Method for recovering proteins in protein wastewater

A protein wastewater and protein technology, which is applied in peptide preparation methods, chemical instruments and methods, organic chemistry, etc., can solve the problems of limited acid adjustment ability, high recycling cost, unfavorable industrialization, etc., and achieve high production safety and low cost , Improve the effect of removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The present embodiment reclaims protein from protein wastewater by the following methods:

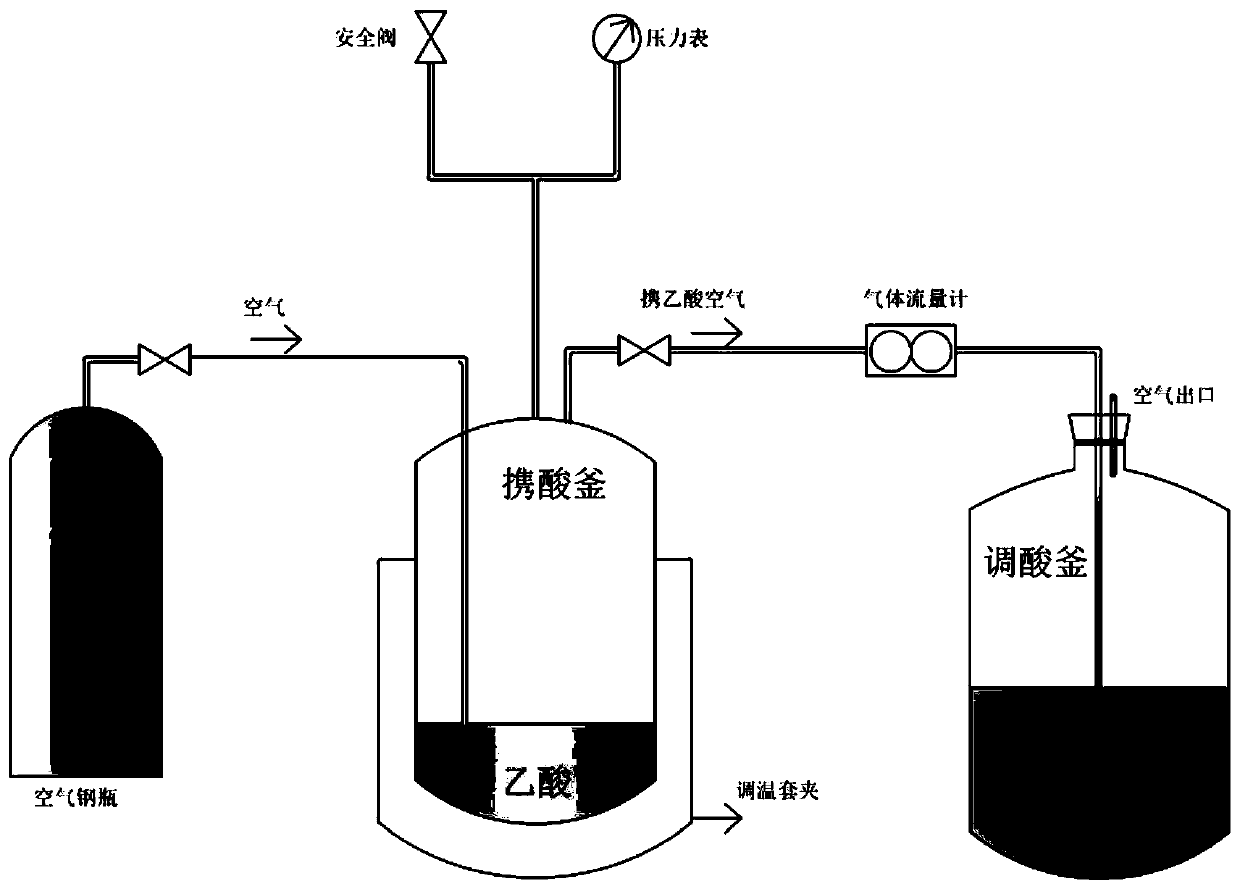

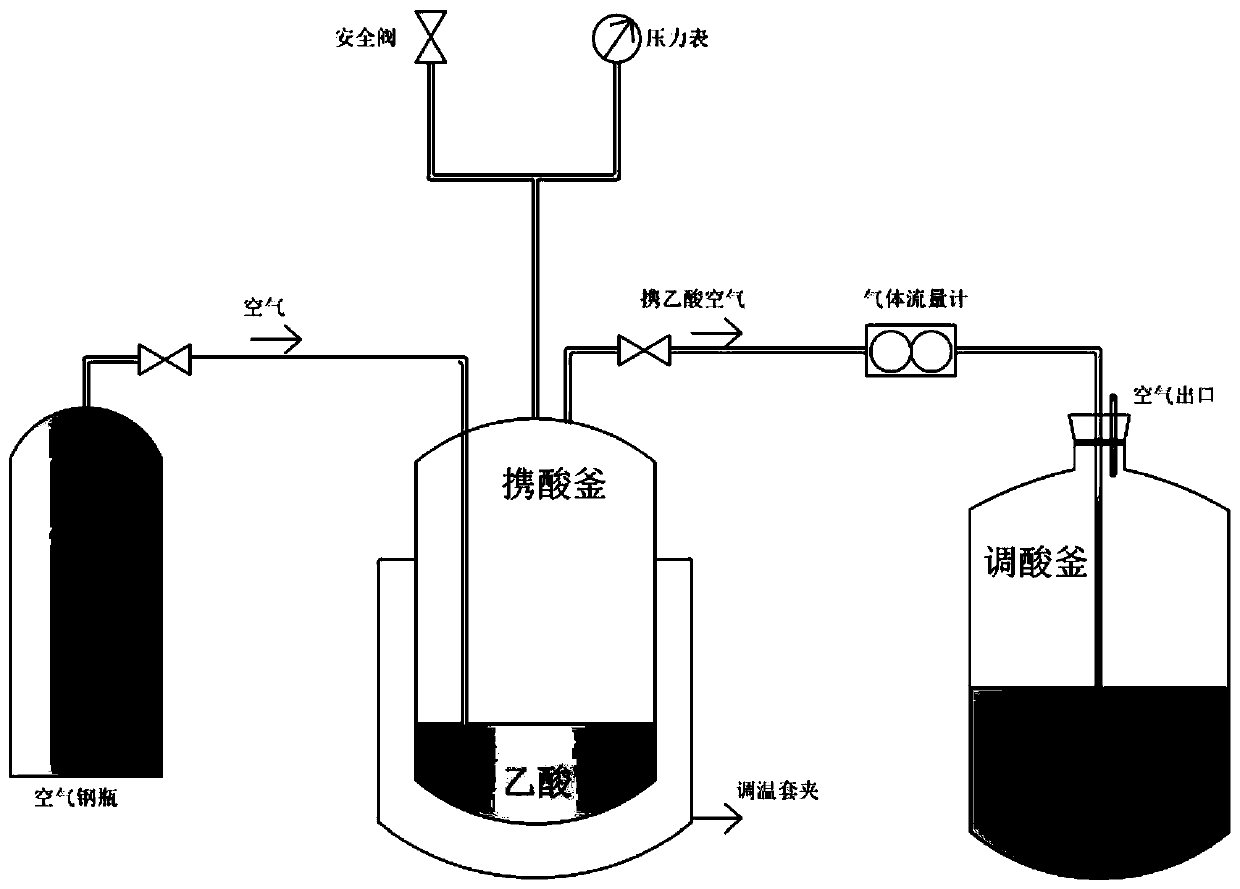

[0050] Select a kind of waste water produced after processing pollock surimi. The initial pH value of the surimi wastewater is about 7.0. According to the analysis of protein components, the protein concentration of the waste water is 7.6 mg / mL after centrifugation pretreatment, and the isoelectric point is relatively dense. Concentrated in the vicinity of 6.40, 5.10 and 4.30, according to the analysis results, the proteins are divided into three levels according to the isoelectric point of the protein from the largest to the smallest. Among them, recycling equipment such as figure 1 shown.

[0051] First-level isoelectric precipitation, adding acetic acid to the acid-carrying kettle, passing air through the pressure buffer steel cylinder, and feeding air into the acid-carrying kettle, the safety valve of the acid-carrying kettle is kept at an absolute pressure of 1.5atm, and th...

Embodiment 2

[0055] The present embodiment reclaims protein from protein wastewater by the following methods:

[0056] Select a kind of wastewater produced after processing blue cod surimi. The initial pH value of the surimi wastewater is about 7.2. According to the analysis of protein components, the protein concentration of the wastewater after centrifugation pretreatment is 7.1mg / mL, and the isoelectric point is relatively dense. Concentrated in the vicinity of 6.45, 5.20 and 3.25, according to the analysis results, the proteins are divided into three levels according to the isoelectric point of the protein from the largest to the smallest.

[0057] First-level isoelectric precipitation, add acetic acid to the acid-carrying kettle, pass air through the pressure buffer steel cylinder, and feed air into the acid-carrying kettle. The acid-adjusting kettle maintains normal temperature and pressure, and the pH value of the acid-adjusting kettle reaches 6.45±0.05. After the gas in the acid a...

Embodiment 3

[0061] The present embodiment reclaims protein from protein wastewater by the following methods:

[0062] Select a kind of wastewater produced after processing mixed surimi. The initial pH value of the surimi wastewater is about 7.2. According to the analysis of protein components, the protein concentration of the wastewater after centrifugation pretreatment is 8.9 mg / mL, and the isoelectric point is relatively dense. Concentrated in the vicinity of 6.40, 5.15, 4.30 and 3.25, according to the analysis results, the proteins are divided into three levels according to the isoelectric point of the protein from the largest to the smallest.

[0063] First-level isoelectric precipitation, adding acetic acid to the acid-carrying kettle, passing air through the pressure buffer steel cylinder, and passing air into the acid-carrying kettle, the safety valve of the acid-carrying kettle is kept at an absolute pressure of 1.3atm, and the temperature of the acid-carrying kettle is 25°C. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com