Pump driven two-phase fluid loop evaporator

A fluid circuit and evaporator technology, used in the field of pump-driven two-phase fluid circuit evaporators, can solve the problems of easy accumulation of liquid, large contact thermal resistance, large thermal resistance, etc. Effect of Evaporative Heat Transfer Coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will contribute to the skill in the art

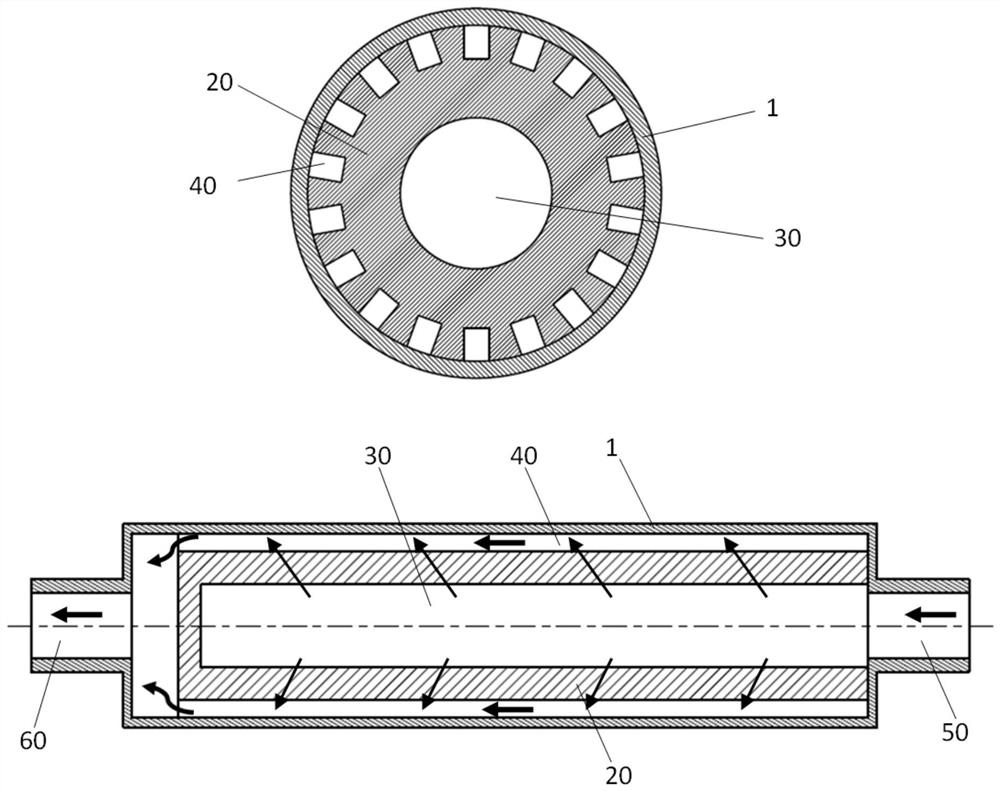

[0037] As shown in Figure 1, Figure 3 to Figure 6, a pump-driven two-phase fluid circuit evaporator provided according to the present invention. for

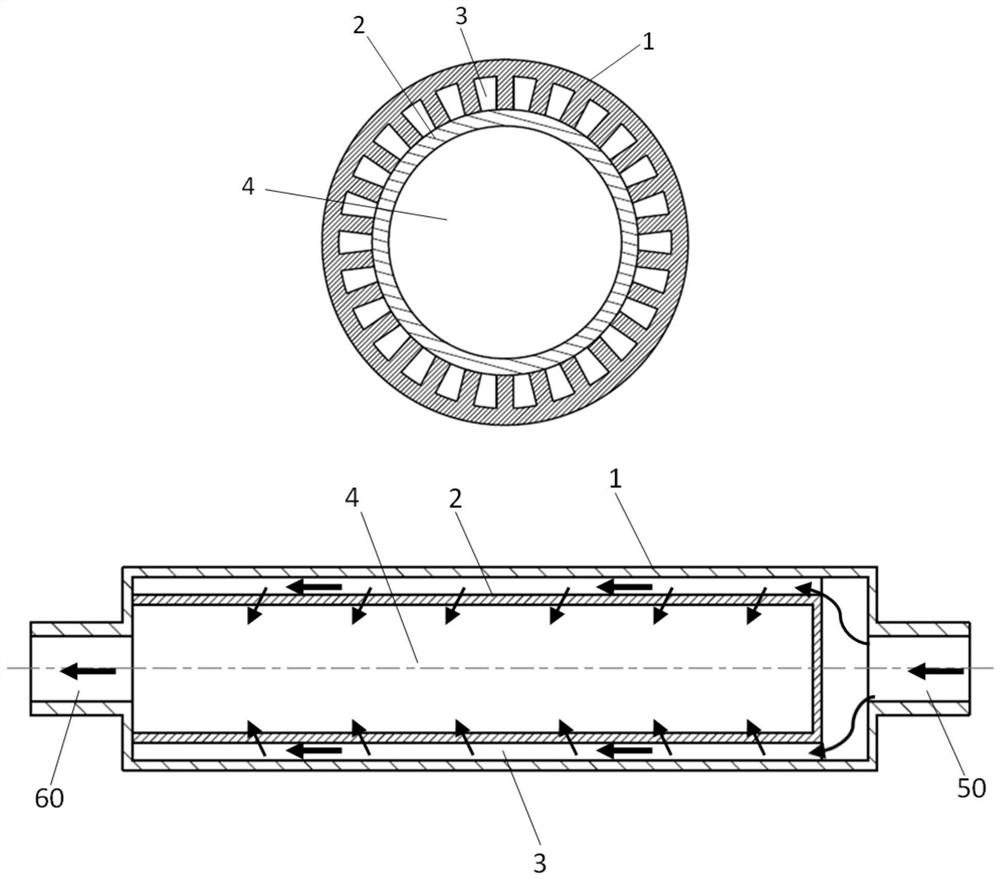

[0038] The design of a conventional two-phase fluid loop cylindrical evaporator is shown in Figure 2. The evaporator uses a hydrophilic reverse

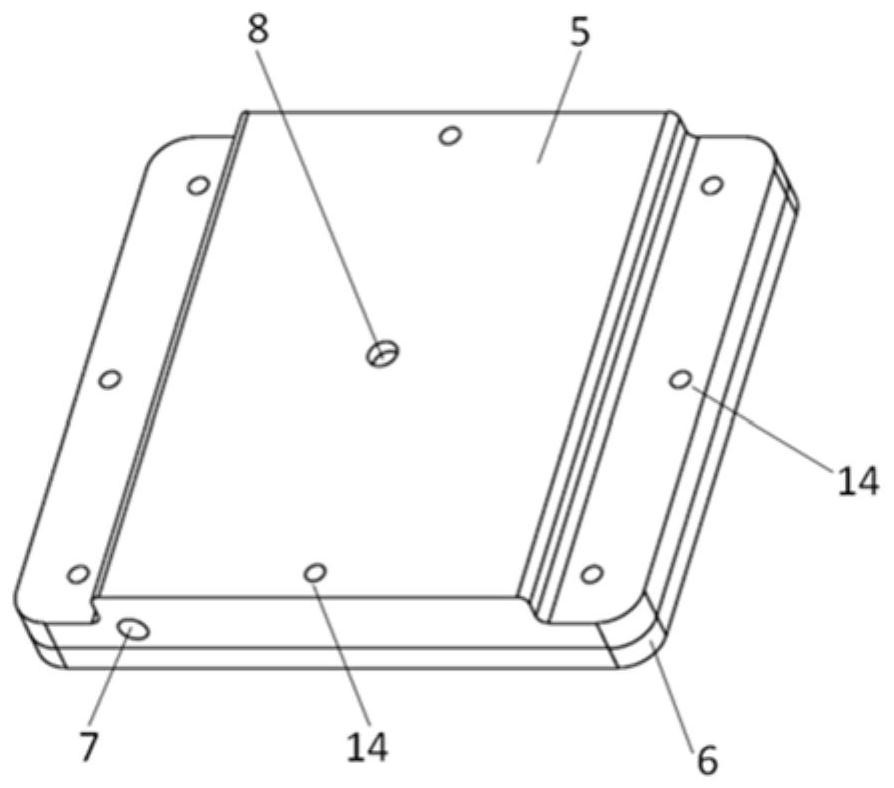

[0039] Further, for the specific implementation example of the flat plate evaporator, as shown in FIG. 3 and FIG. 4 . Its structure includes: top cover

[0040] Further, it also includes: a slit 12; the slit 12 communicates with the liquid flow channel through hole 7. under the slit 12

[0042] The specific embodiments of the present invention have been described above. It should be understood that the present invention is not limited to the above

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com