Liquid trap of rectification tower

A rectification tower and liquid collection technology, which is applied in the field of rectification tower liquid collection devices, can solve the problems of unsuitable installation of redistributors in rectification towers, uncontrollable wall flow phenomenon of rectification towers, and reduced overall performance of rectification towers. , to achieve the effect of low manufacturing cost, simple design and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

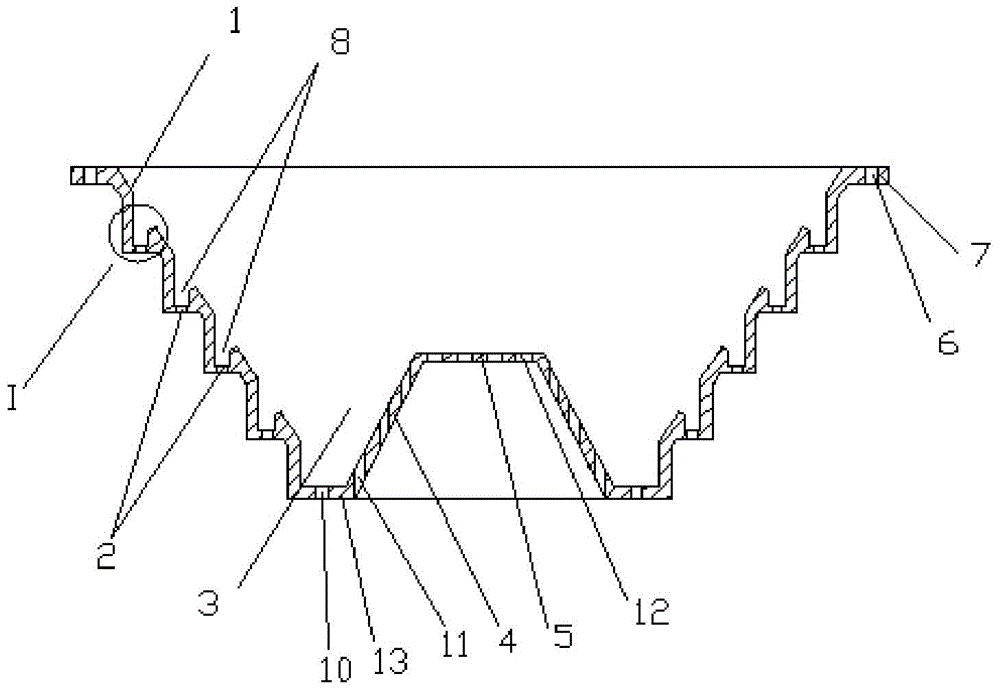

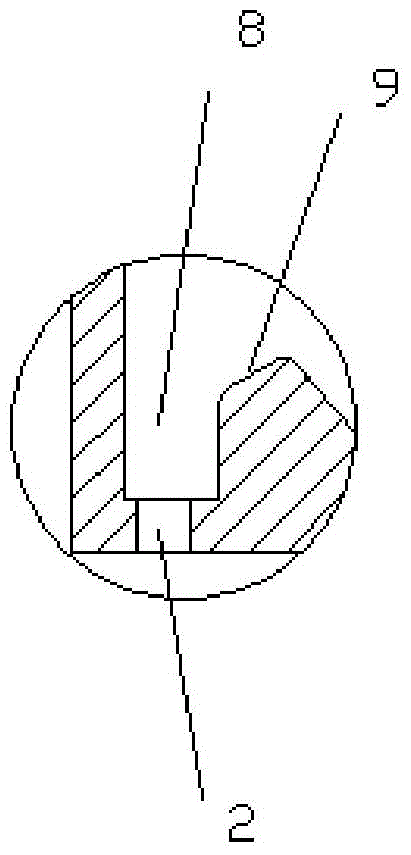

[0025] Such as figure 1 , figure 2 As shown, the rectifying tower liquid collection device includes an outer ring wall 1 and an inner ring wall 4, the height of the outer ring wall 1 is greater than the height of the inner ring wall 4, and the diameter of the top of the outer ring wall 1 is greater than that of the bottom end diameter, the top diameter of the inner ring wall 4 is smaller than the bottom end diameter, the bottom of the inner ring wall 4 and the bottom of the outer ring wall 1 are horizontally connected with a bottom plate 13, and the top of the inner ring wall 4 is horizontally provided with a top plate 5, the The outer ring wall 1, the bottom plate 13 and the inner ring wall 4 form the second liquid collection tank 3, and the outer ring wall 1, the inner ring wall 4, the bottom plate 13 and the top plate 5 form a liquid coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com