Grinding wheel vibration monitoring and alarming device for grinding machine and using method thereof

A technology of vibration monitoring and alarm equipment, which is applied in the direction of grinding/polishing equipment, grinding machines, metal processing equipment, etc., which can solve the problems of accelerated spindle wear, life-threatening, and offset between the center of mass of the grinding wheel and the center of rotation, etc., to reduce Danger, the effect of improving stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

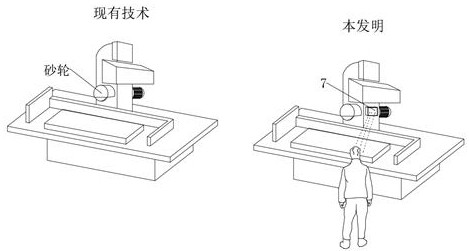

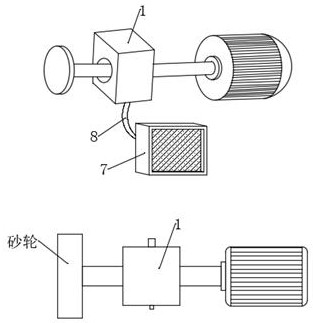

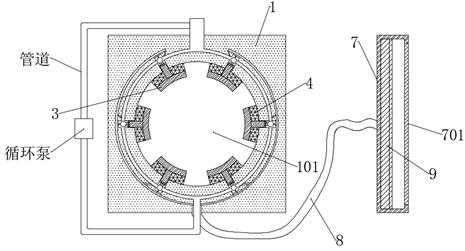

[0049] see Figure 1-10 , a grinding wheel vibration monitoring and alarm device for grinding machines, including the grinding machine body, see figure 1 , 2 , 4, 5. The grinding machine body includes a grinding wheel, a main shaft and a drive motor. The inside of the grinding machine body is fixedly connected with a vibration sensor 1 set outside the main shaft. The inner wall of the device 1 is provided with a closed paint circulation flow channel 102, and the vibration sensor 1 is located outside the paint circulation flow channel 102 and has an unclosed overflow channel 103. A connecting channel 104, a circulation loop is formed by a pipeline between the bottom and the upper part of the paint circulation flow channel 102, and a plurality of connecting channels 104 are all set up with the horizontal line as the standard, because the connecting channel 104 communicates with the paint circulation flow channel 102, in order to prevent The liquid paint in the paint circulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com