PHC tubular pile pile-sinking device used for penetrating deep and dense sand (gravel) layer

A PHC pipe pile, dense technology, applied in the field of foundation engineering, can solve problems such as difficult control of construction quality, unstable bearing capacity, excessive erosion, etc., to achieve the effect of guaranteed penetration effect and quality, convenient installation and operation, and easy guarantee of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

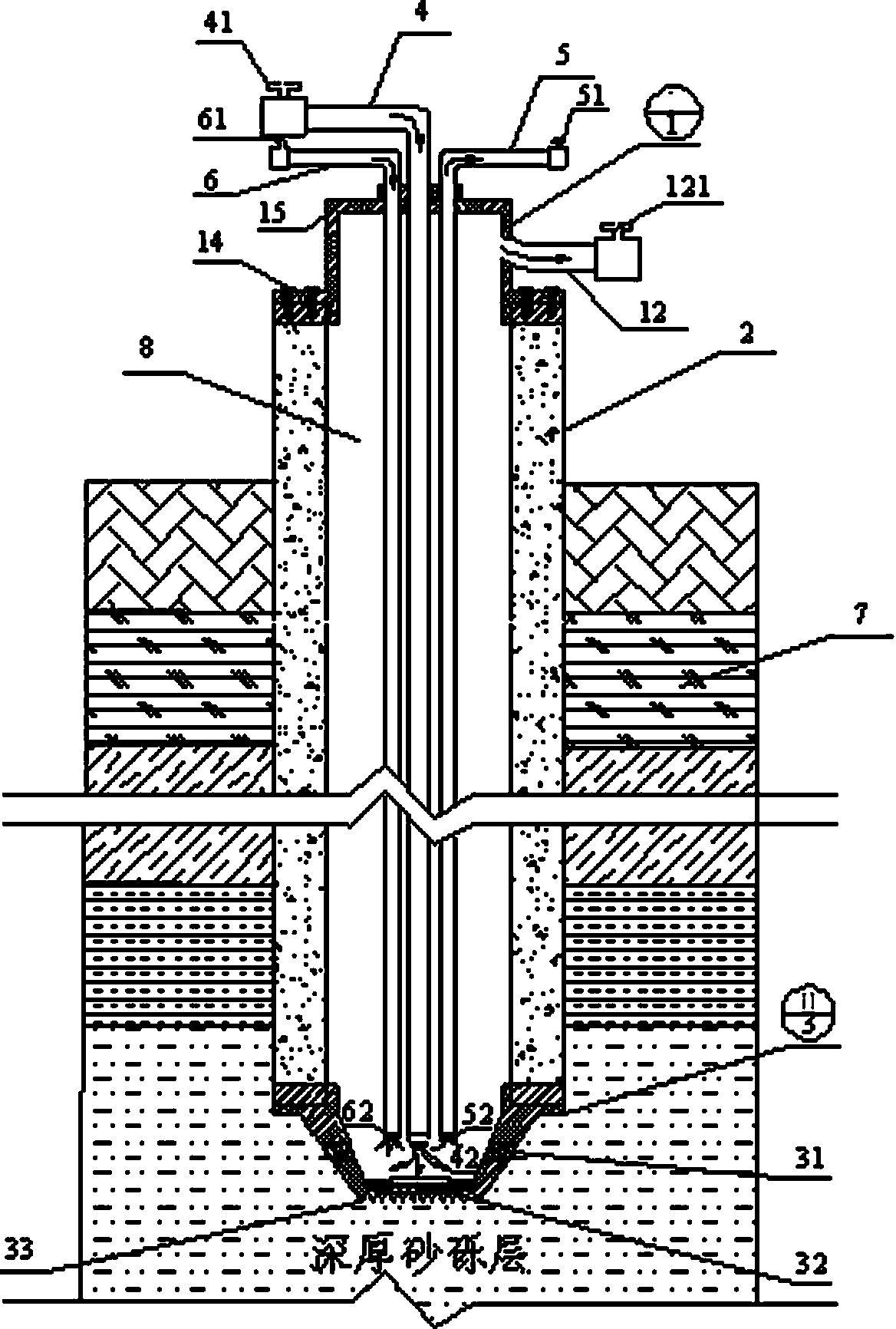

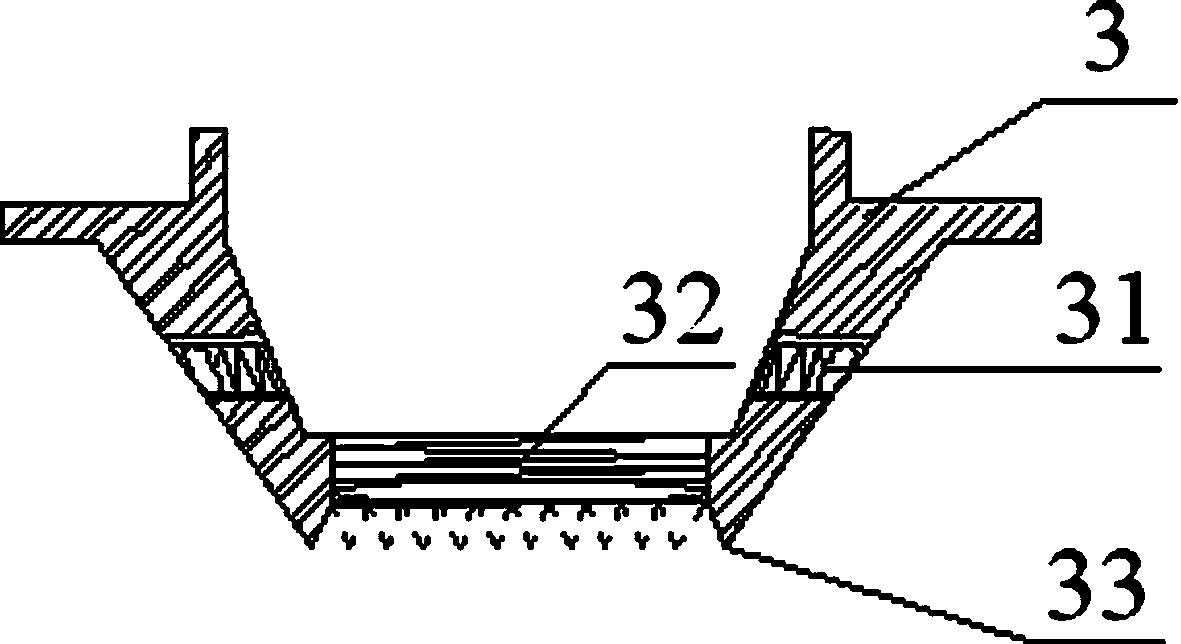

[0021] Further illustrate the present invention below in conjunction with accompanying drawing.

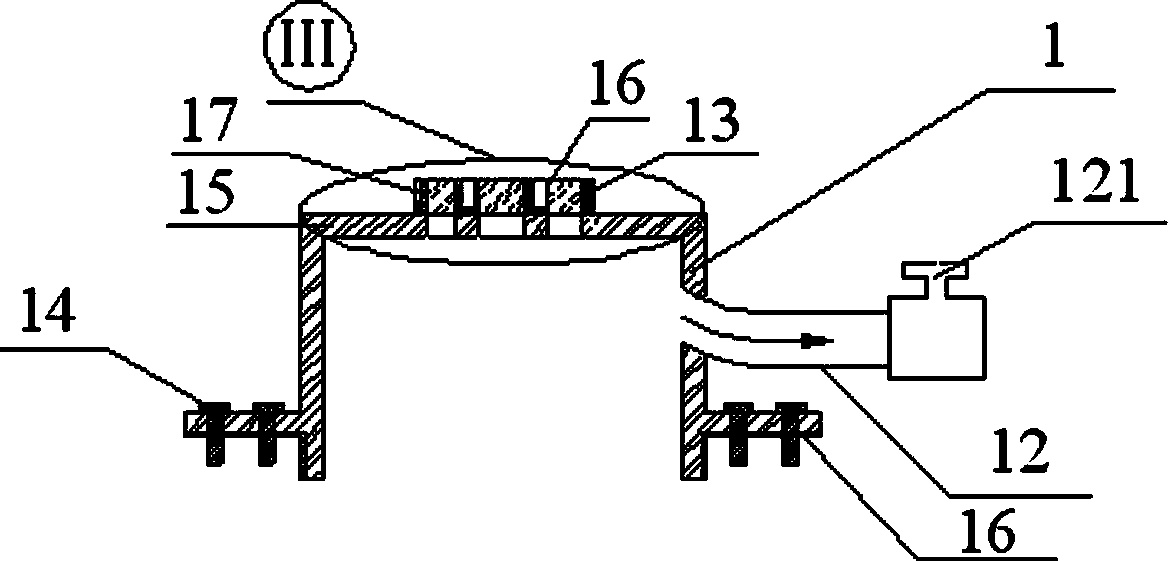

[0022] Such as figure 2 , 4 As shown, there is a slurry outlet pipe (12) on the side of the pile cap (1), and the upper metal partition (15) of the pile cap (1) has a slurry inlet pipe (4), an air intake pipe (6), and an exhaust pipe. The hollow area (B) where the pipe (5) is lowered and the airtight fixing device (A) and (Aˊ), wherein the airtight fixing device (A) and (Aˊ) are connected through the movable sheet (13), and the airtight fixing device (A) and The upper metal partition (15) is integrated, the lower metal baffle (Bˊ) of the airtight fixture (Aˊ) is slightly higher than the upper metal partition (15), and can move around the movable leaf (13), and the lower metal baffle (Bˊ) The shape and size match the hollow area (B), and the bolt holes (181), (182) and (183) are used for sealing when sealing and fixing. The pile cap (1) and the PHC pipe pile (2) and There are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com