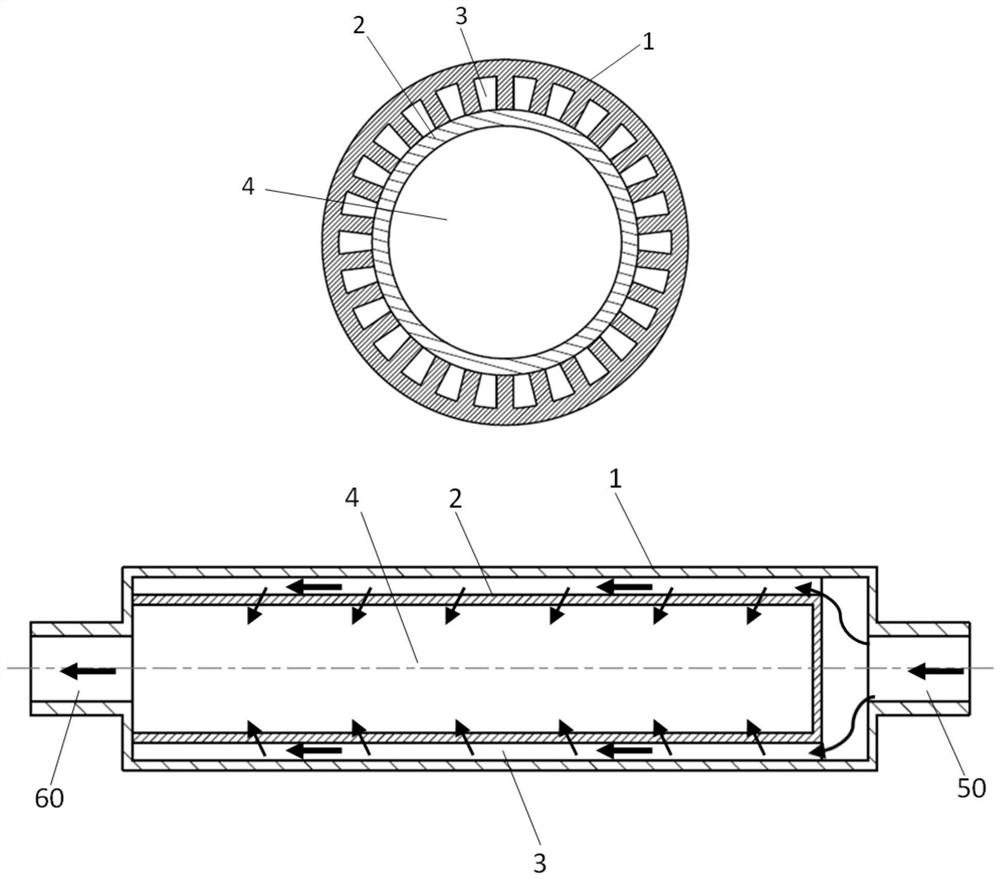

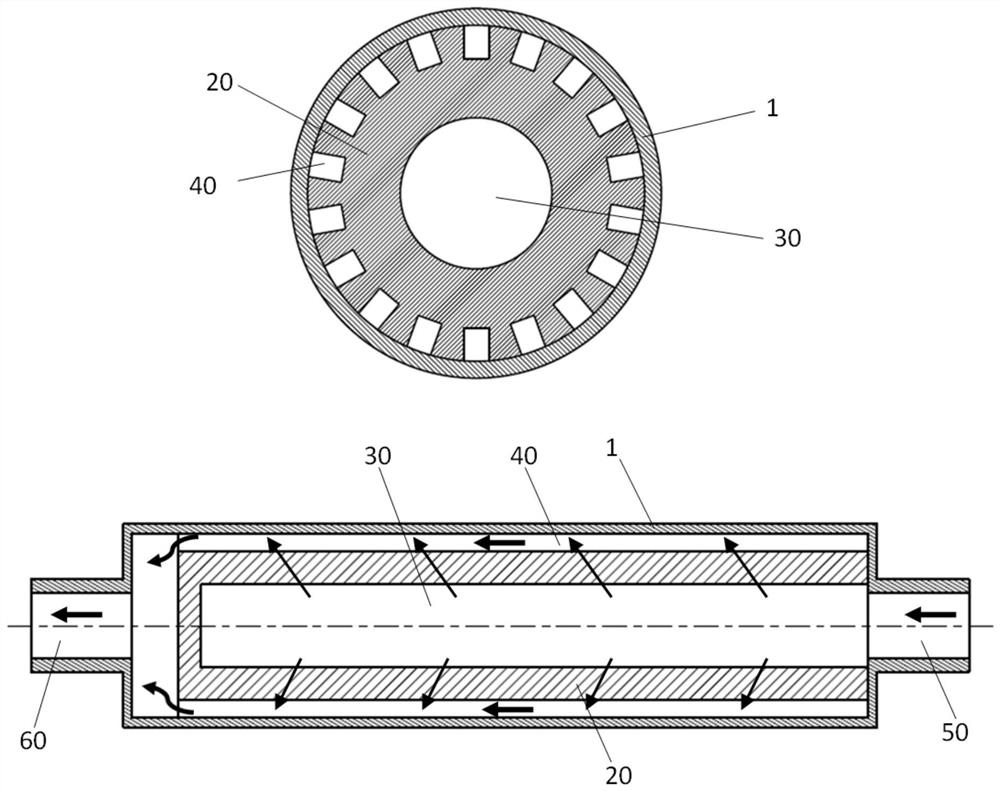

Pump-driven two-phase fluid loop evaporator

ActiveCN111504103ALarge thermal resistanceLarge evaporation heat transfer coefficientIndirect heat exchangersHydrophobeMechanics

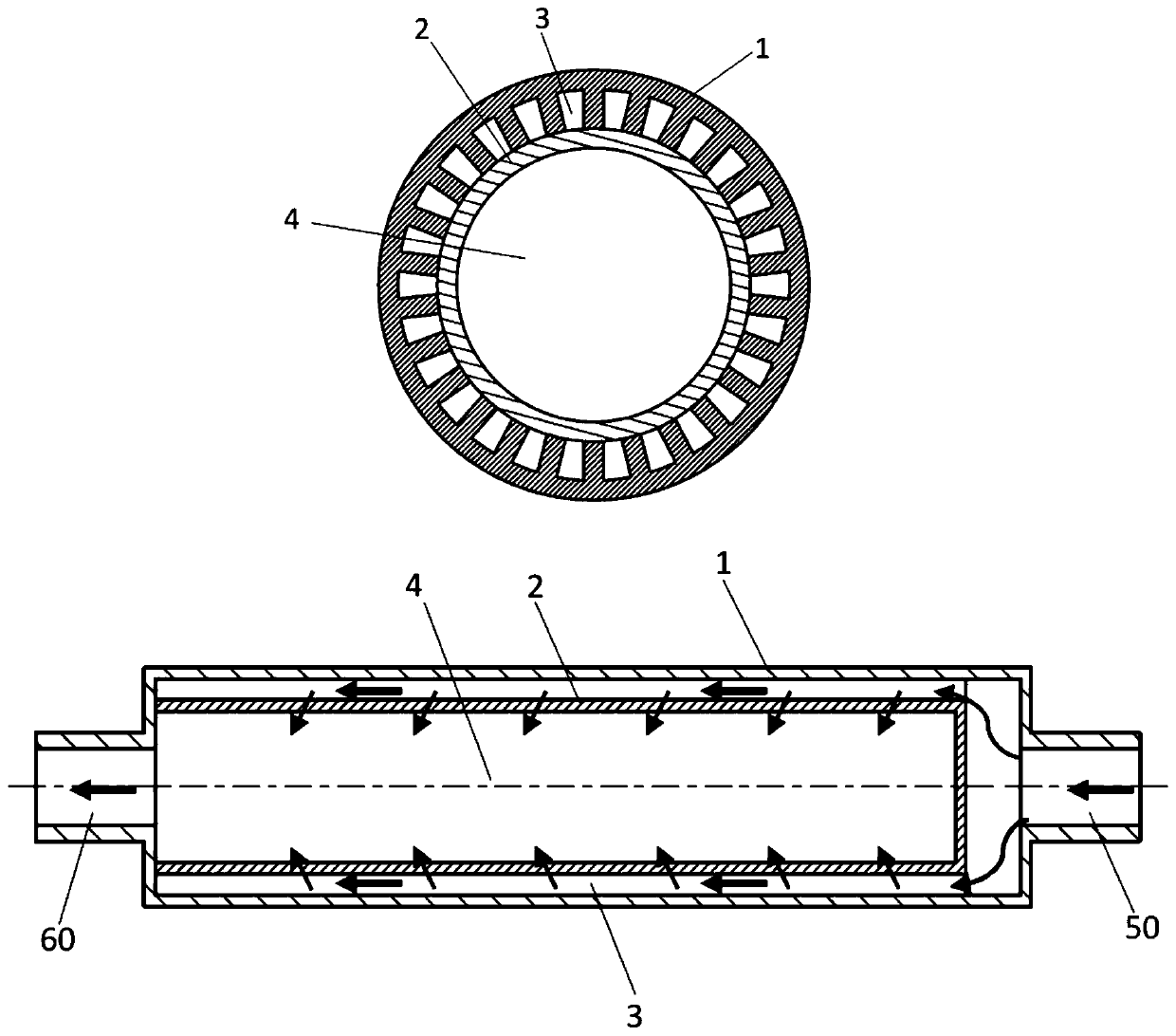

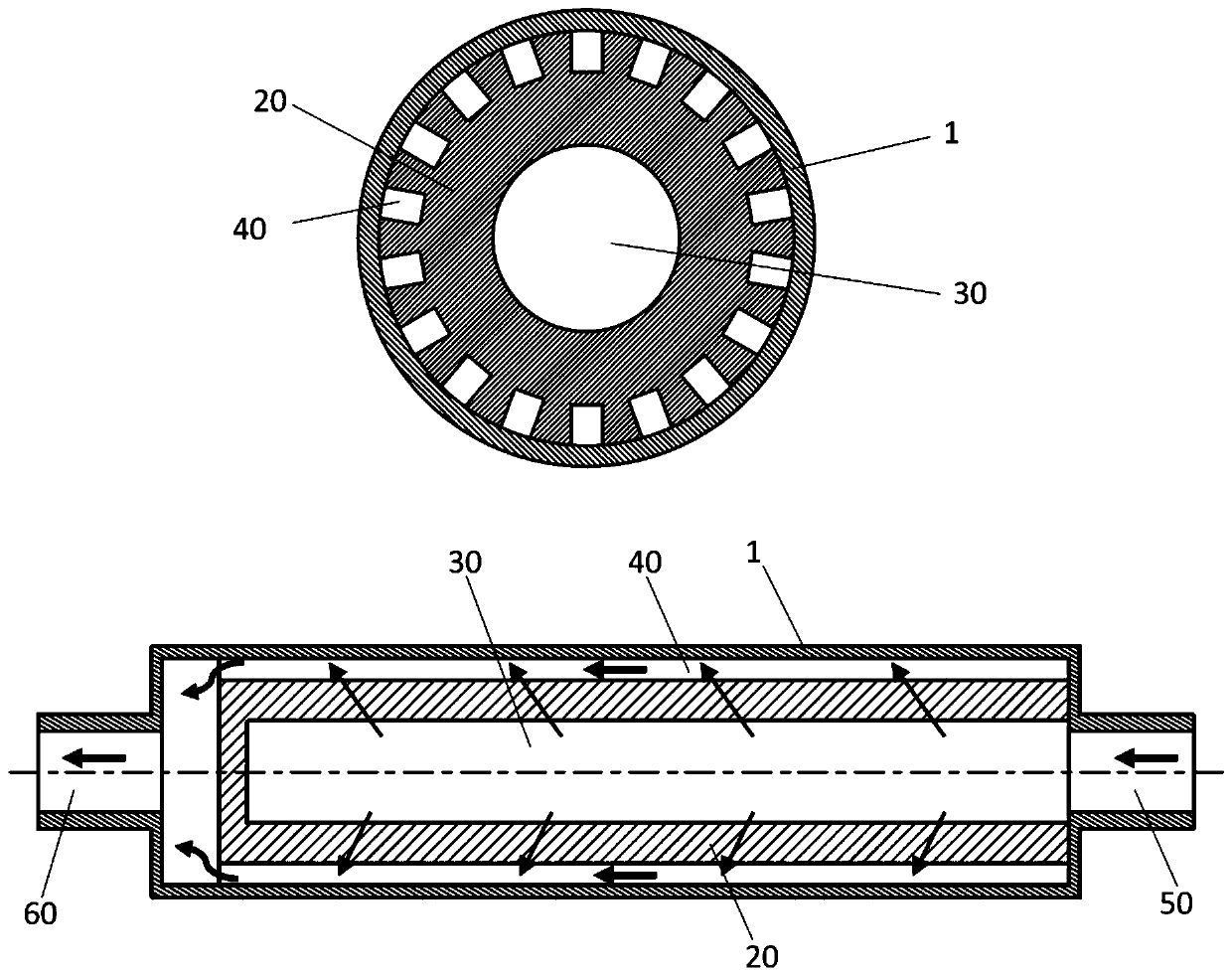

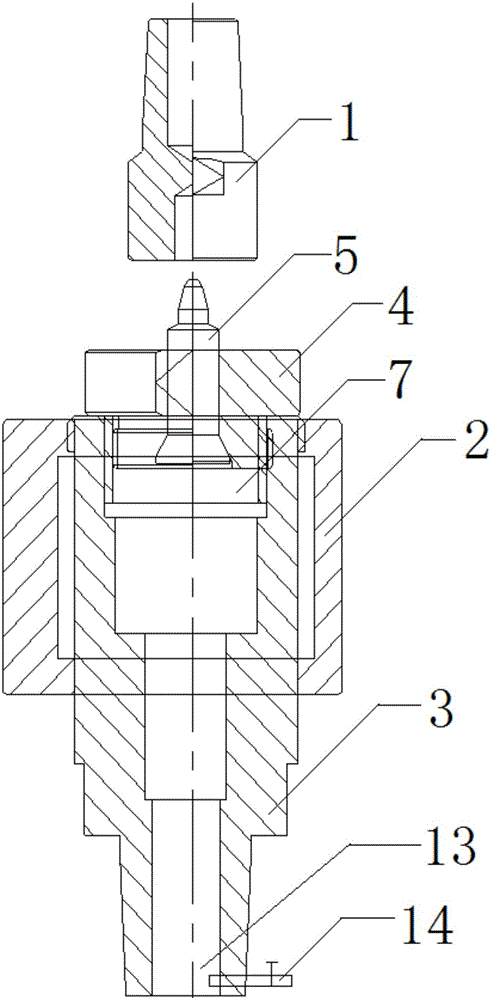

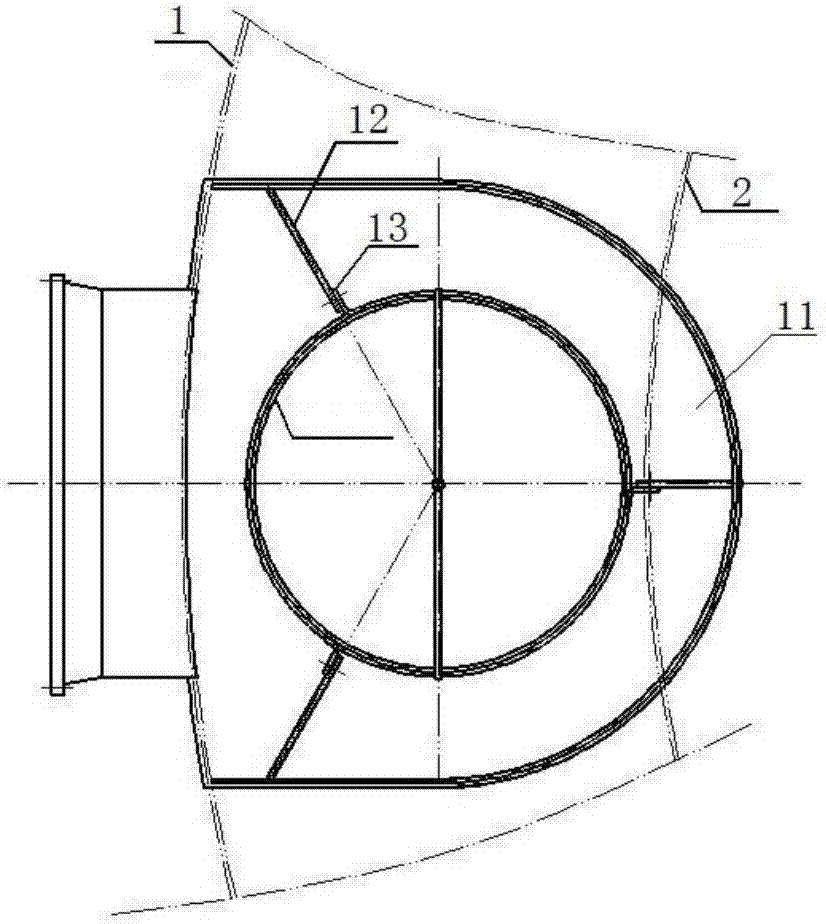

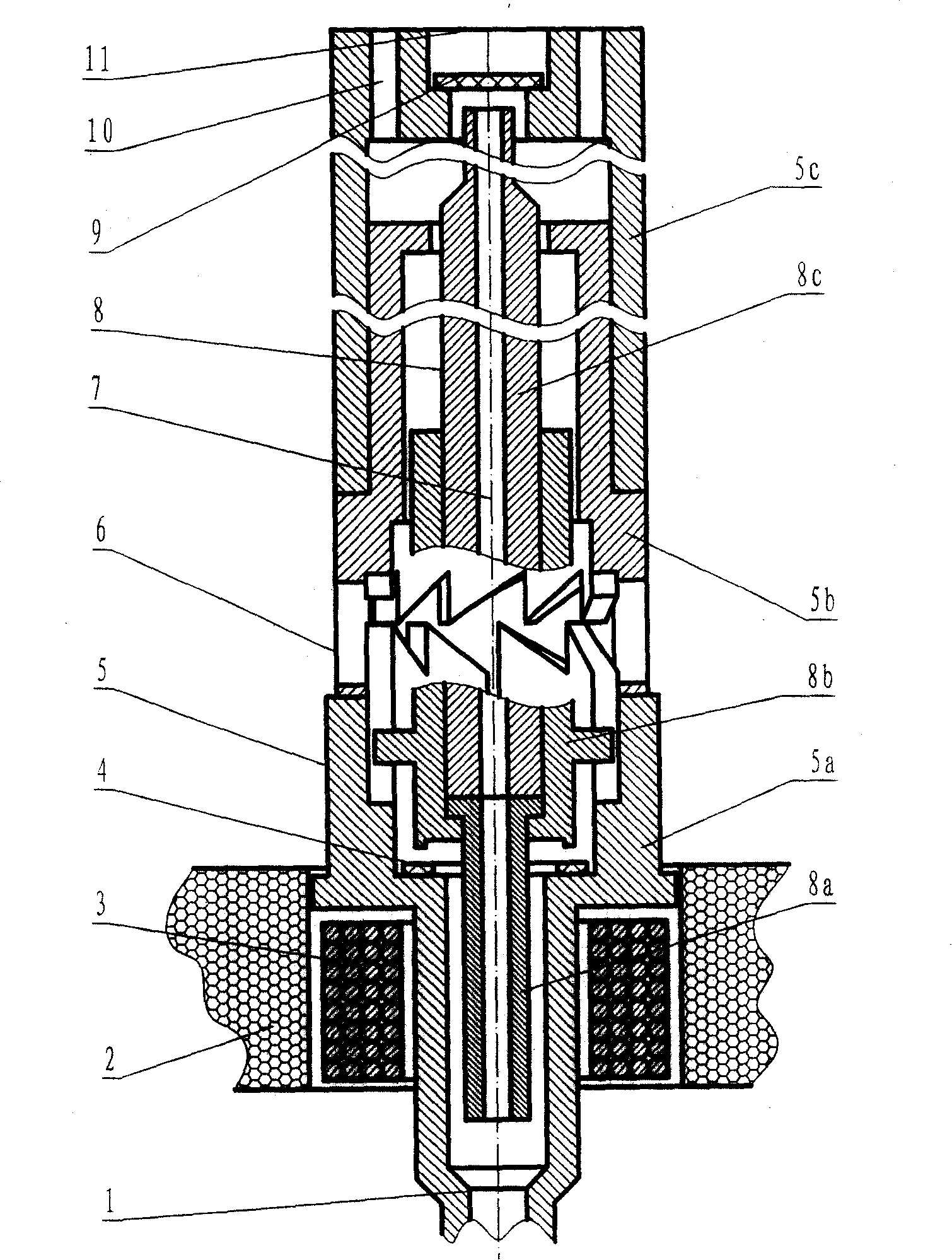

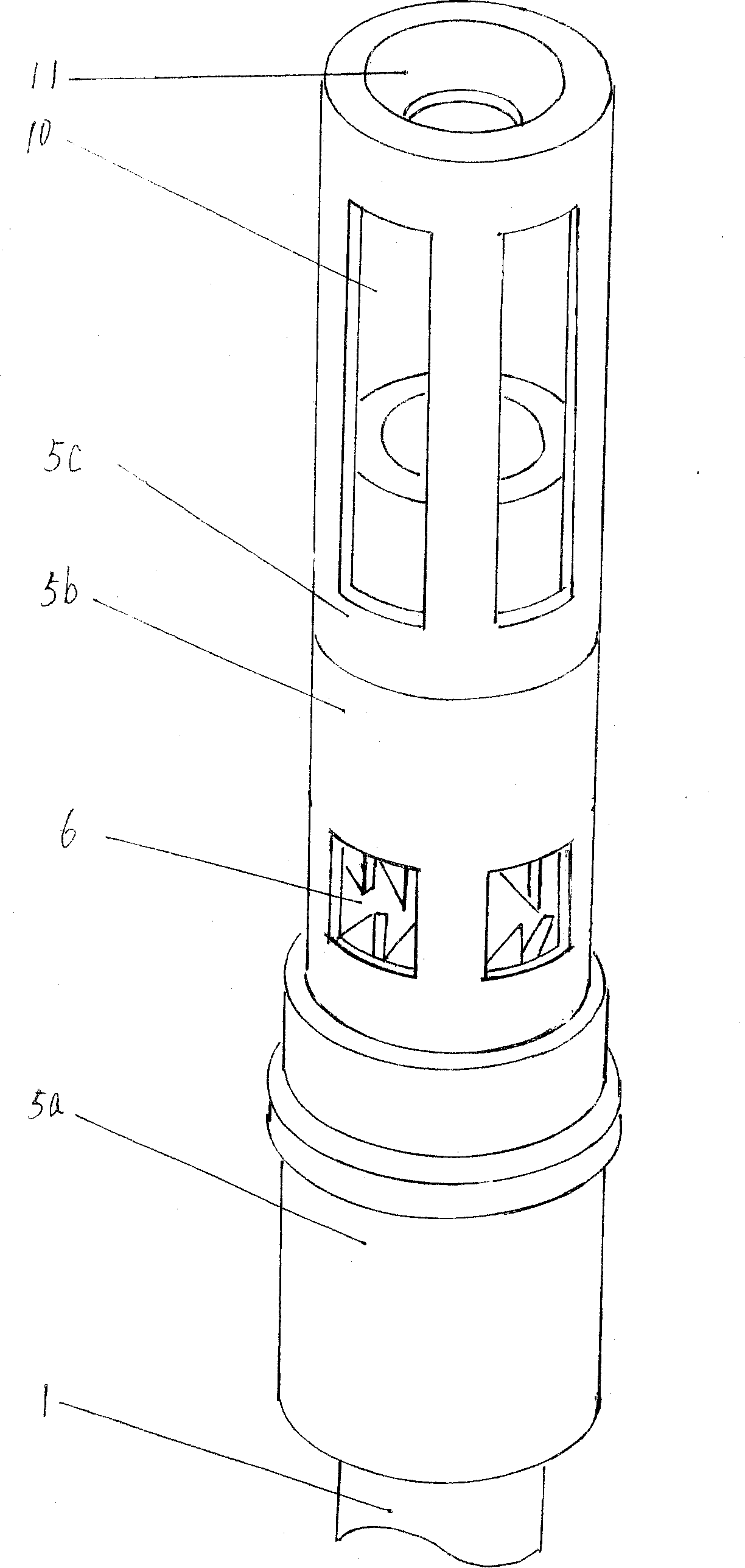

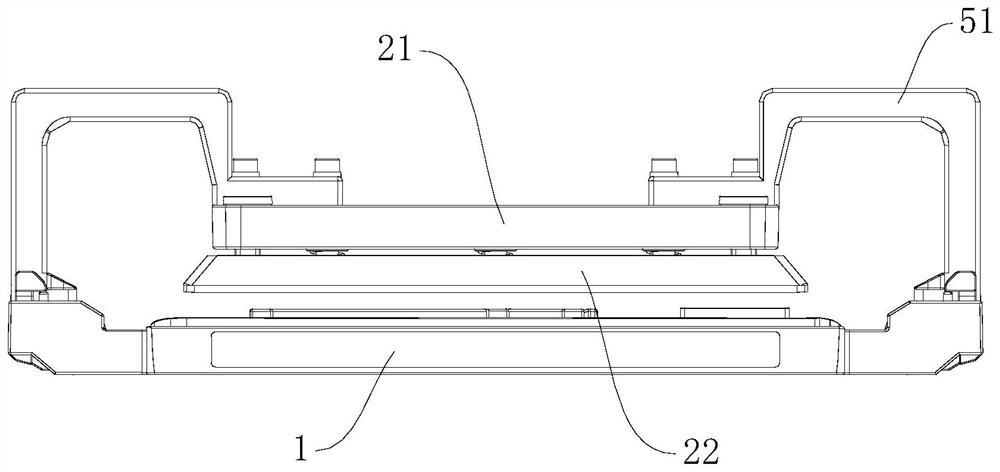

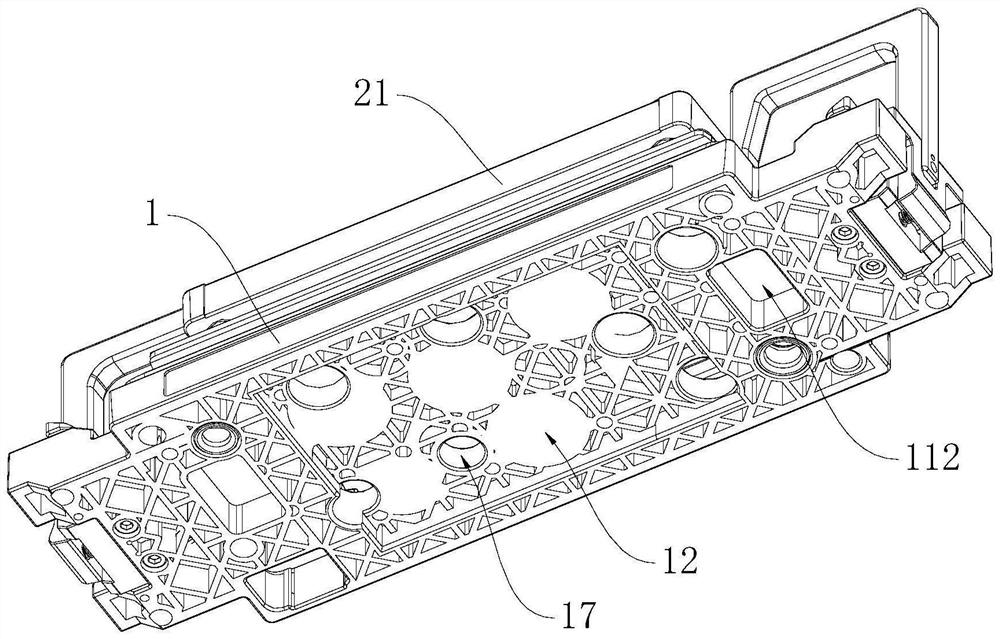

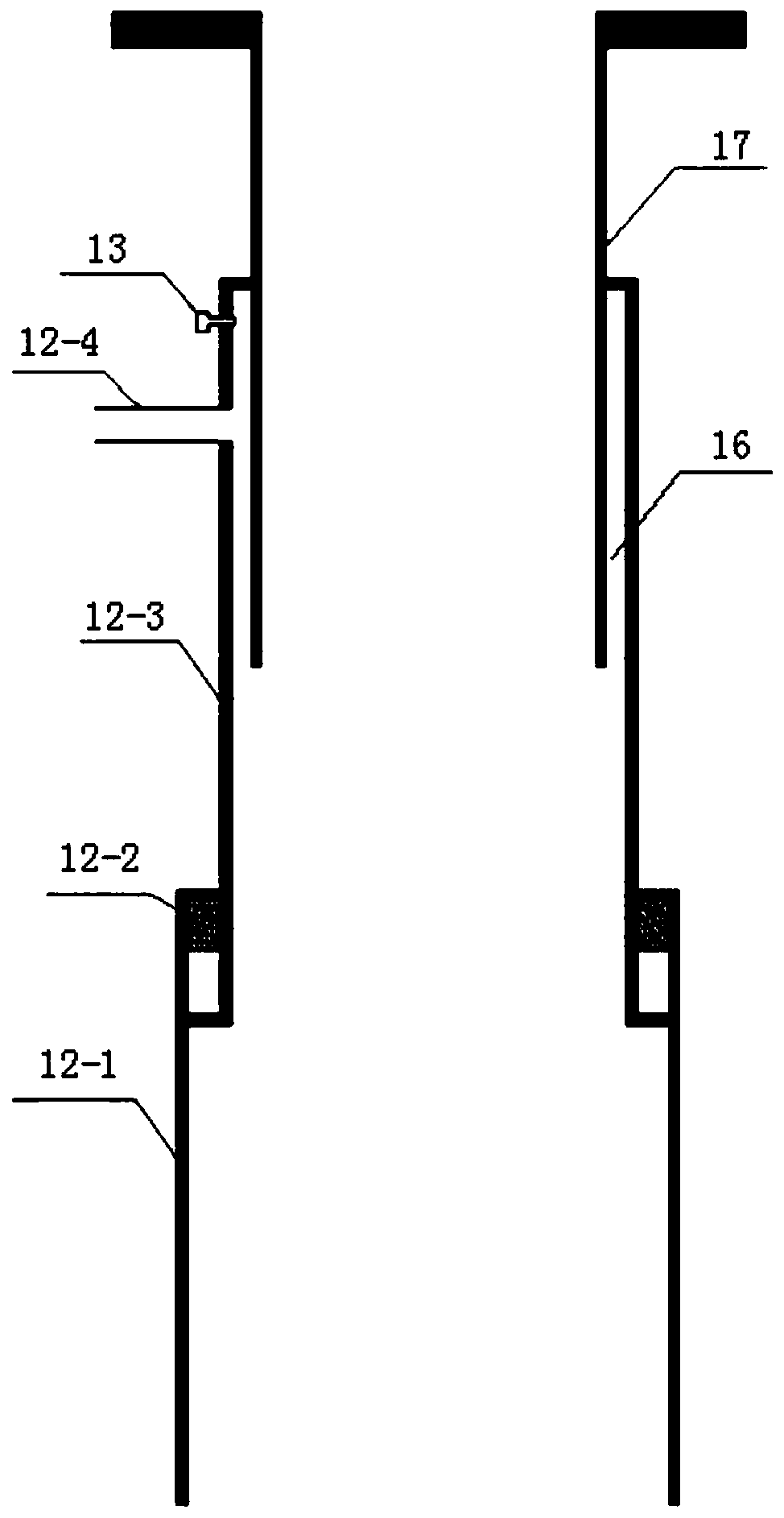

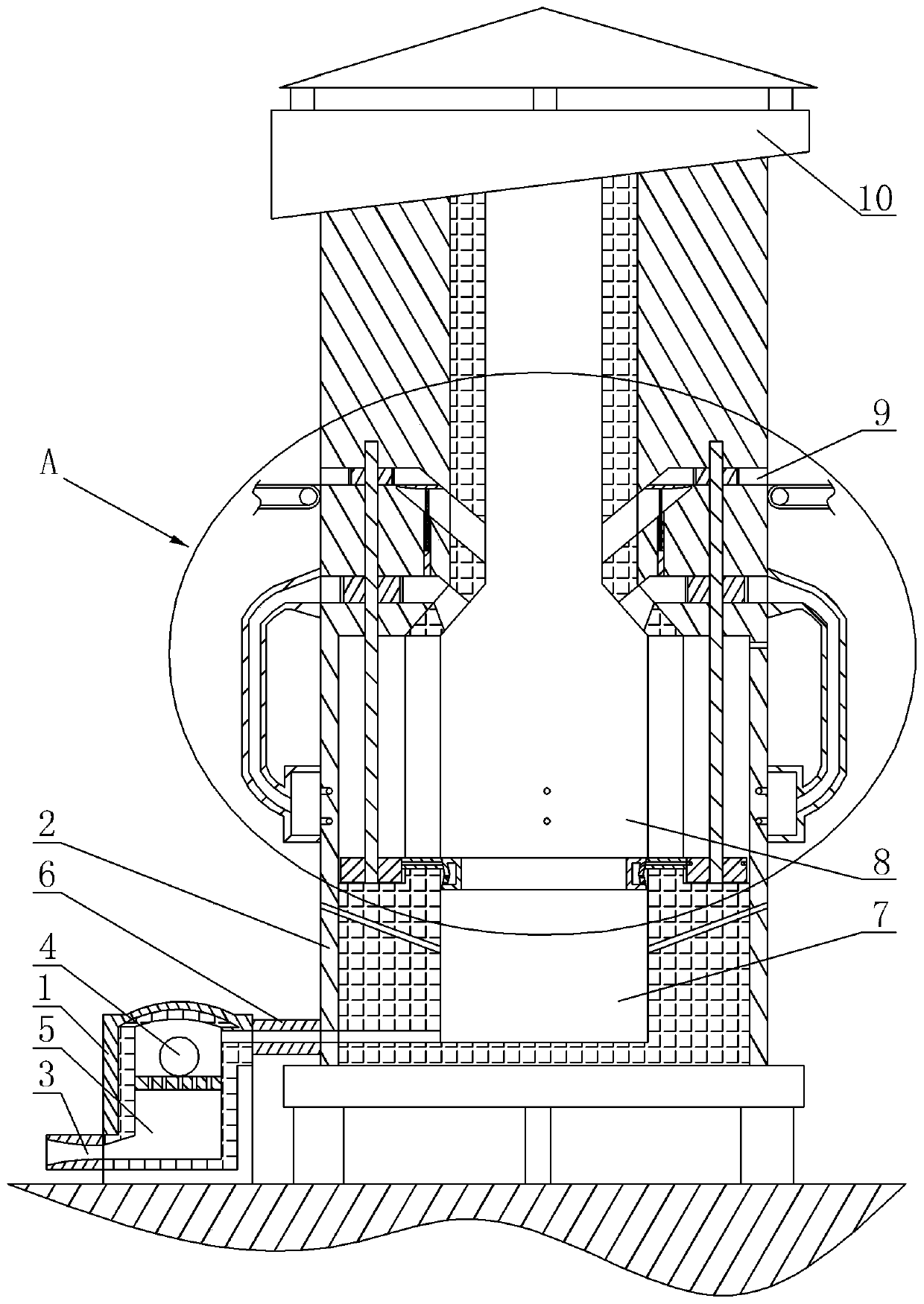

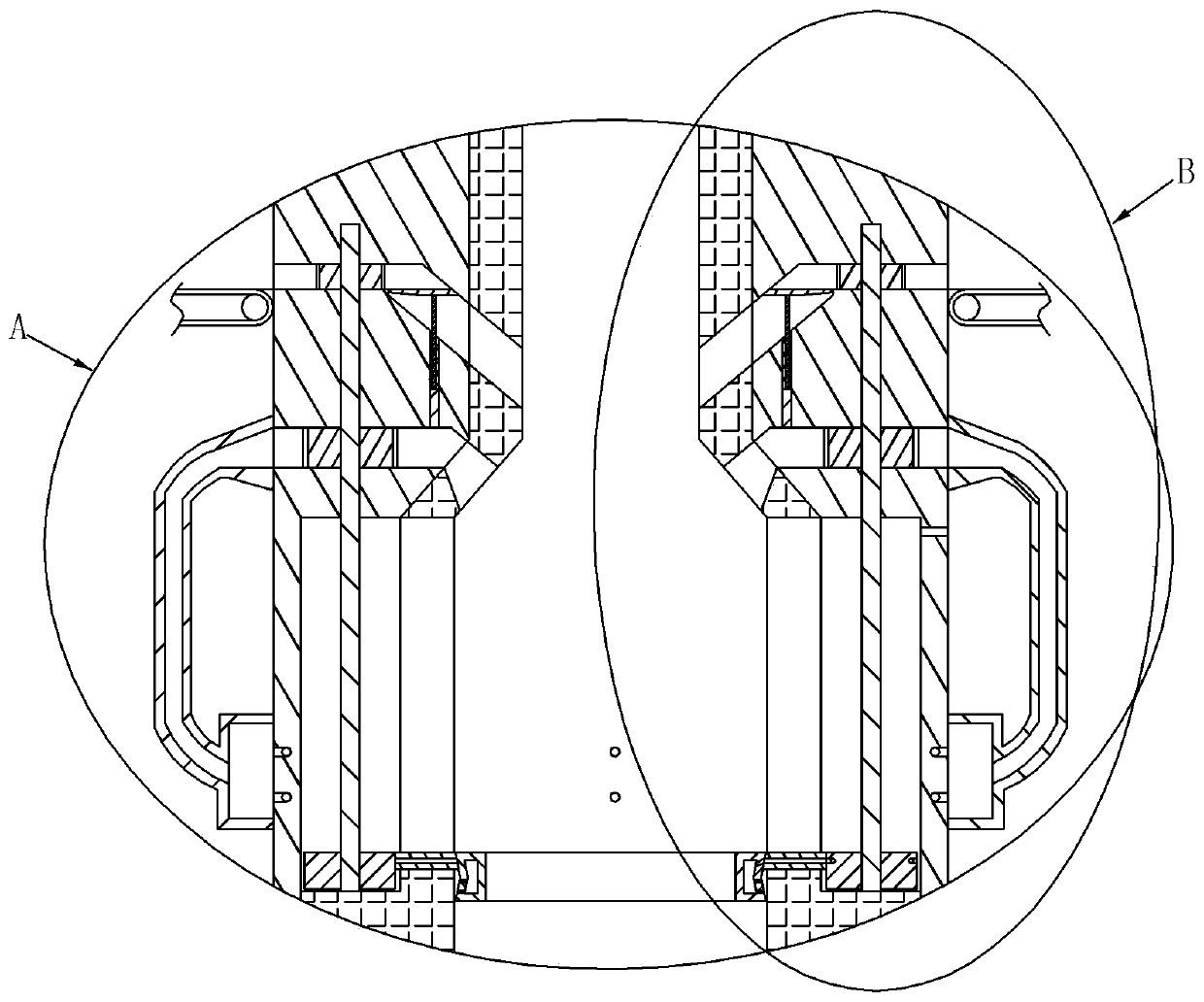

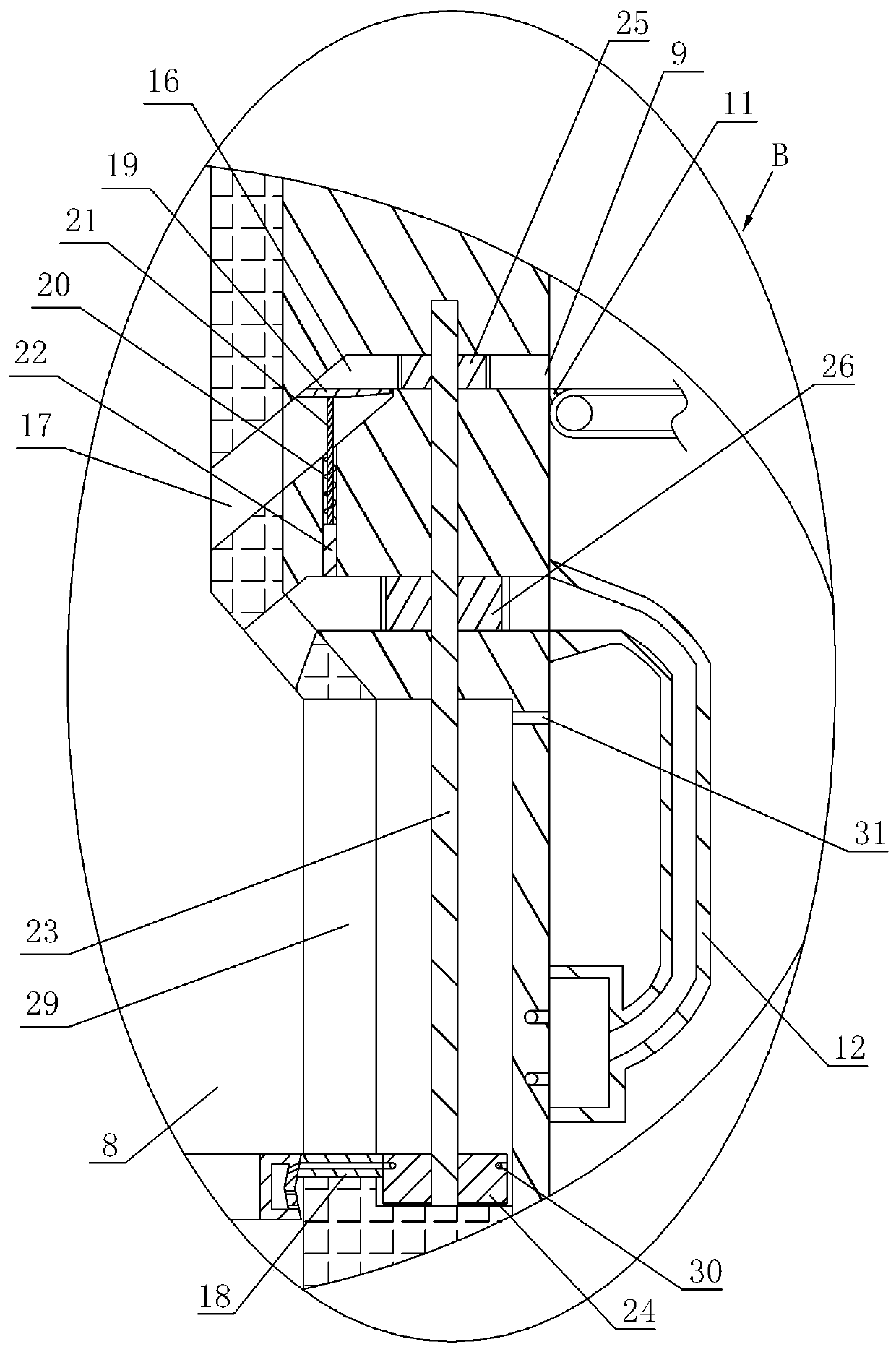

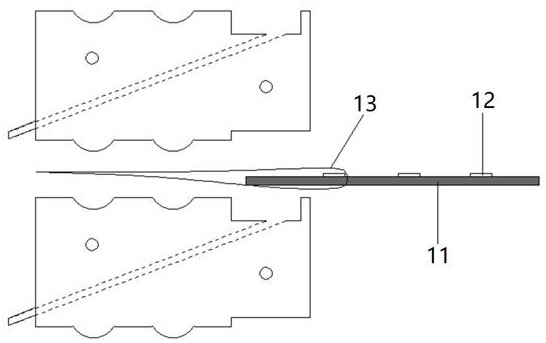

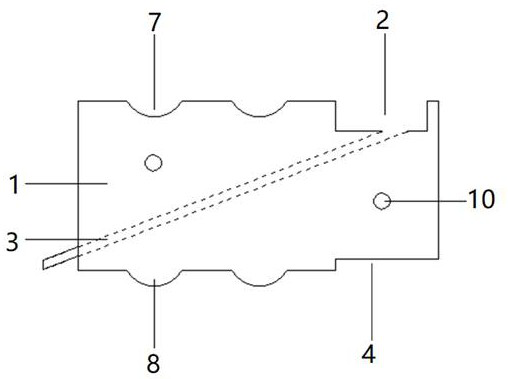

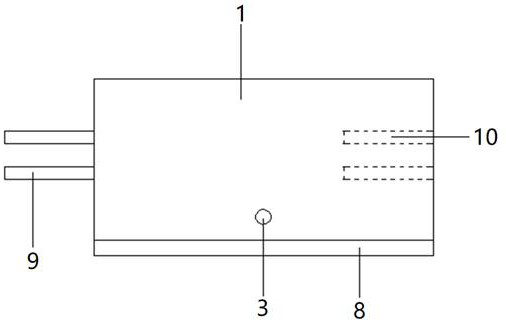

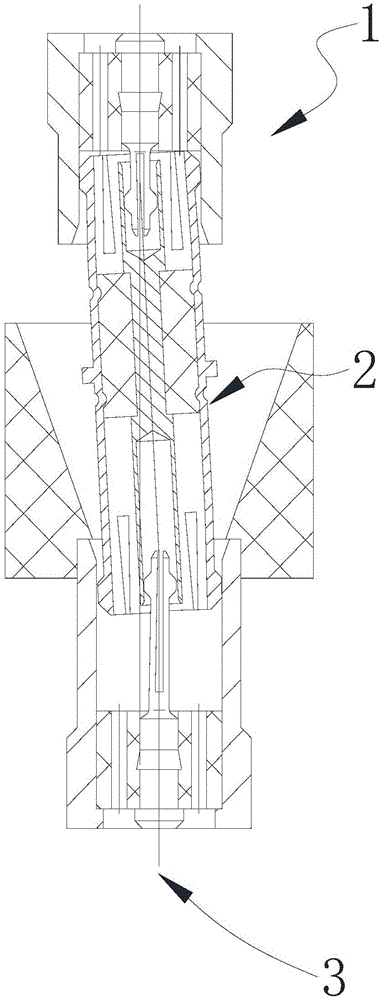

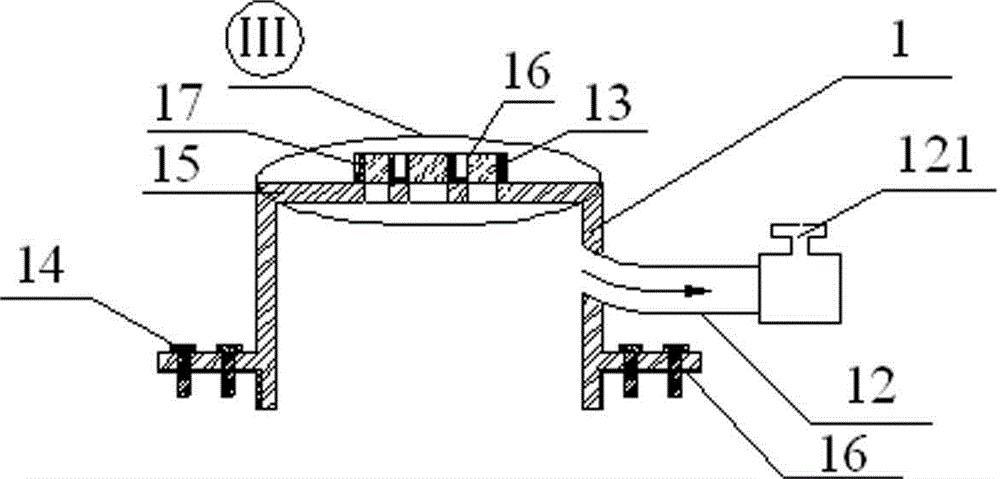

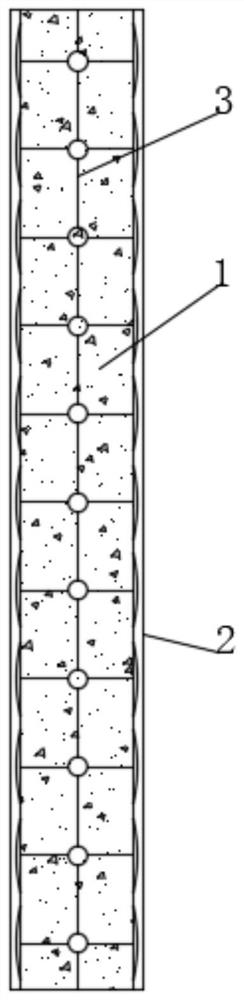

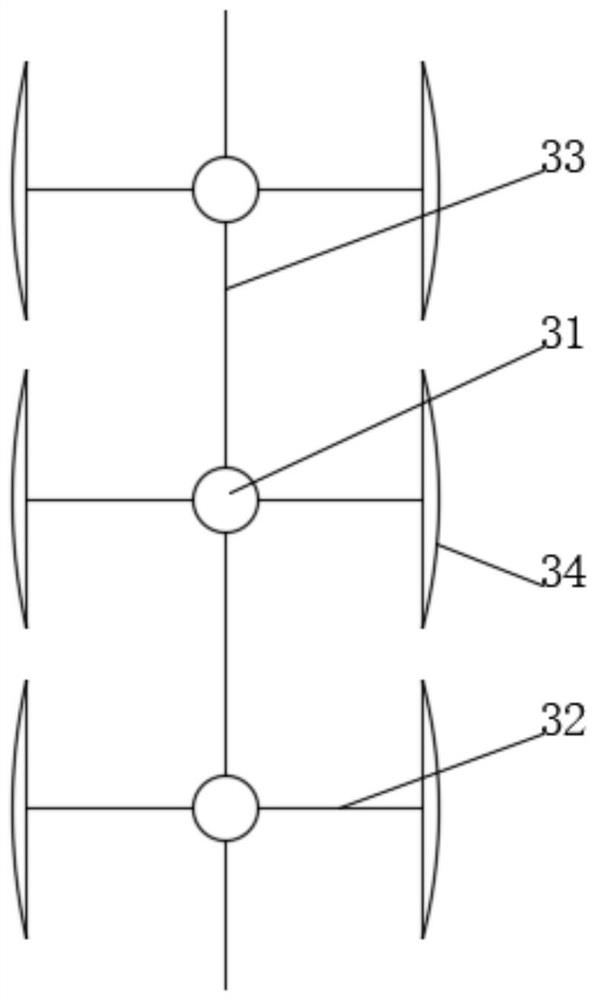

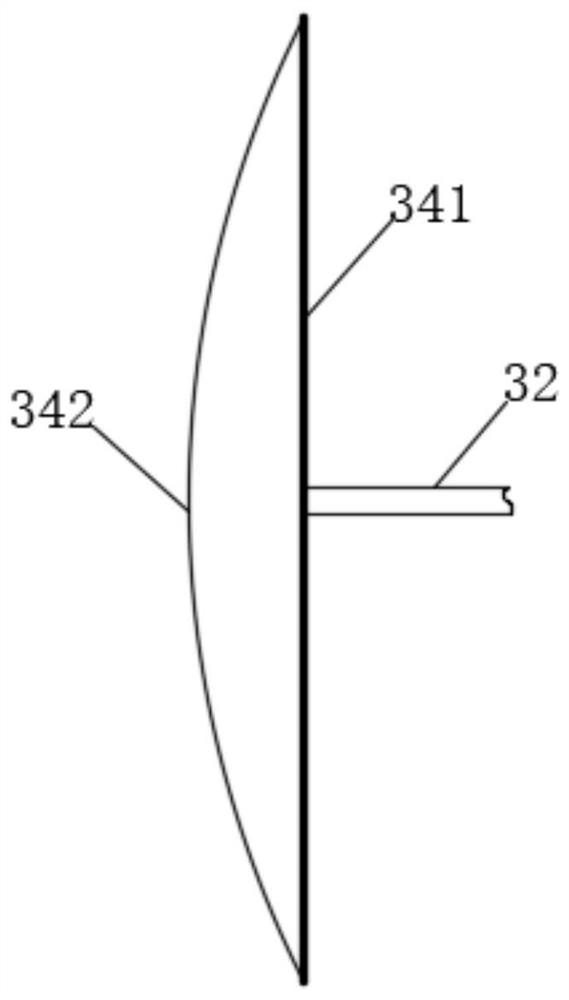

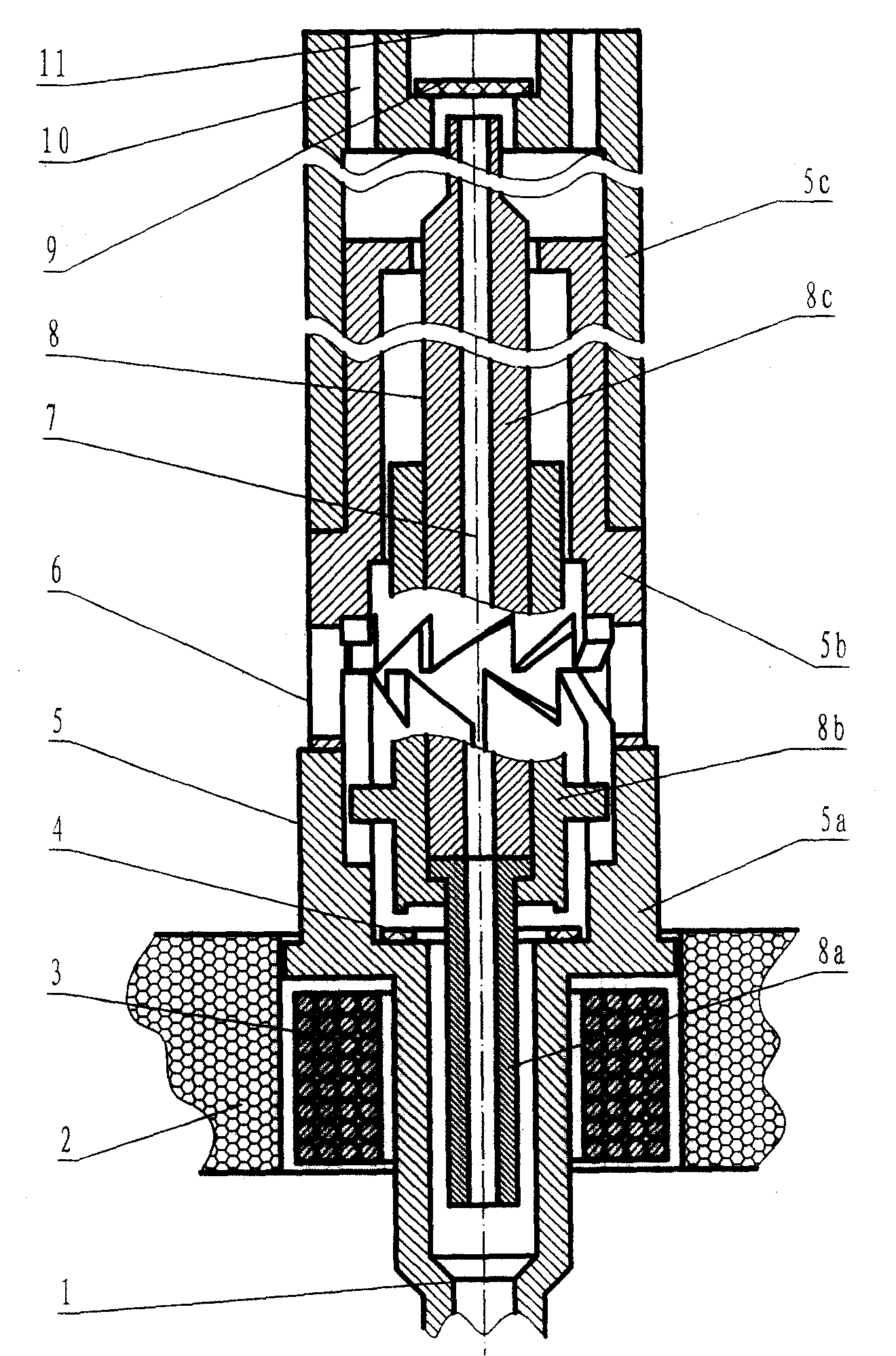

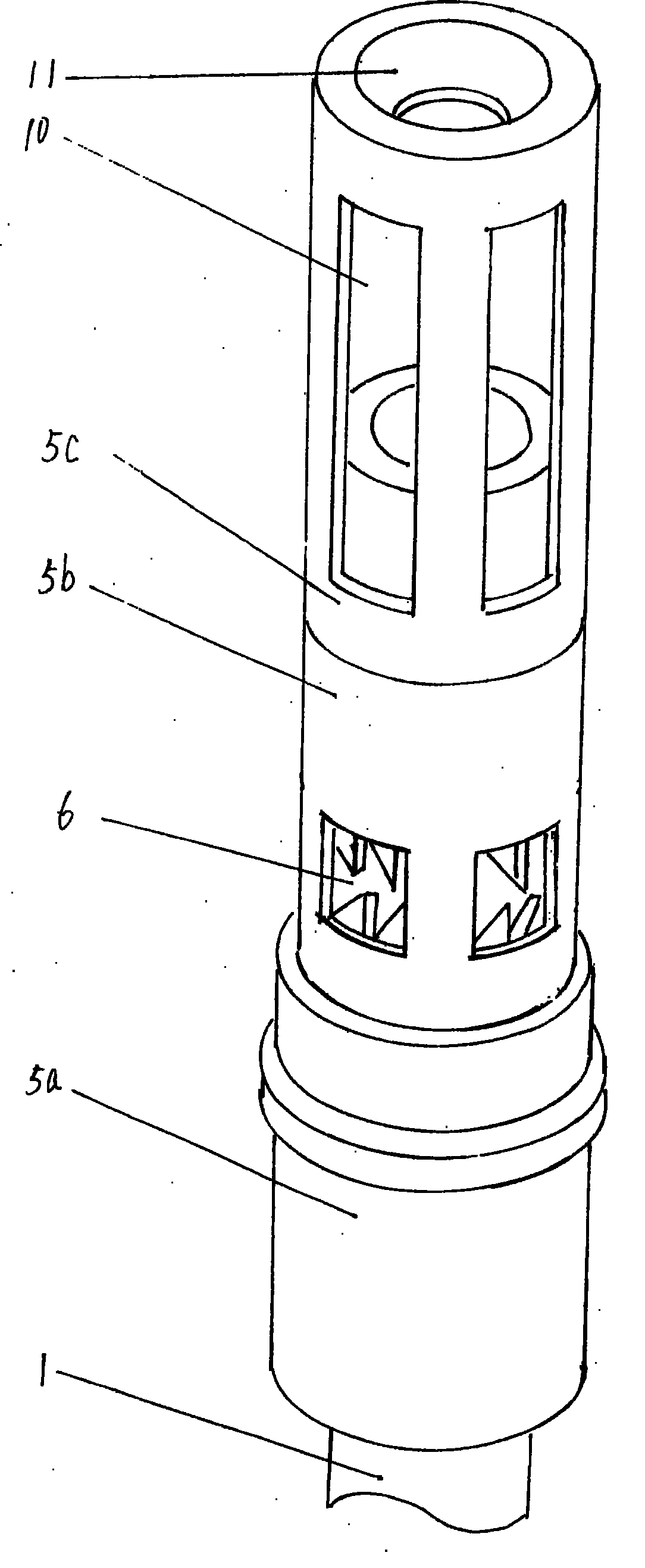

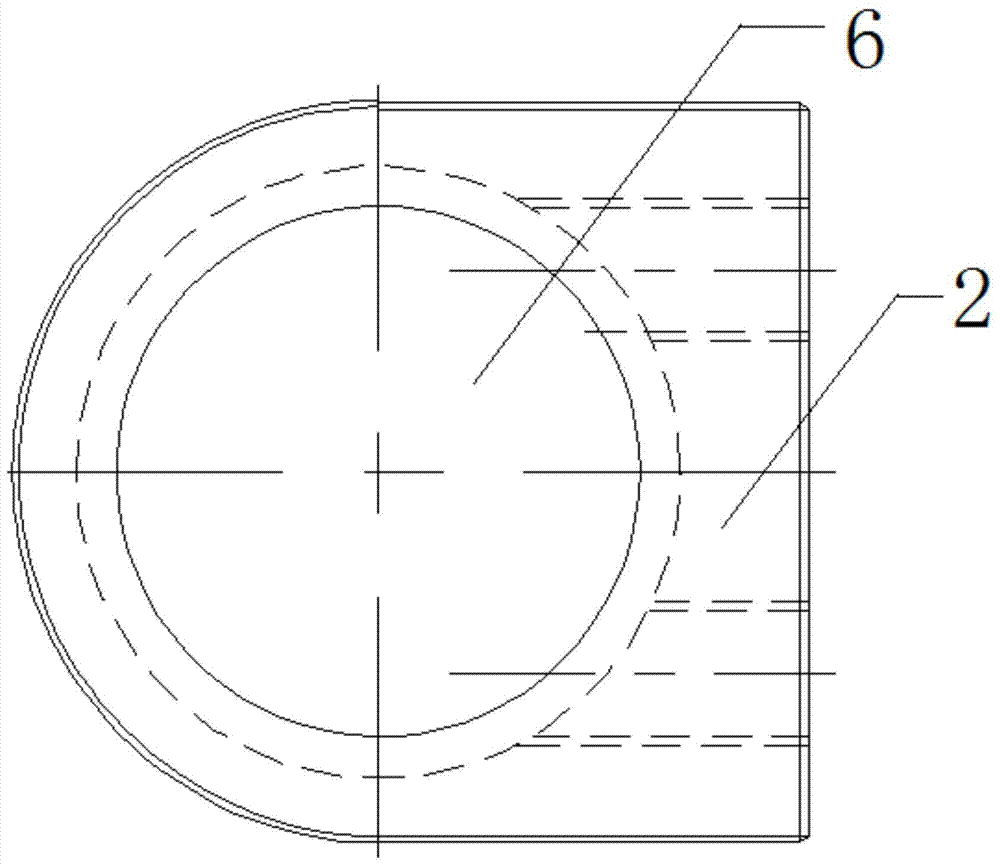

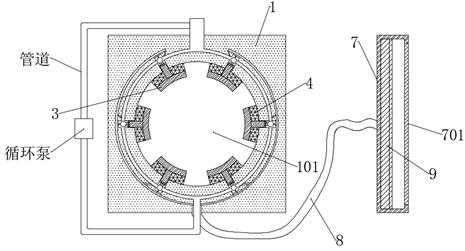

The invention provides a pump-driven two-phase fluid loop evaporator. The pump-driven two-phase fluid loop evaporator comprises an evaporator shell 1, a hydrophobic capillary core 2, axial liquid channels 3 and an axial steam main channel 4; the hydrophobic capillary core 2 is mounted inside the evaporator shell 1; the plurality of axial liquid channels 3 are arranged between the evaporator shell1 and the hydrophobic capillary core 2; and the axial steam main channel 4 is arranged inside the hydrophobic capillary core 2. For a two-phase fluid loop driven by a capillary pump, a hydrophobic porous material is used for covering the surface of the open type tiny channel of the evaporator, so that liquid cannot occupy the space of the steam main channel due to condensation under the influenceof various orientations or gravity, meanwhile, steam bubbles possibly existing in the liquid channels can smoothly overflow out of the channels, smooth starting of the evaporator is facilitated, the superheat degree during starting is reduced, and the heat exchange coefficient in the evaporation process is increased.

Owner:SHANGHAI SATELLITE ENG INST

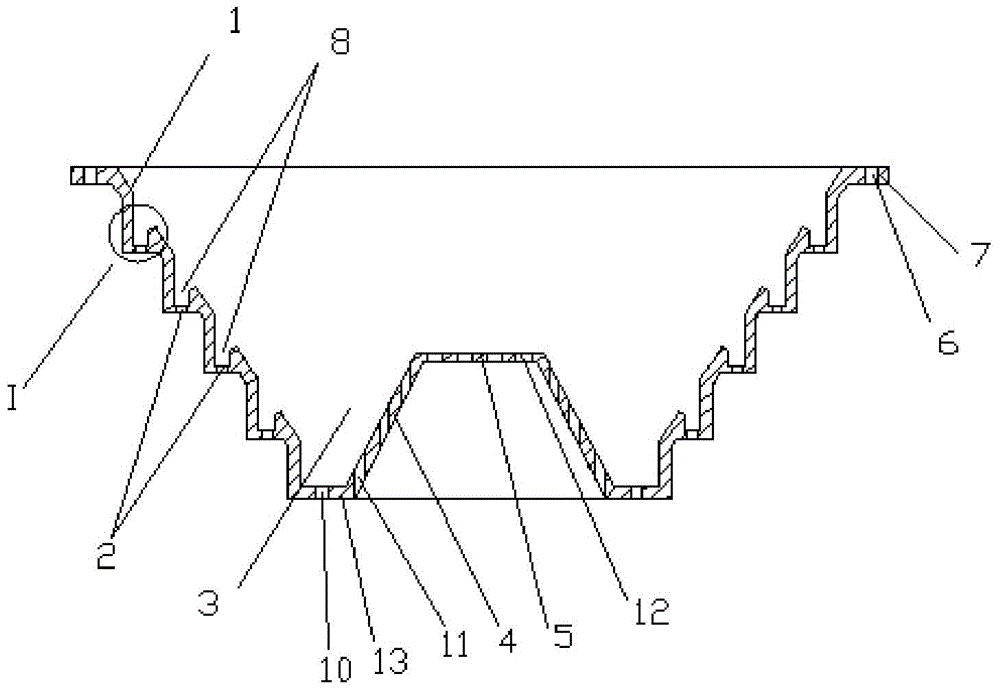

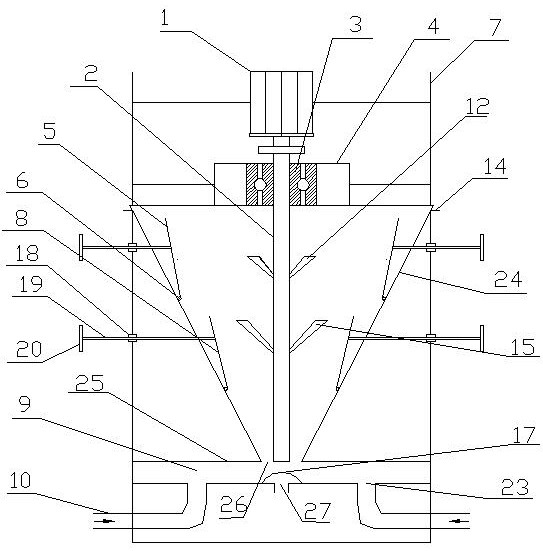

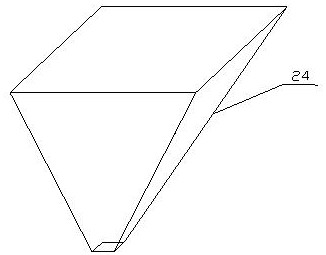

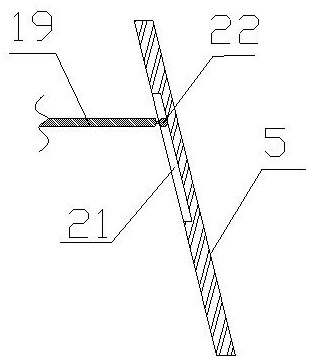

Liquid trap of rectification tower

InactiveCN105617705AGuaranteed uniformityImprove efficiencyFractional distillationTrappingEngineering

The invention provides a liquid trap of a rectification tower. The liquid trap comprises an outer annular wall and an inner annular wall, wherein a base plate is horizontally connected between the bottom of the inner annular wall and the bottom of the outer annular wall; the top of the inner annular wall is horizontally provided with a top plate; the outer annular wall, the base plate and the inner annular wall form a second liquid trapping groove; the outer annular wall, the inner annular wall, the base plate and the top plate form a liquid trapping cavity; the inner side of the outer annular wall is provided with a plurality of annular first liquid trapping grooves from top to bottom; the plurality of first liquid trapping grooves are respectively horizontally formed and are distributed in the outer annular wall in a stepped mode; the groove bottoms of the first liquid trapping grooves are horizontally formed; the groove openings of the first liquid trapping grooves are vertically upward; the bottom of each first liquid trapping groove is vertically provided with a plurality of first holes; the base plate is vertically provided with a plurality of second holes, and the second holes are uniformly formed; the inner annular wall is provided with a plurality of third holes which are used for communicating the liquid trapping cavity and the exterior; and the top plate is vertically provided with a plurality of fourth holes.

Owner:TIANJIN HEAD HAOTIAN TECH DEV CO LTD

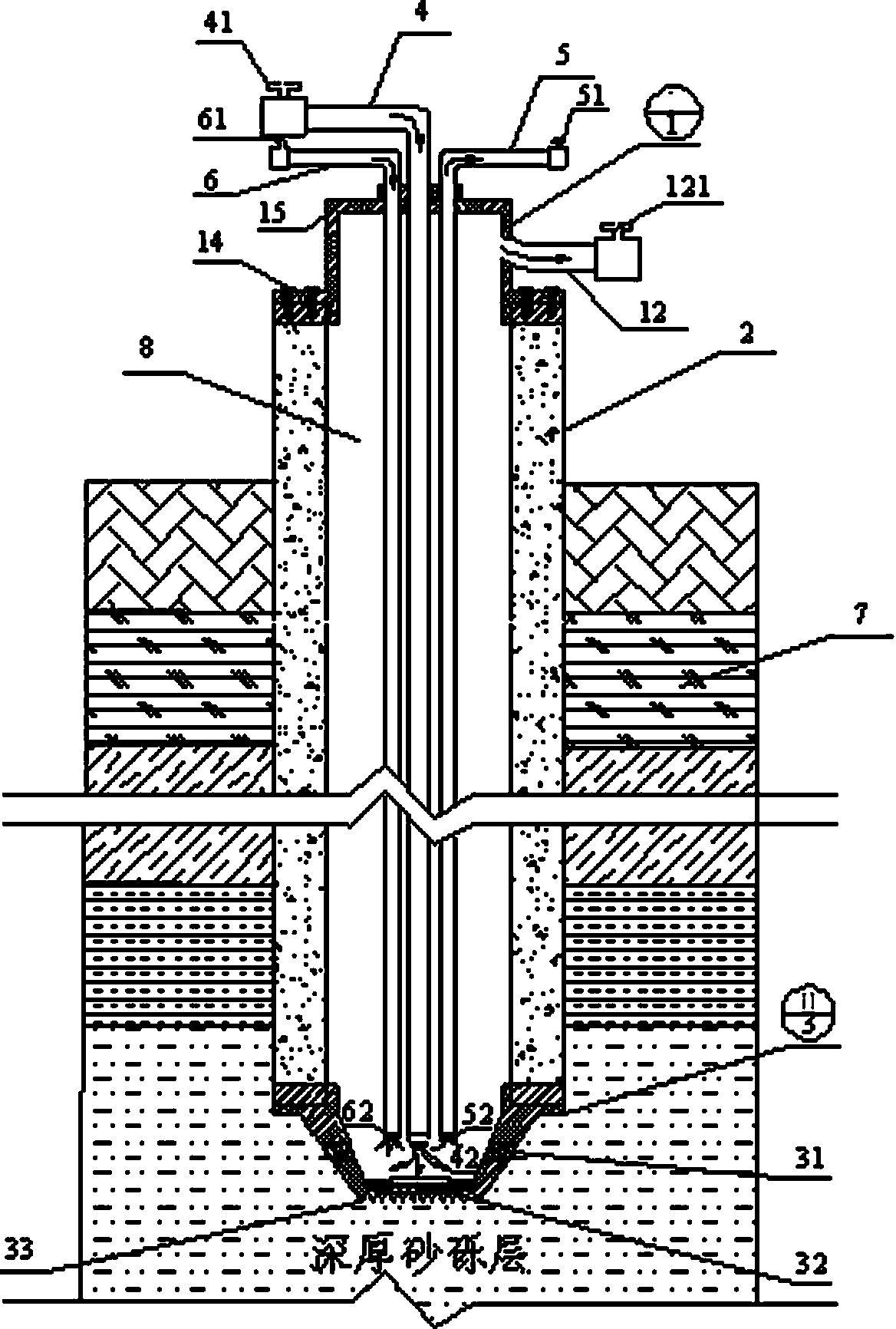

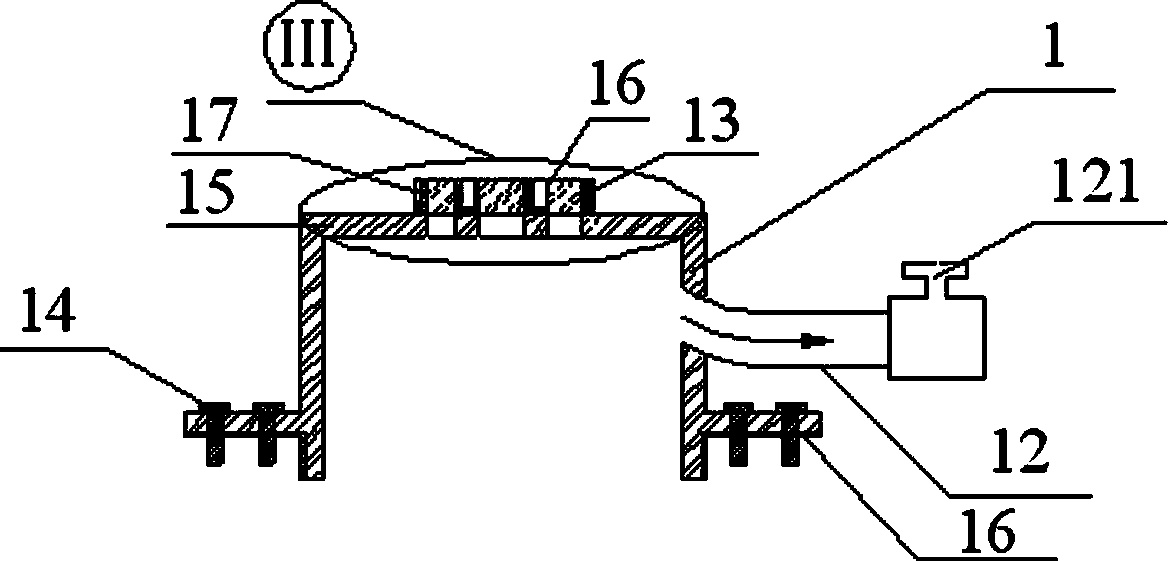

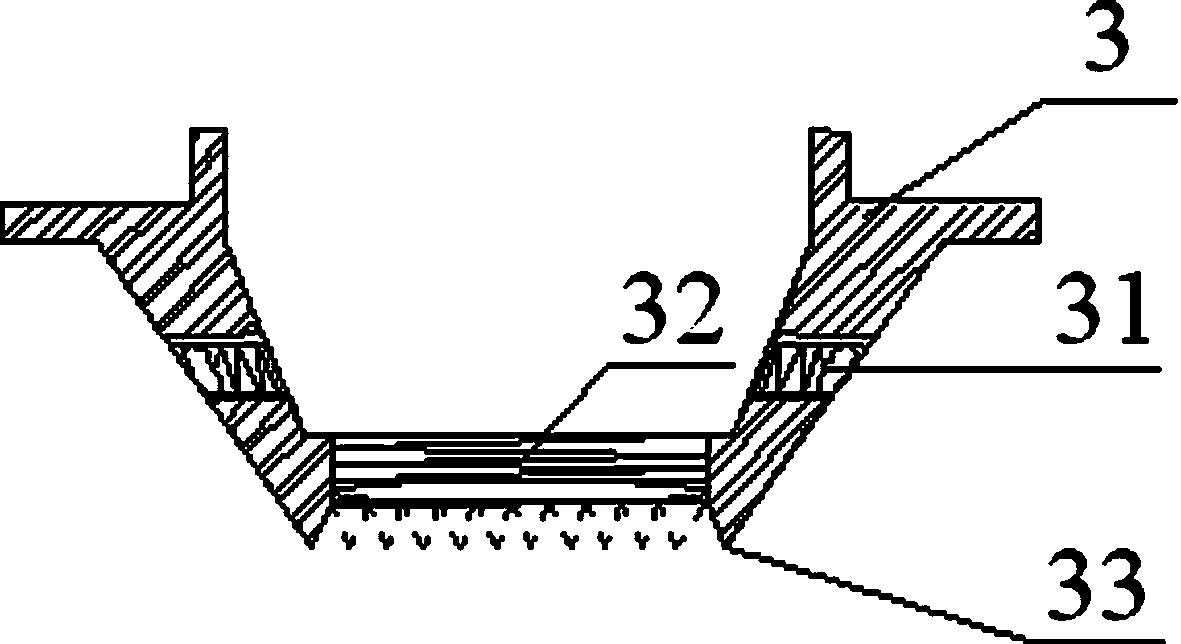

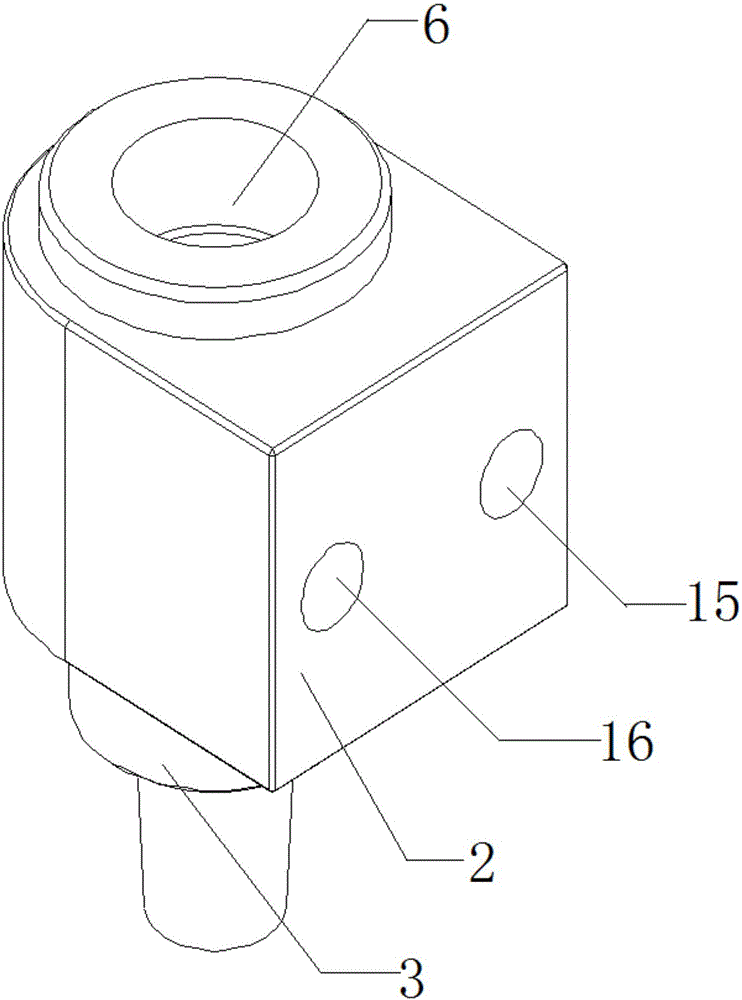

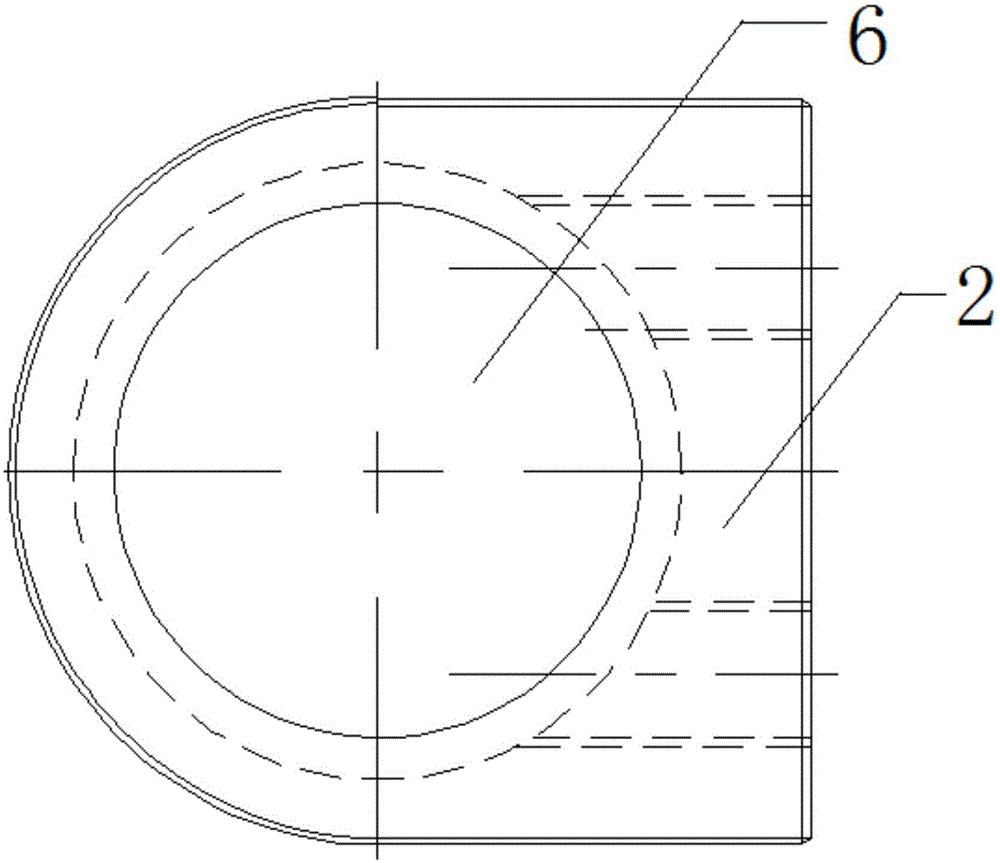

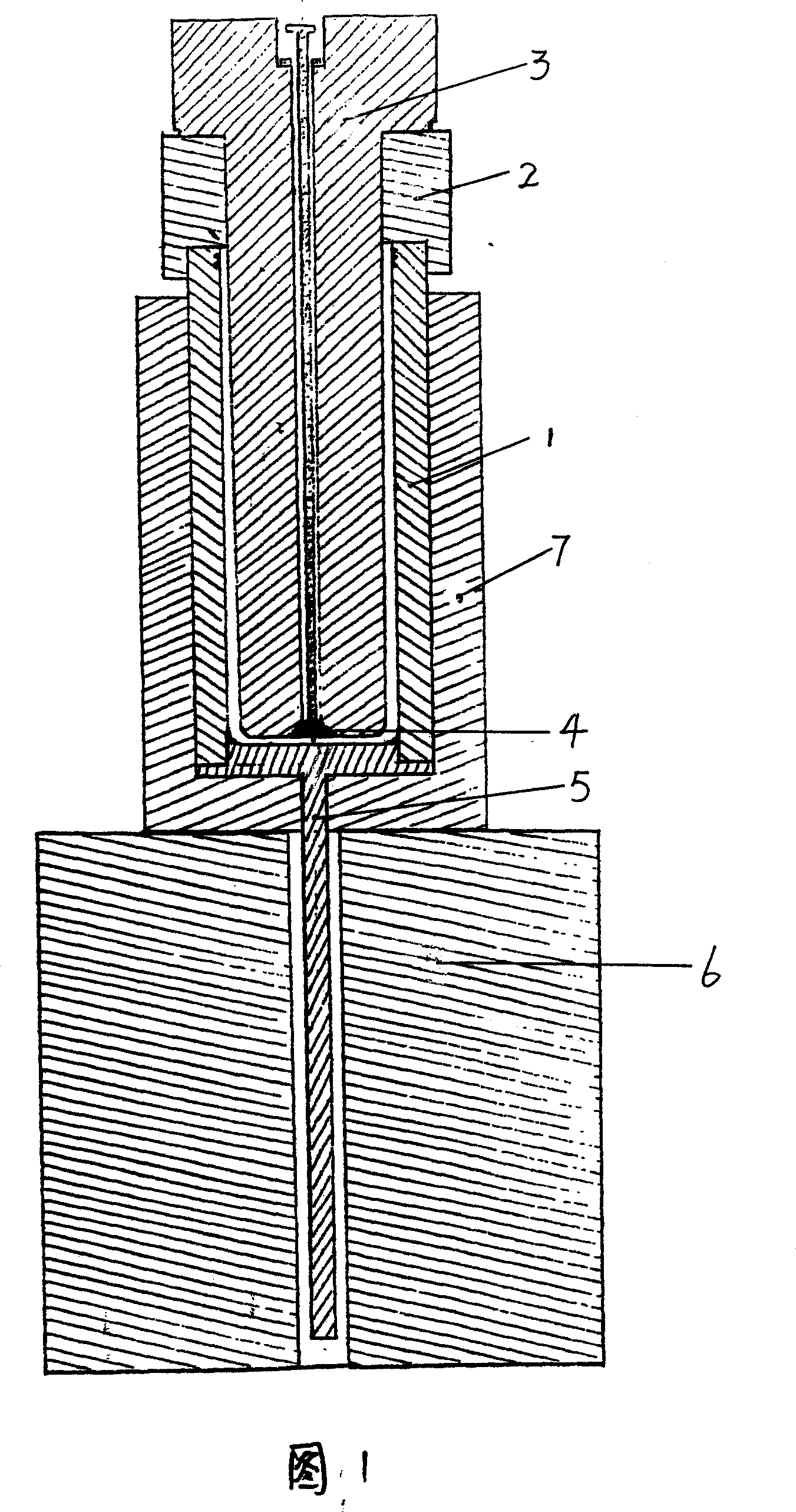

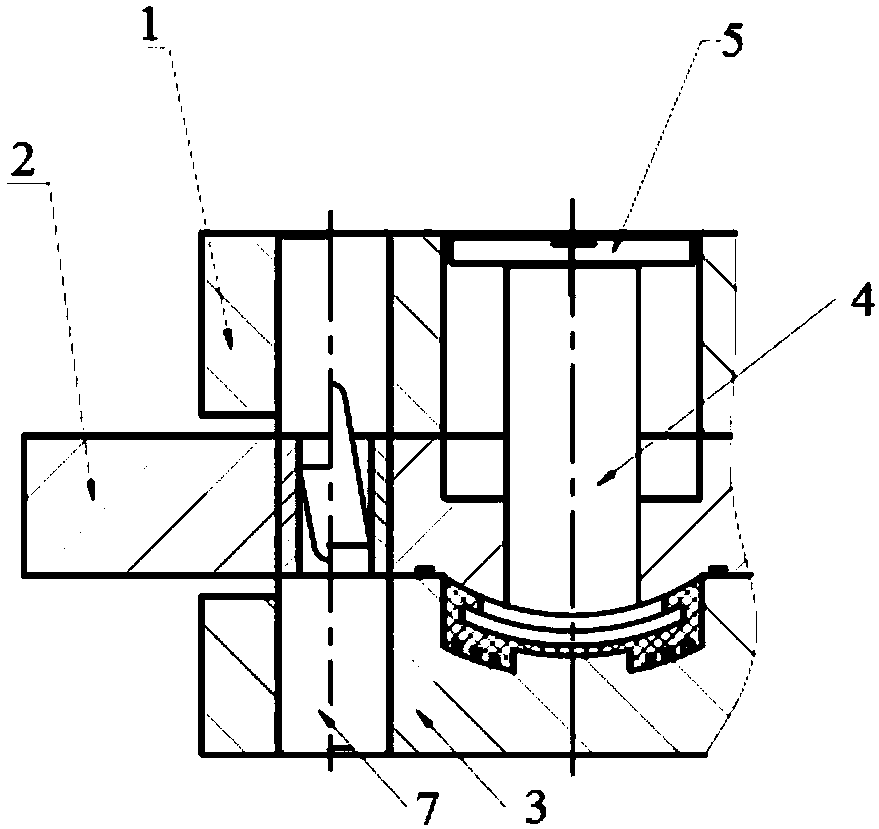

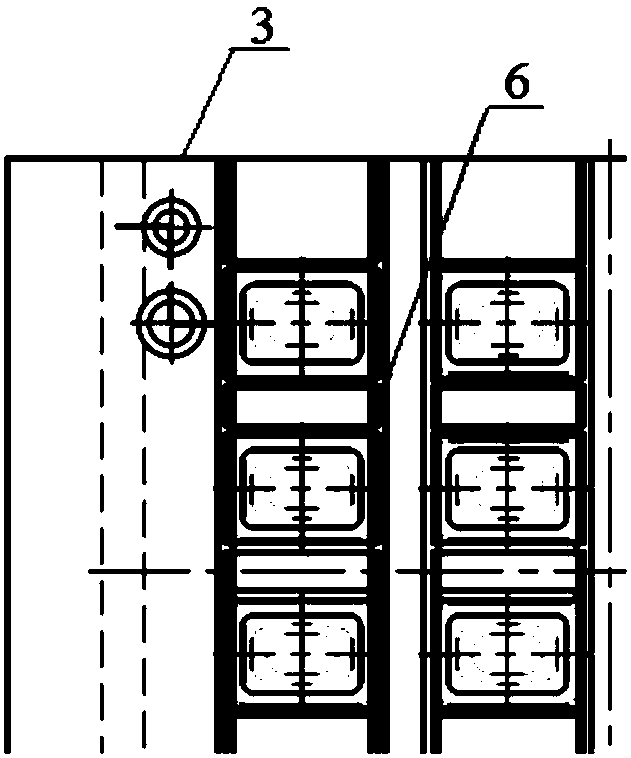

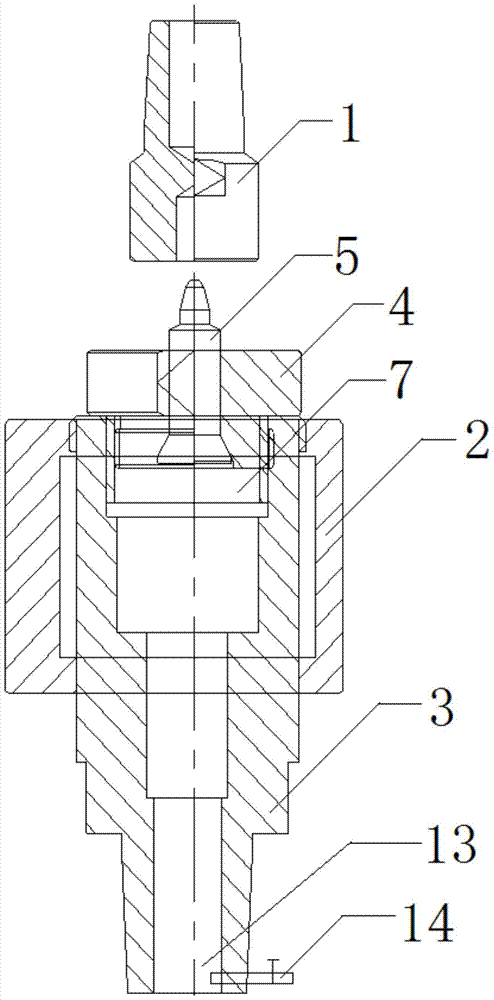

PHC tubular pile pile-sinking device used for penetrating deep and dense sand (gravel) layer

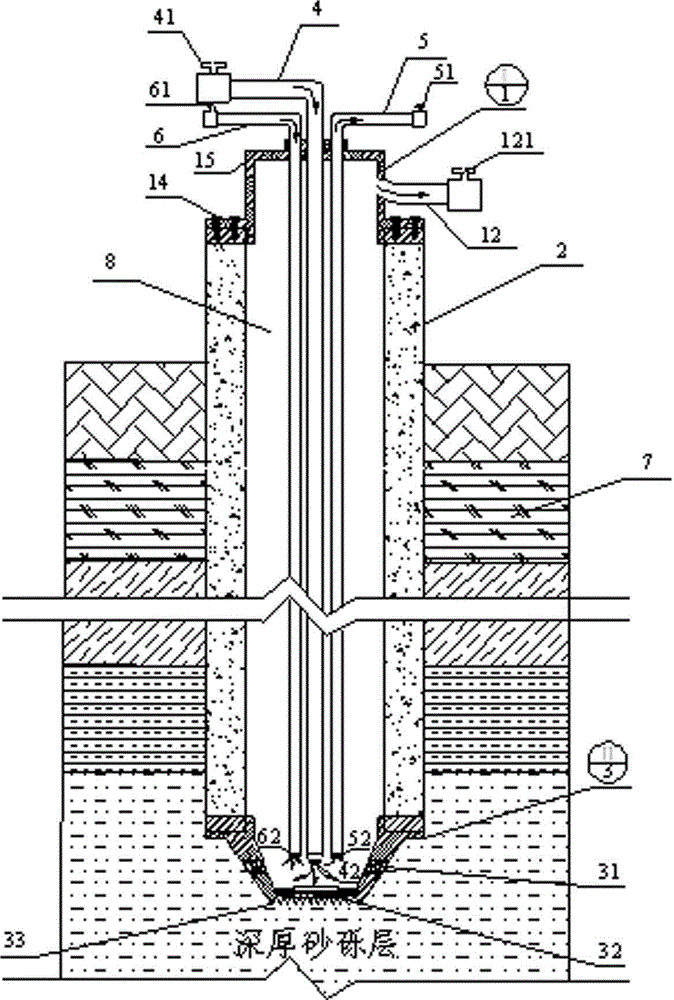

A PHC tubular pile pile-sinking device used for penetrating a deep and dense sand (gravel) layer comprises a PHC tubular pile (2), wherein both the upper part and the lower part of the PHC tubular pile (2) are provided with a pile cap (1) and a pile shoe (3) respectively in a connecting manner; a slurry inlet pipe (4), an air inlet pipe (6) and an air exhaust pipe (5) penetrate holes in the pile caps (1) to be mounted in inner holes of the PHC tubular pile (2). The PHC tubular pile pile-sinking device used for penetrating the deep and dense sand (gravel) layer has the advantages of: 1, guaranteeing successful overflow of returned slurry, 2, preventing excessive washing, 3, controlling placement positions of the slurry inlet pipe, the air inlet pipe and the air exhaust pipe quantitatively and guaranteeing penetration effect and quality, 4, changing traditional water washing into slurry washing, ensuring phenomena of hole collapse and quicksand not to happen easily in the sand (gravel) layer washing process as the slurry is made of traditional drilling slurry, cement of about 5%-10% and a retarding agent of 0.2%, avoiding excessive washing, and guaranteeing side friction of the PHC tubular pile and quality of guided holes, and 5, achieving rational design, simple structure, installation and operation convenience, reliable sealing performance and good penetration effects, and being economic and practical.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

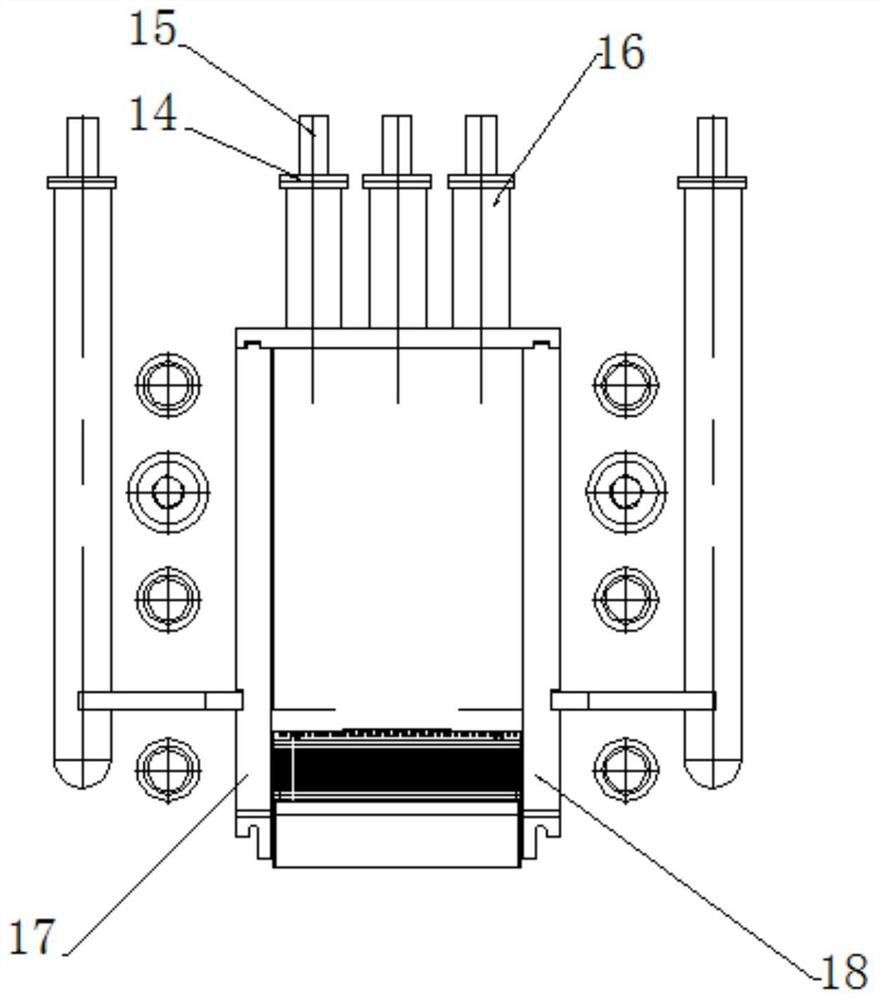

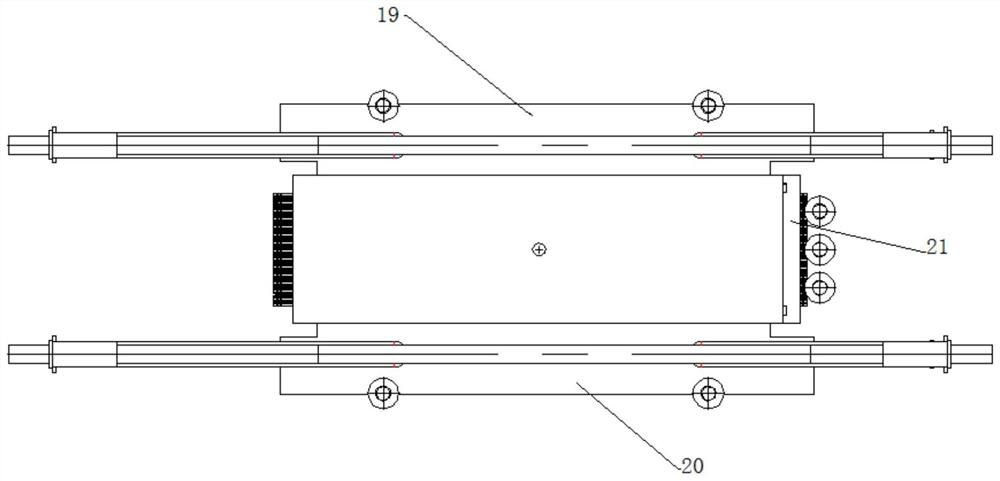

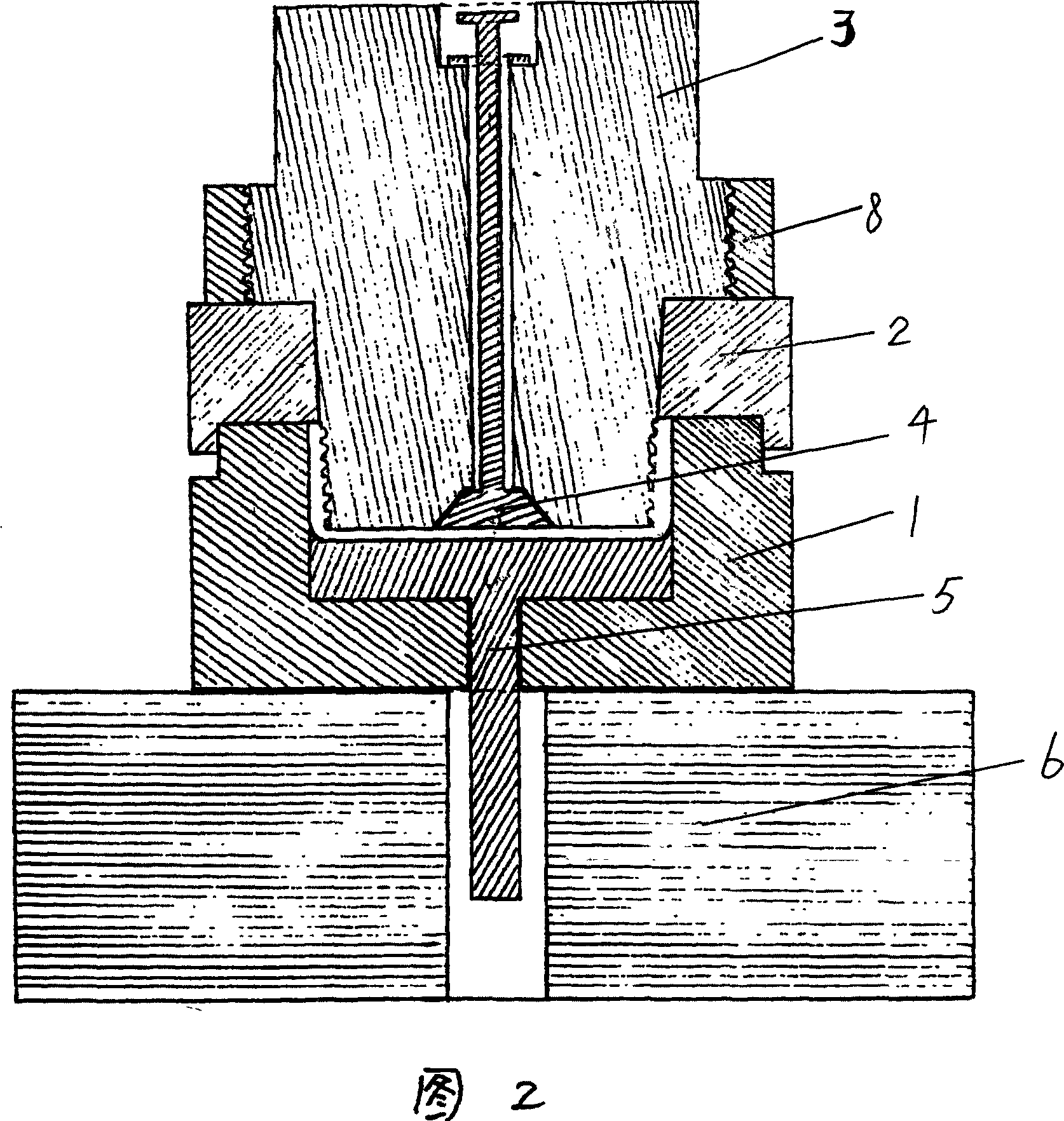

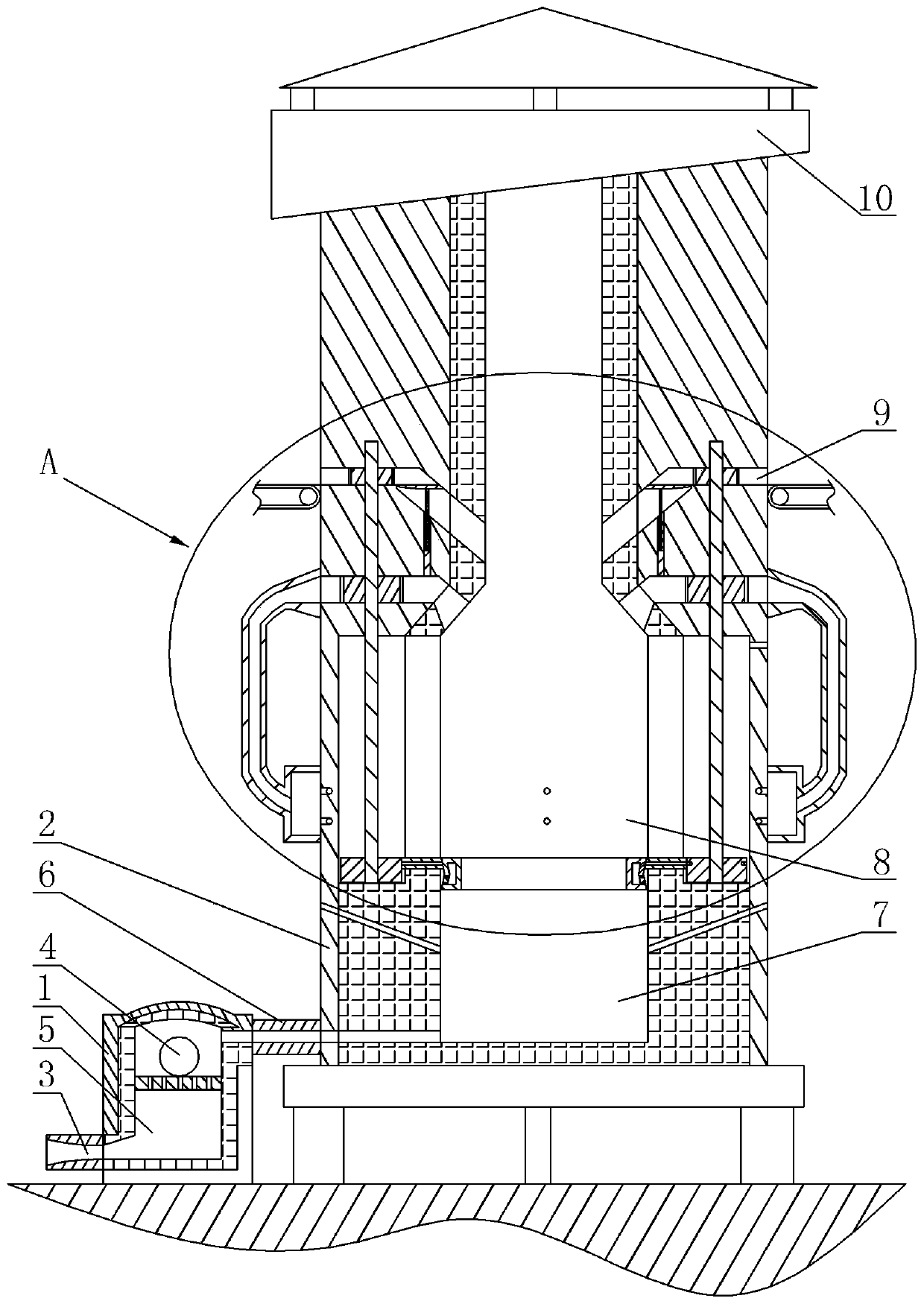

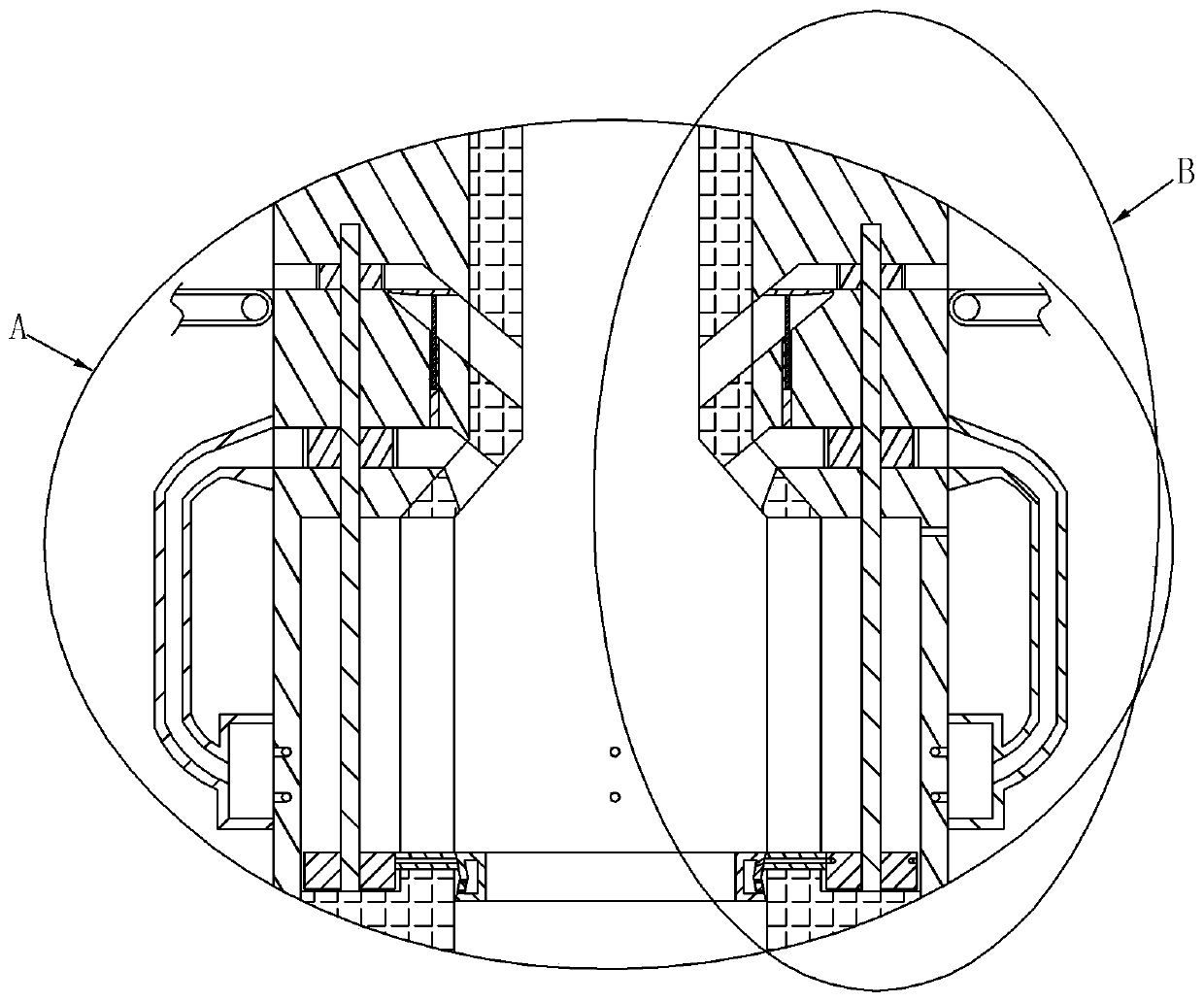

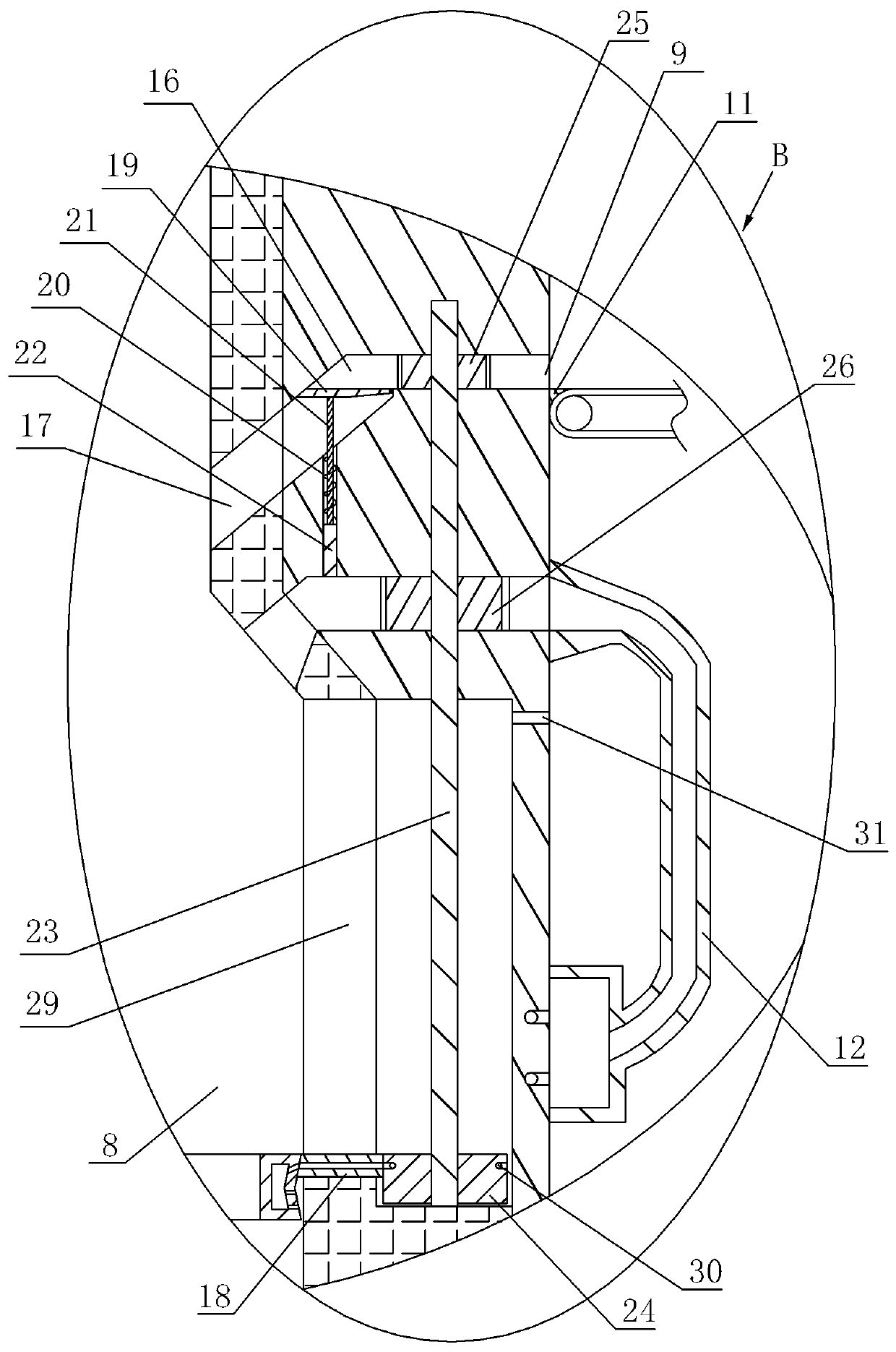

Electrode for projection welding of resistor

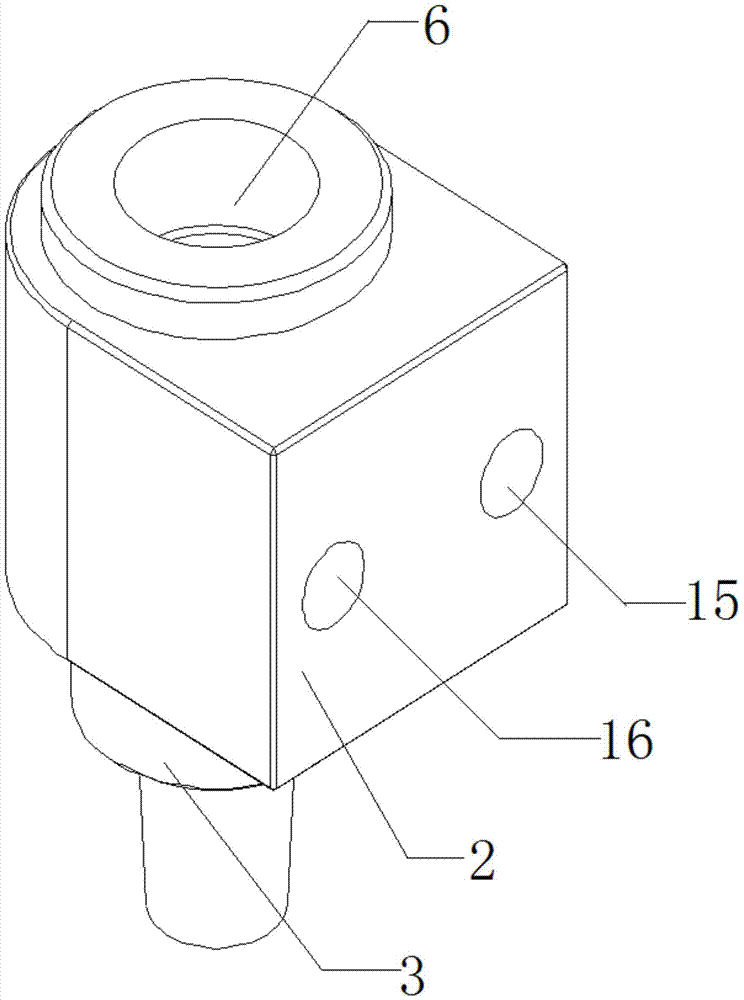

ActiveCN105057870AImprove cooling effectAvoid problems with poor coolingElectrode featuresCooling effectEngineering

The invention relates to an electrode for projection welding of a resistor. The electrode comprises an upper electrode assembly and a lower electrode assembly. The upper electrode assembly comprises an upper electrode body. The lower electrode assembly comprises a circulation water cooling block, an electrode holder, an electrode cover and a positioning pin. The circulation water cooling block is provided with a cooling hole, a connecting block is embedded in the cooling hole, and the top end of the electrode holder is embedded in one end of the cooling hole. The electrode cover comprises a cover body and a base, the base of the electrode cover is embedded in the other end of the cooling hole, and the top end of the electrode holder is connected with the base of the electrode cover through the connecting block. The positioning pin comprises a positioning body and a positioning head, the positioning body is embedded in the electrode cover, and the positioning head corresponds to the upper electrode body. By means of the electrode for projection welding of the resistor, the cooling effect of the electrode cover is improved, damage to the electrode holder is avoided, the use cost of the electrode assemblies can be saved, and management burden is relieved.

Owner:DIGITAL DIE STAMPING TECH WUHAN

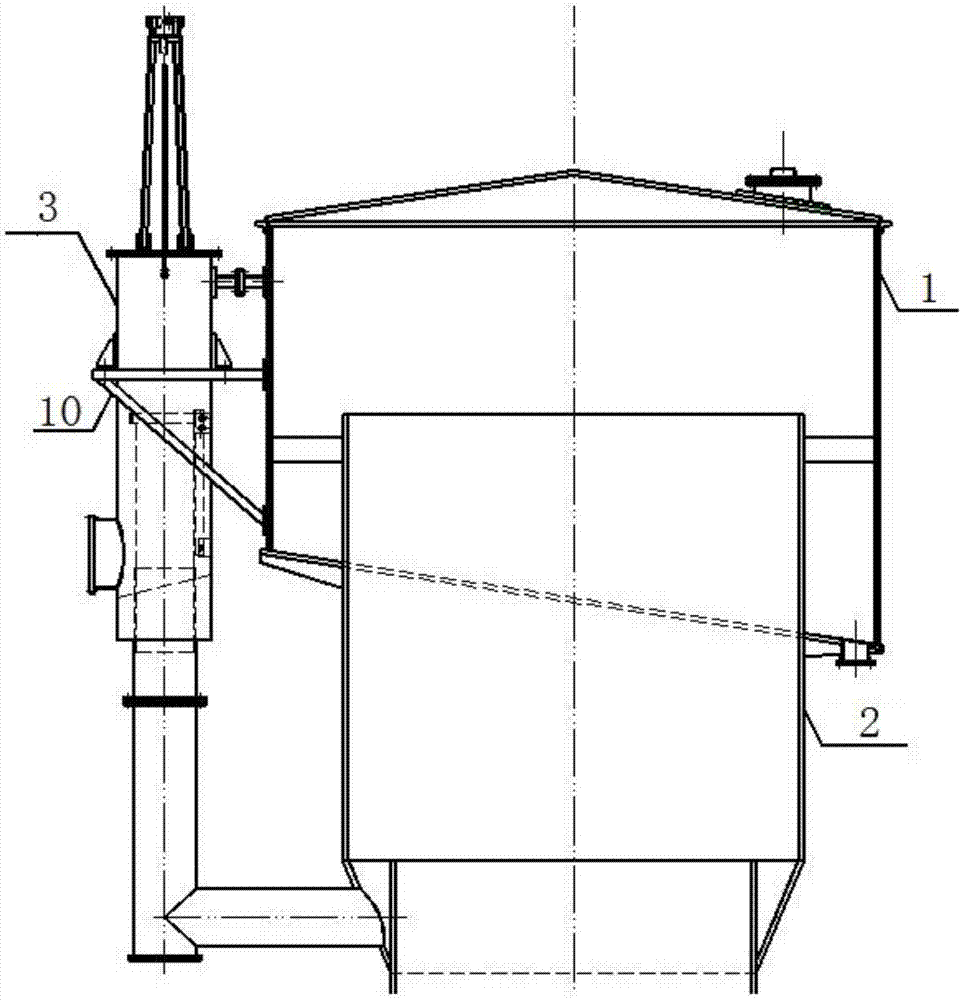

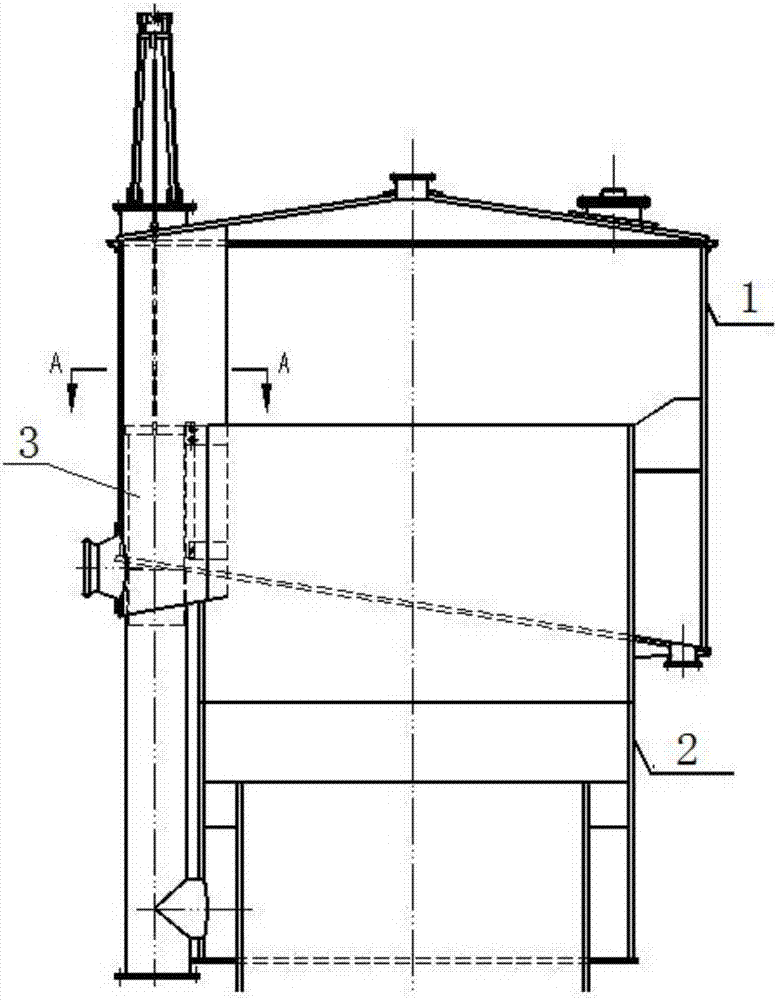

Sulphur truck loading tail gas collecting system and method

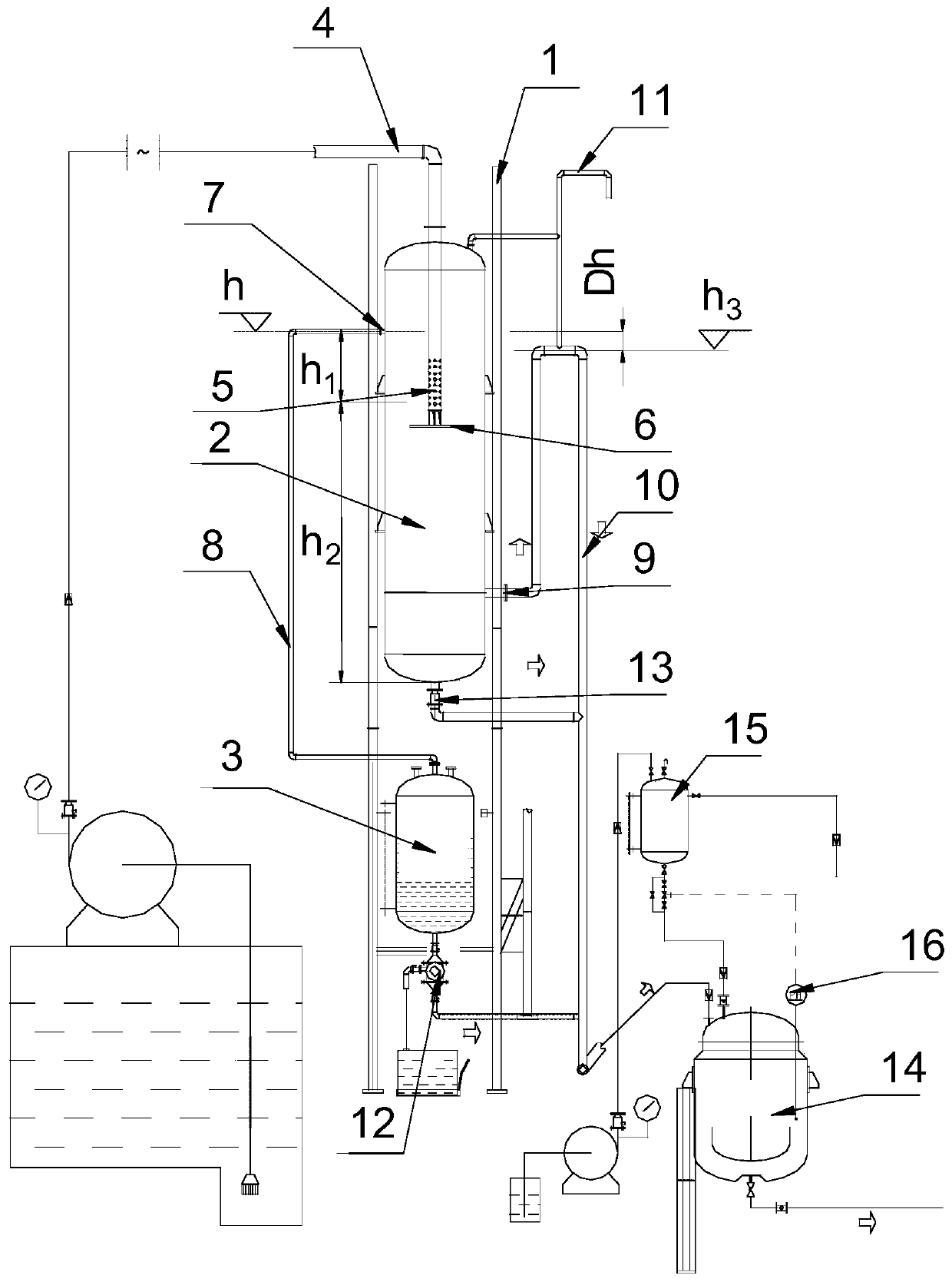

ActiveCN109806750AAutomatic speed adjustmentSmooth overflowDispersed particle separationVapor condensationLiquid-ring pumpTank truck

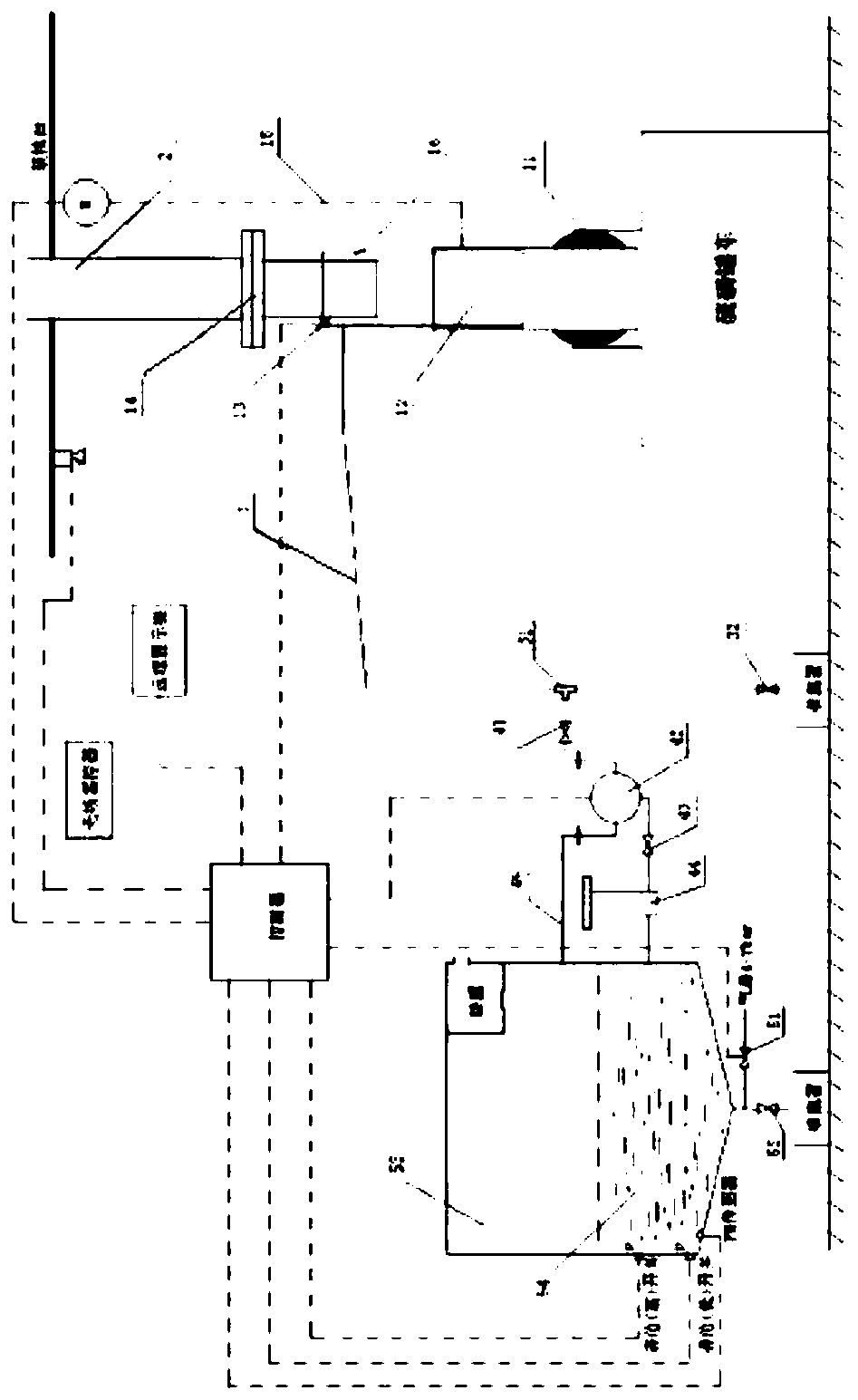

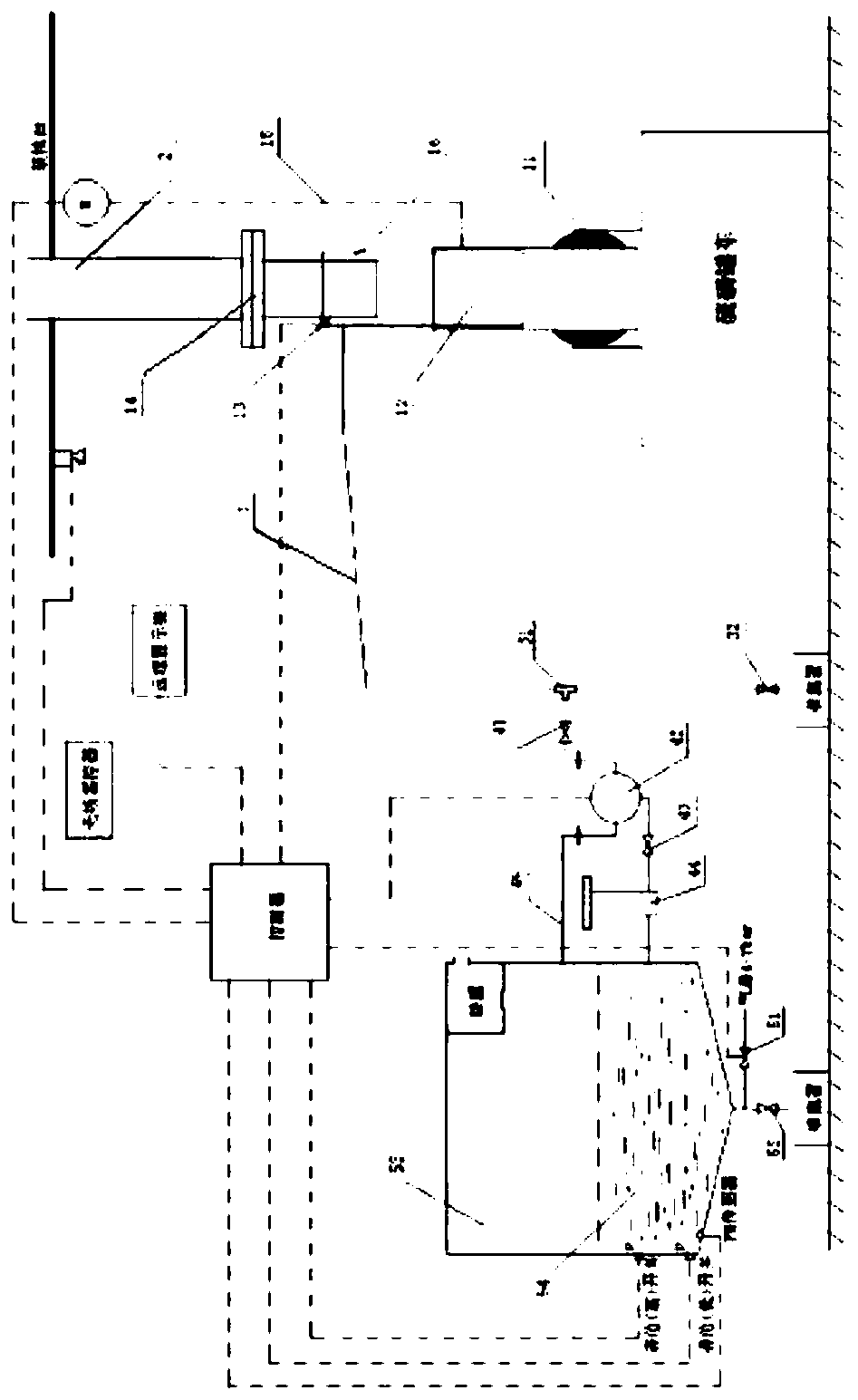

The invention discloses a sulphur truck loading tail gas collecting system and method. The sulphur truck loading tail gas collecting system and method are used for processing truck loading overflow tail gas overflowing from a tank port of a sulphur tank truck and preventing damage towards human bodies and environments when a sulphur tank truck loads liquid sulphur in a canning mode. Specifically,when the sulphur tank truck loads the liquid sulphur in a canning mode, the gap between the outer pipe wall of a feeding pipe and the tank port of the sulphur tank truck is sealed; the position for outputting the truck loading overflow tail gas of the feeding pipe is arranged to be of a clamping wall structure, after the truck loading overflow tail gas flows through the clamping wall, the truck loading overflow tail gas flows out from a tail gas output connector on the outer pipe at the clamping wall position, and the truck loading overflow tail gas is prevented from being not capable of beingdischarged and influencing normal working of the sulphur tank truck for loading the liquid sulphur in a canning mode; and then the truck loading overflow tail gas flowing out from the tail gas outputconnector enters a liquid ring pump under the vacuum suction action provided by the liquid ring pump and is mixed with a liquid ring formed by alkaline liquor in the liquid ring pump to perform purification treatment on the truck loading overflow tail gas.

Owner:江苏星亚迪环境科技有限公司

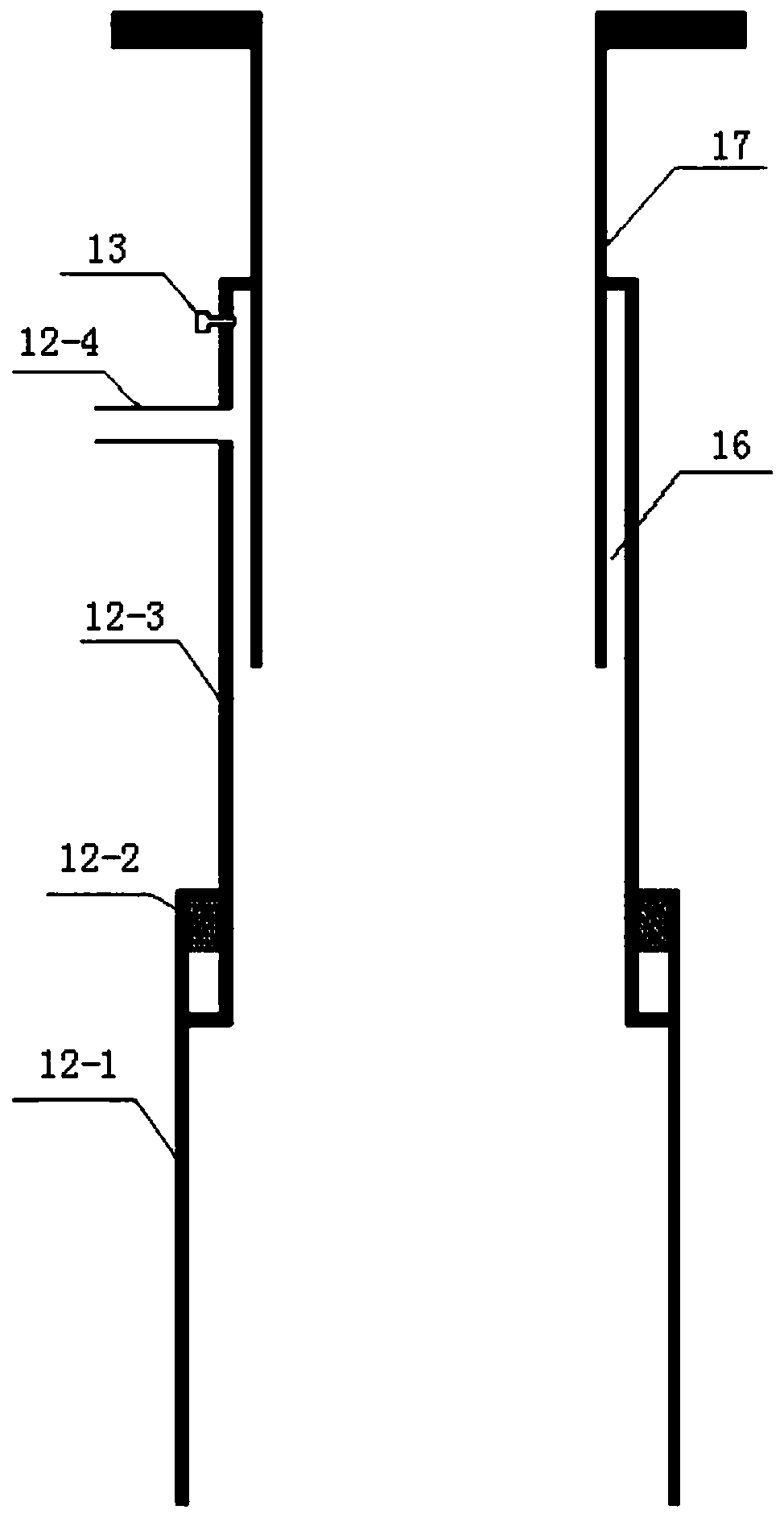

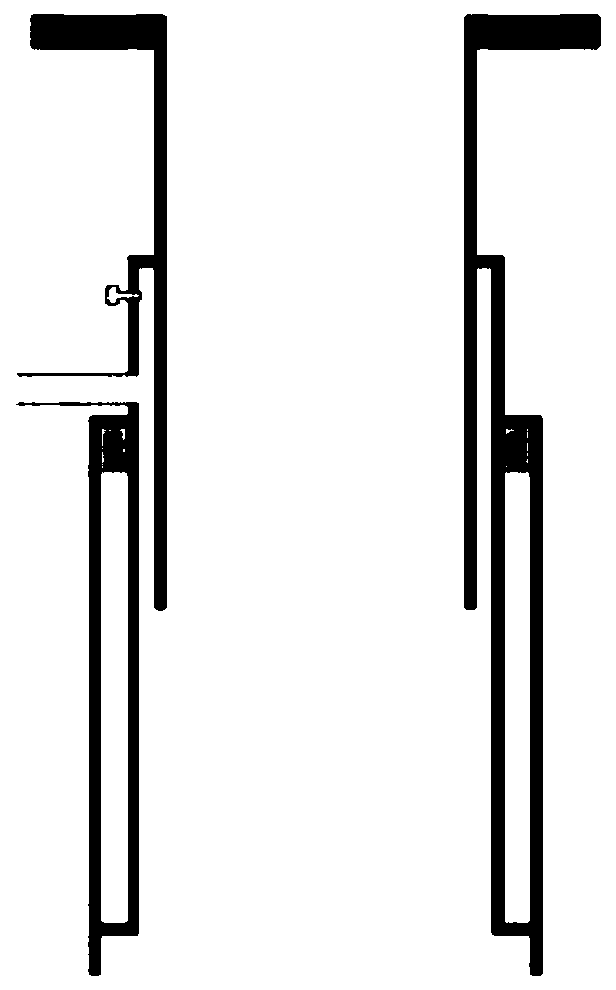

Desulphurization regeneration tower electric liquid level adjusting device, and regeneration tower working method

PendingCN107400540ASave materialSave spaceLevel controlDispersed particle separationEngineeringActuator

The invention relates to a desulphurization regeneration tower electric liquid level adjusting device, and a regeneration tower working method. A desulphurization regeneration tower is provided with a desulfurized solution tank and a foam tank; a desulfurized solution storage tank is arranged between the desulfurized solution tank and the foam tank; an electric liquid level adjusting device is arranged in the desulfurized solution storage tank; the electric liquid level adjusting device comprises a desulfurized solution overflow pipe, a liquid level adjusting pipe, and an electric actuator; the liquid level adjusting pipe is driven by a lead screw to move upward and downward in the desulfurized solution overflow pipe; the top of the lead screw is provided with the electric actuator as a driving device; the desulfurized solution overflow pipe is taken as guide rail of the liquid level adjusting pipe in moving; the upper part of the desulfurized solution overflow pipe is provided with a plurality of desulfurized solution overflow outlets along the circumference; and the corresponding parts of the desulfurized solution storage tank are provided with desulfurized solution outlets. The desulphurization regeneration tower electric liquid level adjusting device is capable of adjusting the interface of desulfurized solution with sulfur foam rapidly and reliably, reducing labor intensity in artificial dredging, adjusting response in time and accurately, ensuring regeneration tower processing effect; construction is convenient and simple; materials are saved; and labor cost is reduced.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

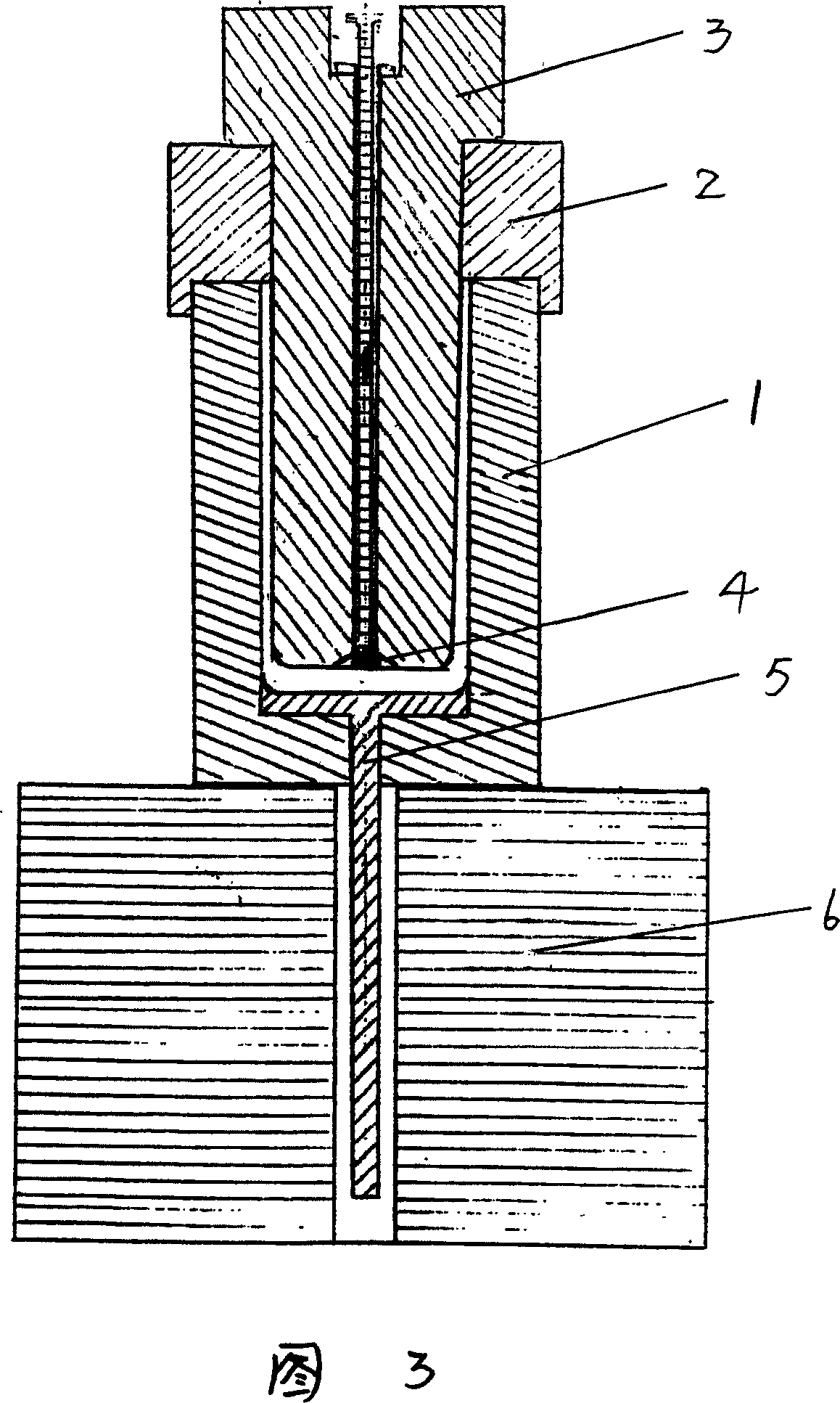

Solar water heater electric, manual double-purpose pipeline empty valve

InactiveCN101235899AChange switch stateAchieve emptyingOperating means/releasing devices for valvesLift valveSolar waterInternal cavity

The invention provides an electric-operated and manual-operated dual-purpose pipe blow-off valve for solar water heaters, which belongs to a valve. The invention is particularly adapted for intake and drainage pipes, which has functions of intake, drainage and emptying pipes. The invention comprises a valve body and a valve plug disposed in the inner chamber of the valve body, which is characterized in that the valve body is in an elongated pole shape, one end of the tall narrow pole is an air outlet end which extends at the top of the water tank of the solar water heater and is above water all the time, the other end of the tall narrow pole is a pipe end which is fixed on the water tank of the solar water heater and is communicated with an in-out water pipe, a magnetic coil is arranged out of the valve body, an in-out air hole is opened at one side of the air outlet end of the valve body, and an in-out water hole is opened at the position which is corresponding with a ring groove on the valve body. The valve plug is equipped with a central through-hole, an air cover is disposed at the position which is corresponding with the central through-hole on the valve body, and the valve plug portion which is corresponding with the magnetic coil is an iron work. The dual-purpose pipe blow-off valve being electric-operated and manual-operated of solar water heater not only can be manual-operated, but also be electric-operated, is simple and convenient in operation, and has not air gap when draining water.

Owner:冯建银

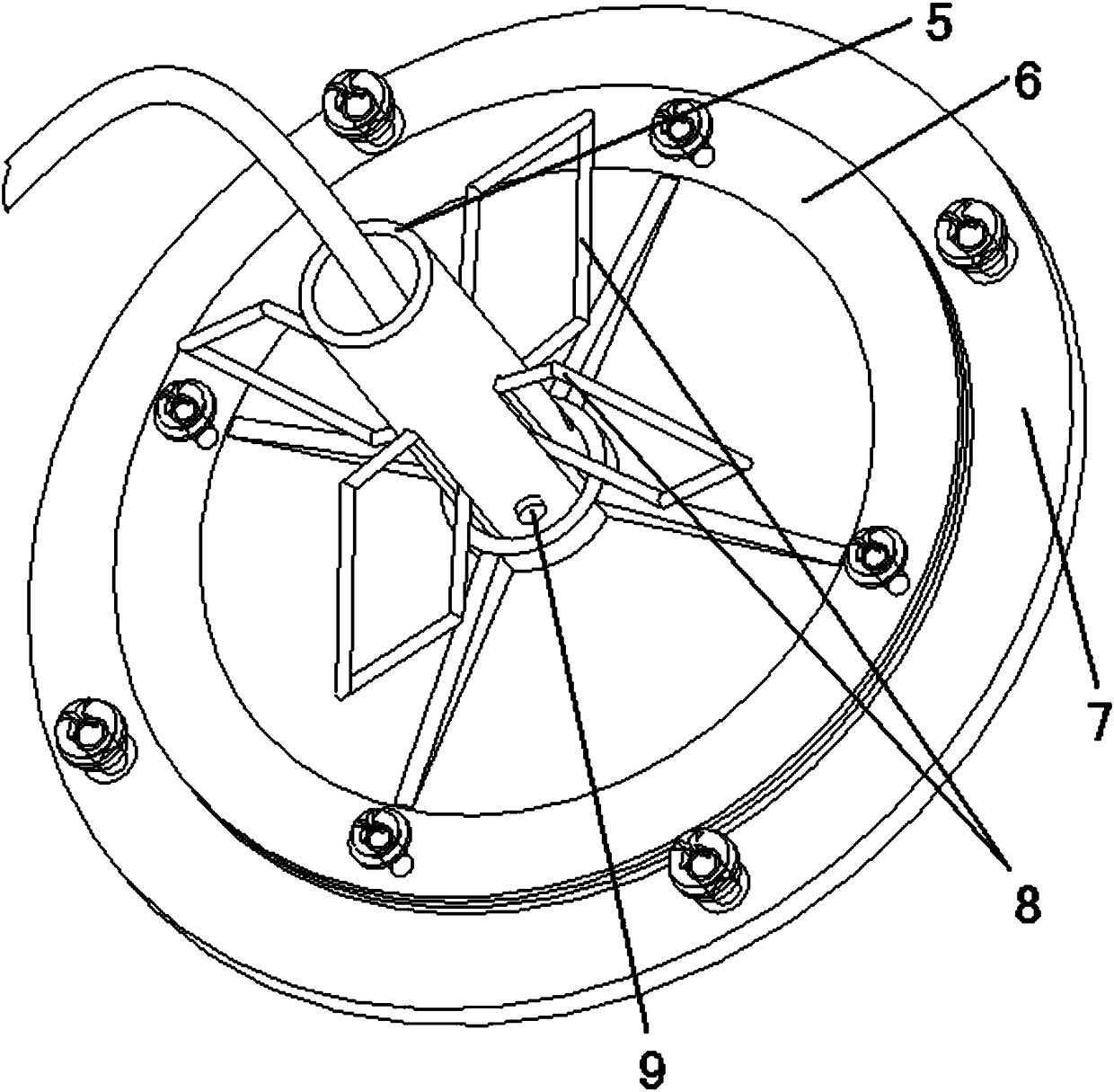

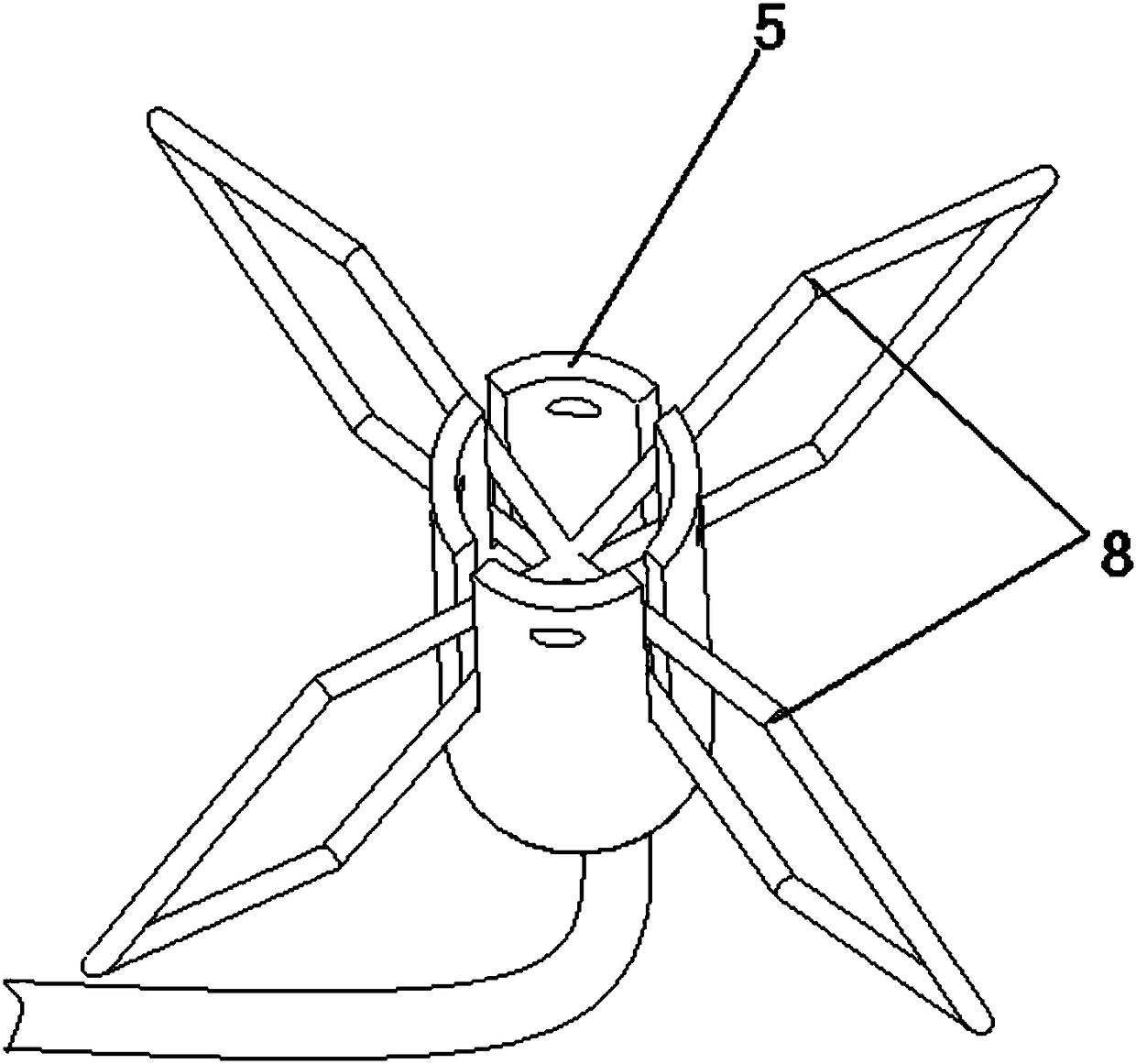

Antenna structure and installation method for wireless network coverage manhole cover

ActiveCN105720353BEasy to installAvoid displacementAntenna supports/mountingsRadiating elements structural formsEngineeringElectric power

Owner:康威通信技术股份有限公司

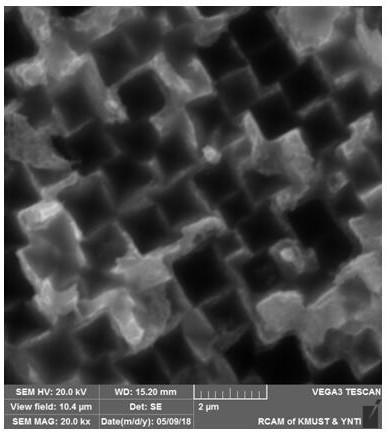

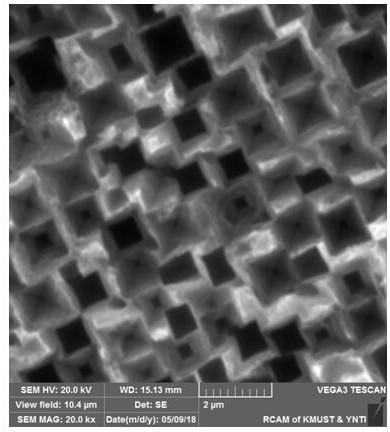

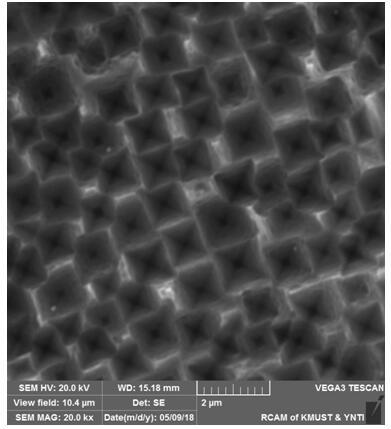

A method for smoothing the surface of copper-catalyzed etching textured silicon wafers

ActiveCN109087853BRealize structural smoothnessAttenuation of differences in anisotropic reaction ratesFinal product manufactureSemiconductor/solid-state device manufacturingEtchingWire cutting

Owner:KUNMING UNIV OF SCI & TECH

Muffle furnace silicon carbide heating system for manufacturing flexible glass and muffle furnace

PendingCN113654343ASmooth overflowStable temperatureMuffle furnacesRetort furnacesCarbide siliconTemperature control

The invention discloses a muffle furnace silicon carbide heating system for manufacturing flexible glass. The muffle furnace silicon carbide heating system comprises a silicon carbide box body, a bottom heating rod, a middle heating rod and a top heating rod are sequentially arranged on the two sides of the silicon carbide box body from bottom to top, near-end heating rods and far-end heating rods are correspondingly arranged on the two sides of the near end of the silicon carbide box body and the two sides of the far end of the silicon carbide box body, the far-end heating rods and the near-end heating rods are located on the same horizontal plane, the far-end heating rods and the near-end heating rods are not in contact, and the near-end heating rods and the far-end heating rods are located between the middle heating rods and the top heating rods; a plurality of far-end vertically-inserted heating rods are arranged at the far-end part of the silicon carbide box body; and side vertically-inserted heating rods are further arranged on the two sides of the near end of the silicon carbide box body and the two sides of the far end of the silicon carbide box body, the bottom heating rod, the middle heating rod, the top heating rod, the near-end heating rods and the far-end heating rods are all located between the side vertically-inserted heating rods and the side wall of the silicon carbide box body. The temperature of the silicon carbide box body is accurately controlled.

Owner:CAIHONG COLOUR KINESCOPE GENERAL FACTORY

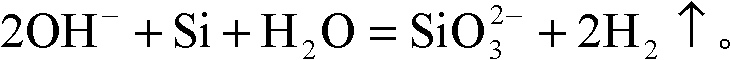

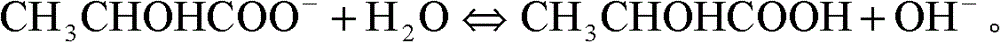

A kind of monocrystalline silicon texturizing agent and the preparation method of textured monocrystalline silicon

ActiveCN103184523BImprove decontamination abilityIncrease buoyancyAfter-treatment detailsFinal product manufactureSodium lactateAmmonia

Owner:JETION SOLAR HLDG

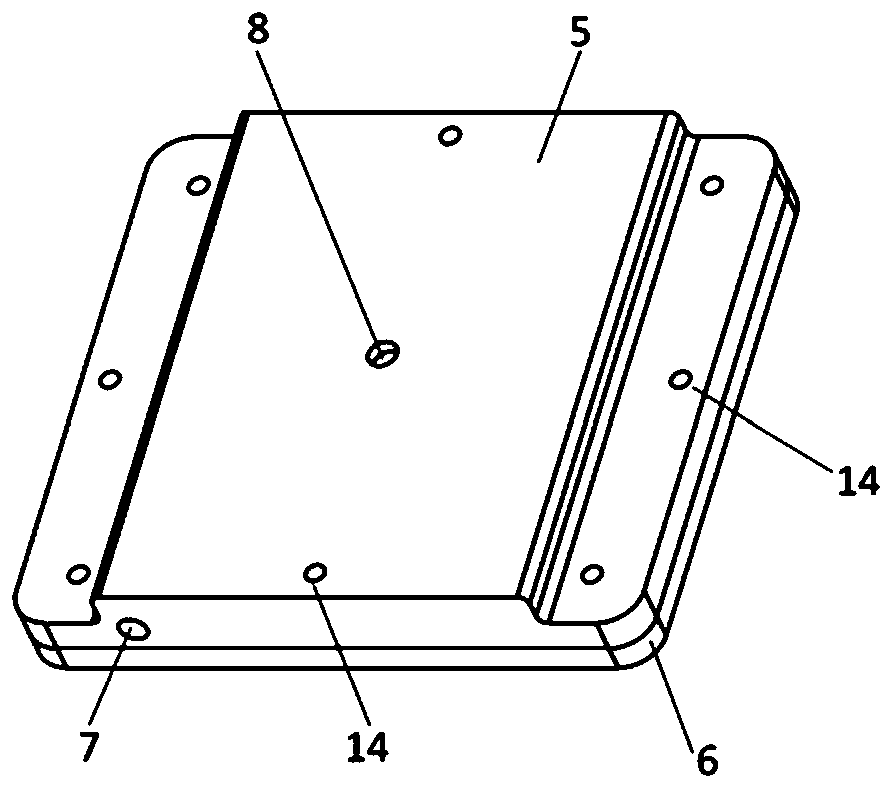

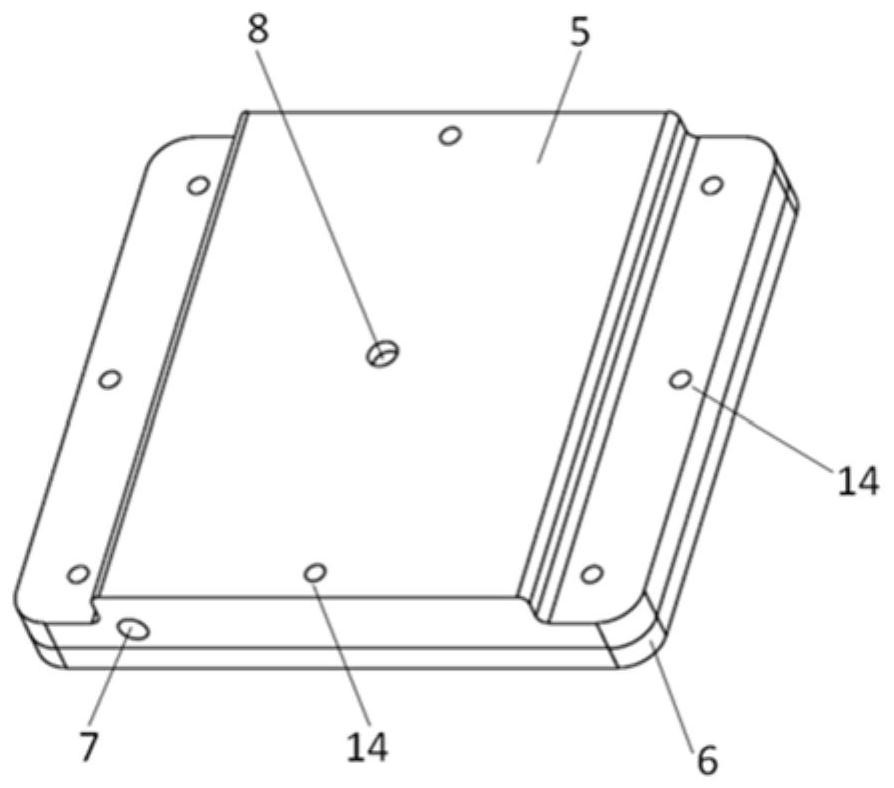

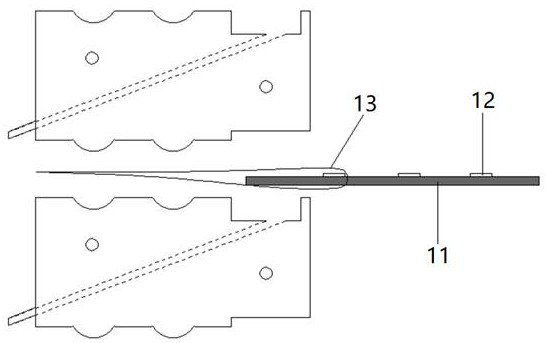

Fixing fixtures and gluing equipment for gluing equipment

ActiveCN111451177BPrevent looseningSmooth overflowMaterial analysis by optical meansCleaning using toolsAdhesive glueMechanical engineering

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

Sulfur loading tail gas collection system and method

ActiveCN109806750BSmooth overflowPrevent overflowDispersed particle separationVapor condensationLiquid-ring pumpCollection system

The invention discloses a sulphur truck loading tail gas collecting system and method. The sulphur truck loading tail gas collecting system and method are used for processing truck loading overflow tail gas overflowing from a tank port of a sulphur tank truck and preventing damage towards human bodies and environments when a sulphur tank truck loads liquid sulphur in a canning mode. Specifically,when the sulphur tank truck loads the liquid sulphur in a canning mode, the gap between the outer pipe wall of a feeding pipe and the tank port of the sulphur tank truck is sealed; the position for outputting the truck loading overflow tail gas of the feeding pipe is arranged to be of a clamping wall structure, after the truck loading overflow tail gas flows through the clamping wall, the truck loading overflow tail gas flows out from a tail gas output connector on the outer pipe at the clamping wall position, and the truck loading overflow tail gas is prevented from being not capable of beingdischarged and influencing normal working of the sulphur tank truck for loading the liquid sulphur in a canning mode; and then the truck loading overflow tail gas flowing out from the tail gas outputconnector enters a liquid ring pump under the vacuum suction action provided by the liquid ring pump and is mixed with a liquid ring formed by alkaline liquor in the liquid ring pump to perform purification treatment on the truck loading overflow tail gas.

Owner:江苏星亚迪环境科技有限公司

Forming mold for purple sand cup/lid and screw thread mouth purple sand cup/lid and producing method

InactiveCN100343032CSmooth overflowReduce distortionCeramic shaping mandrelsCeramic shaping coresScrew threadMaterials science

Owner:MENGLONG CUP IND YIXING CITY

A Cupola and Its Restoration Technology

ActiveCN109945639BReduce manual labor intensityImprove cast iron efficiencyLinings repairVertical furnacesBall screwFire brick

The invention relates to the field of iron casting, in particular to a cupola and a repair process thereof. The cupola comprises a back furnace; the back furnace comprises a waist furnace and a charging port; the waist furnace is provided with a hot air pipe and a repair mechanism; the repair mechanism comprises a repair block and multiple auxiliary pushing units; a charging channel communicatingwith the charging port is formed in the side wall of the back furnace; a hot air channel is formed in the side wall of the upper end of the waist furnace; each auxiliary pushing unit comprises a ballscrew pair, an auxiliary pushing pipe and a blockage module; the blockage module can intermittently block the charging channel and the hot air channel; the ball screw pair comprises a screw rod and anut base; and the nut base is connected with the repair block through the auxiliary pushing pipe. The repair process of the cupola comprises the following steps: (1) the hot air channel is blocked; and the nut base moves down; (2) iron shots on refractory bricks are removed; and meanwhile, the inner side walls of the refractory bricks are repaired; and (3) the repair block is used for repair and mud injection. The cupola can automatically remove the iron shots, and meanwhile, can repair the refractory bricks.

Owner:CHONGQING GAS COMPRESSOR FACTORY

Concrete blocks for reinforced earth retaining walls and methods of joining them

ActiveCN114150700BSmooth overflowIncrease flow rateArtificial islandsUnderwater structuresButt jointGeogrid

The invention provides a concrete block for a reinforced soil retaining wall and a connection method thereof. The concrete block comprises: a block body having an inner side facing the wall and an outer side facing away from the wall; a top of the block body There is a water collection tank set through the surface, and the inside of the block body is provided with a drainage hole connected with the water collection tank, and the drainage hole extends outward to the outer surface of the block body; along the height direction of the wall, two adjacent blocks The block body is adapted to butt up and down to form an accommodation space suitable for insertion of the longitudinal ribs of the drainage geogrid, and the accommodation space communicates with the water collection tank. The longitudinal rib of the drainage geogrid in the present invention is placed in the accommodation space, and the gravity of the concrete block will not be applied to the longitudinal rib of the drainage geogrid, so the outlet of the drainage geogrid longitudinal rib will not be deformed or blocked Phenomenon: the water body in the longitudinal rib of the drainage geogrid can smoothly overflow into the sump, and then be discharged through the drainage hole.

Owner:CHINA THREE GORGES CORPORATION

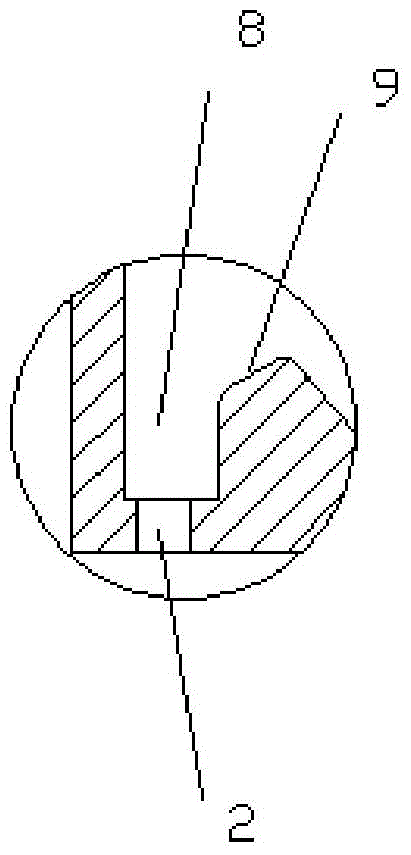

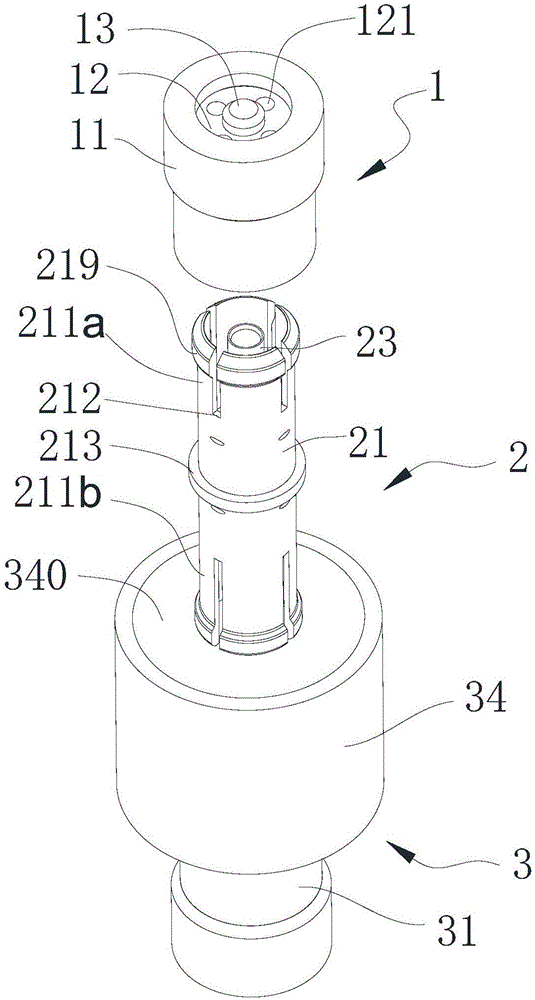

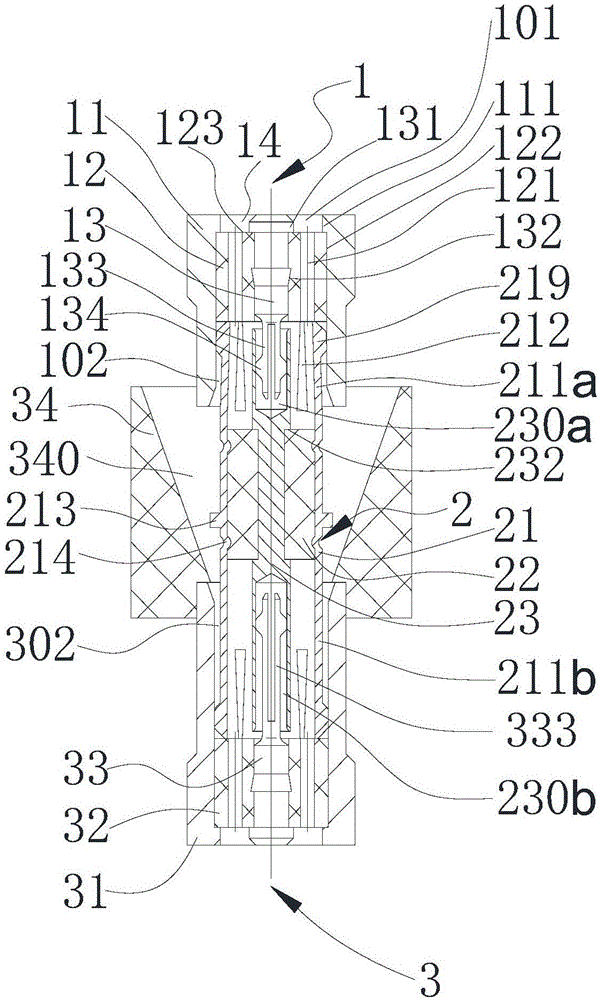

A socket connector and coaxial connector

ActiveCN103682842BSmooth overflowGuaranteed RF LeakageCoupling device detailsDielectricElectrical conductor

The invention discloses a socket connector and a coaxial connector. The socket connector comprises an outer socket conductor, a socket dielectric and an inner socket conductor. The outer socket conductor is cylindrical and of an inner cylindrical cavity. The inner socket conductor is rod-like and inserted in the inner cylindrical cavity. The socket dielectric is fixed between the outer socket conductor and the inner socket conductor. A circular process groove is formed between the fixed end of the inner socket conductor and the second end of the outer socket conductor, and a floating groove is formed between the connecting end of the inner socket conductor and the first end of the outer socket conductor. Vent holes communicating the floating groove with the process groove are formed in the socket dielectric. As the process groove is formed between the inner socket conductor and the outer socket conductor, the vent holes can guarantee smooth spilling of weld gas during welding, slotting of the outer socket conductor is avoided, the outer socket conductor can fit a PCB to form full shield to avoid radiofrequency leakage of the outer socket conductor after welding, and excellent electromagnetic compatibility is achieved. The coaxial connector comprises the socket connector and an adapter component.

Owner:HUAWEI TECH CO LTD

Method for recovering proteins in protein wastewater

ActiveCN110003307AHigh removal rateLow carry efficiencyPeptide preparation methodsWastewaterTotal protein

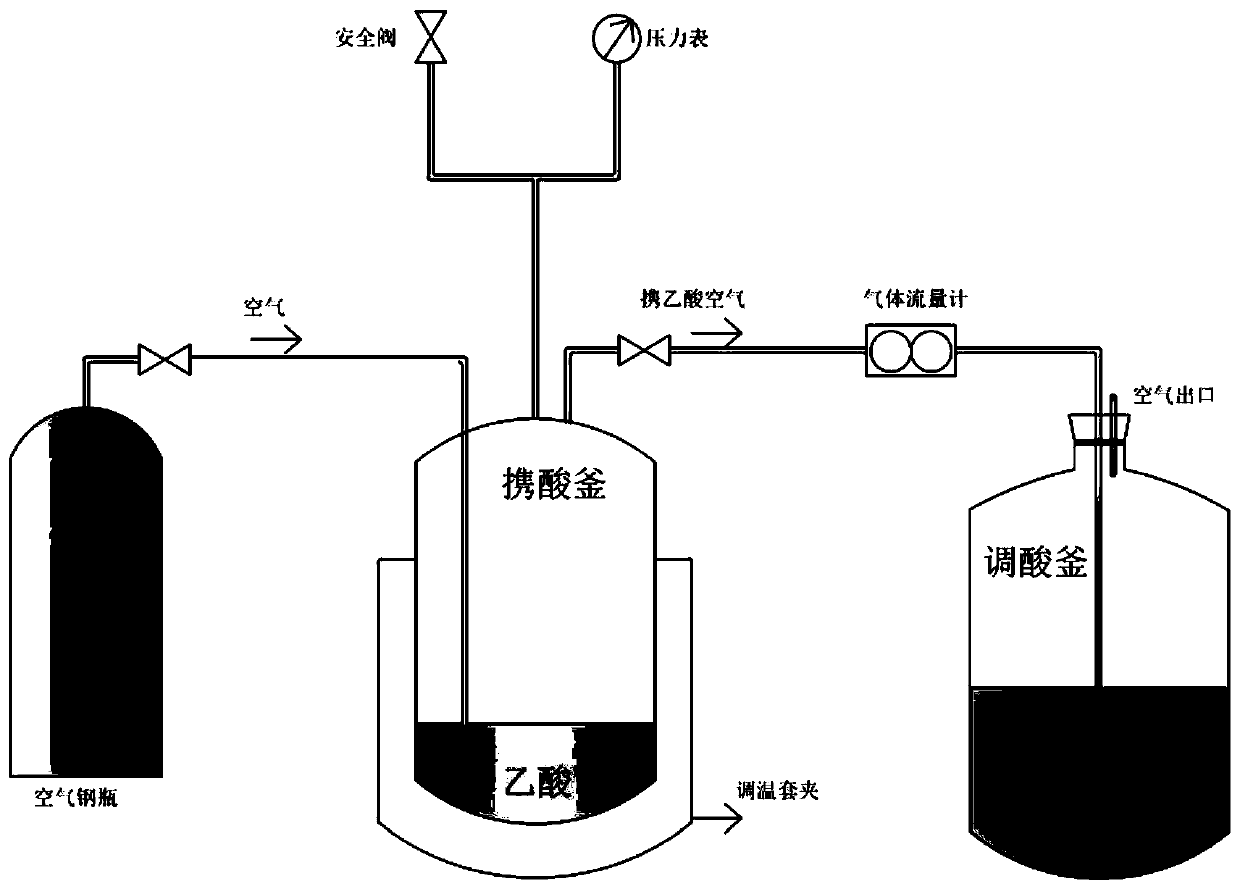

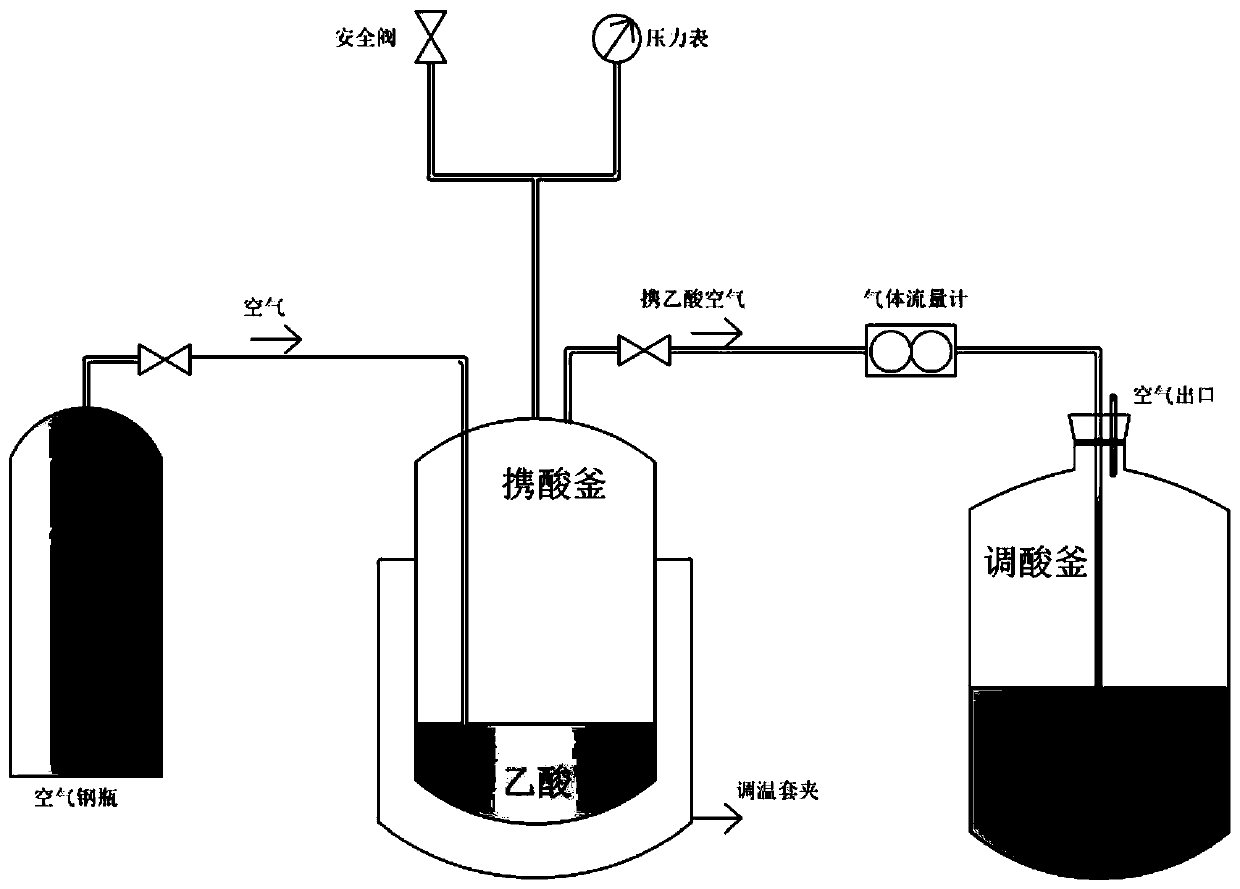

The invention provides a method for recovering proteins in protein wastewater. The method comprises the steps of introducing an air-carried volatile acid into the protein wastewater to adjust the pH value to a protein isoelectric point; performing precipitation to recover the proteins from the protein wastewater. According to the provided method, the air-carried volatile acid is used as an acid adjusting means, the pH value of the wastewater with high protein concentration can be adjusted to the isoelectric point of each protein under low pressure through air pressure, the carrying temperature, the carrying time and the like, the proteins with different isoelectric points in the wastewater are separately precipitated and removed, the protein removal rate is increased, the total protein recovery rate can reach about 95% or above, industrial production is facilitated, and the method has a high value in practical application.

Owner:OCEAN UNIV OF CHINA

A PHC pipe pile driving device for traversing deep and dense sand layers

ActiveCN103556636BPressure is easy to controlOpen smoothlyBulkheads/pilesEngineeringStructural engineering

A PHC tubular pile pile-sinking device used for penetrating a deep and dense sand (gravel) layer comprises a PHC tubular pile (2), wherein both the upper part and the lower part of the PHC tubular pile (2) are provided with a pile cap (1) and a pile shoe (3) respectively in a connecting manner; a slurry inlet pipe (4), an air inlet pipe (6) and an air exhaust pipe (5) penetrate holes in the pile caps (1) to be mounted in inner holes of the PHC tubular pile (2). The PHC tubular pile pile-sinking device used for penetrating the deep and dense sand (gravel) layer has the advantages of: 1, guaranteeing successful overflow of returned slurry, 2, preventing excessive washing, 3, controlling placement positions of the slurry inlet pipe, the air inlet pipe and the air exhaust pipe quantitatively and guaranteeing penetration effect and quality, 4, changing traditional water washing into slurry washing, ensuring phenomena of hole collapse and quicksand not to happen easily in the sand (gravel) layer washing process as the slurry is made of traditional drilling slurry, cement of about 5%-10% and a retarding agent of 0.2%, avoiding excessive washing, and guaranteeing side friction of the PHC tubular pile and quality of guided holes, and 5, achieving rational design, simple structure, installation and operation convenience, reliable sealing performance and good penetration effects, and being economic and practical.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

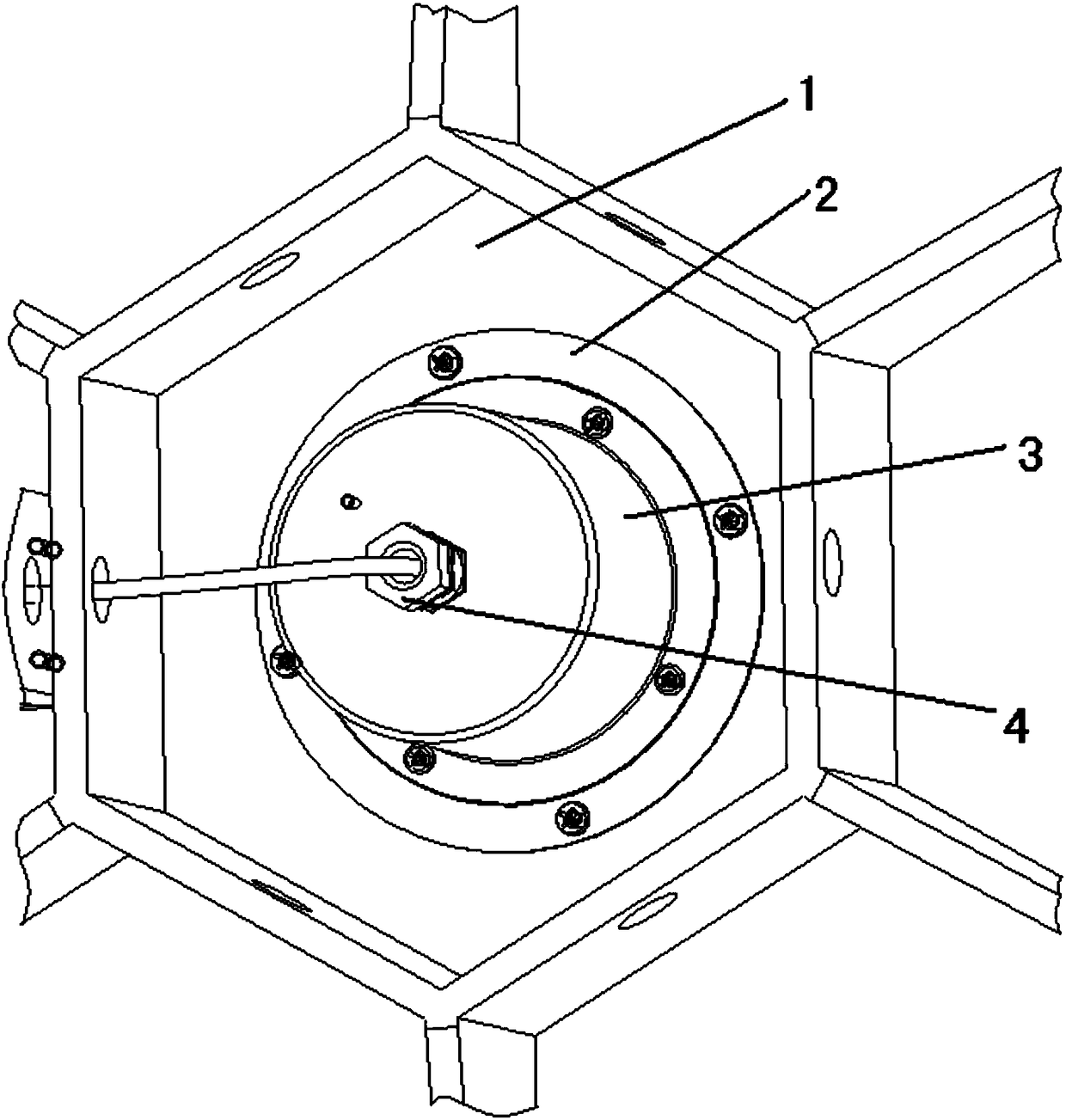

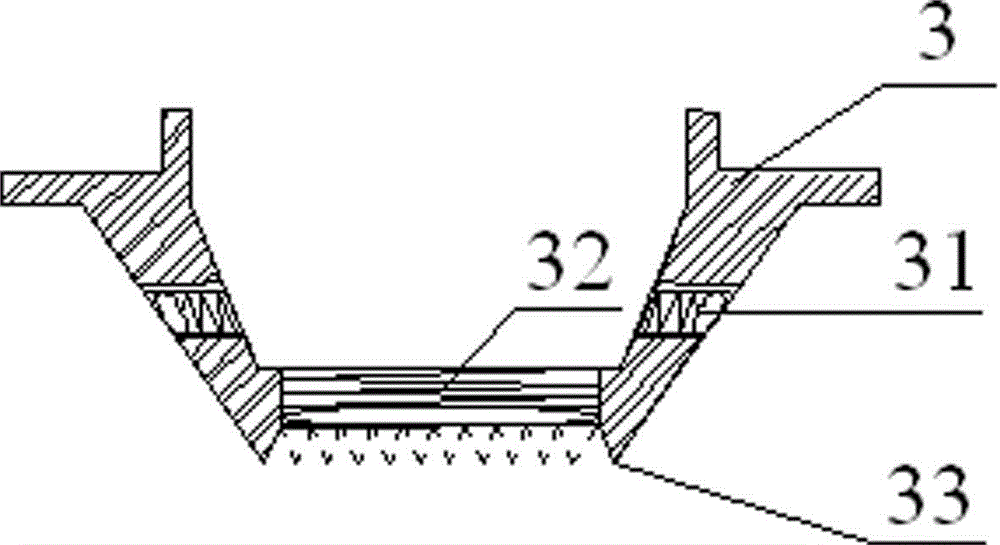

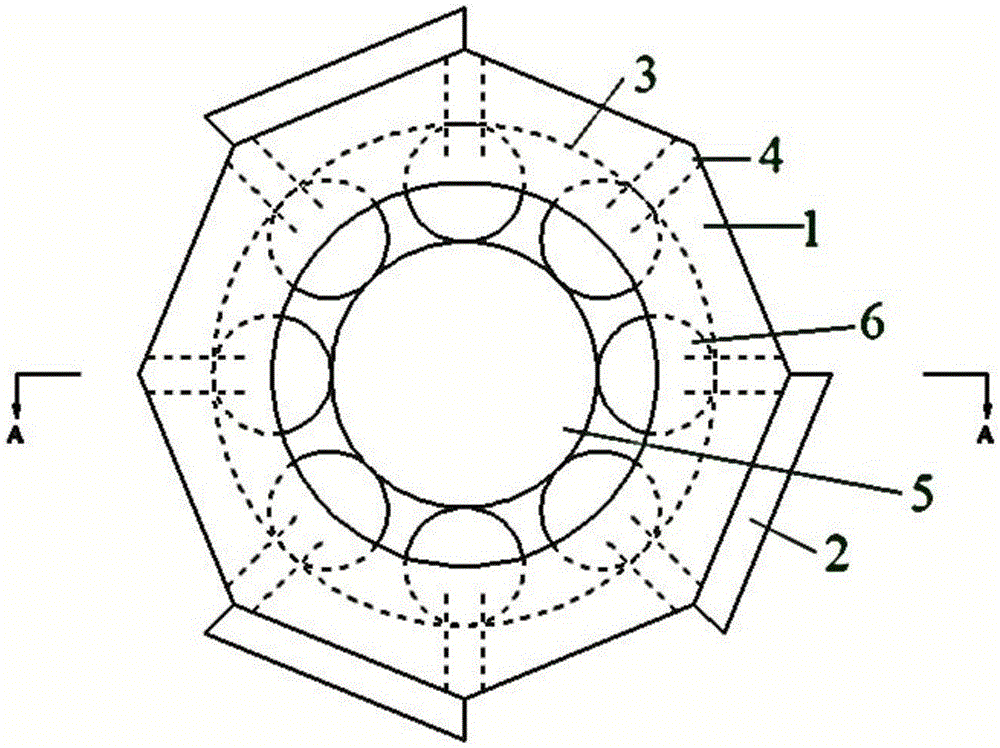

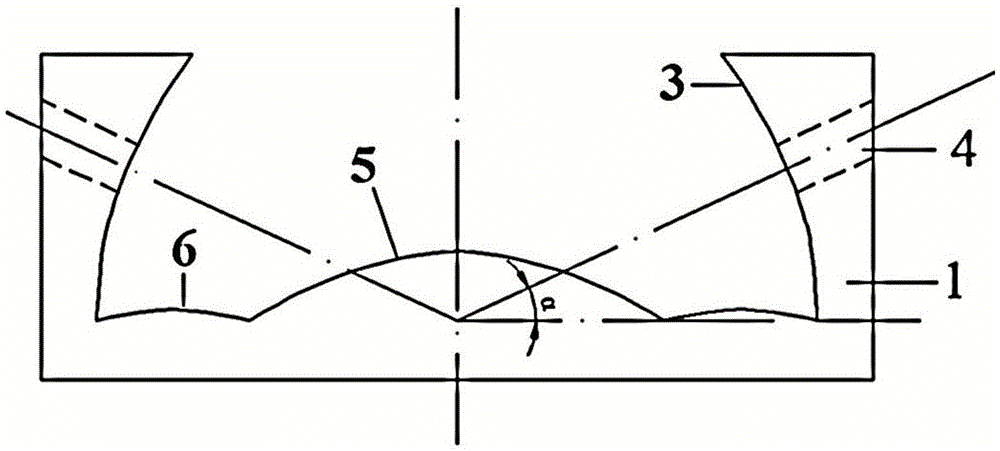

A continuous casting tundish turbulence device

The invention relates to a continuous casting tundish turbulator. The external structure of the tundish is an octagonal prism (1), with three bosses (2) spaced on its eight cylinders; the interior of the tundish is is a cavity, the inner side of the cavity is a paraboloid of rotation (3), eight guide holes (4) are evenly distributed on the inner wall of the cavity, and the bottom of the cavity is a paraboloid of rotation (3) at the center of the bottom 5), eight small paraboloids (6) are evenly distributed along the outside of the bottom center rotating paraboloid (5); the turbulator of the present invention has the advantages of enhanced metallurgical function, prevention of floating and long service life.

Owner:SHANDONG IRON & STEEL CO LTD +2

A skin-like anti-seepage water warning exterior wall

The invention discloses a skin-like anti-seepage water early-warning exterior wall, which belongs to the field of exterior wall waterproofing. After water seepage, under the setting of multi-point water diversion rods and water diversion fluff, due to the water absorption of the two, the water spreads faster on the two than between the concrete of the outer wall, so that the early warning scattered points It can touch the water before the middle part of the wall seeps into the water, so as to generate gas in time and enter the self-bulging laminate, so that the self-bulging laminate will bulge like the skin after being bitten by a mosquito, so as to remind the residents in time The water seepage of the wall is convenient for timely maintenance and repair. Compared with the existing technology, an early warning response can occur in advance, and the safety hazard and economic loss caused by the water seepage of the outer wall can be effectively reduced.

Owner:淮北德林机械设备有限公司

Ink printing transferred rubber pedal pad vulcanization forming mould and manufacturing method

PendingCN108437308AFlow restrictionPrevent deformation and aliasingDomestic articlesCoatingsVulcanizationEngineering

The invention belongs to the technical field of ink transferred rubber products and discloses an ink printing transferred rubber pedal pad vulcanization forming mould and a manufacturing method. The ink printing transferred rubber pedal pad vulcanization forming mould comprises an upper mould, a middle mould, a lower mould and a floating core mould, the lower surface of the middle mould and the upper surface of the lower mould are provided with mould cavities which jointly form a rubber cavity for to-be-formed ink printing transferred rubber pedal pads after mould closing, and the middle mouldand the upper mould are internally provided with holes allowing vertical movement of the floating core mould. By adoption of the technical scheme, ink printings can be clearly transferred to special-shaped rubber surfaces while deformation and deflection of printed patterns are avoided, and high rate of finished products is realized.

Owner:南京金三力高分子科技有限公司

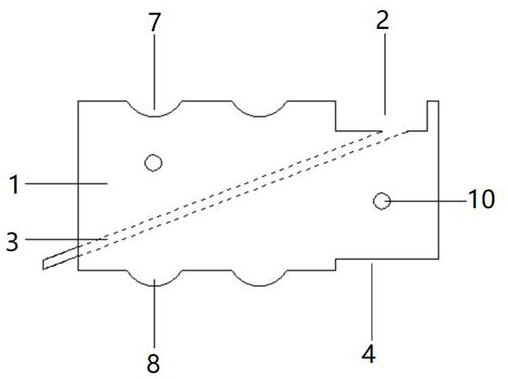

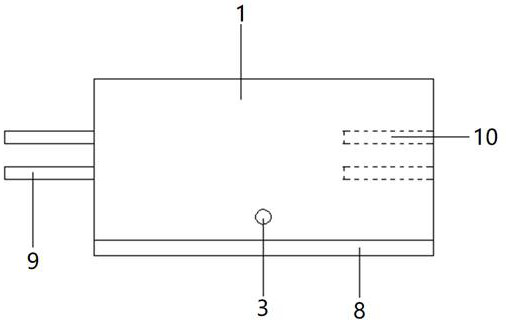

Pump driven two-phase fluid loop evaporator

ActiveCN111504103BLarge thermal resistanceLarge evaporation heat transfer coefficientIndirect heat exchangersEngineeringHydrophobe

The present invention provides a pump-driven two-phase fluid circuit evaporator, comprising: an evaporator shell 1, a hydrophobic capillary core 2, an axial liquid channel 3 and an axial steam main channel 4; the hydrophobic capillary core 2 is installed Inside the evaporator shell 1; a plurality of axial liquid channels 3 are arranged between the evaporator shell 1 and the hydrophobic capillary core 2; internal. For the two-phase fluid circuit driven by the capillary pump, the present invention uses hydrophobic porous materials to cover the surface of the open micro channels of the evaporator, so that the liquid cannot occupy the space of the main steam channel due to condensation under various orientations or the influence of gravity. The steam bubbles that may exist in the liquid channel can be smoothly overflowed from the channel, which is beneficial to the smooth start of the evaporator and the reduction of the superheat at the start, and improves the heat transfer coefficient of the evaporation process.

Owner:SHANGHAI SATELLITE ENG INST

Concrete block for reinforced earth retaining wall and connecting method thereof

ActiveCN114150700ASmooth overflowIncrease flow rateArtificial islandsUnderwater structuresGeogridRetaining wall

The invention provides a concrete block for a reinforced earth retaining wall and a connecting method thereof, and the concrete block comprises a block body which is provided with an inner side surface facing a wall body and an outer side surface deviating from the wall body; a water collecting groove is formed in the top surface of the building block body in a penetrating manner, and a drainage hole communicated with the water collecting groove is formed in the building block body and extends outwards to the outer side surface of the building block body; in the height direction of the wall body, every two adjacent building block bodies are suitable for being in butt joint up and down so as to form a containing space suitable for being inserted by a drainage geogrid longitudinal rib, and the containing space is communicated with the water collecting groove. The drainage geogrid longitudinal ribs are arranged in the containing space, the gravity of the concrete blocks cannot be applied to the drainage geogrid longitudinal ribs, and therefore the drainage openings of the drainage geogrid longitudinal ribs cannot deform or be blocked; water in the longitudinal ribs of the drainage geogrid can smoothly overflow into the water collecting tank and then is drained through the drainage holes.

Owner:CHINA THREE GORGES CORPORATION

Oily industrial wastewater treatment device and treatment method

PendingCN110217943ALess investment in infrastructureLow running costWater treatment parameter controlFatty/oily/floating substances removal devicesIndustrial wastewater treatmentCapital investment

The invention relates to the field of environmental protection and particularly relates to an oily industrial wastewater treatment device and a treatment method. The oily industrial wastewater treatment device comprises a frame body, an oil-water separation overhead tank and a floating oil receiving tank. According to the oily industrial wastewater treatment device and the treatment method, the height of an upper-layer floating oil liquid column can be guaranteed, and increasingly-accumulated floating oil can successfully overflow and enter the floating oil receiving tank. Oil-water separationis achieved in a continuous automatic overflowing manner, and the device and the method have the characteristics that capital investment is reduced, the operating cost is reduced, and the operating efficiency of the device is increased.

Owner:ZHEJIANG BOJU NEW MATERIALS CO LTD

Cupola and repair process thereof

ActiveCN109945639AReduce manual labor intensityImprove cast iron efficiencyLinings repairVertical furnacesBrickEngineering

The invention relates to the field of iron casting, in particular to a cupola and a repair process thereof. The cupola comprises a back furnace; the back furnace comprises a waist furnace and a charging port; the waist furnace is provided with a hot air pipe and a repair mechanism; the repair mechanism comprises a repair block and multiple auxiliary pushing units; a charging channel communicatingwith the charging port is formed in the side wall of the back furnace; a hot air channel is formed in the side wall of the upper end of the waist furnace; each auxiliary pushing unit comprises a ballscrew pair, an auxiliary pushing pipe and a blockage module; the blockage module can intermittently block the charging channel and the hot air channel; the ball screw pair comprises a screw rod and anut base; and the nut base is connected with the repair block through the auxiliary pushing pipe. The repair process of the cupola comprises the following steps: (1) the hot air channel is blocked; and the nut base moves down; (2) iron shots on refractory bricks are removed; and meanwhile, the inner side walls of the refractory bricks are repaired; and (3) the repair block is used for repair and mud injection. The cupola can automatically remove the iron shots, and meanwhile, can repair the refractory bricks.

Owner:CHONGQING GAS COMPRESSOR FACTORY

Solar water heater electric, manual double-purpose pipeline empty valve

InactiveCN101235899BChange switch stateAchieve emptyingOperating means/releasing devices for valvesLift valveSolar waterDual purpose

The invention provides an electric-operated and manual-operated dual-purpose pipe blow-off valve for solar water heaters, which belongs to a valve. The invention is particularly adapted for intake and drainage pipes, which has functions of intake, drainage and emptying pipes. The invention comprises a valve body and a valve plug disposed in the inner chamber of the valve body, which is characterized in that the valve body is in an elongated pole shape, one end of the tall narrow pole is an air outlet end which extends at the top of the water tank of the solar water heater and is above water all the time, the other end of the tall narrow pole is a pipe end which is fixed on the water tank of the solar water heater and is communicated with an in-out water pipe, a magnetic coil is arranged out of the valve body, an in-out air hole is opened at one side of the air outlet end of the valve body, and an in-out water hole is opened at the position which is corresponding with a ring groove on the valve body. The valve plug is equipped with a central through-hole, an air cover is disposed at the position which is corresponding with the central through-hole on the valve body, and the valve plug portion which is corresponding with the magnetic coil is an iron work. The dual-purpose pipe blow-off valve being electric-operated and manual-operated of solar water heater not only can be manual-operated, but also be electric-operated, is simple and convenient in operation, and has not air gap when draining water.

Owner:冯建银

Electrode for resistance projection welding

ActiveCN105057870BImprove cooling effectAvoid problems with poor coolingElectrode featuresCooling effectEngineering

The invention relates to an electrode for projection welding of a resistor. The electrode comprises an upper electrode assembly and a lower electrode assembly. The upper electrode assembly comprises an upper electrode body. The lower electrode assembly comprises a circulation water cooling block, an electrode holder, an electrode cover and a positioning pin. The circulation water cooling block is provided with a cooling hole, a connecting block is embedded in the cooling hole, and the top end of the electrode holder is embedded in one end of the cooling hole. The electrode cover comprises a cover body and a base, the base of the electrode cover is embedded in the other end of the cooling hole, and the top end of the electrode holder is connected with the base of the electrode cover through the connecting block. The positioning pin comprises a positioning body and a positioning head, the positioning body is embedded in the electrode cover, and the positioning head corresponds to the upper electrode body. By means of the electrode for projection welding of the resistor, the cooling effect of the electrode cover is improved, damage to the electrode holder is avoided, the use cost of the electrode assemblies can be saved, and management burden is relieved.

Owner:DIGITAL DIE STAMPING TECH WUHAN

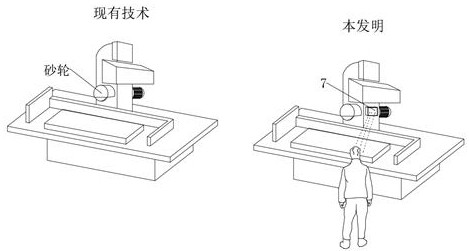

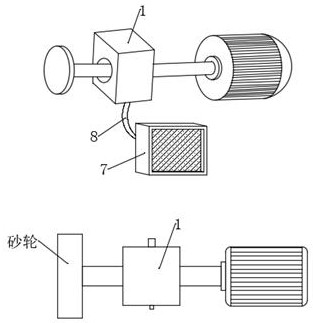

Grinding wheel vibration monitoring and alarming device for grinding machine and using method thereof

ActiveCN113524042BGuaranteed uptimeRun fastGrinding feed controlGrinding machinesThermal dilatationEngineering

The invention discloses a grinding wheel vibration monitoring and alarming device for a grinding machine and a use method thereof, which belong to the field of machine tool alarming equipment. The vibration of the grinding wheel can be detected in advance by adding a vibration sensor and a color development shell on the basis of the existing grinding wheel spindle, and the vibration of the grinding wheel can be effectively improved. The stable operation of the grinding wheel, through the installation of frictional heat generating parts inside the vibrating sensor to make it rub against the vibrating grinding wheel spindle to generate heat, transfer heat to the thermal expansion ball to make it expand and block the circulation flow channel, and then let the pigment overflow to the In the overflow channel, the liquid-guiding effect of the liquid-guiding tape and the liquid-guiding parts is used to make the pigment appear on the absorbent paper in the color-developing shell, so that the workers can see it in time, so that the vibration of the grinding wheel can be detected early so that adjustment measures can be taken in time , and the workers can know the situation at a position far away from the grinding machine, which can effectively reduce the danger faced by people when they are close to the inspection, and it is also to prevent the workers from inhaling the fine sand and metal shavings splashed out.

Owner:南通斯高蕊机械设备有限公司

Apparatus and method adaptable to different fine-grained minerals interfering with sedimentation sorting flow field control

ActiveCN111111904BSmooth overflowThe flow field characteristics are suitable forWet separationHydrologyConical cavity

The invention discloses a device and method capable of adapting to different fine-grained minerals to interfere with the regulation and control of the sedimentation and sorting flow field. The blades, the upper adjustment side wall board, the lower adjustment side wall board, the upper adjustment mechanism and the lower adjustment mechanism; both sides of the bottom of the rectangular cavity are provided with bottom top water ports, and the bottom top water ports are respectively connected with water inlet pipes. Compared with the prior art, the present invention can be used to adjust the distance between the upper adjustment side wall plate and the side wall of the tapered cavity, the lower adjustment side wall plate and the side wall of the tapered cavity through the upper adjustment mechanism and the lower adjustment mechanism, respectively. The included angle strengthens the side wall flow field and provides side wall sorting effect for the particle group. At the same time, it can adjust the problem that the particle group moves to the middle of the conical cavity and begins to appear chaotic trajectory, so that the fine particles can smoothly pass through the conical cavity. Top edge overflow provides protection.

Owner:HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com