Muffle furnace silicon carbide heating system for manufacturing flexible glass and muffle furnace

A muffle furnace silicon carbide and heating system technology, applied in muffle furnaces, lighting and heating equipment, furnaces, etc., can solve the problems of unfavorable temperature control of the silicon carbide box glass liquid and difficult temperature control of the silicon carbide box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

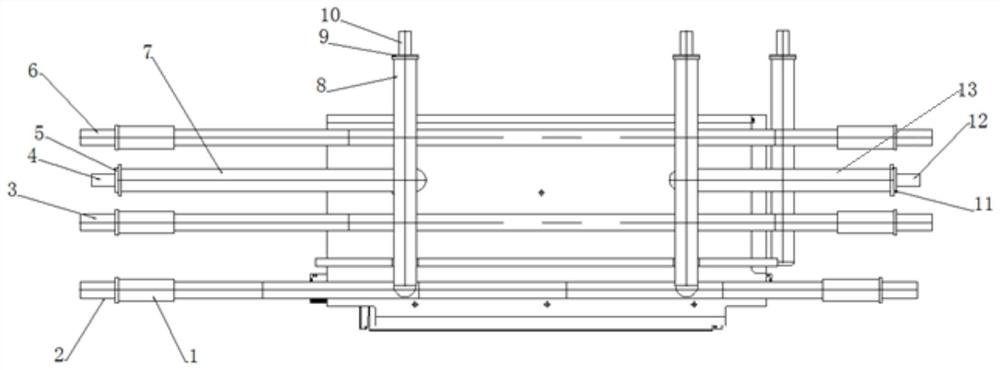

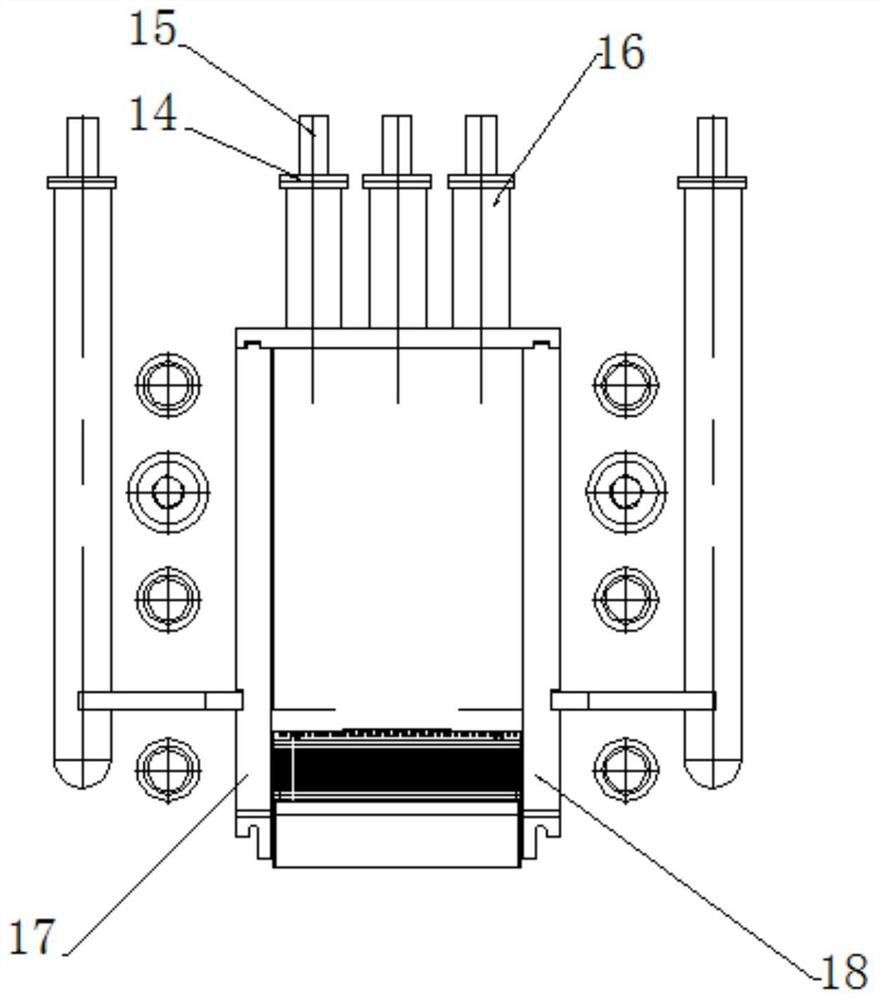

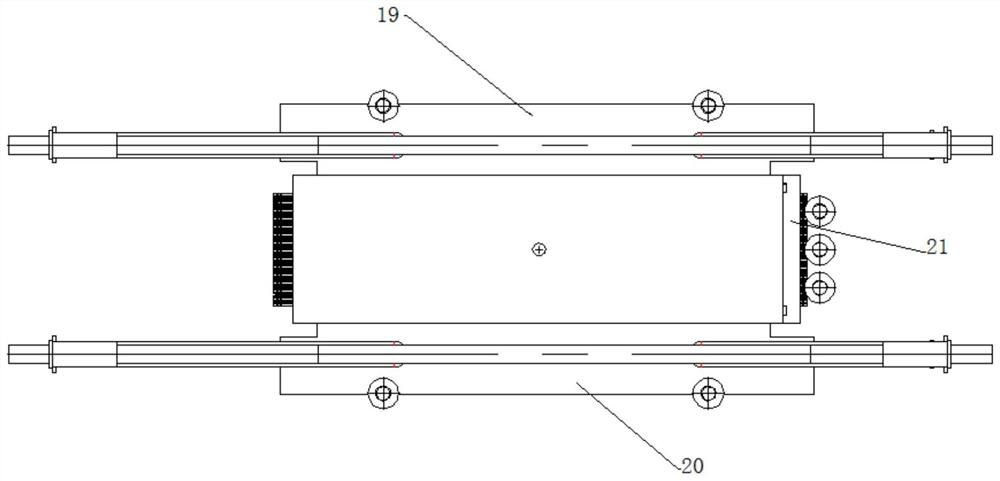

[0037] Such as figure 1 and figure 2 and image 3 As shown, the present invention provides a muffle furnace silicon carbide heating system for manufacturing flexible glass, including a silicon carbide box, and seven groups of heating rods are arranged around the silicon carbide box, which are respectively the first bottom heating group, the second The second central heating group, the third proximal heating group, the fourth top heating group, the fifth side vertical insertion heating group, the sixth distal heating group and the seventh distal vertical insertion heating group, the seven heating rods are respectively Arranged around the silicon carbide box according to the law, forming heat supplement for the silicon carbide box, and adjusting the power of the silicon carbide heating rod at a corresponding position at any time according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com