A continuous casting tundish turbulence device

A continuous casting tundish and turbulator technology, which is applied in the field of iron and steel metallurgy equipment to achieve the effects of reducing turbulence and jetting, improving overall life and reducing scouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described now in conjunction with accompanying drawing.

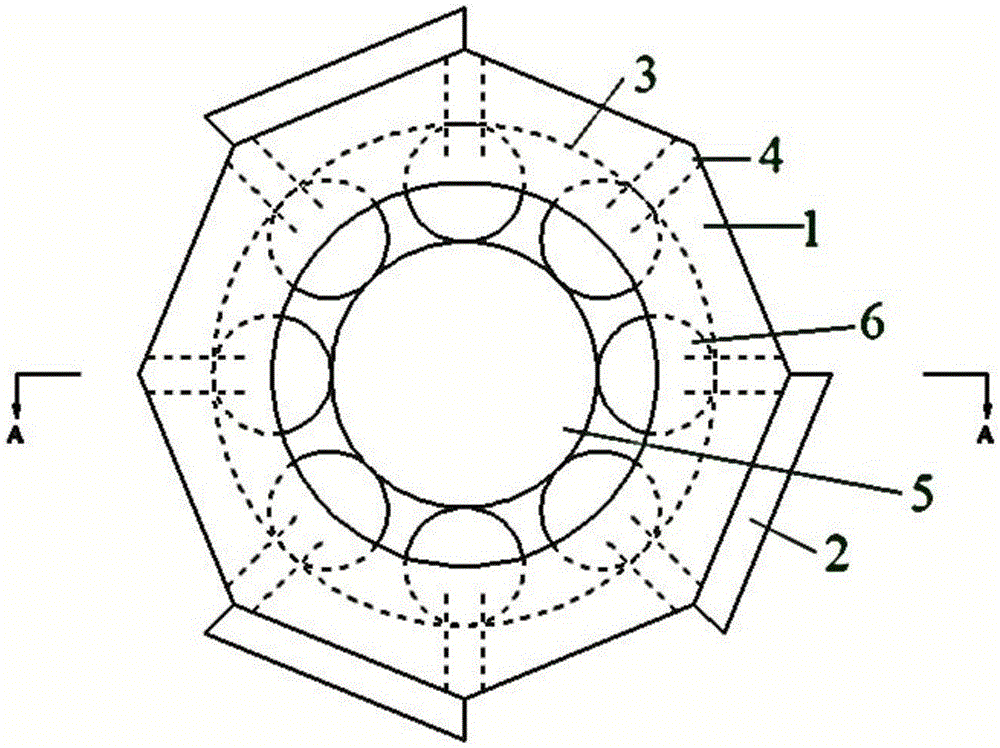

[0026] The invention provides a continuous casting tundish turbulator, which is installed under the ladle shroud and inside the tundish. Such as figure 1 As shown, the external structure of the turbulator is an octagonal prism 1, and three bosses 2 are distributed on its eight cylinders at intervals. A cylinder, set the first boss on this cylinder, set the second boss at two cylinders in the clockwise direction, and then set the third boss at one cylinder; three bosses 2 in When the tundish is built, it is built into the bottom of the tundish, which can effectively fix the turbulence device, prevent the turbulence device from floating in the early stage of use of the tundish, and ensure that the turbulence device does not float after the tundish is used in the later stage of use.

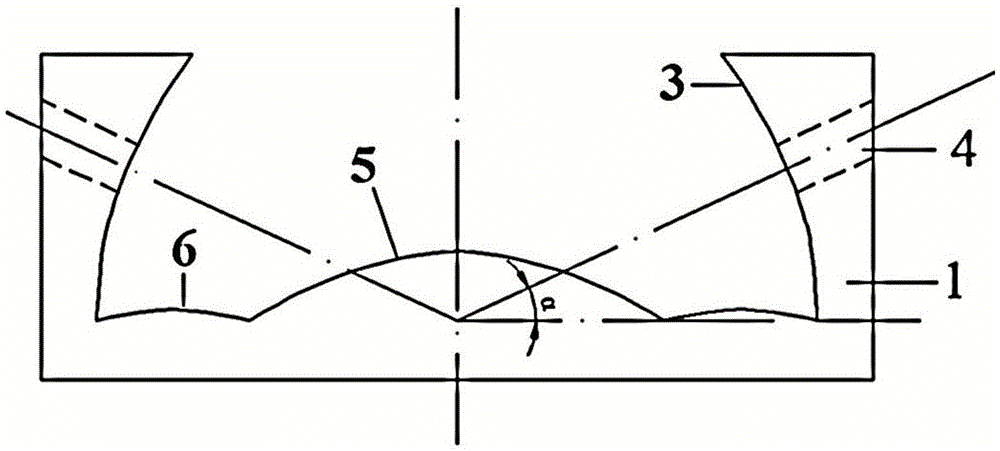

[0027] Such as figure 1 and figure 2 As shown, the inside of the turbulator is a cavity, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com