Patents

Literature

30results about How to "Not easy to collapse holes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

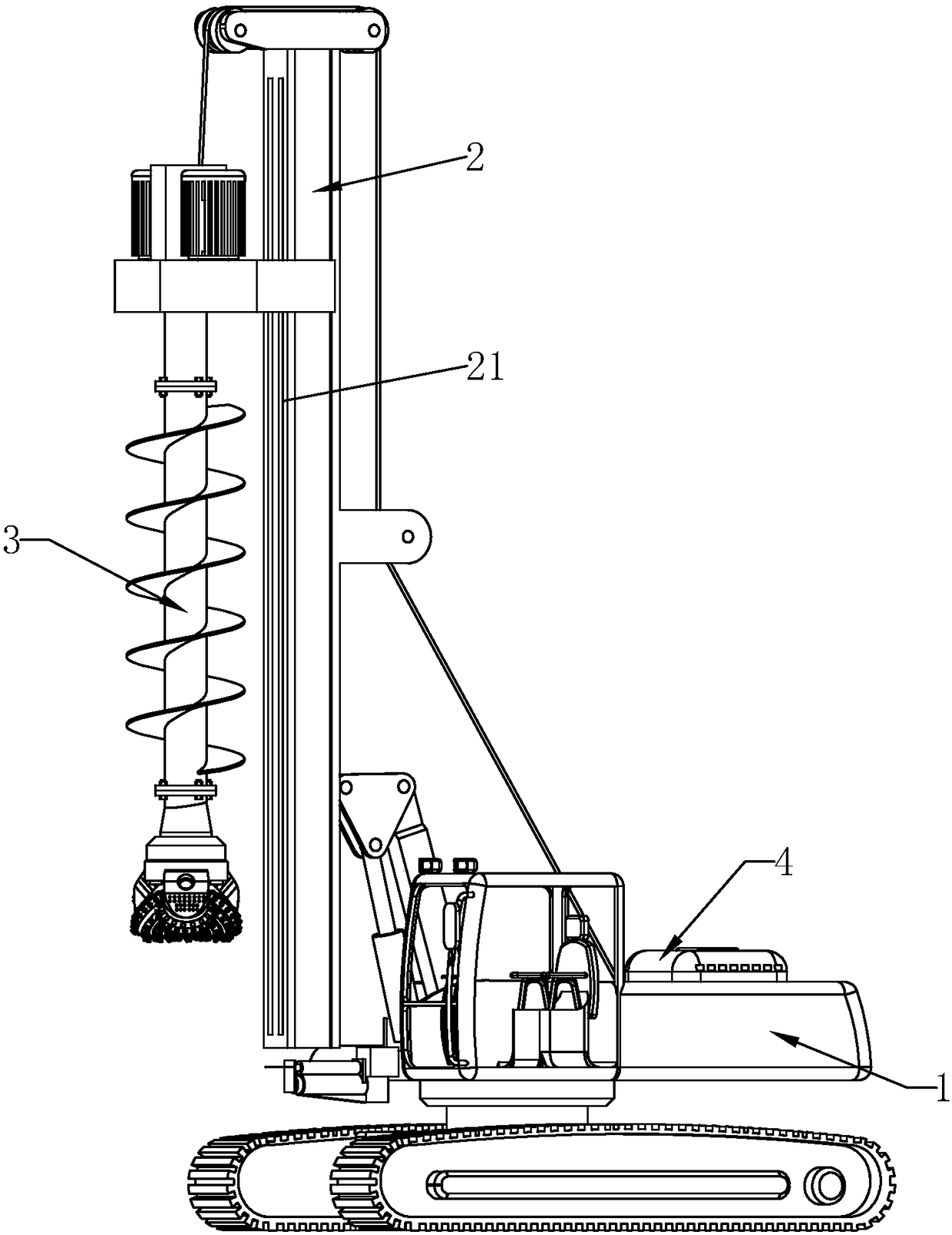

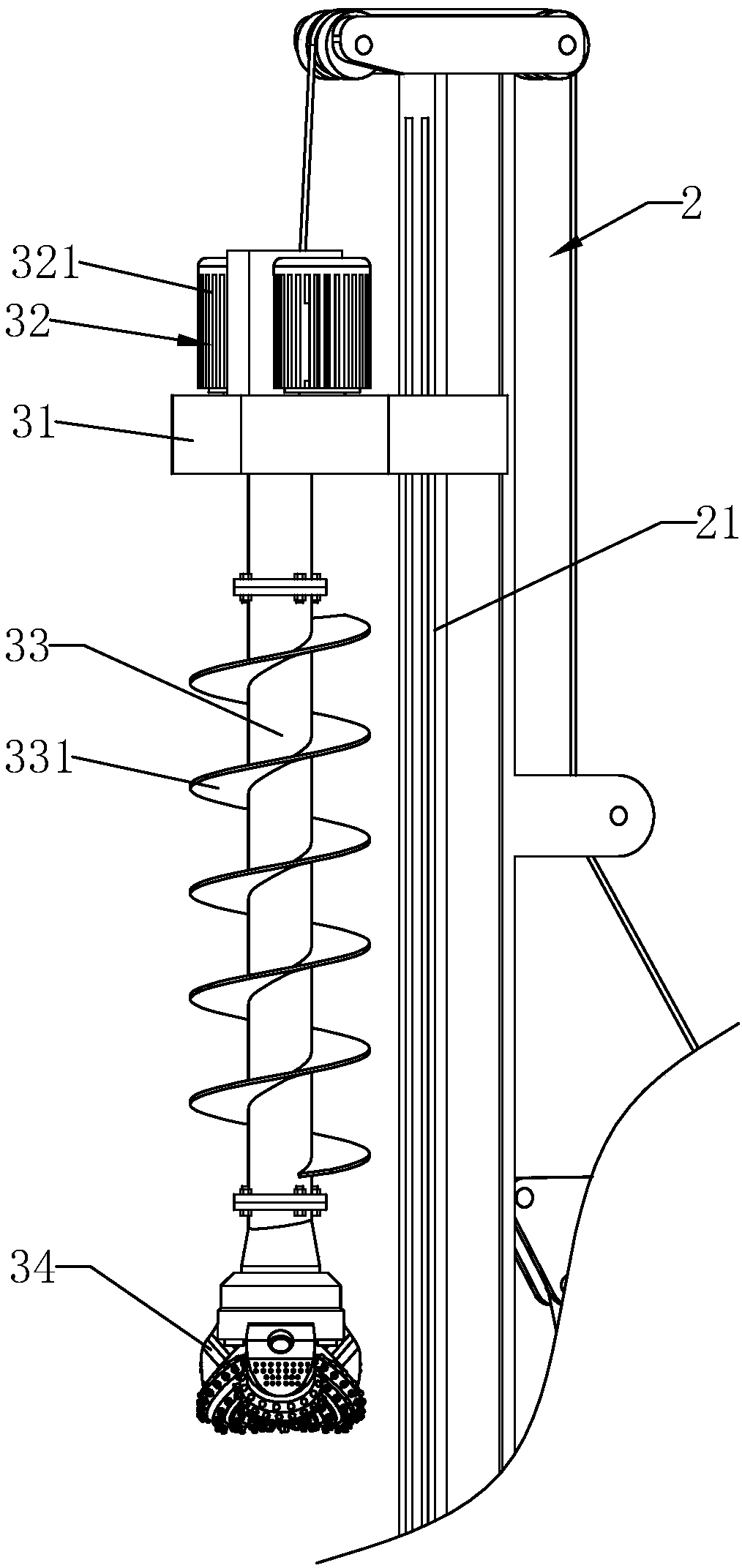

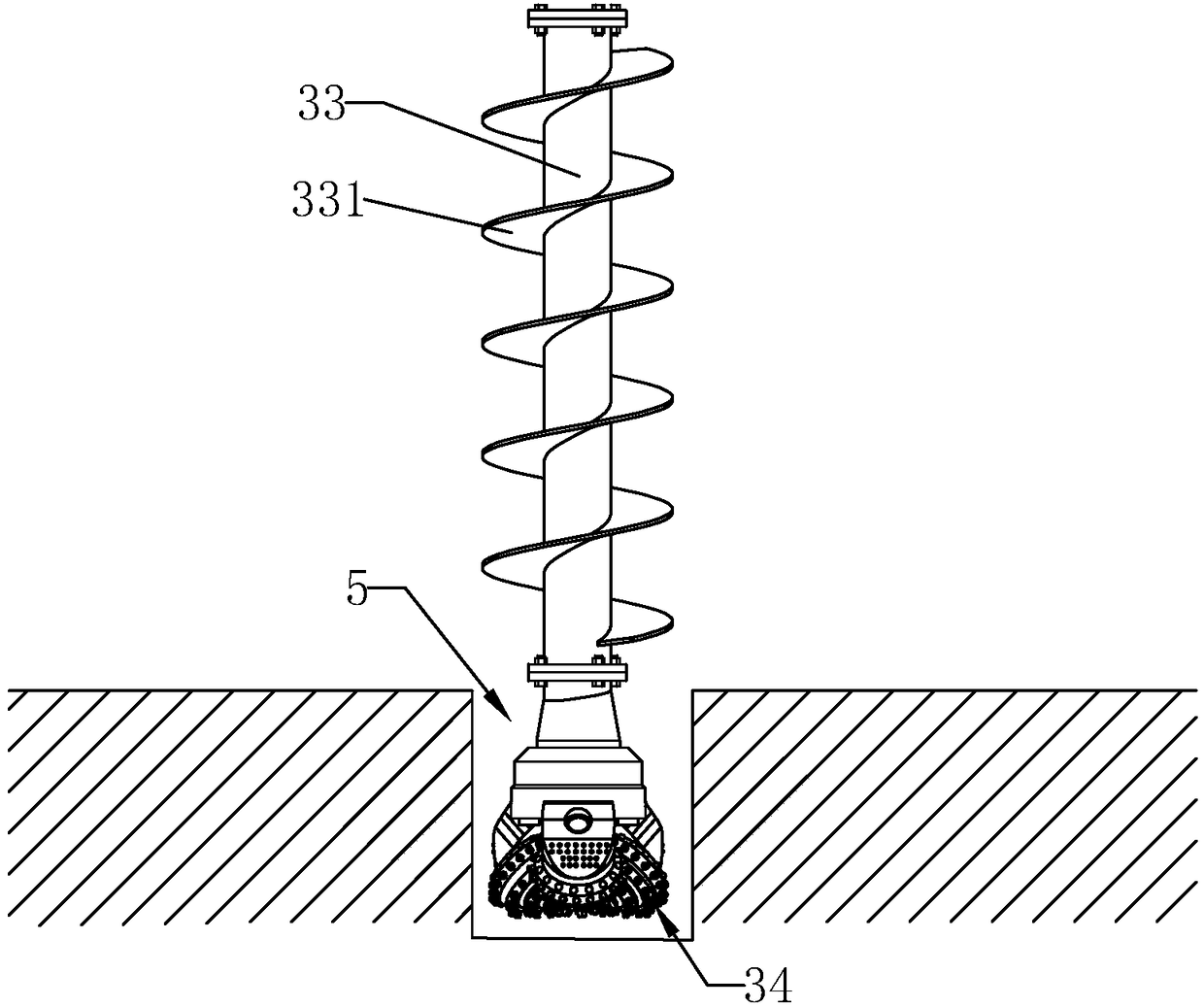

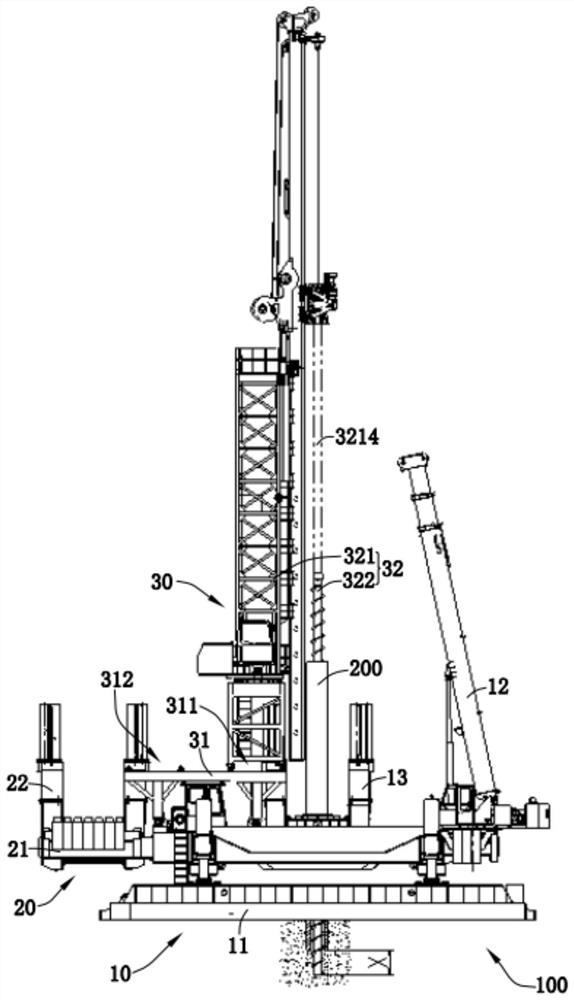

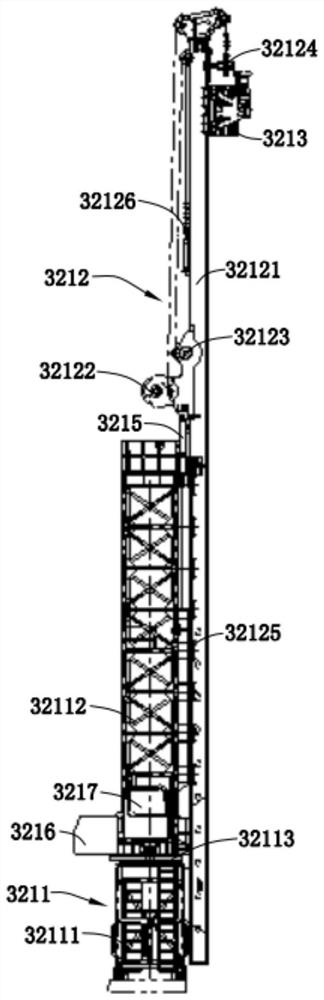

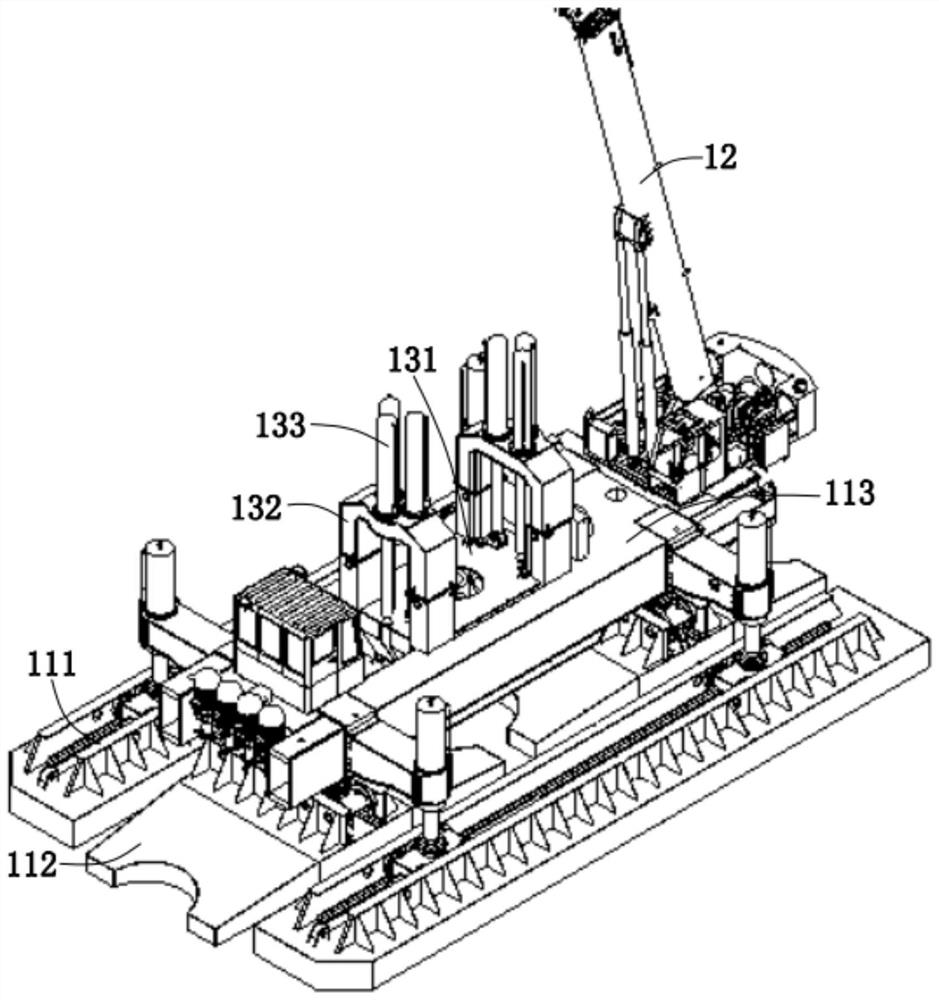

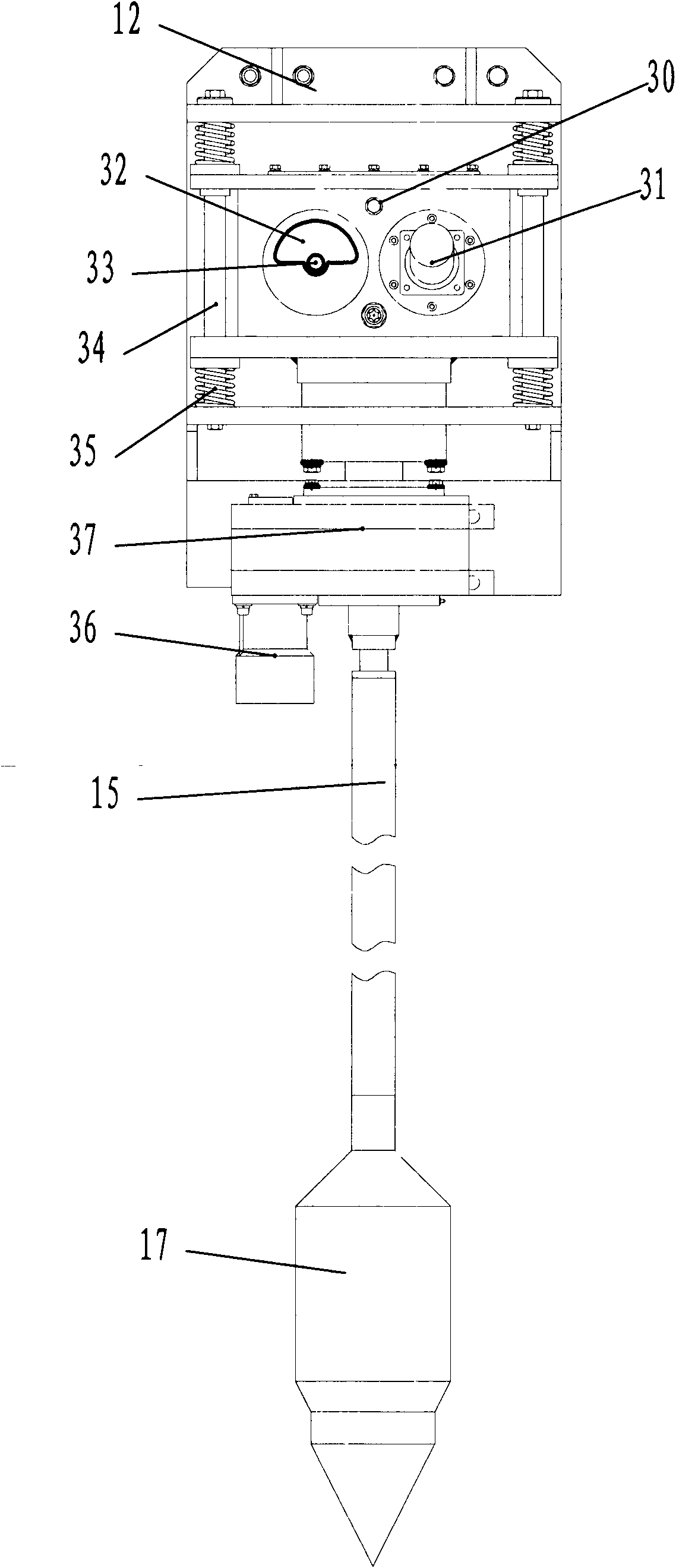

Long spiral extrusion pile drilling machine and drilling method thereof

PendingCN108086910AReduce hole collapseEasy to drillDirectional drillingSealing/packingHole drilling methodDrilling machines

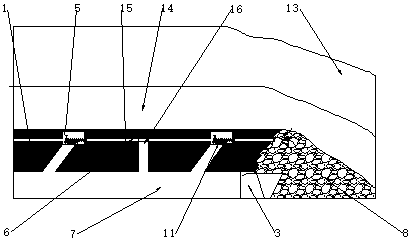

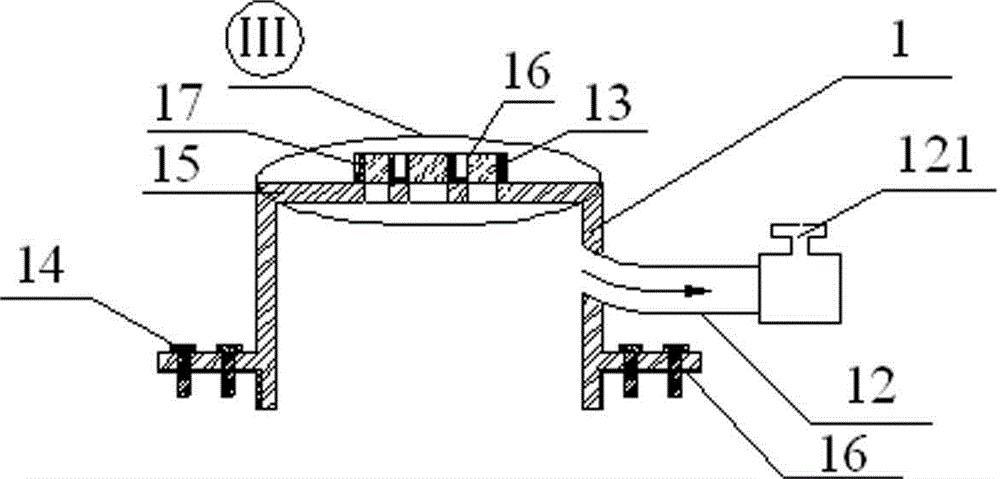

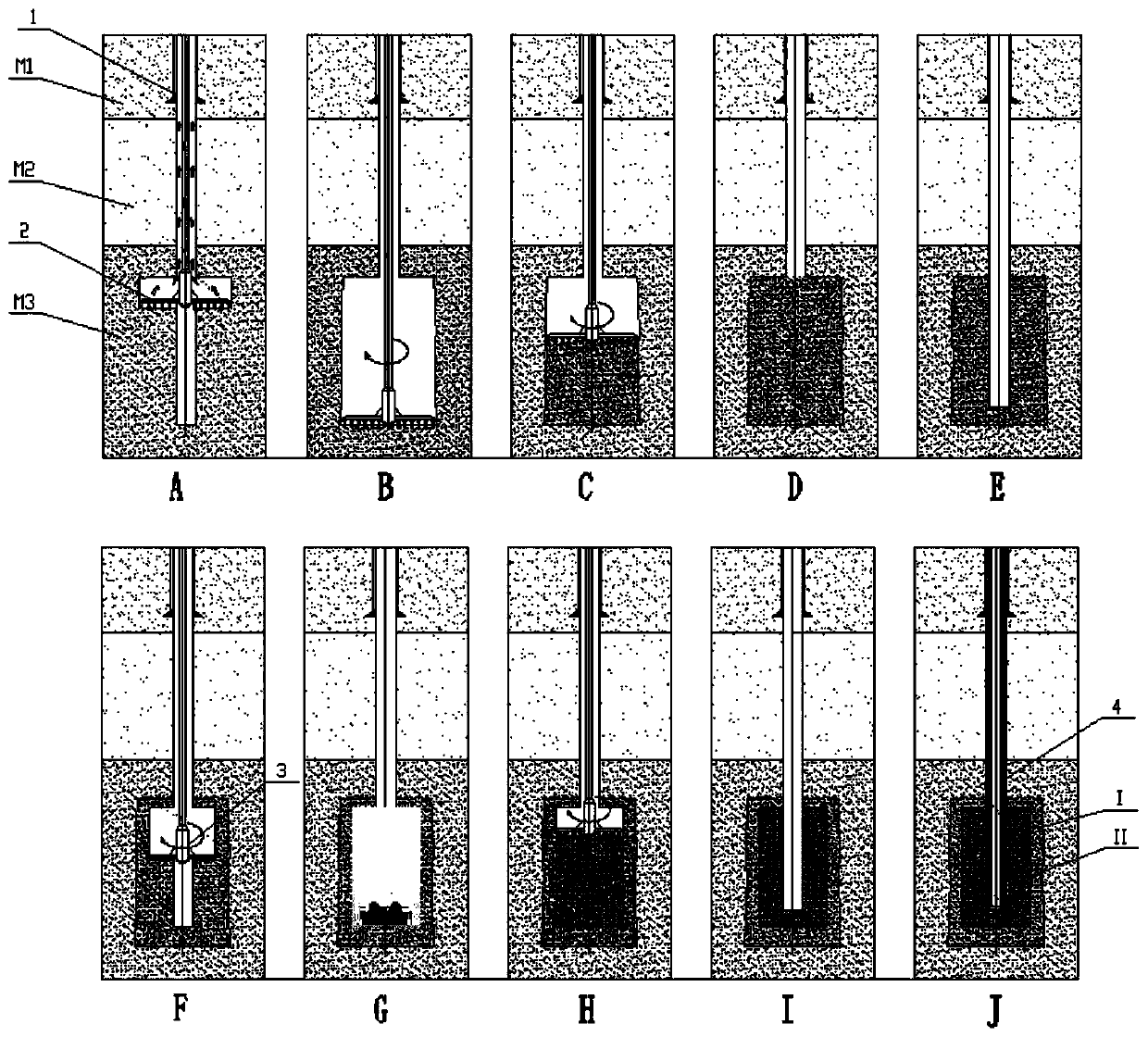

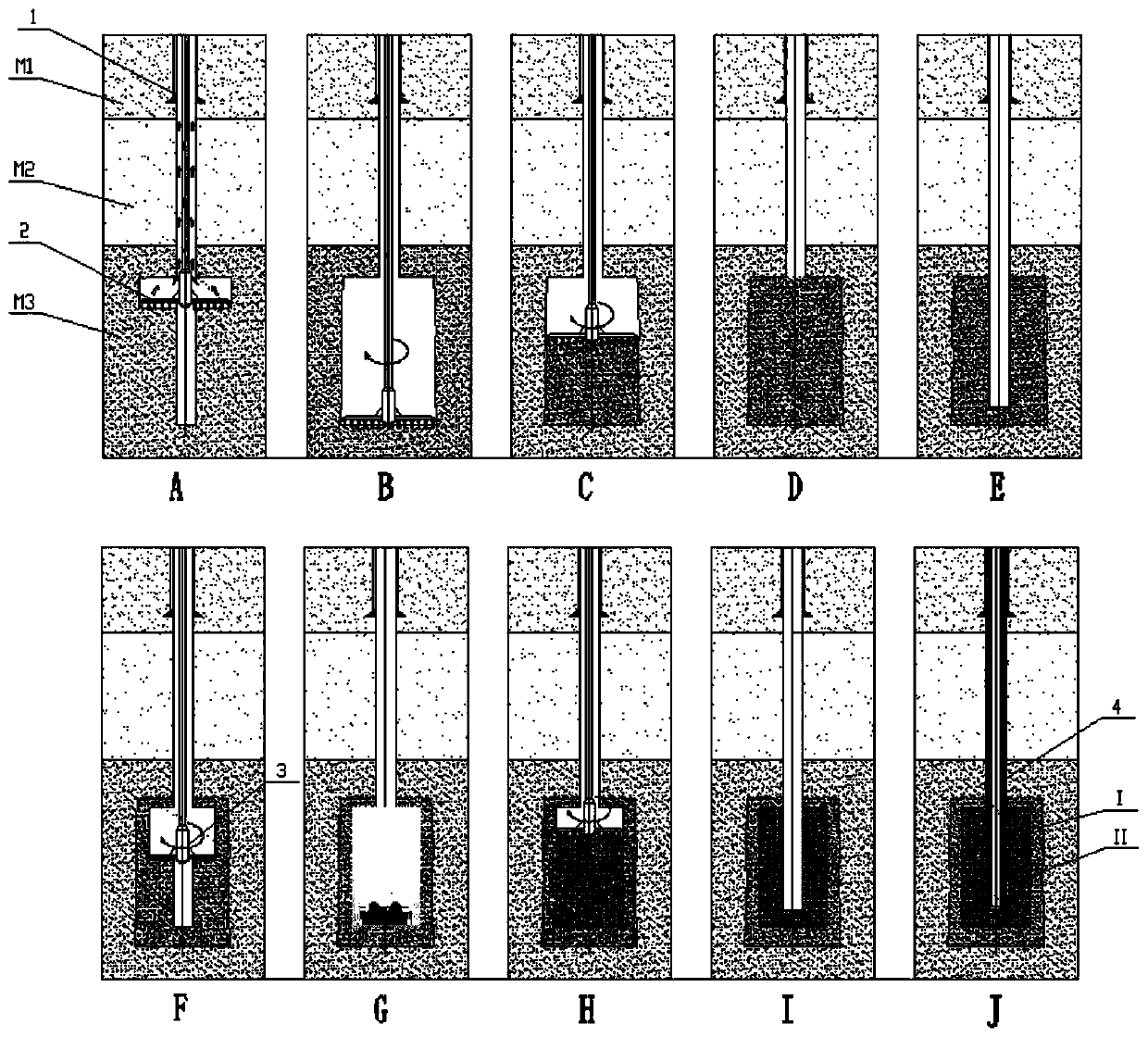

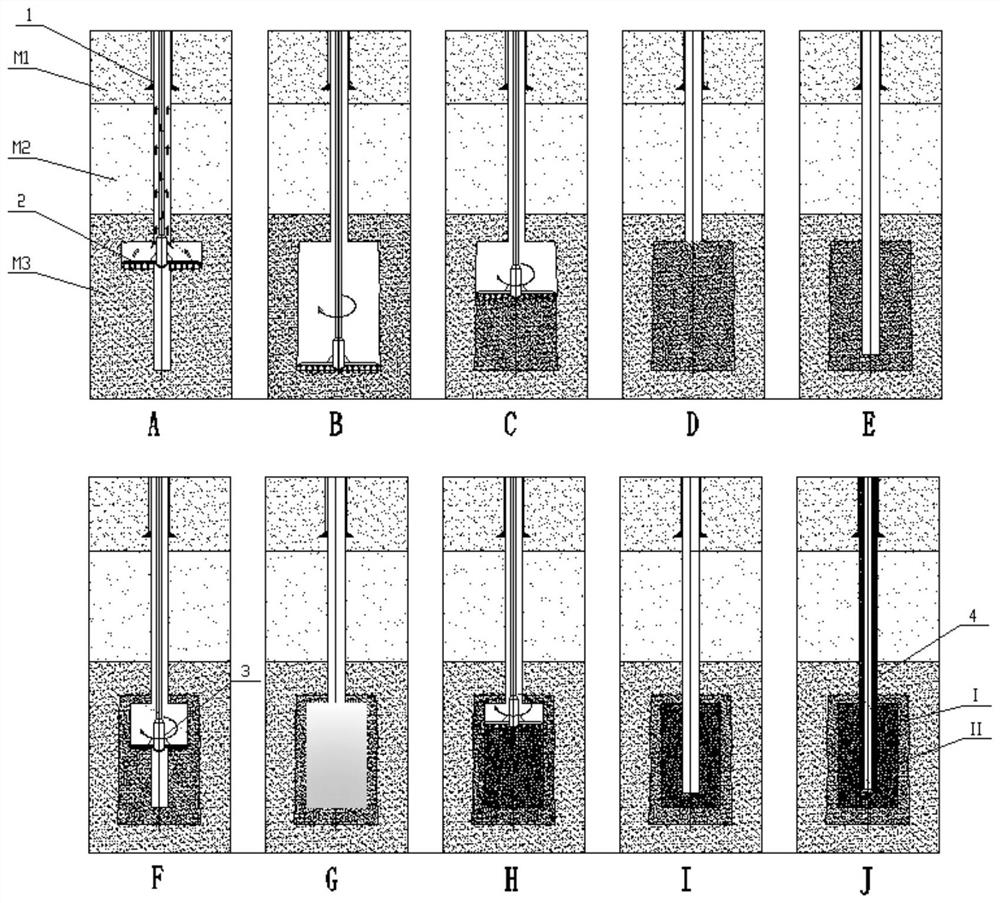

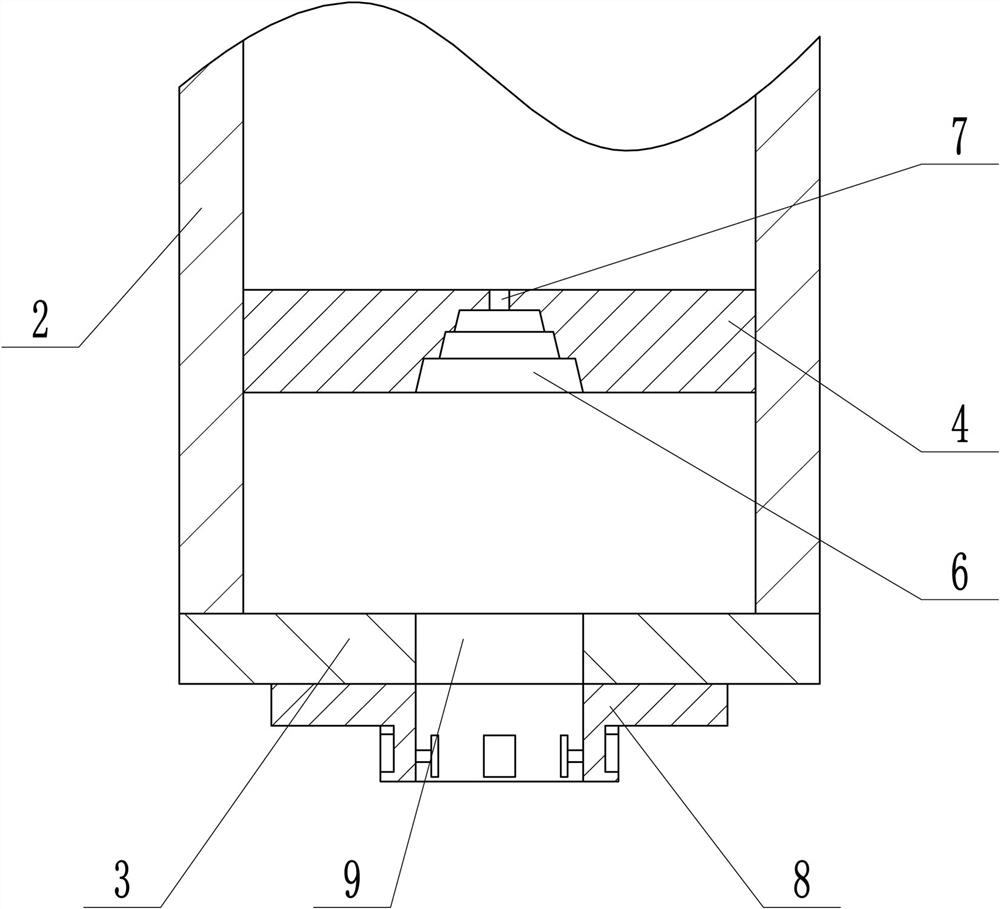

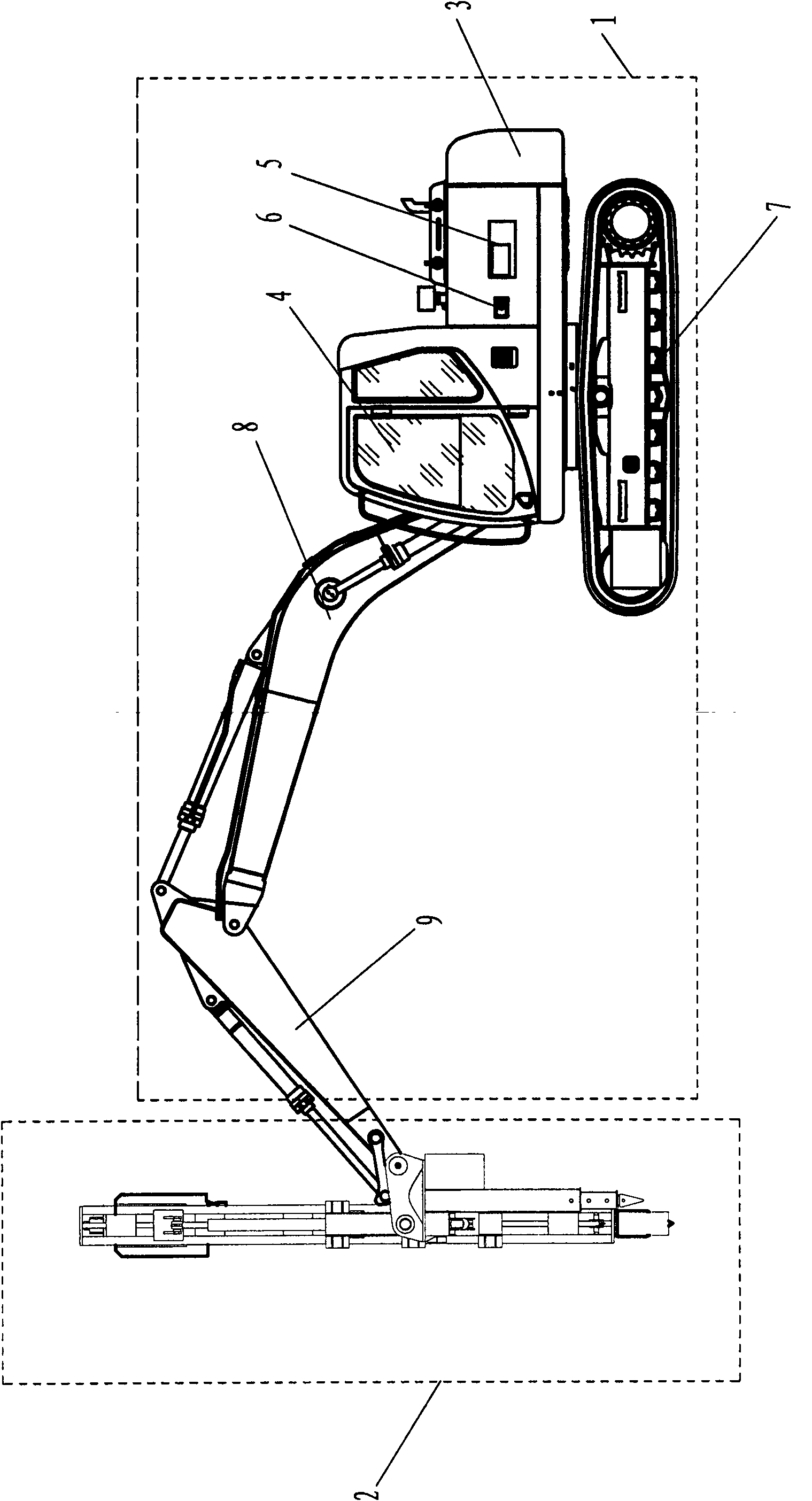

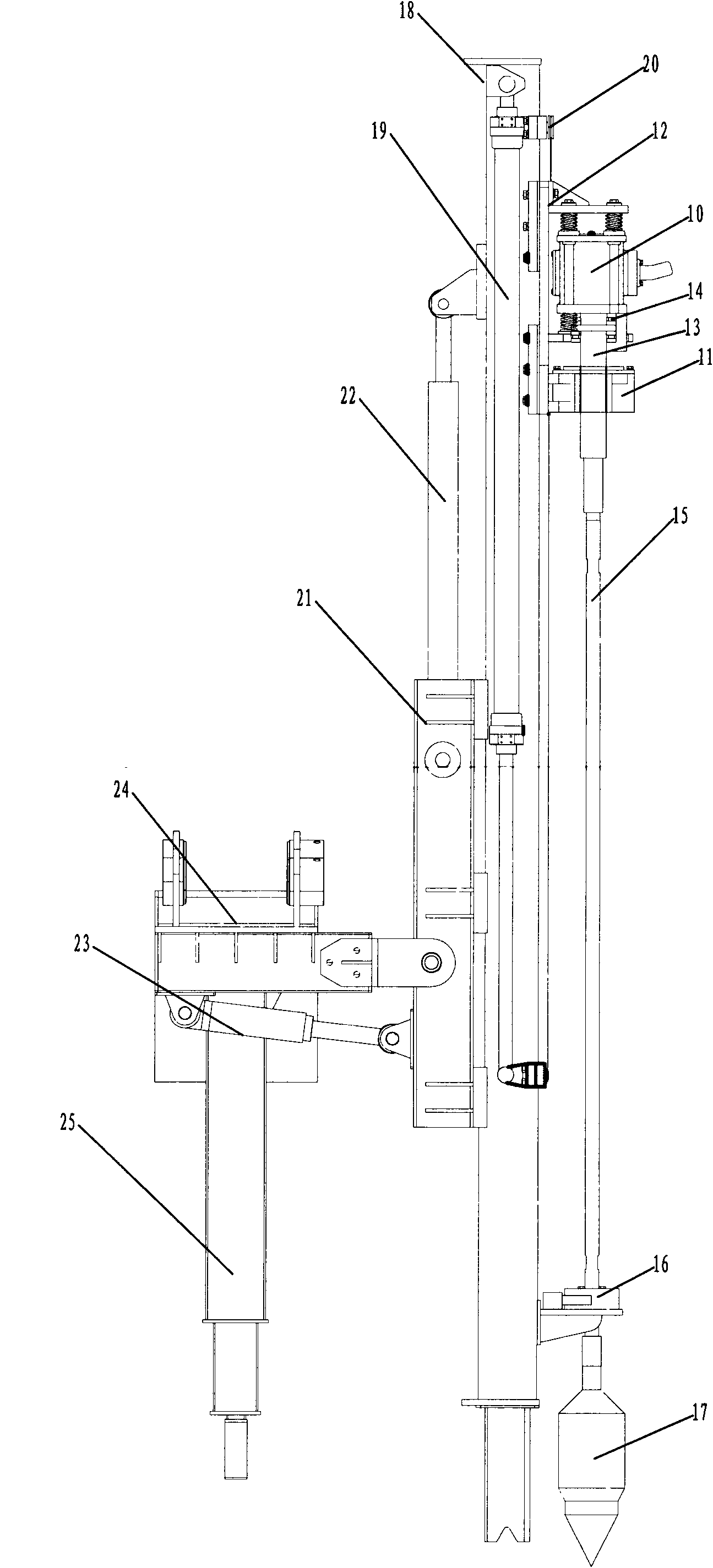

The invention discloses a drilling method of a long spiral extrusion pile drilling machine. The drilling method includes step a, pushing a drill pipe vertically and downwardly to drill a hole; step b,when the drill pipe reaches a certain drilling depth, pulling up the drill pipe; step c, adding an assistant extruder into the drill hole, and re-pushing the drill pipe; step d, repeating the steps S2 and S3 until the drill hole is formed. The invention further discloses the long spiral extrusion pile drilling machine. The long spiral extrusion pile drilling machine comprises an extruding machinebody, a pile frame, a drilling mechanism and a hoisting mechanism. The pile frame is vertically fixed to the extruding machine body, the drilling mechanism slides on the pile frame, and the hoistingmechanism used for driving the drilling mechanism to lift up and down is arranged on the extruding machine body. The drilling mechanism comprises a mounting plate, a power head, the drill pipe and a roller bit. The mounting plate is connected to the pile frame slidably. The power head is fixed to the mounting plate. The drill pipe is arranged on the lower side of the mounting plate, and is connected with the power head rotationally. The roller bit is fixed to one end, away from the power head, of the drill pipe. During drilling, the drill hole is reinforced, drill pipe lifting can be realized,and accordingly, the drill hole is not easy to collapse.

Owner:BEIJING G&M ENG CONSTR CO LTD

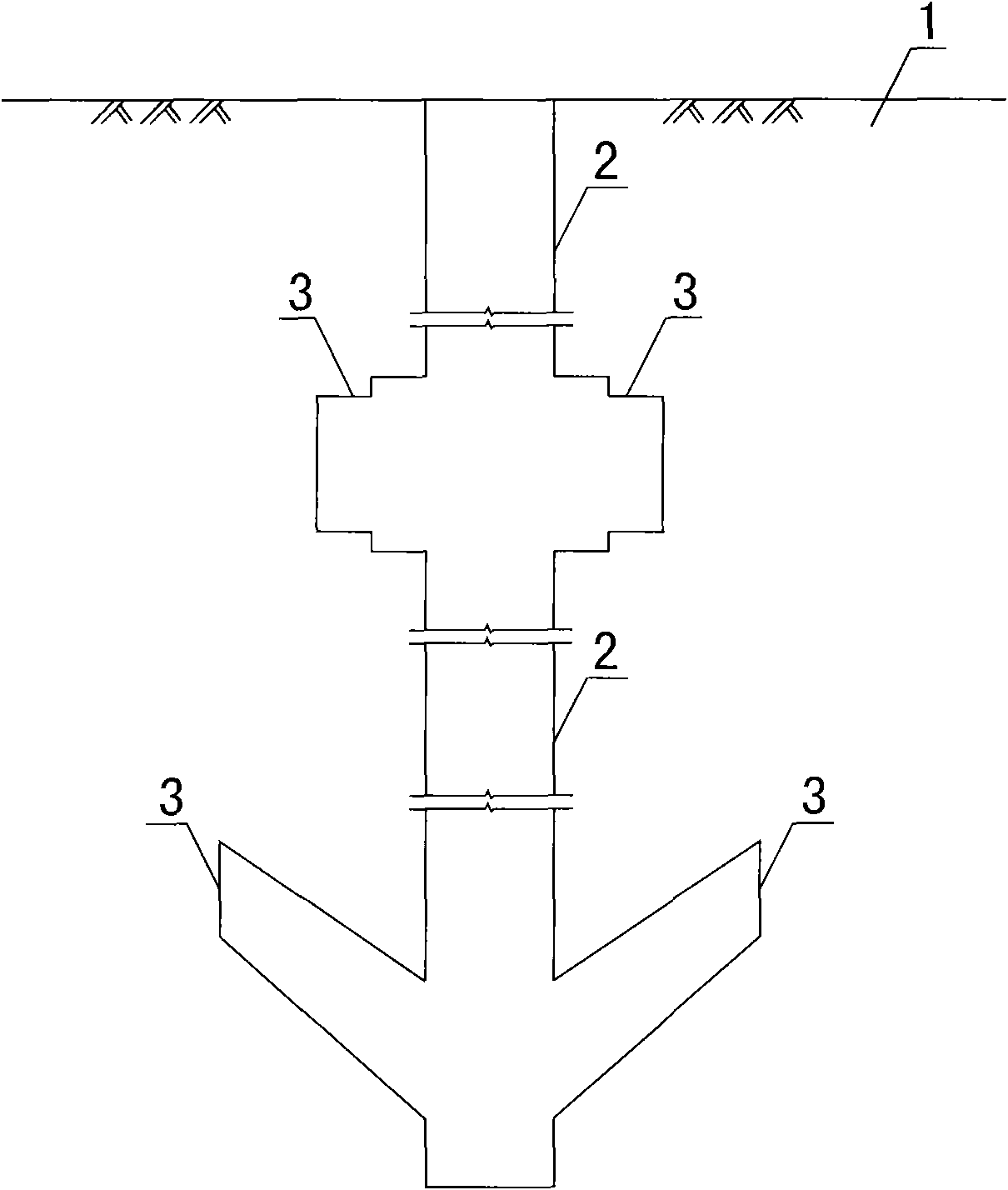

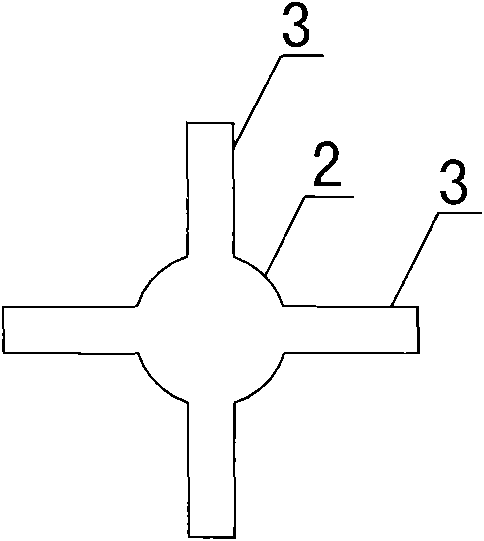

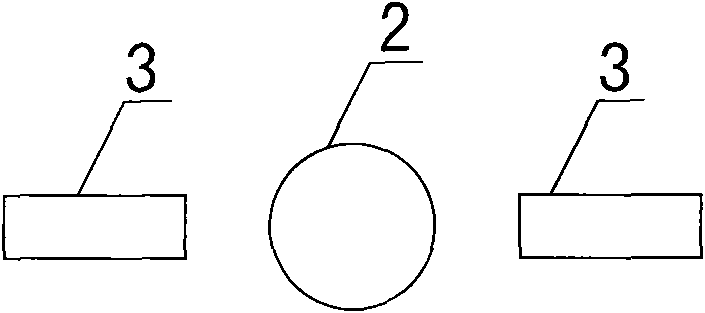

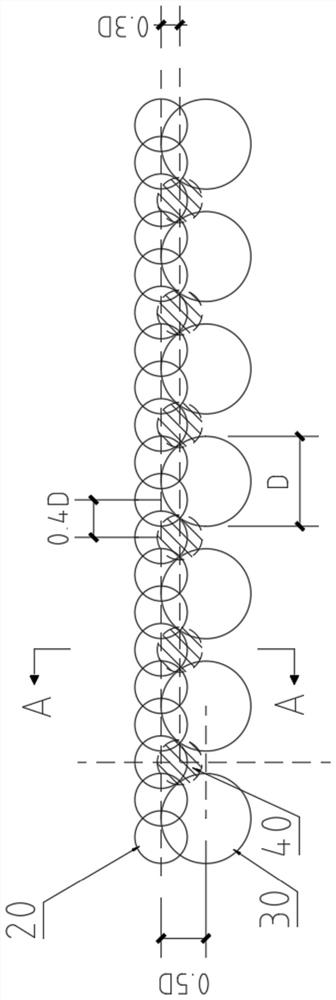

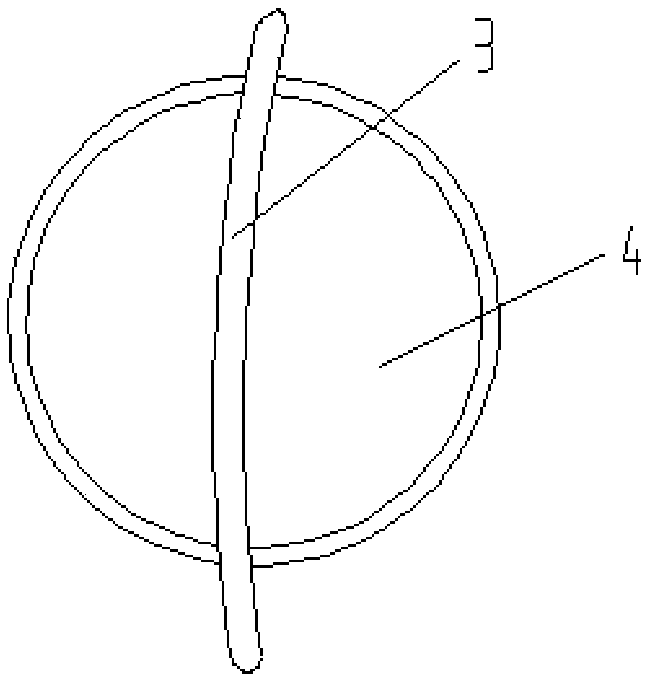

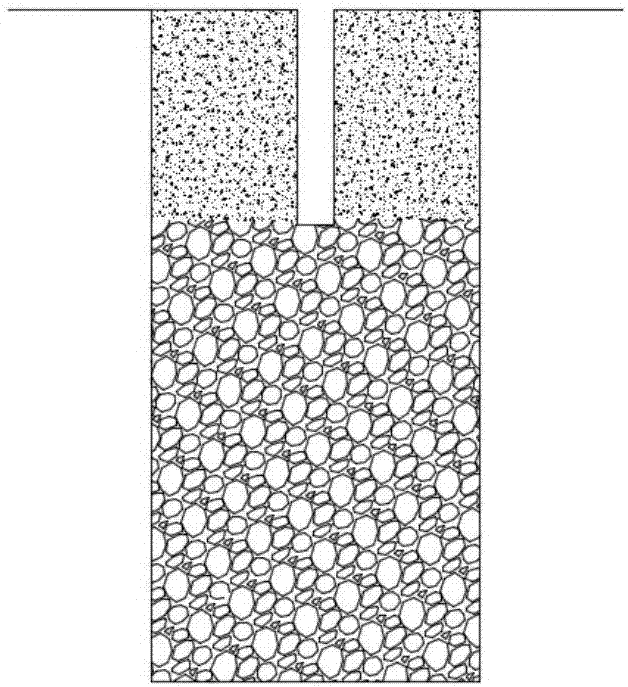

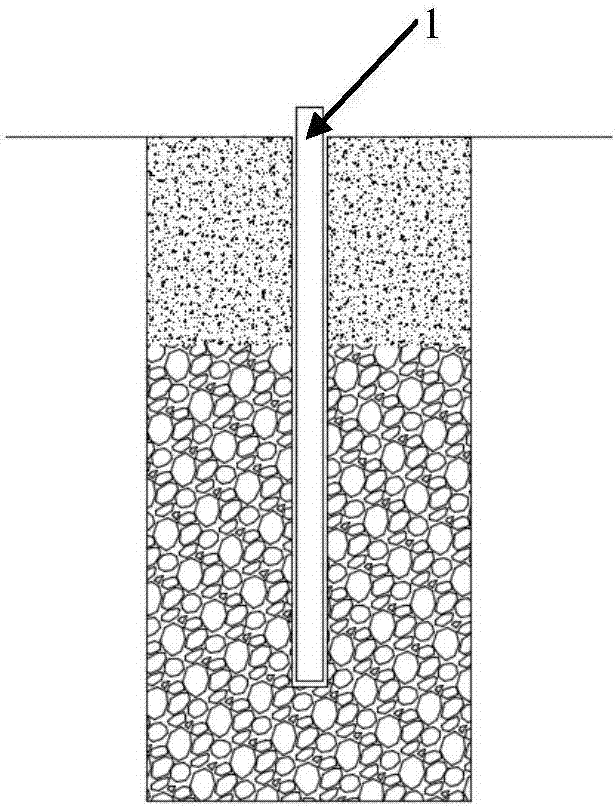

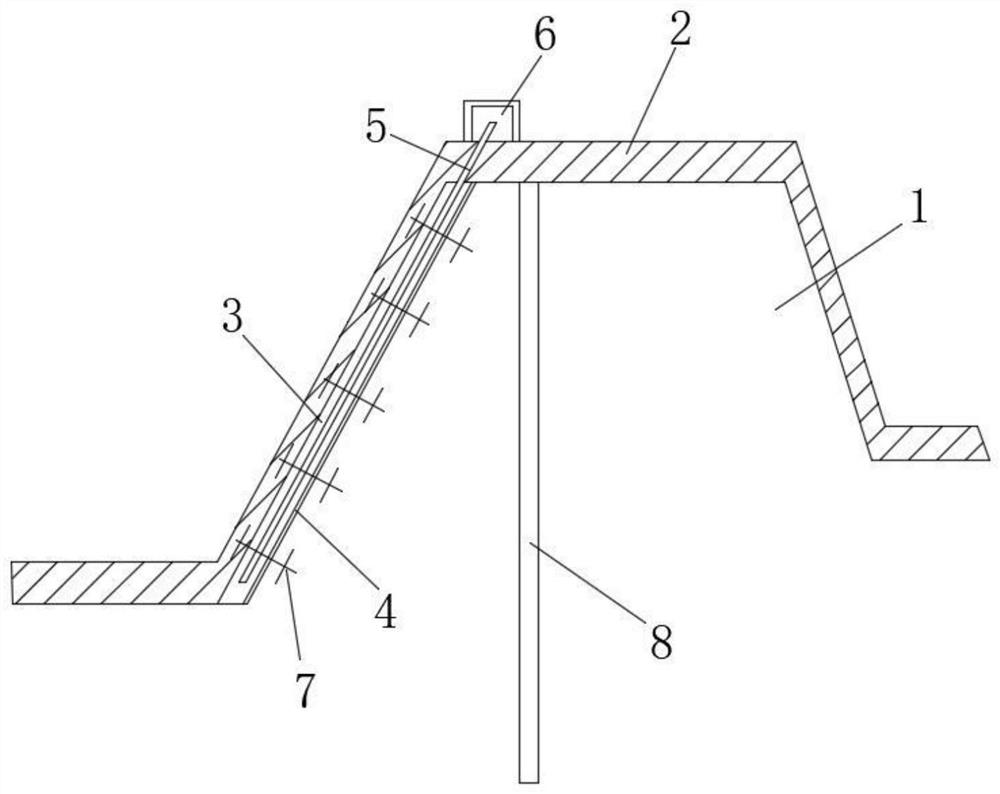

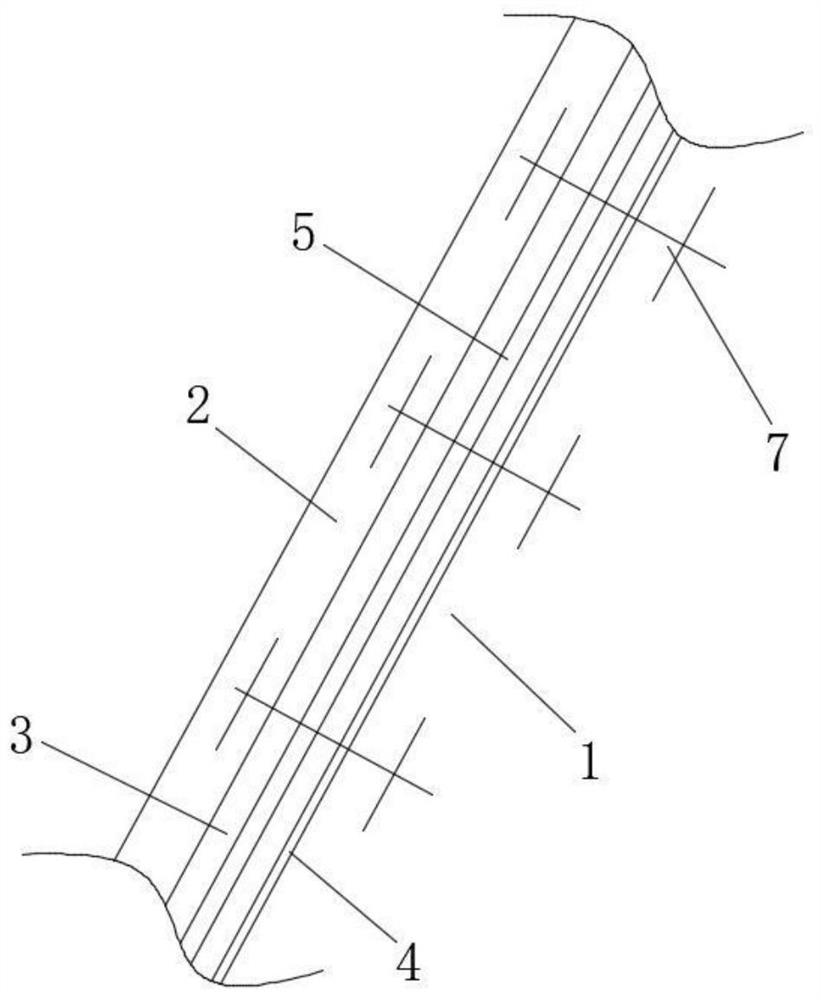

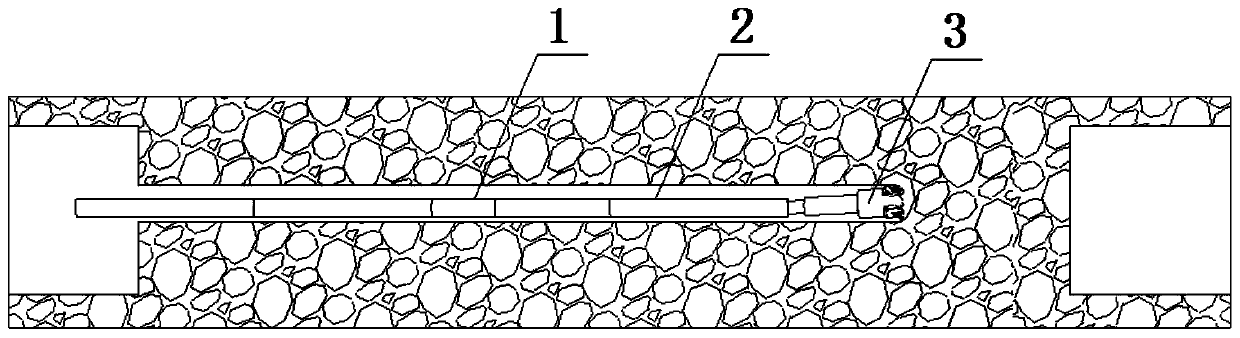

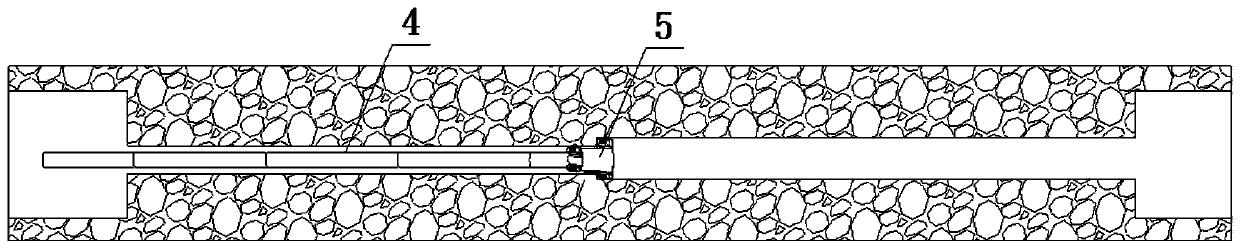

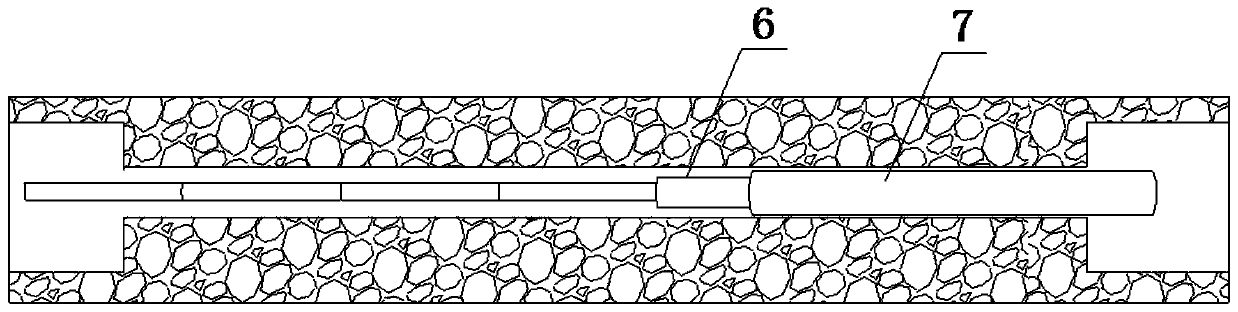

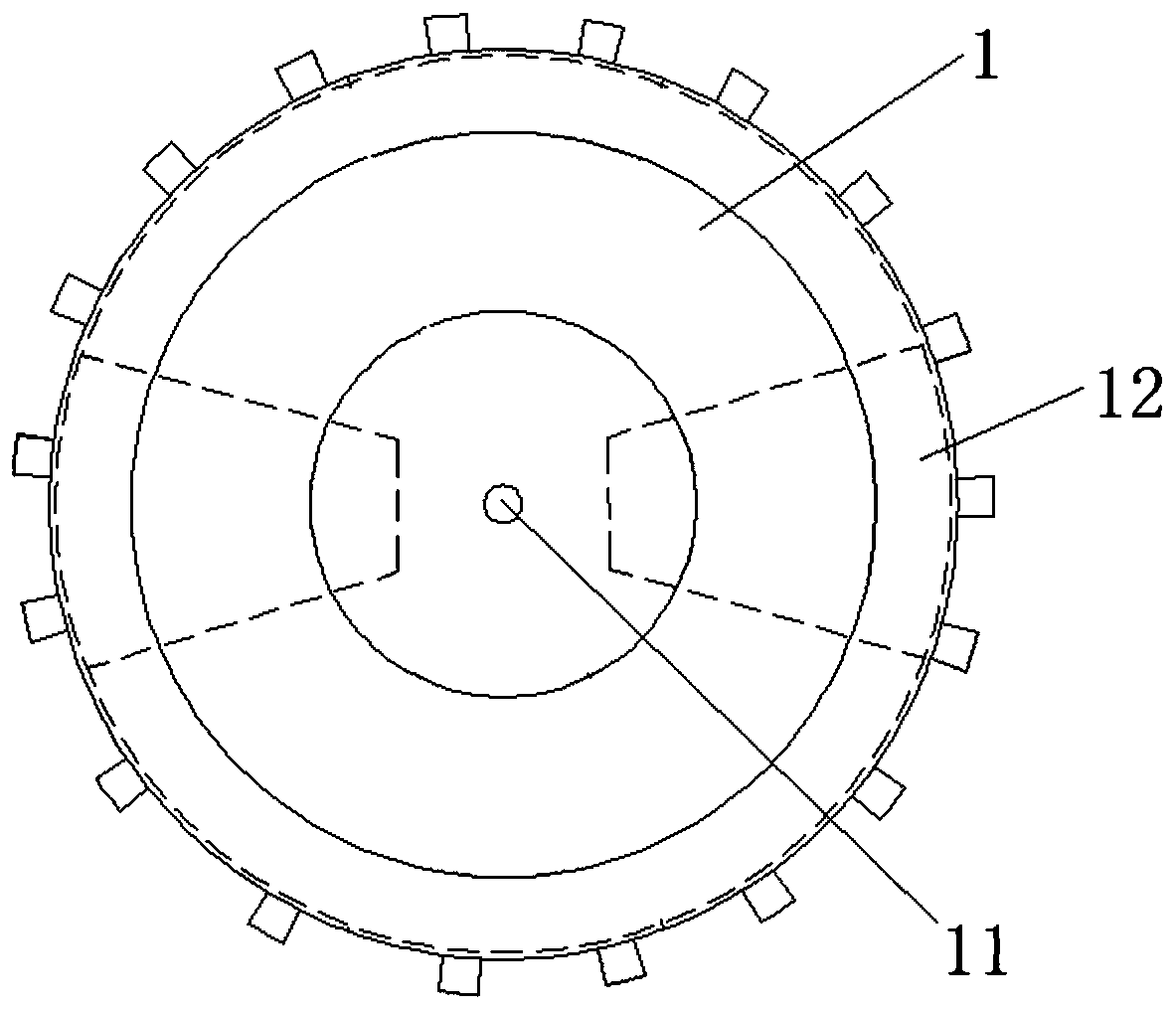

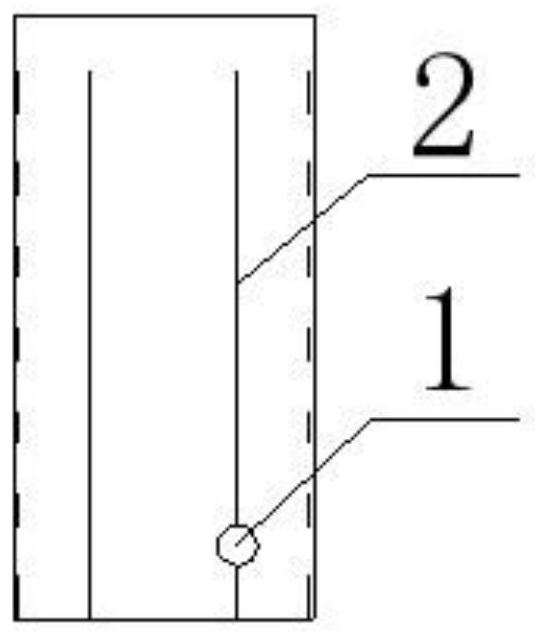

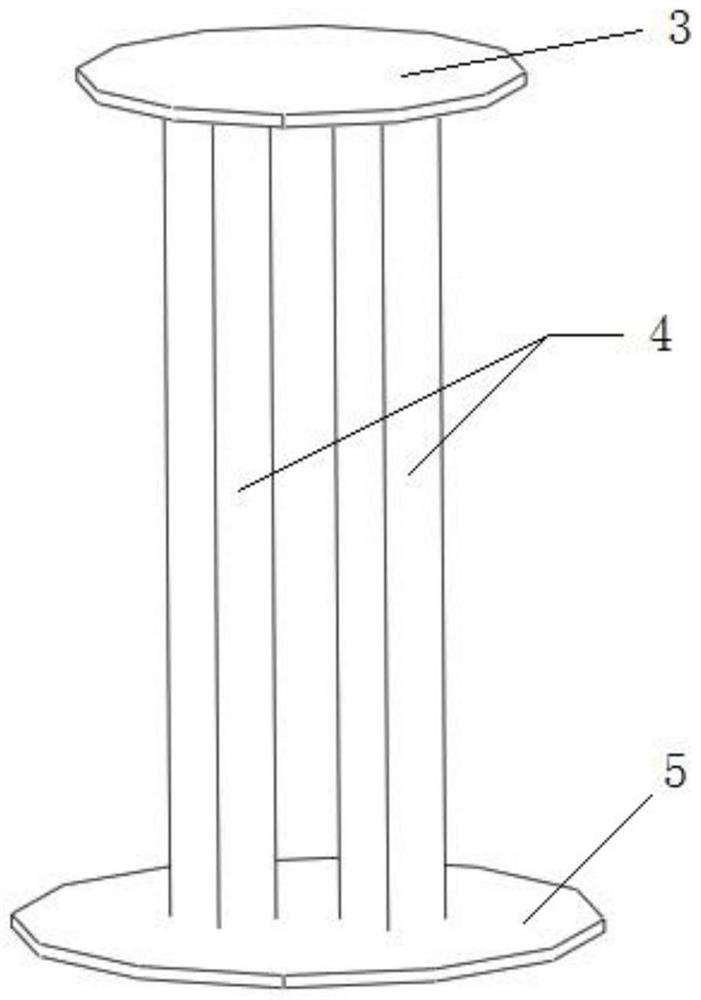

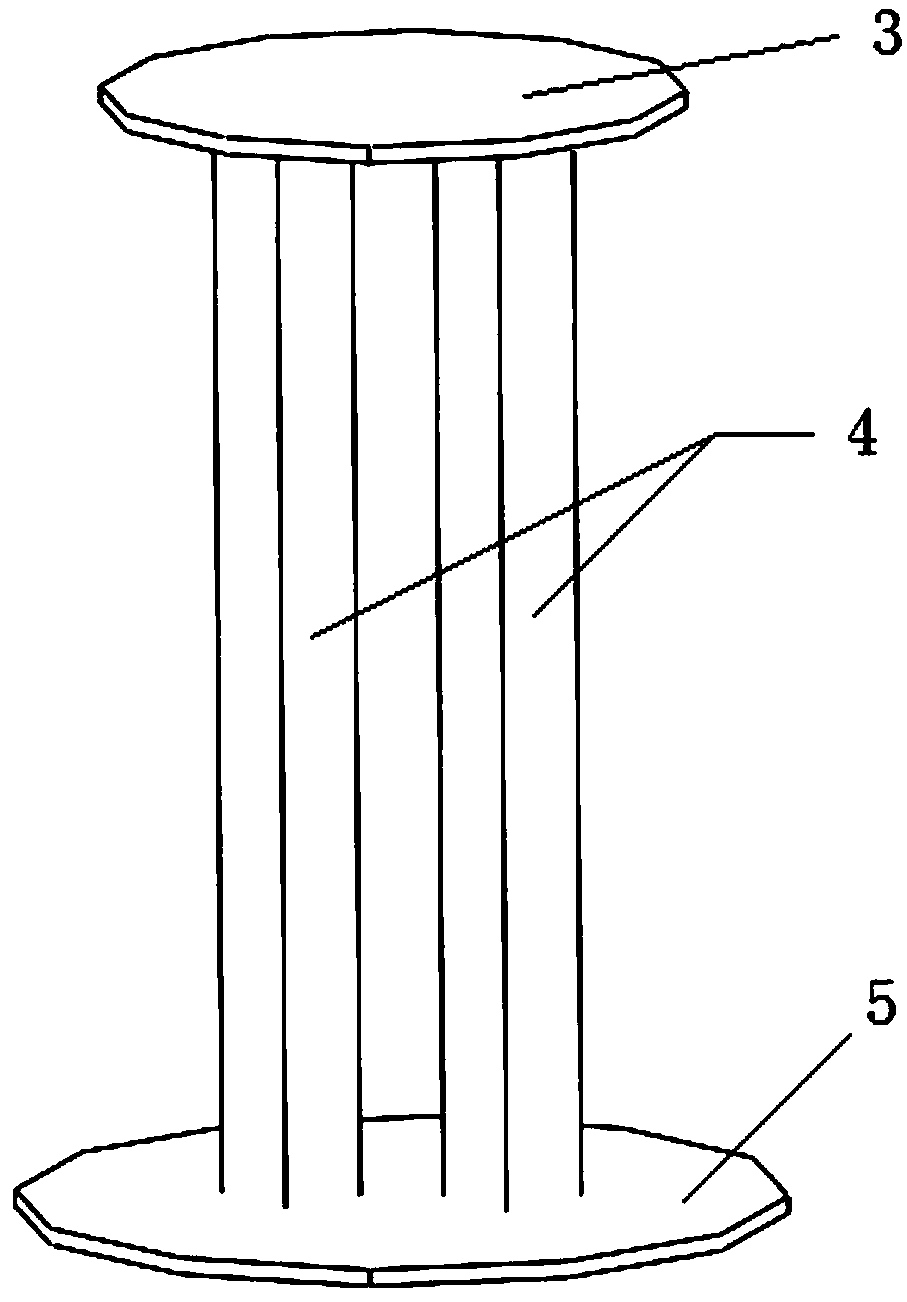

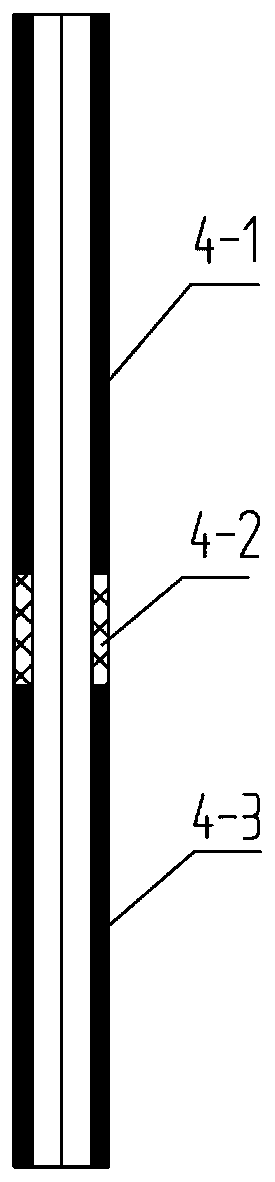

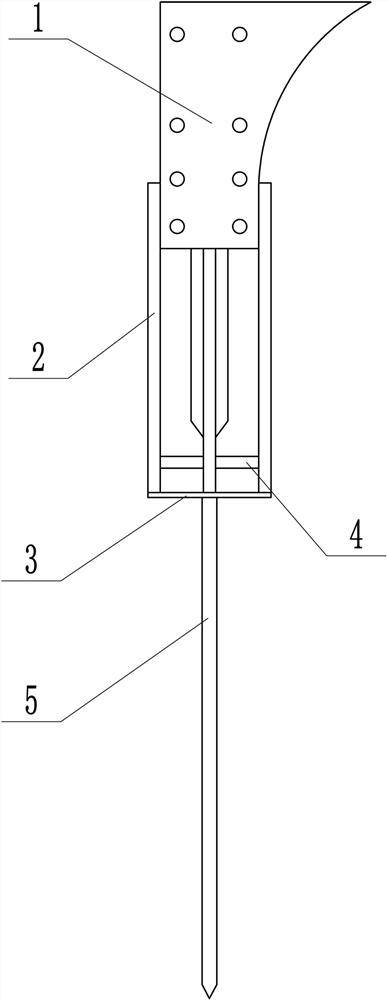

Wing-added hole-expanding pile and wing-added hole expander

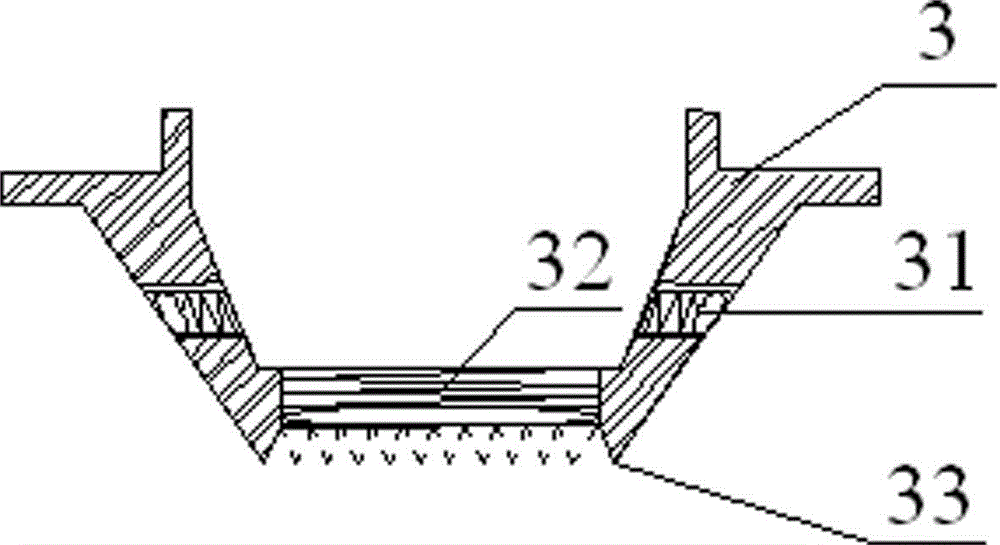

InactiveCN101649611ANot easy to collapse holesImprove single pile pullout resistanceSoil-shifting machines/dredgersBulkheads/pilesCompression deviceContour line

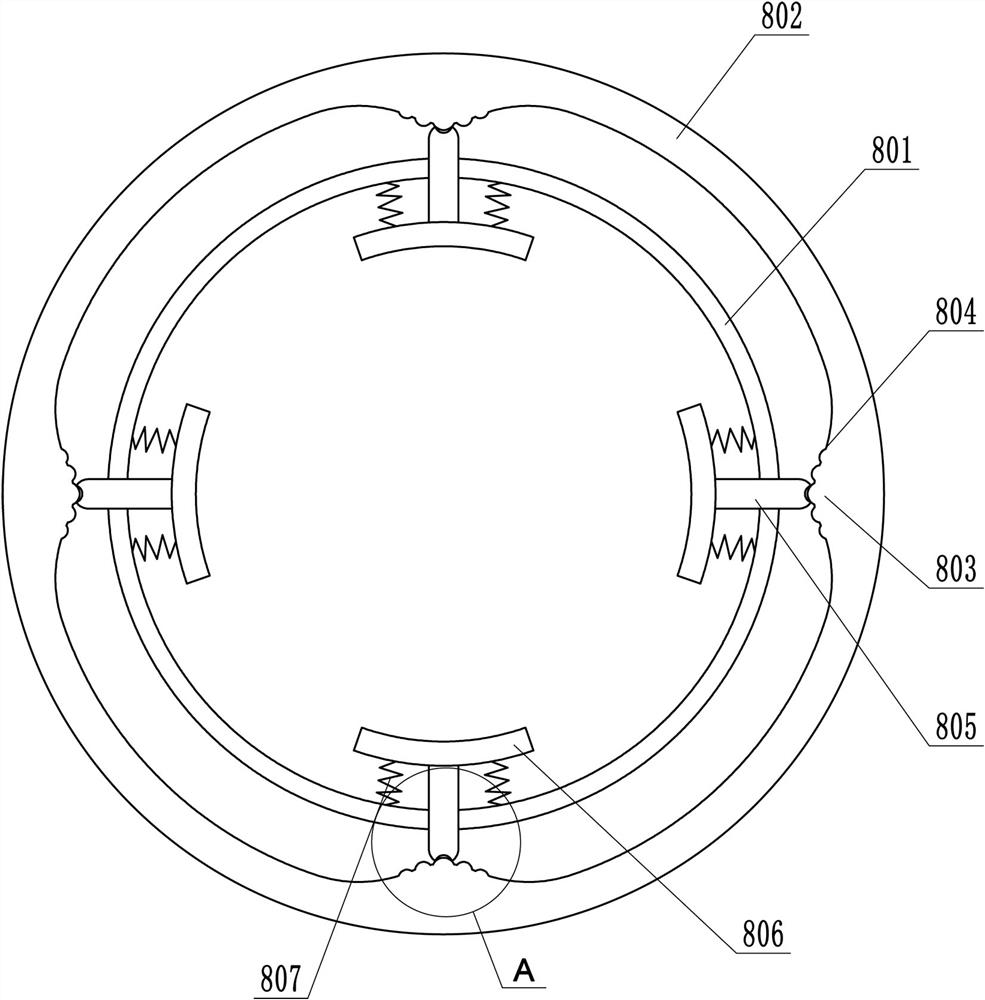

The invention provides a wing-added hole-expanding pile and a wing-added hole expander. The wing-added hole-expanding pile can be added with stiffening wings (3) in a rock-soil mass (1) along a pile body (2). After hole-expanding construction is completed, the outer contour line of the section of the hole-expanding section pile is a concave curve or a combination of not less than two closed curves; large-scale hole-expanding construction around and on the bottom of the pile can be realized; holes are not easy to collapse after the hole-expanding construction; few pile-body materials are neededfor filling expanded holes; and a compact solid pile body can be formed after the hole-expanding construction is completed. Therefore, the anti-pulling / anti-compression bearing capacity of single pile can be greatly improved, and cost for pile foundation is saved. Compared with the prior hole-expanding equipment, the wing-added hole expander used in the construction of the wing-added hole-expanding pile has great improvement. The wing-added hole expander has the advantages of producing no slurry in a hole-expanding process and greatly reducing engineering cost for anti-pulling / anti-compression devices in geotechnical engineering, along with simple structure, high hole-expanding efficiency, good matching property with the prior piling machinery and capability of repeated use.

Owner:张继红

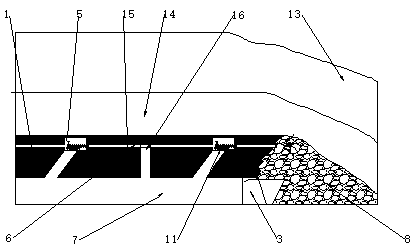

Large diameter bedding drill hole drainage goaf along roof and upper corner gas technology

ActiveCN108798758AEliminate overrun functionReduce the amount of constructionGas removalEngineeringStreamflow

The invention relates to a large diameter bedding drill hole drainage goaf along a roof and upper corner gas technology. The large diameter bedding drill hole drainage goaf along the roof and upper corner gas technology is characterized by comprising that steps that a high level coal seam drilling field is constructed in a return airway; (1), a crawler-type electric drilling machine is used for constructing a long-distance large-diameter drill hole in a drilling field in the mining direction separately forwards and backwards, after a drill tool is exited, a processed borehole protection sleevewith sieve holes of a certain length is pushed into the large-diameter drill hole to seal the large-diameter drill hole; (2), in the main roadway or up a hill, the borehole protection sleeve with thesieve holes and the corresponding extraction pipeline are connected to extract gas in a goaf and upper corner. The amount of drilling construction is nearly 50% less than that of fan-shaped arrangement in a high level drilling field, the cost is low, the large-diameter drill hole is constructed in a coal seam, the construction speed is faster than rock stratum holes, part of the coal is extractedduring the construction to save the cost of coal mining, gas extraction flow rate is large, the borehole protection sleeve is arranged in the large-diameter drill hole, holes are not prone to collapsing, the gas extraction effect is better, and the overlimit function of gas in roadways is effectively eliminated.

Owner:CCTEG SHENYANG RES INST

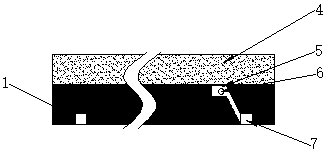

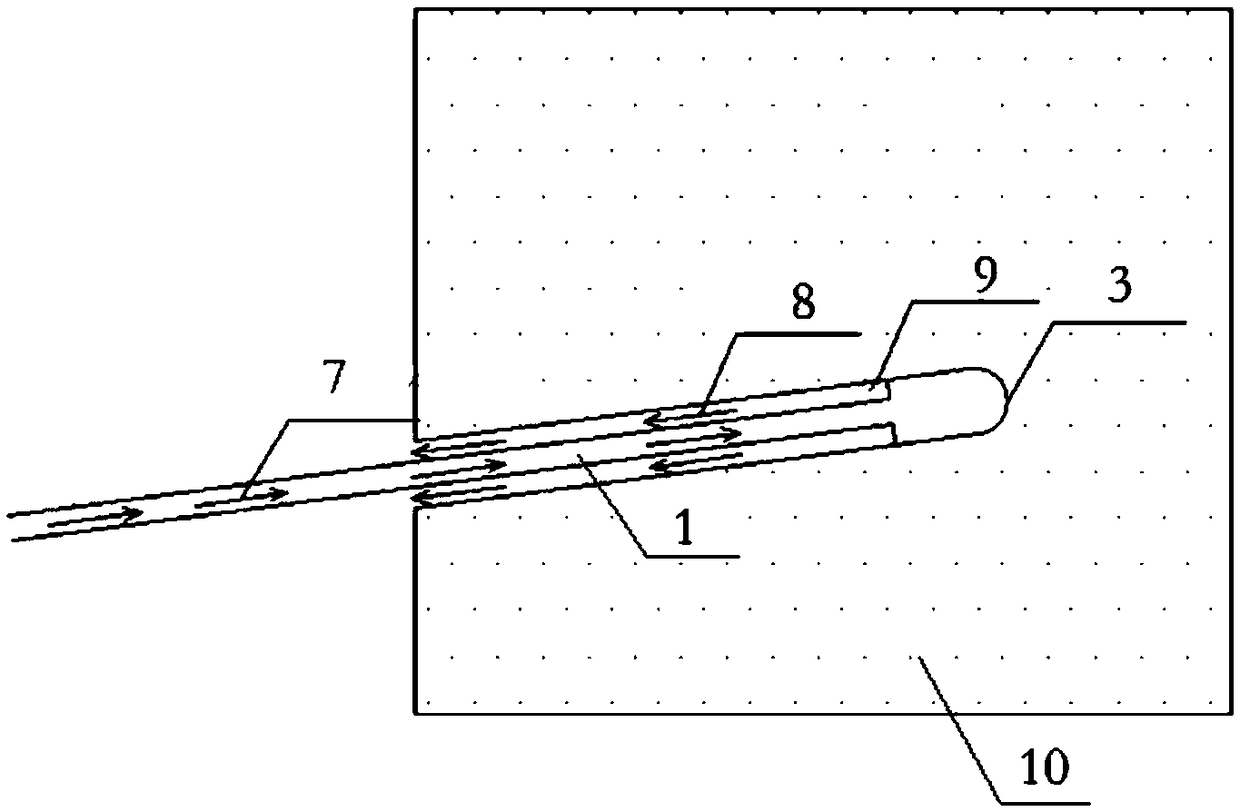

Construction method for precision perforation drainage holes in coal mine underground roadways

ActiveCN106988781APrecise pairingPrecise control of drilling trajectoryDrainageStructural engineeringEngineering

A construction method for precision perforation drainage holes in coal mine underground roadways comprises a precision opposed perforation directional drilling tool assembly, a pull back-type reaming bit, a wall protective steel casing and the like. The method utilizes a measurement while drilling system, a deflecting drilling tool and a precise drilling track control technology to work accurately to perforate drilling holes to connect a water outlet roadway and a drainage roadway, after the drilling holes are perforated, the pull back-type reaming bit is replaced to expand in the reverse direction without lifting a drill, multistage reaming is conducted repeatedly, a variable diameter is changed in a perforation roadway, the wall protective casing with a large aperture is connected, the wall protective casing is cased off in the whole process in a pull-back mode, grouting solidification is conducted, and a drainage shock tube is mounted for filtering debris in water of the water outlet roadway. Therefore, the construction method of the precision perforation drainage holes in the coal mine underground roadways can effectively ensure that the drilling holes in the drainage roadway are perforated precisely and the large-diameter casing are cased off in the whole process, so that special drainage roadway excavation construction are replaced effectively, and cost of coal mine water treatment is greatly reduced.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

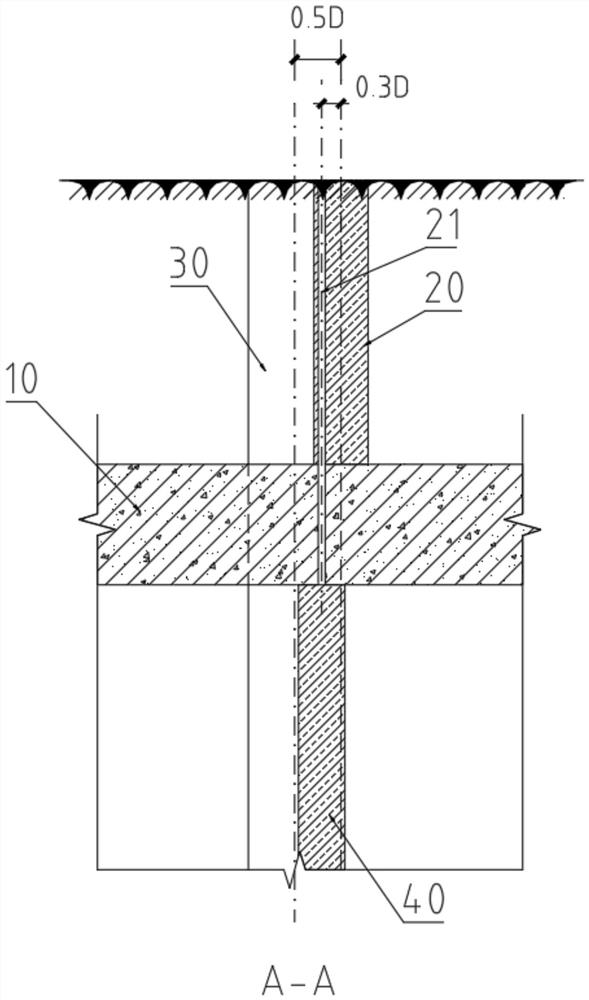

Structure for supporting and crossing of water-stop curtain through old bottom plate obstacle, and construction method of structure

PendingCN111636440ARealize crossingImprove integrityExcavationsBulkheads/pilesStructural engineeringMechanical engineering

The invention relates to a structure for supporting and crossing of a water-stop curtain through an old bottom plate obstacle, and a construction method of the structure. The structure comprises the basement bottom plate obstacle, a cement stirring occlusive soldier pile, a grouting soldier pile and a high-pressure jet grouting pile. A mode of 'cement stirring-existing old basement bottom plate obstacle-high-pressure jet grouting' is adopted to form a deep stirring and jetting water-stop curtain comprehensive body, the problem that as for a conventional deep foundation pit support water-stop curtain construction method, the large-thickness old basement bottom plate obstacle cannot be crossed can be solved, meanwhile the problem that old buildings are concentrated on the periphery of a construction area, and consequently the upper part is not suitable for directly adopting high-pressure jet grouting for pile forming is solved, and the structure is suitable for terrain working conditionswith complex sites.

Owner:广州珠江建设发展有限公司

Open caisson vibroflotation pile composite foundation construction process

The invention discloses a construction process of a caisson vibro pile composite foundation, the construction method comprising the following steps: a. positioning; b. embedding a casing; c. vibrating sinking debugging; d. . Vibration sinking; f. Prefabricated tube well extension; g. Continue vibrating sinking; h. Filling; k. Vibration density, pile formation; The invention has the characteristics of reliable technology, simple and convenient construction, not easy to collapse the hole during the hole forming process, easy to ensure the quality of the pile body, fast foundation reinforcement speed, good effect, high foundation bearing capacity and the like.

Owner:IANGSU COLLEGE OF ENG & TECH

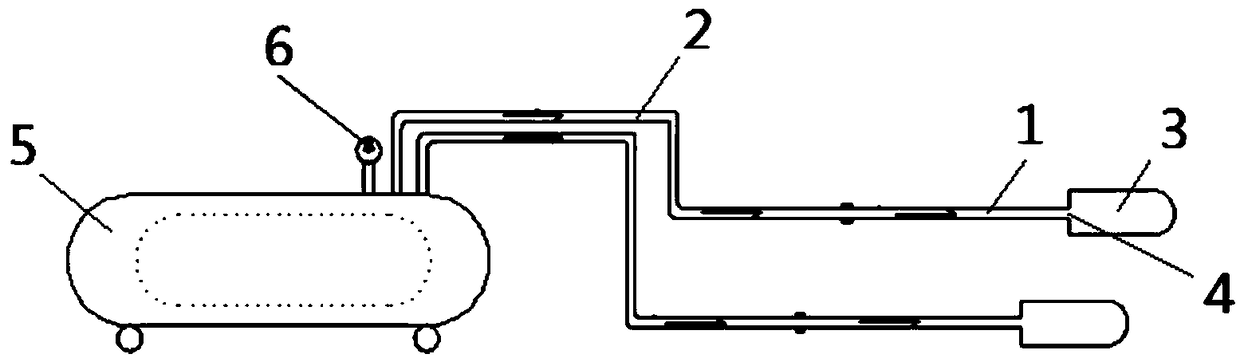

Jet-type hole forming tool and hole forming construction method

InactiveCN108952579AReduce disturbanceNot easy to collapse holesConstructionsLiquid/gas jet drillingHigh pressureShovel

The invention provides a jet-type hole forming tool. The jet-type hole forming tool comprises a Luoyang shovel with a hollow shovel handle, an air supply pipeline is connected to an air inlet of the tail end of the shovel handle, and an air blowing hole facing to a shovel body is formed in the other end of the shovel handle. The width of the shovel body is greater than the diameter of the shovel handle. The jet-type hole forming tool uses the shovel body at the front end of the Luoyang shovel to cut soil mass, the soil mass cut by the Luoyang shovel is blown by an air jet formed by high pressure air generated by an air compressor, the soil mass is discharged from a gap between the Luoyang shovel and hole bodies, disturbance to the soil mass is less, hole collapse is not prone to being caused, the hole collapse rate is low, power consumption is low, energy is saved, the construction speed is high, hole forming efficiency is high, and the construction period can be effectively shortened.Meanwhile, the number of construction personnel is small, the use position of equipment is flexible, a required working face is small, and disassembly and installation are convenient.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

Long spiral cast-in-place pile construction process

PendingCN113089649ANot easy to collapse holesImprove construction efficiencyDirectional drillingExcavationsArchitectural engineeringSlurry

The invention discloses a long spiral cast-in-place pile construction process which includes the steps that step one, a long spiral pile machine is used for spirally and rotationally cutting a soil body downwards till a drill rod reaches a pile bottom elevation designed for construction; step two, prepared slurry is pumped through the drill rod of the long spiral pile machine, and the drill rod is lifted upwards while pumping the slurry till the bottom of the drill rod reaches the ground; step three, the long spiral pile machine moves, the steps are repeated, and hole-forming drilling process procedures of a next pile is carried out; and step four, a reinforcement cage is put down into a pile-formed hole where the slurry is pumped through a crane, and then concrete is poured to a pile top elevation of a construction design. According to the long spiral cast-in-place pile construction process, by pumping the prepared slurry into the pile-formed hole for protecting a wall, the pressure of surrounding soil is balanced, hole collapse is not likely to happen, the long spiral pile machine can continuously form holes, and the construction efficiency is greatly improved; the reinforcement cage is adjusted from a rear position to a front position, so that quality is guaranteed; and meanwhile, only common concrete is poured, so that cost is reduced, the multiple pile-formed holes can be poured together, and construction time is saved.

Owner:浙江省地矿建设有限公司

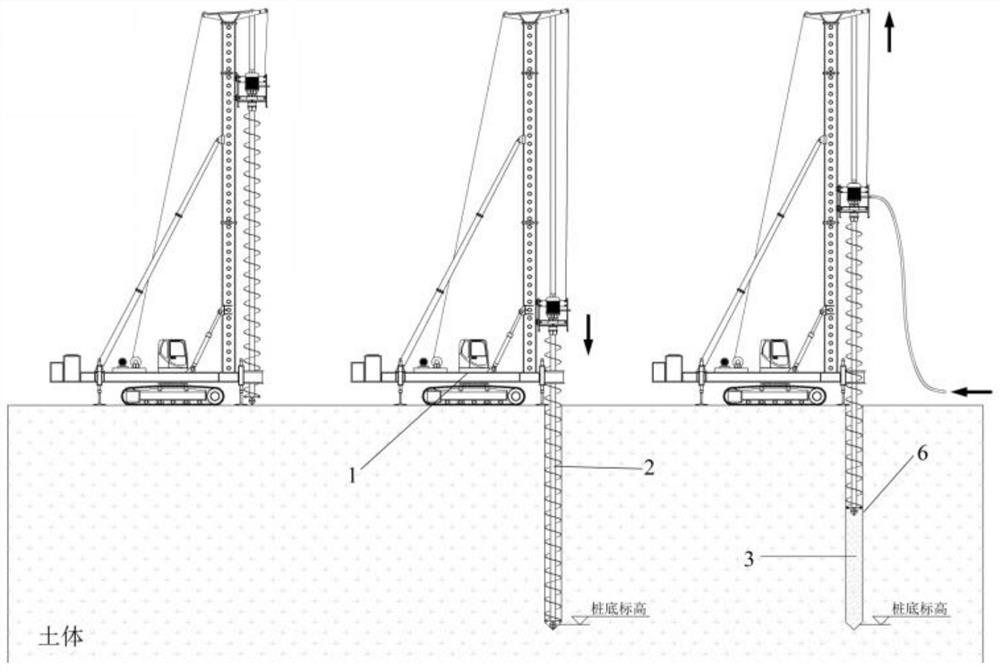

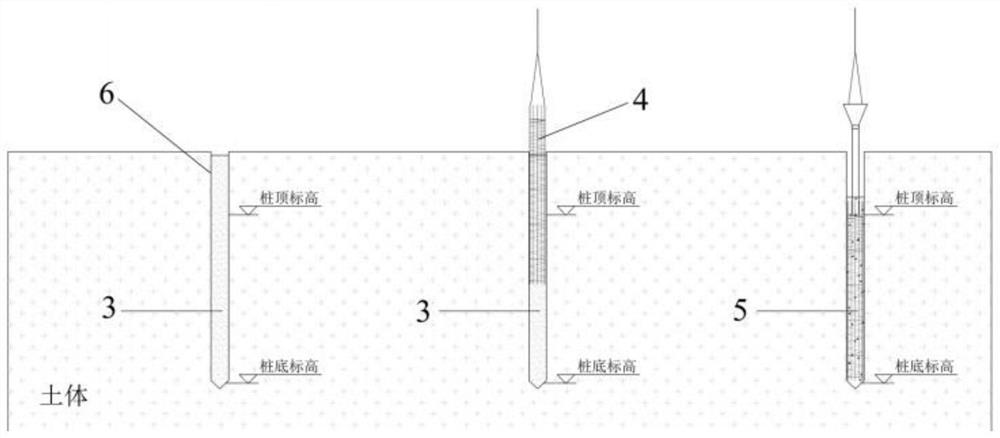

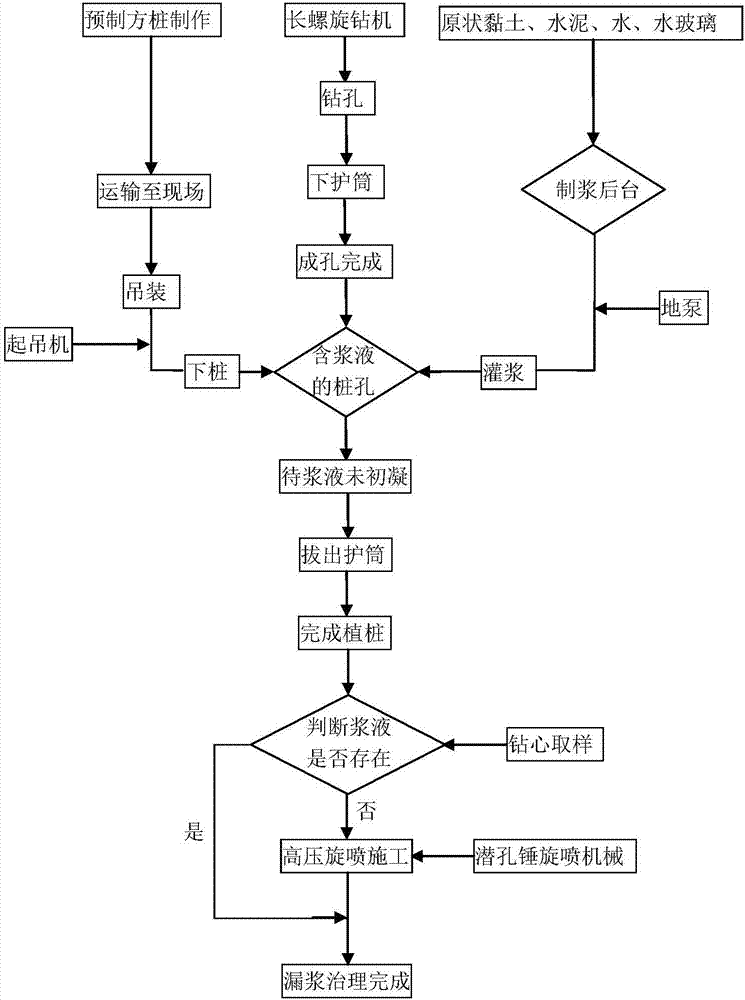

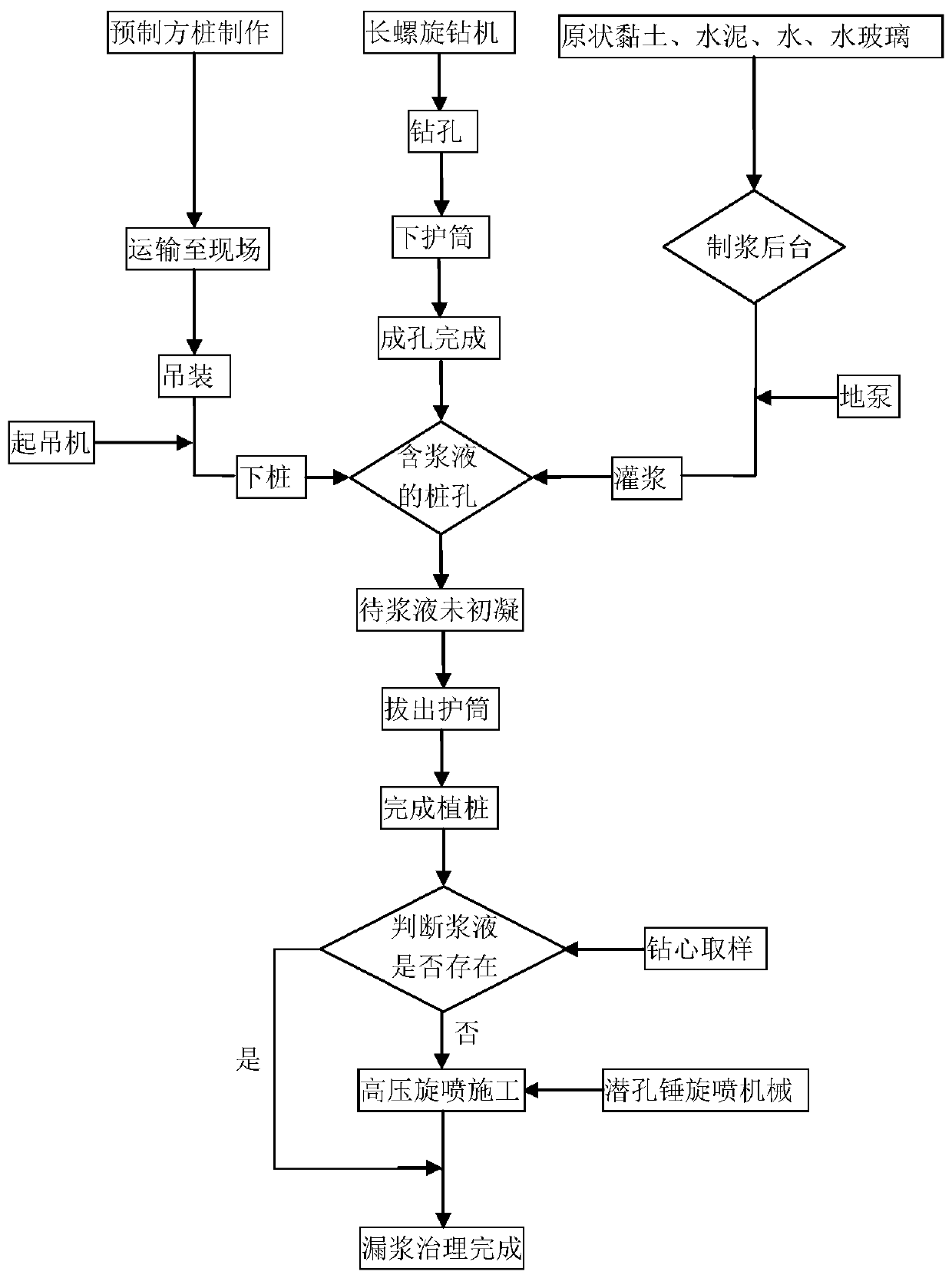

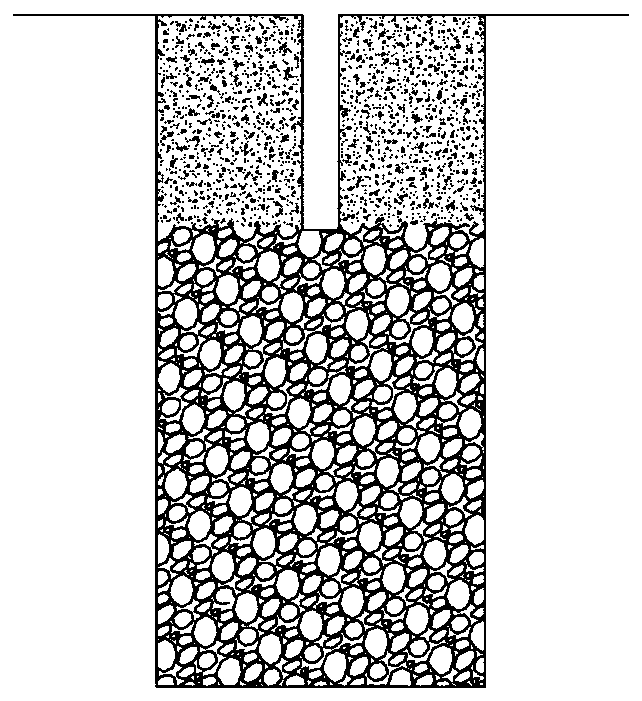

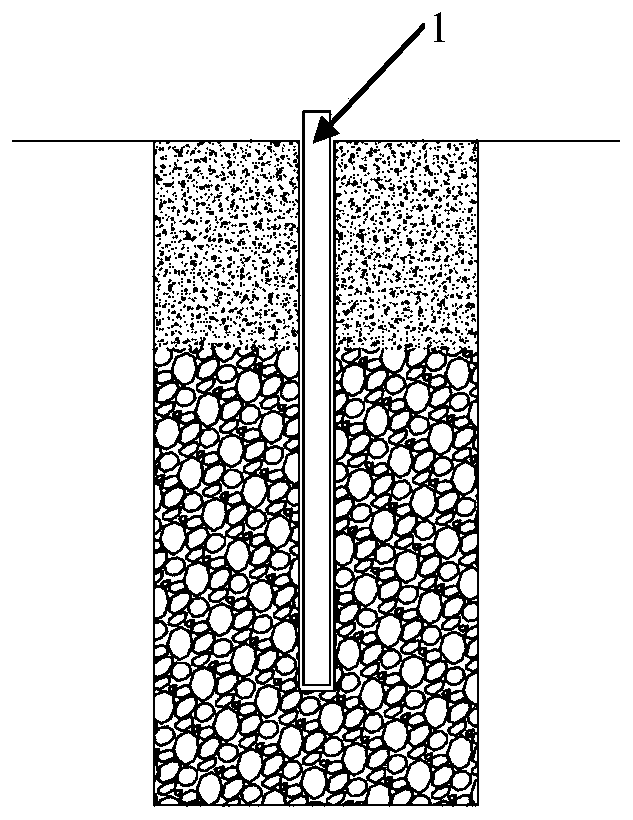

Grout runout treatment method for planting of precast pile in rubble layer

The invention discloses a grout runout treatment method for planting of a precast pile in a rubble layer. Through the grout runout treatment method, the grout runout problem occurring to the precast pile in the rubble layer is solved. A protective barrel is used during hole forming, thus stratum stability during hole forming is ensured, hole collapse is not liable to occur, after poured grout is poured in, conditions can be provided for initial setting time of the grout, and the effect that before initial setting of the grout, the rubble layer containing water does not collapse towards the inside of the hole is ensured. According to the technical scheme of the grout runout treatment method, the grout runout treatment method comprises the following steps that the precast pile is made and is transported to a pile planting site; the hole position of the precast pile is determined, the precast pile is put into the pile hole after drilling, and the protective barrel is put in the pile hole; the poured grout is made with a set ratio, and the grout is poured into the pile hole from bottom to top; the protective barrel is clamped by a vibration hammer to be matched with a crawler crane and is taken out, and grouting is completed; after grout is solidified for the set time, coring observation is conducted on the grout, and whether the grout runs off is judged; and if yes, holes are formed in the two sides of the pile hole, grout is sprayed, and the grout is reinforced.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

Soft soil layer foundation pit side slope anchor rod drilling device

ActiveCN111550197AReduce dustNot easy to collapse holesDrilling rodsReciprocating drilling machinesSteel tubeDrill hole

The invention relates to a soft soil layer foundation pit side slope anchor rod drilling device. The soft soil layer foundation pit side slope anchor rod drilling device comprises a mounting bracket arranged on a breaking hammer head of a hydraulic breaking hammer, a first mounting plate arranged at the bottom of the mounting bracket and a steel pipe arranged on the first mounting plate and used for drilling. The steel pipe is arranged on the breaking hammer head of the hydraulic breaking hammer to form a drill rod, and the hydraulic function of the breaking hammer head is used for ejecting the steel pipe into a soil layer, and a hole is formed after the steel pipe reaches the design depth. The soft soil layer foundation pit side slope anchor rod drilling device is suitable for soft soil layer side slopes.

Owner:HEBEI ROAD & BRIDGE GROUP

Construction waste reinforced embankment under sandy soil

ActiveCN112030870BIncrease profitImprove anti-seepage performanceDamsDykesSoil scienceEnvironmental engineering

A river embankment reinforced by construction waste under sandy soil, comprising a river embankment body rammed with sand and a cement concrete layer poured on its surface, with a A modified waterproof layer, the modified waterproof layer is made of collapsible loess, quicklime, cement, fine particle construction waste with a particle size of no more than 10mm, and medium particle construction waste with a particle size of 15-30mm according to the ratio of 1.5:1:3.5 The mass ratio of :2.5:1.5 is mixed and rammed. In the present invention, a special modified waterproof layer is set between the facing surface of the embankment and the cement concrete layer, and construction waste, quicklime, cement, etc. of different grades are used for transformation, and it can be combined and solidified gradually with the water seeping through the cement concrete layer , to prevent seepage from penetrating deep into the dam body, thereby destroying the strength of the dam body, causing hidden dangers, and improving the utilization rate of construction waste, so that waste resources can be reused.

Owner:赣州久创科技有限公司

Construction method of precise intersecting drainage holes in coal mine underground roadway

ActiveCN106988781BPrecise pairingPrecise control of drilling trajectoryDrainageMaterial PerforationDirectional drilling

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

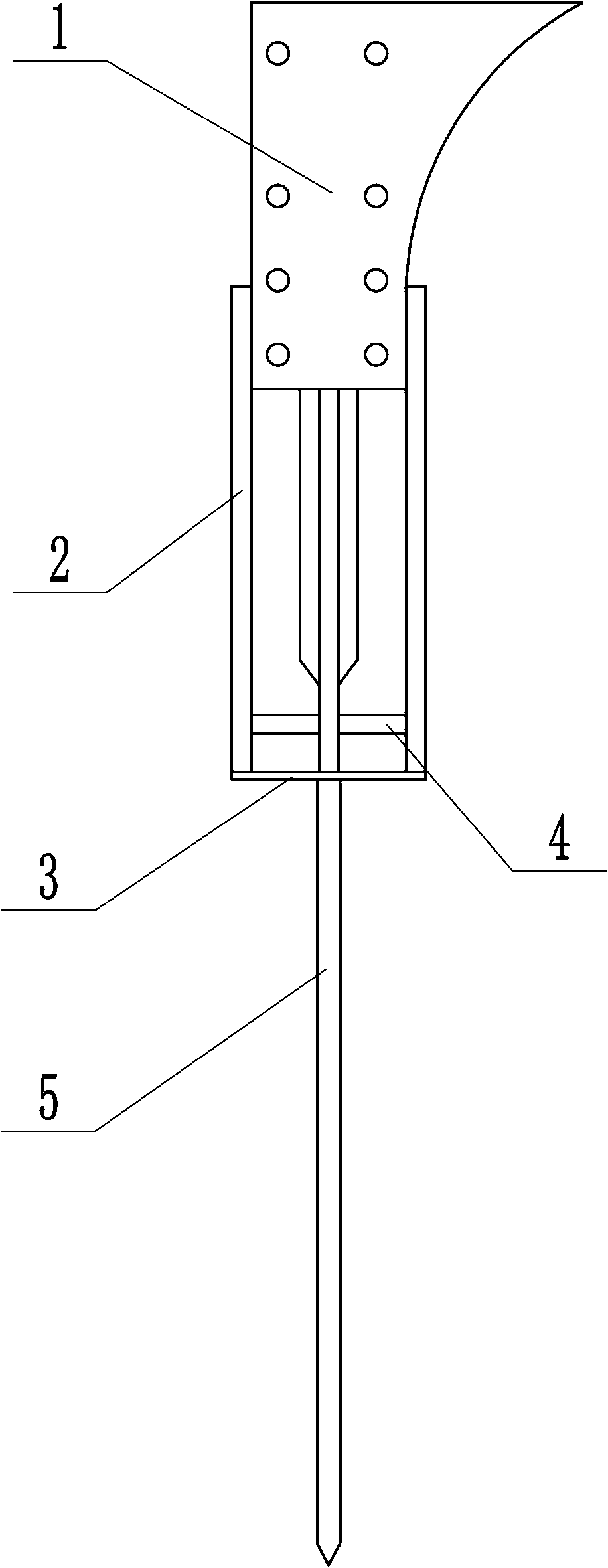

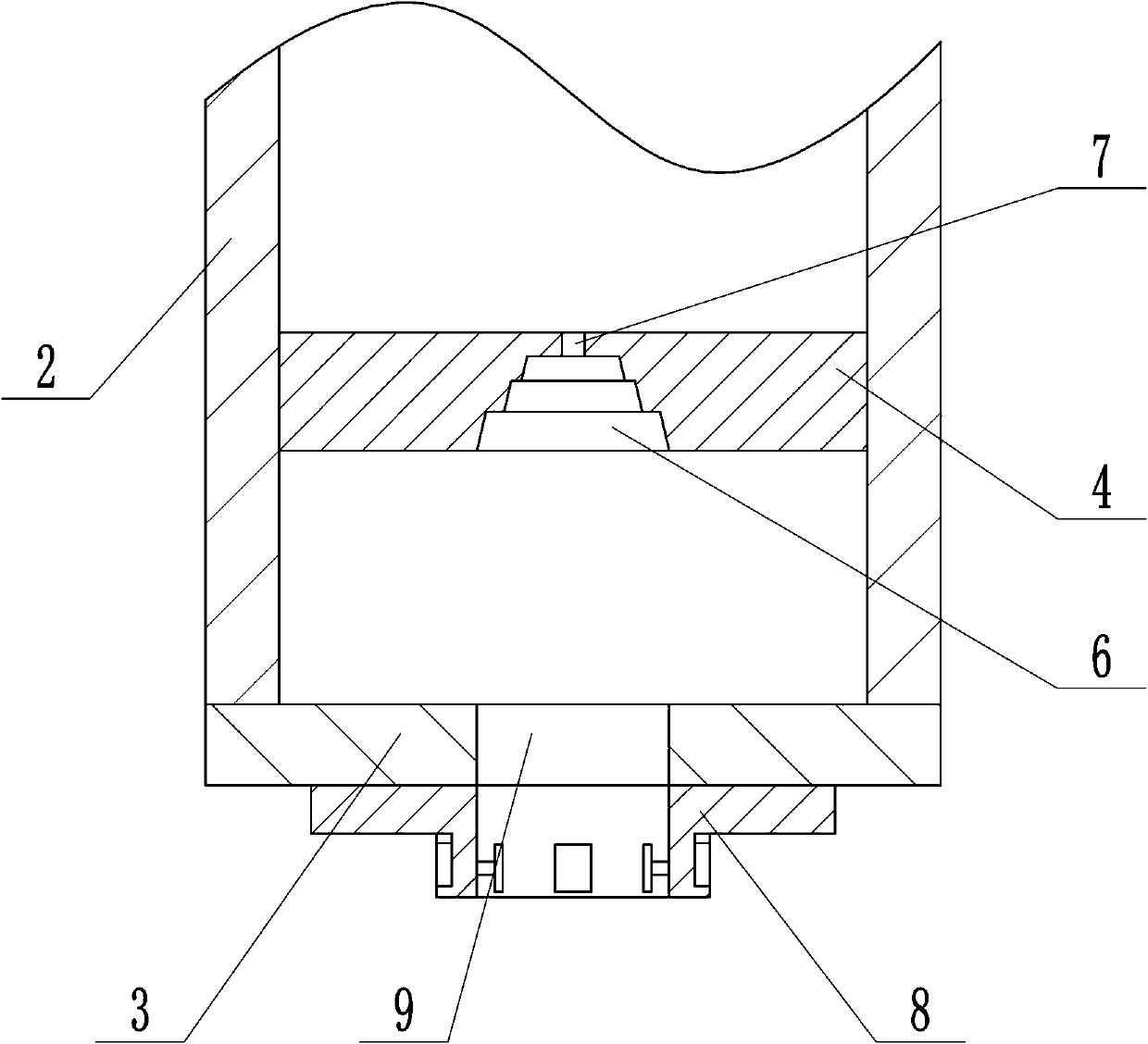

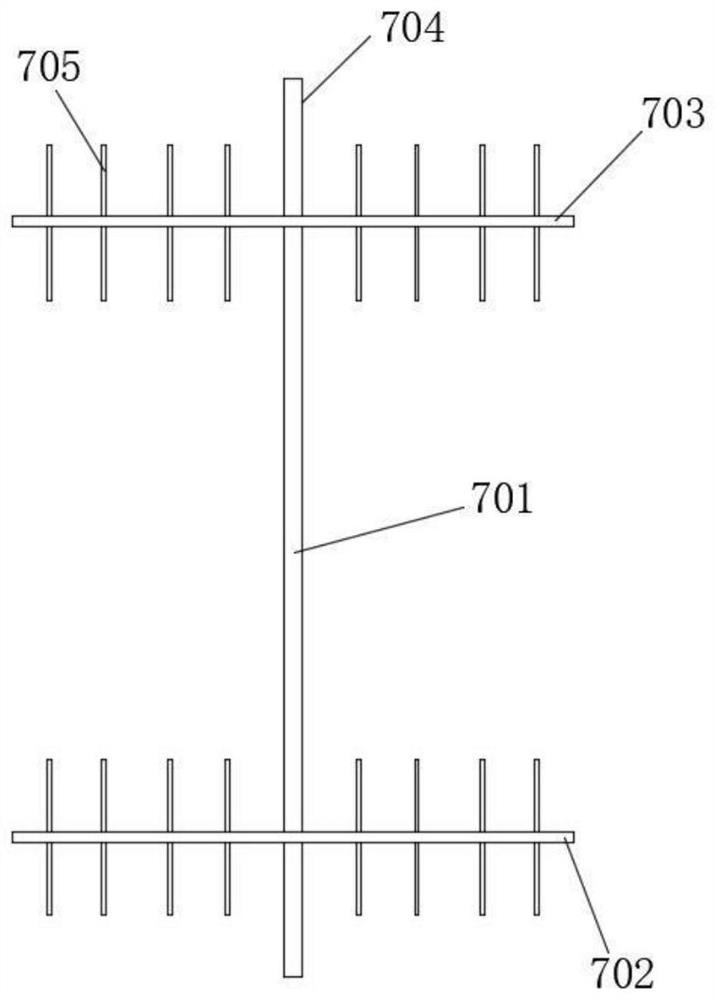

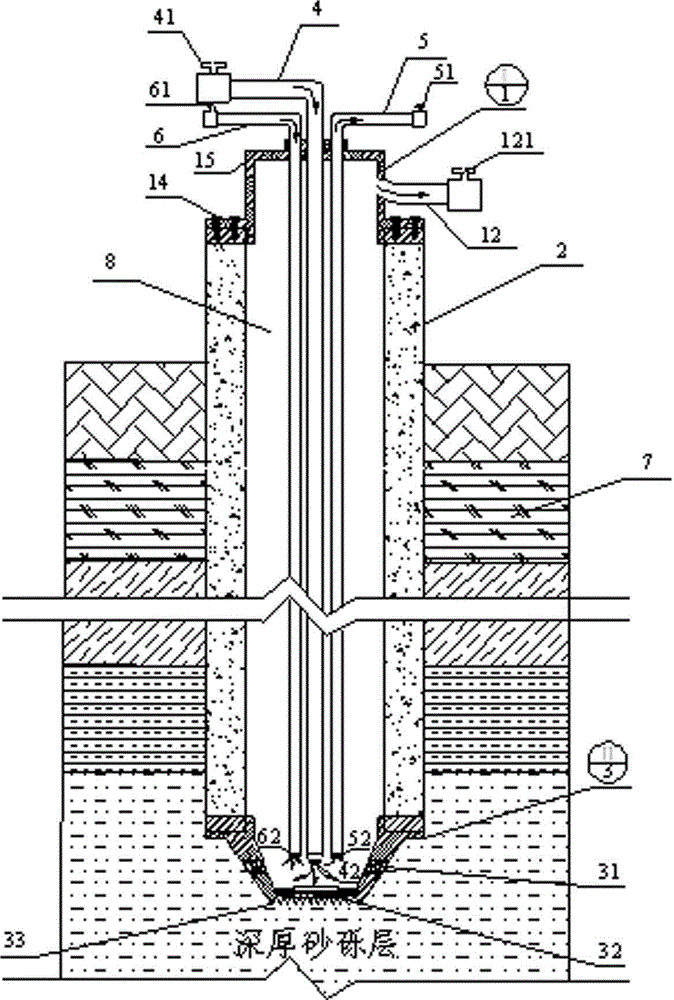

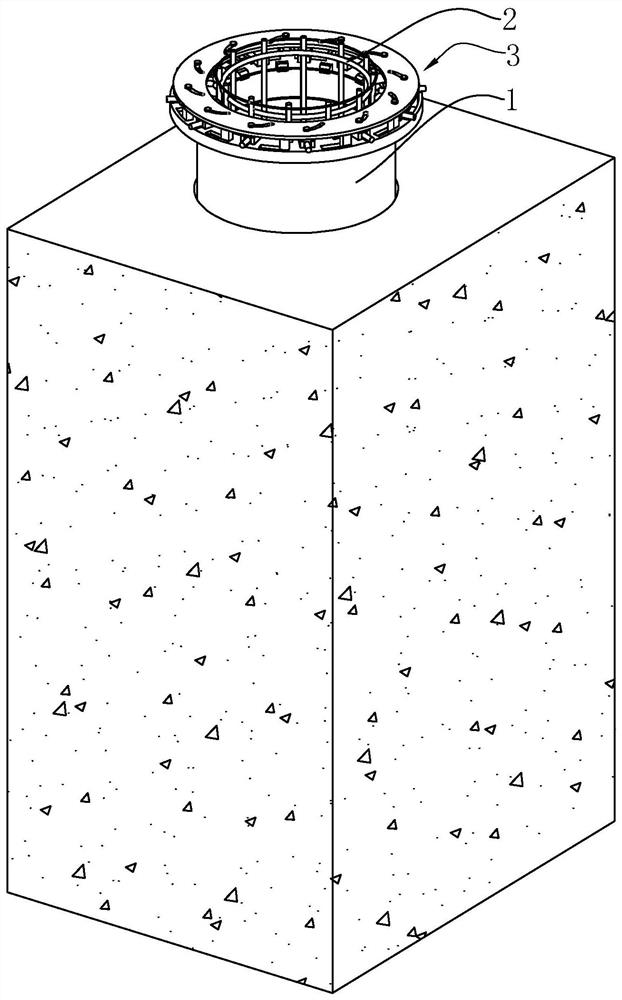

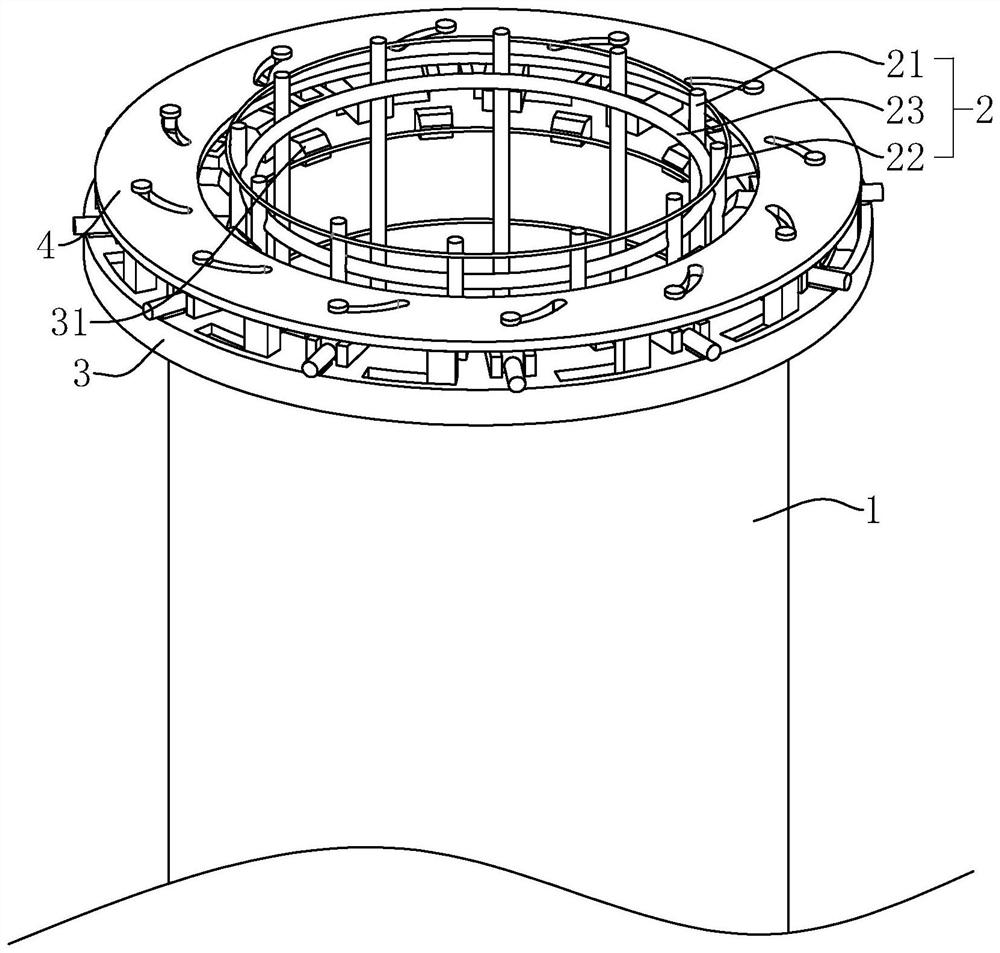

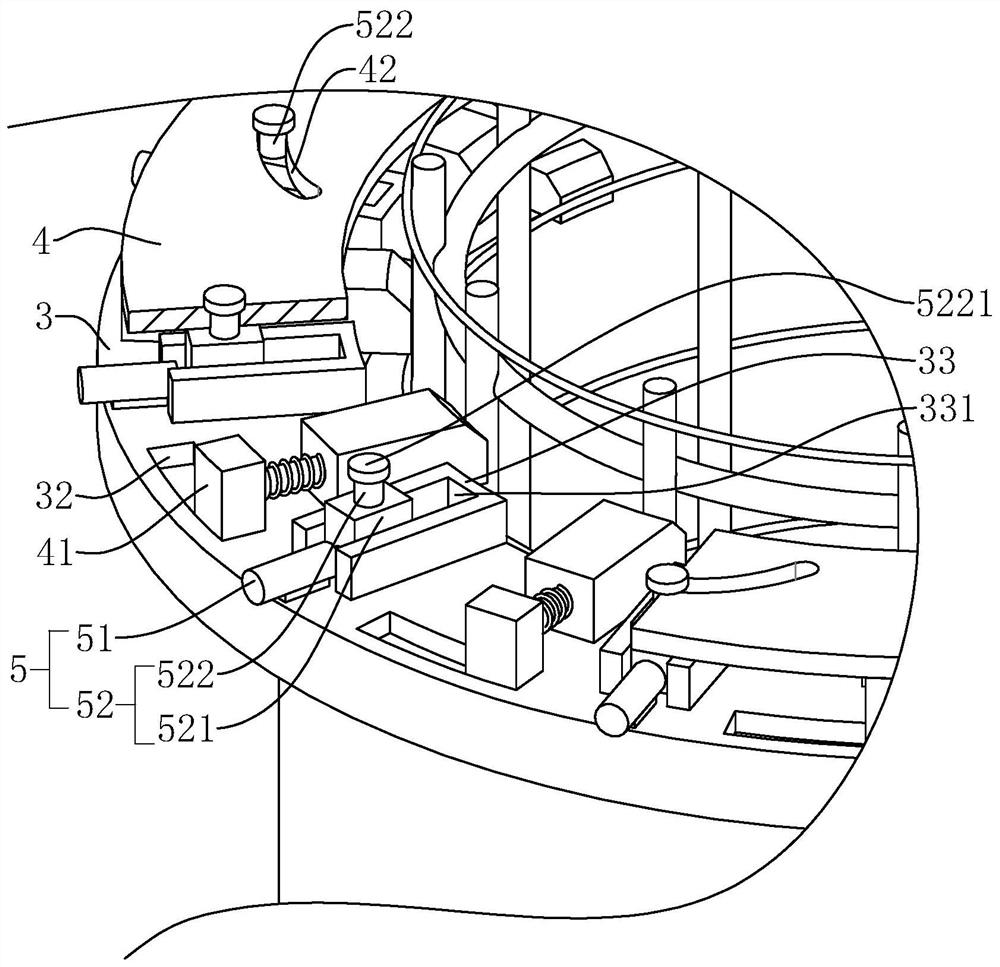

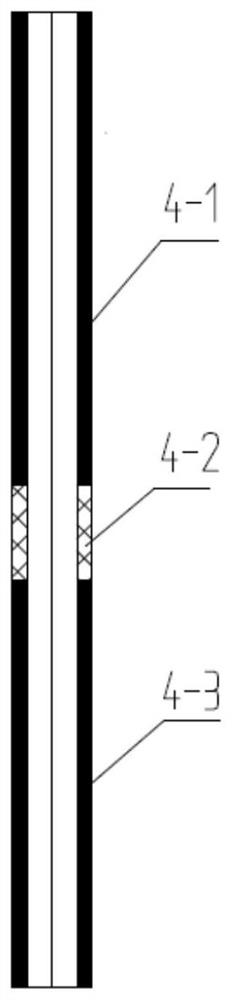

A PHC pipe pile driving device for traversing deep and dense sand layers

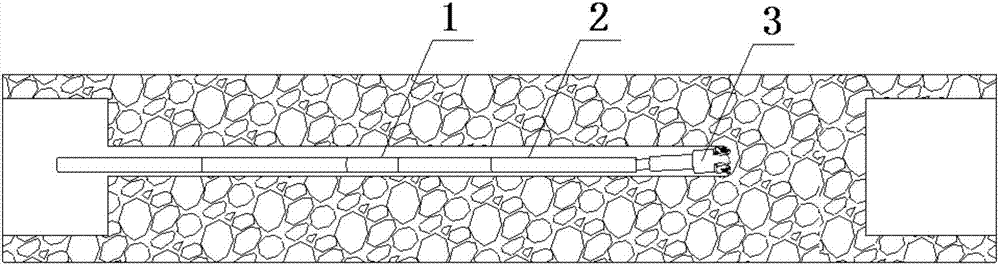

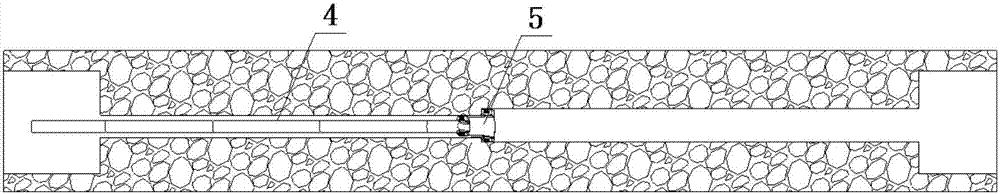

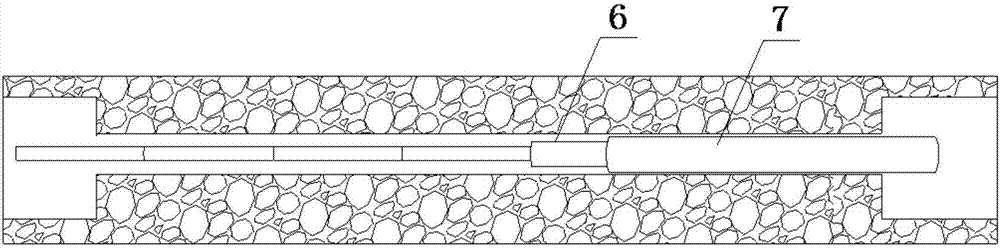

ActiveCN103556636BPressure is easy to controlOpen smoothlyBulkheads/pilesEngineeringStructural engineering

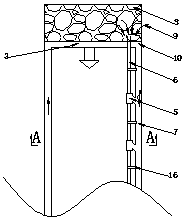

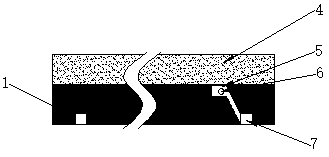

A PHC tubular pile pile-sinking device used for penetrating a deep and dense sand (gravel) layer comprises a PHC tubular pile (2), wherein both the upper part and the lower part of the PHC tubular pile (2) are provided with a pile cap (1) and a pile shoe (3) respectively in a connecting manner; a slurry inlet pipe (4), an air inlet pipe (6) and an air exhaust pipe (5) penetrate holes in the pile caps (1) to be mounted in inner holes of the PHC tubular pile (2). The PHC tubular pile pile-sinking device used for penetrating the deep and dense sand (gravel) layer has the advantages of: 1, guaranteeing successful overflow of returned slurry, 2, preventing excessive washing, 3, controlling placement positions of the slurry inlet pipe, the air inlet pipe and the air exhaust pipe quantitatively and guaranteeing penetration effect and quality, 4, changing traditional water washing into slurry washing, ensuring phenomena of hole collapse and quicksand not to happen easily in the sand (gravel) layer washing process as the slurry is made of traditional drilling slurry, cement of about 5%-10% and a retarding agent of 0.2%, avoiding excessive washing, and guaranteeing side friction of the PHC tubular pile and quality of guided holes, and 5, achieving rational design, simple structure, installation and operation convenience, reliable sealing performance and good penetration effects, and being economic and practical.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

Drainage goaf and upper corner gas technology by bed-based drilling with large diameter along the top

ActiveCN108798758BEliminate overrun functionReduce the amount of constructionGas removalMining engineeringStructural engineering

The invention relates to a large diameter bedding drill hole drainage goaf along a roof and upper corner gas technology. The large diameter bedding drill hole drainage goaf along the roof and upper corner gas technology is characterized by comprising that steps that a high level coal seam drilling field is constructed in a return airway; (1), a crawler-type electric drilling machine is used for constructing a long-distance large-diameter drill hole in a drilling field in the mining direction separately forwards and backwards, after a drill tool is exited, a processed borehole protection sleevewith sieve holes of a certain length is pushed into the large-diameter drill hole to seal the large-diameter drill hole; (2), in the main roadway or up a hill, the borehole protection sleeve with thesieve holes and the corresponding extraction pipeline are connected to extract gas in a goaf and upper corner. The amount of drilling construction is nearly 50% less than that of fan-shaped arrangement in a high level drilling field, the cost is low, the large-diameter drill hole is constructed in a coal seam, the construction speed is faster than rock stratum holes, part of the coal is extractedduring the construction to save the cost of coal mining, gas extraction flow rate is large, the borehole protection sleeve is arranged in the large-diameter drill hole, holes are not prone to collapsing, the gas extraction effect is better, and the overlimit function of gas in roadways is effectively eliminated.

Owner:CCTEG SHENYANG RES INST

Construction method of anti-seepage wall in sandy ground

A construction method for a cut-off wall on sandy ground, in which a row of grouting holes and a row of negative pressure holes are formed by drilling holes along both sides of the width at the planned cut-off wall position, and PC pipes with openings at both ends are inserted into the negative pressure holes Afterwards, while grouting into the grouting hole, negative pressure is applied to the upper end of the PC tube in the negative pressure hole corresponding to the grouting hole being grouted, so that a guiding force is formed between the grouting hole and the negative pressure hole, and the injection Under the action of the guiding force, the slurry in the slurry hole passes through the gap of the sand and gradually solidifies to form an underground cut-off wall. The present invention utilizes the characteristics of good permeability of the sandy soil itself, cooperates with the grouting method, and finally forms an anti-seepage wall formed by mixing sandy soil and cement, which has simple construction, high efficiency, and good anti-seepage effect; the grout is guided by the guiding force The cement paste solidifies the sandy soil stratum, which effectively utilizes the characteristics of high permeability of sandy soil, so that an underground anti-seepage wall can be built without disturbing the stratum, which is beneficial to environmental protection.

Owner:广东志讯建设工程有限公司

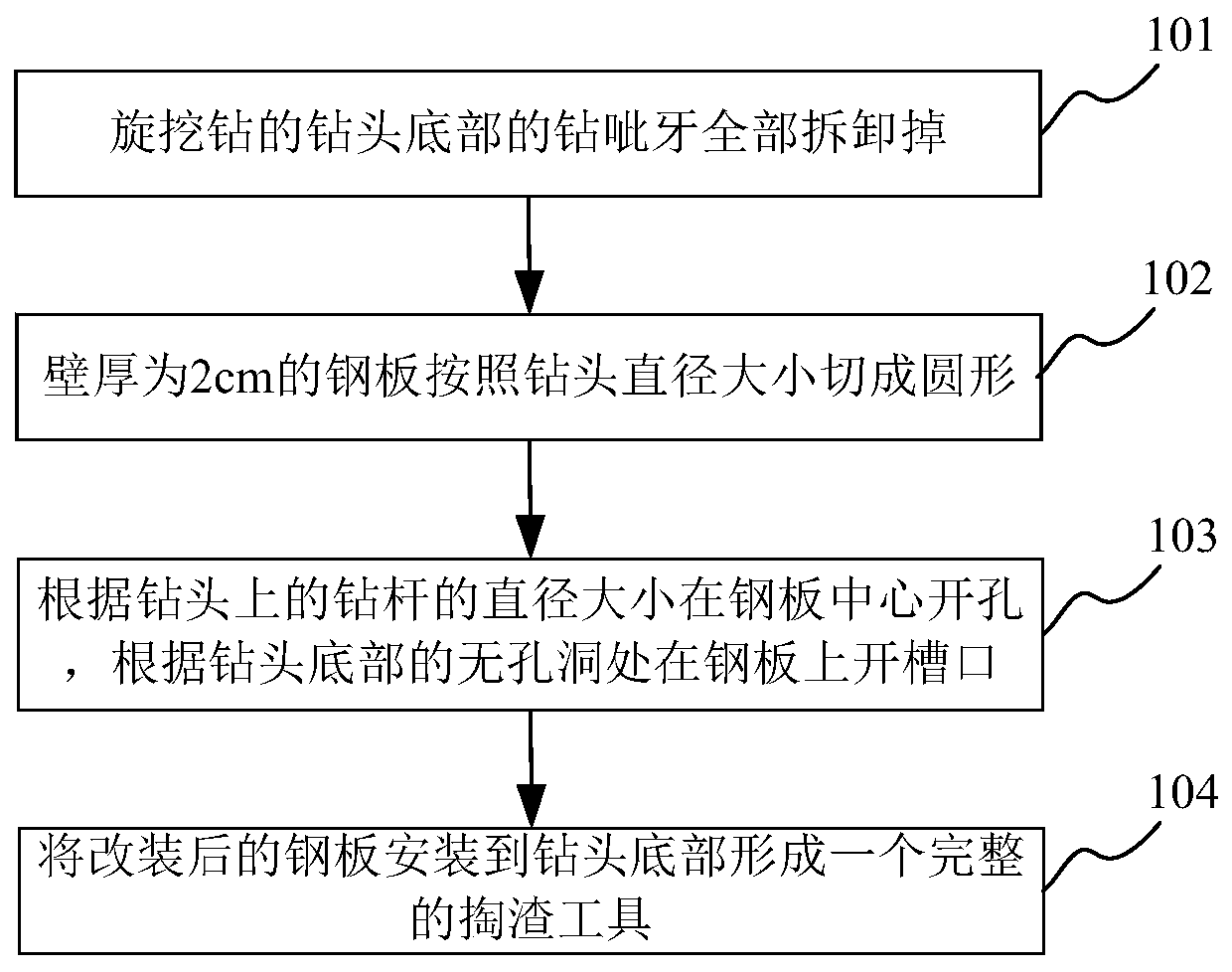

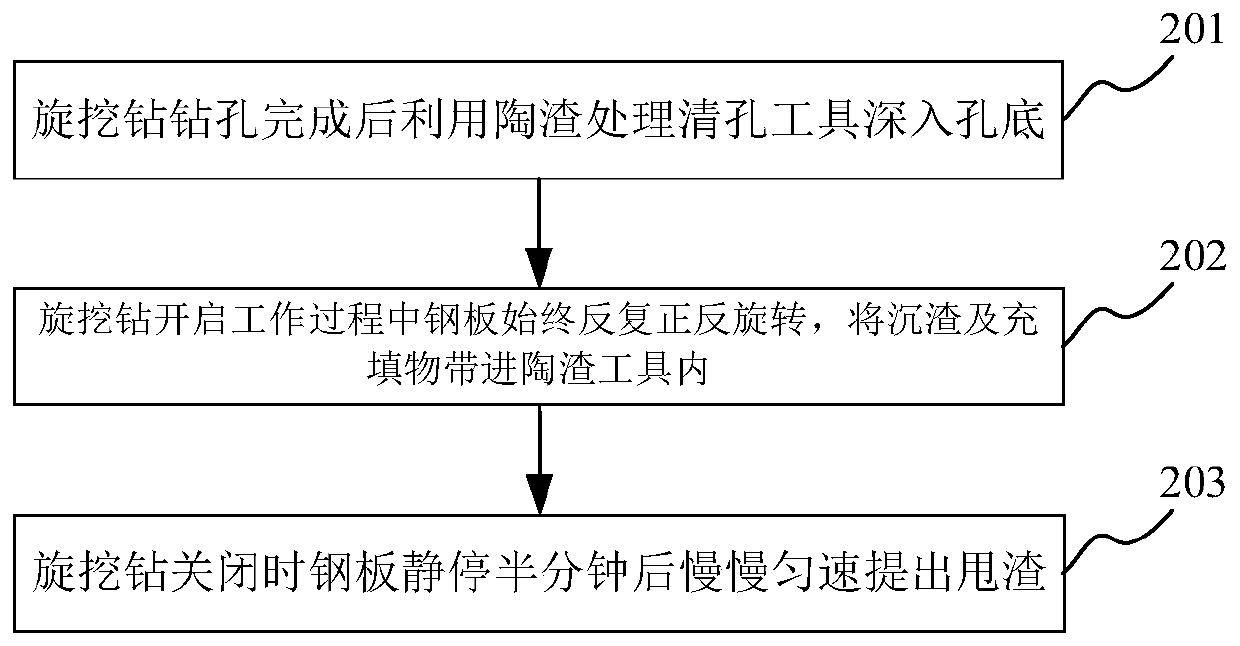

Rotary excavating drill based hole cleaning tool for slag removal in karst area and manufacturing and construction method thereof

A rotary excavating drill based hole cleaning tool for slag removal in karst area comprises a circular steel plate, wherein the diameter of the steel plate is equal to that of the bottom of a drill bit of the rotary excavating drill with the drill teeth removed, an open hole with the diameter equal to that of a drill rod on the drill bit is formed in the center of the steel plate, notches are formed on the two sides of the open hole and in the steel plate and correspond to hole-free parts at the bottom of the drill bit, and the steel plate is installed at the bottom of the drill rod through the open hole. A manufacturing method comprises the steps of: all drill teeth at the bottom of the drill bit of the rotary excavating drill are detached; the steel plate is cut into a round shape according to the diameter of the drill bit; a hole is formed in the center of the steel plate according to the diameter of a drill rod on the drill bit, and notches are formed in the steel plate according to a hole-free part in the bottom of the drill bit; and the modified steel plate is mounted at the bottom of the drill bit to form a complete slag extraction tool. The construction method comprises thesteps of: after drilling is completed, the rotary excavating drill based hole cleaning tool for slag removal is used for going deep into the hole bottom; the steel plate rotates repeatedly all the time in the working process of the rotary excavating drill; and when the rotary excavating drill is closed, the steel plate stands still for half a minute and then is slowly lifted out at a constant speed for throwing out the removed slag.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

A treatment method for grout running out of prefabricated piles planted in crushed stone layers

The invention discloses a grout runout treatment method for planting of a precast pile in a rubble layer. Through the grout runout treatment method, the grout runout problem occurring to the precast pile in the rubble layer is solved. A protective barrel is used during hole forming, thus stratum stability during hole forming is ensured, hole collapse is not liable to occur, after poured grout is poured in, conditions can be provided for initial setting time of the grout, and the effect that before initial setting of the grout, the rubble layer containing water does not collapse towards the inside of the hole is ensured. According to the technical scheme of the grout runout treatment method, the grout runout treatment method comprises the following steps that the precast pile is made and is transported to a pile planting site; the hole position of the precast pile is determined, the precast pile is put into the pile hole after drilling, and the protective barrel is put in the pile hole; the poured grout is made with a set ratio, and the grout is poured into the pile hole from bottom to top; the protective barrel is clamped by a vibration hammer to be matched with a crawler crane and is taken out, and grouting is completed; after grout is solidified for the set time, coring observation is conducted on the grout, and whether the grout runs off is judged; and if yes, holes are formed in the two sides of the pile hole, grout is sprayed, and the grout is reinforced.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

Construction method of sandy soil geological cut-off wall

The invention provides a construction method of a sandy soil geological cut-off wall. A planned position of the cut-off wall is drilled along two sides of the width, so that a row of grouting holes and a row of negative pressure holes are formed; a PC pipe with two opened ends is inserted into each negative pressure hole; then at the same time during grouting into each grouting hole, and a negative pressure is applied to the upper end of the PC pipe in the negative pressure hole corresponding to the grouting hole being grouted, so that guide force is formed between the grouting hole and the negative pressure hole, and paste in the grouting hole penetrates clearance in sandy soil under effects of the guide force and gets cured gradually to form the underground cut-off wall. The method disclosed by the invention has the beneficial effects that the characteristic of good penetration performance of sandy soil geology is utilized, the sandy soil is coordinated with the grouting method, thecut-off wall with mixing of the sandy soil and cement is finally formed, construction is easy, efficiency is high, and anti-seepage effects are good; and the paste forms the wall under guidance of theguide force, a sandy soil stratum is cured by the cement paste, and the characteristic of a high permeability rate of the sandy soil is effectively utilized, so that the underground cut-off wall is built without disturbance of the stratum, and the method is beneficial for environmental protection.

Owner:广东志讯建设工程有限公司

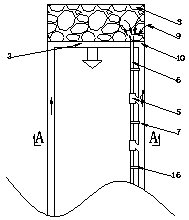

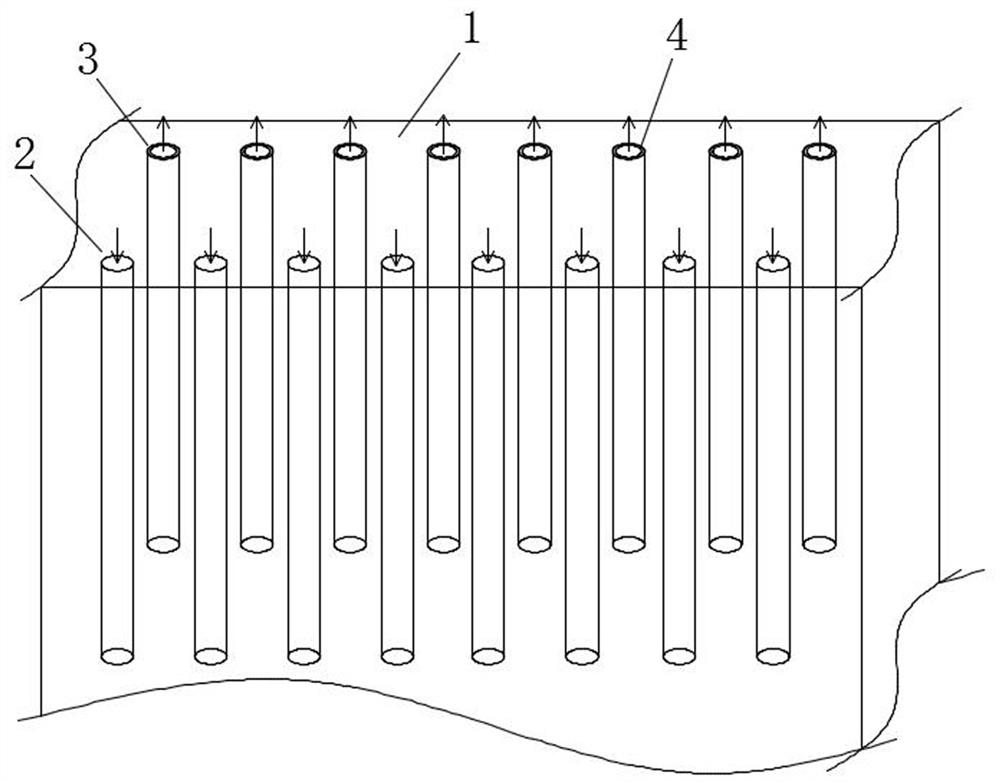

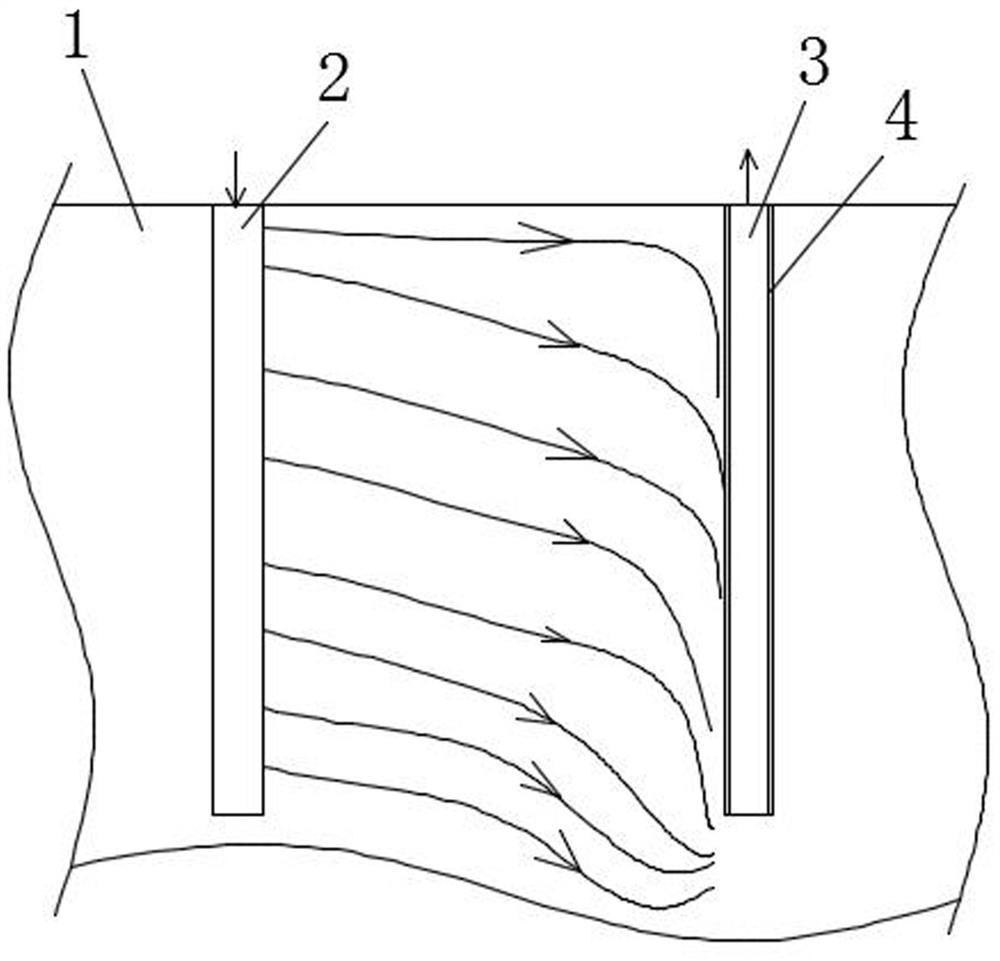

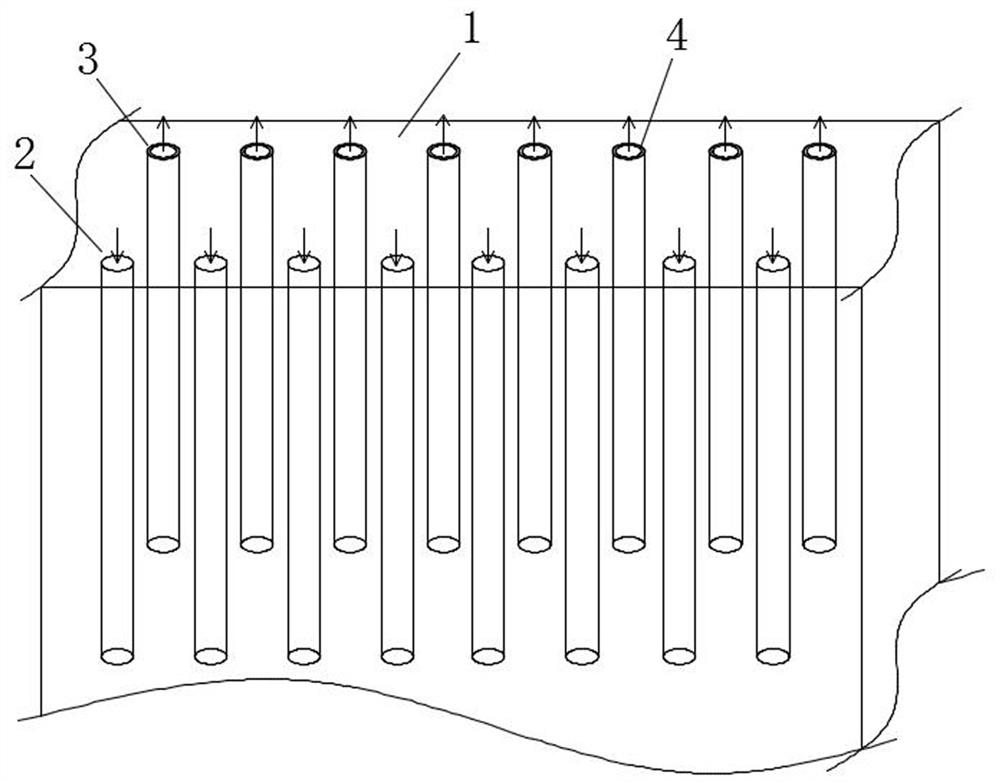

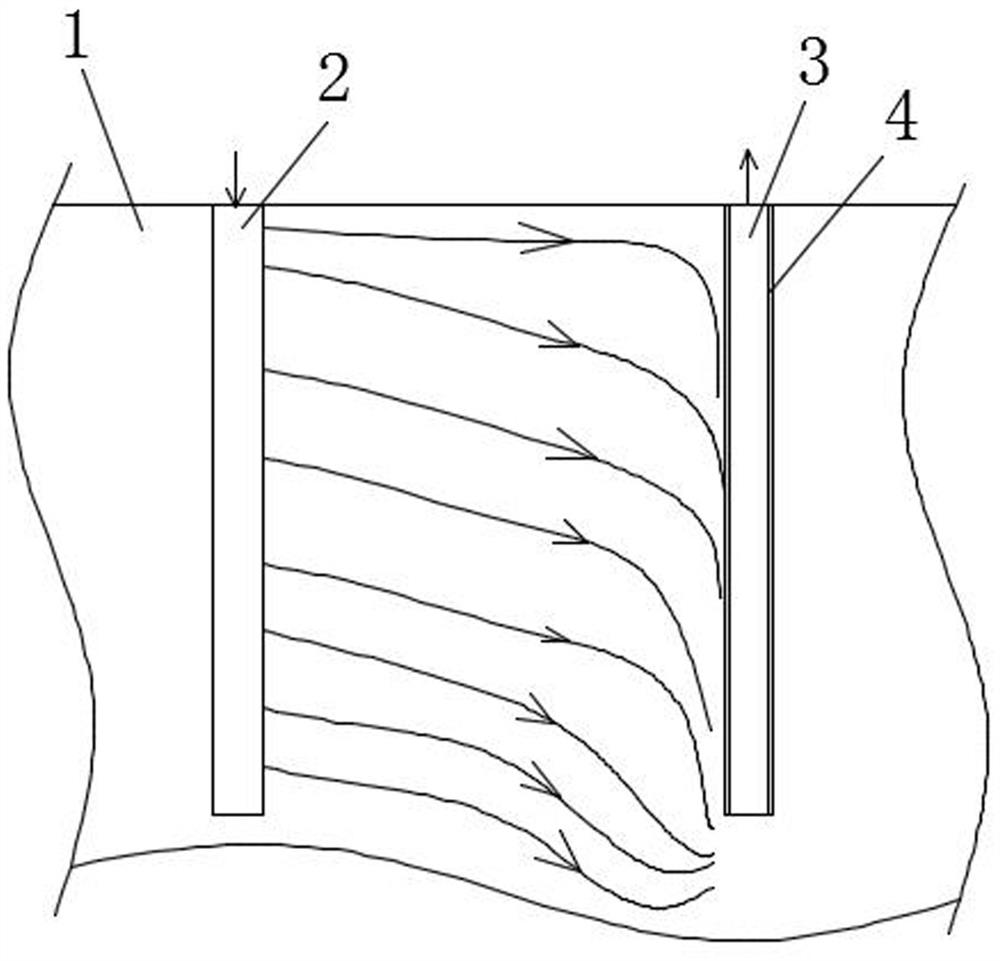

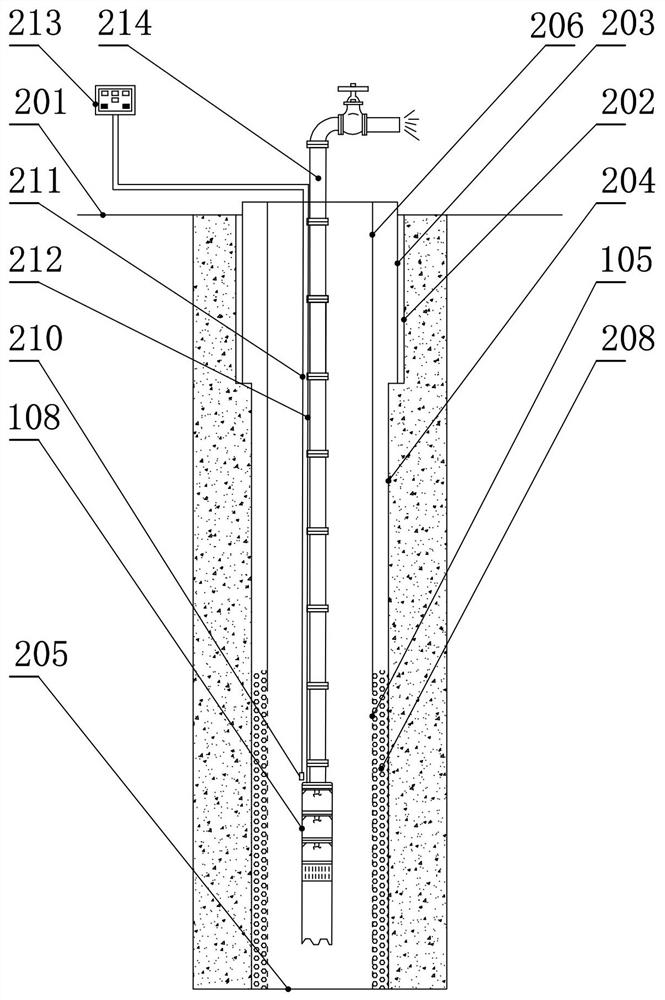

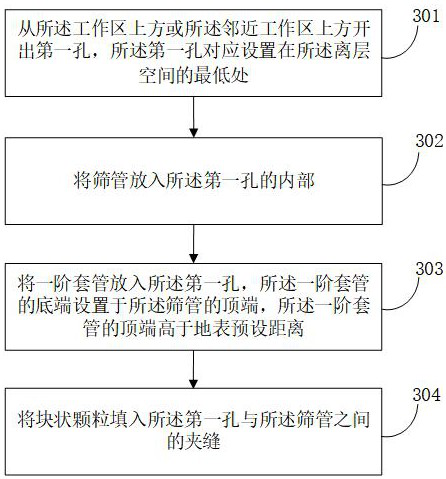

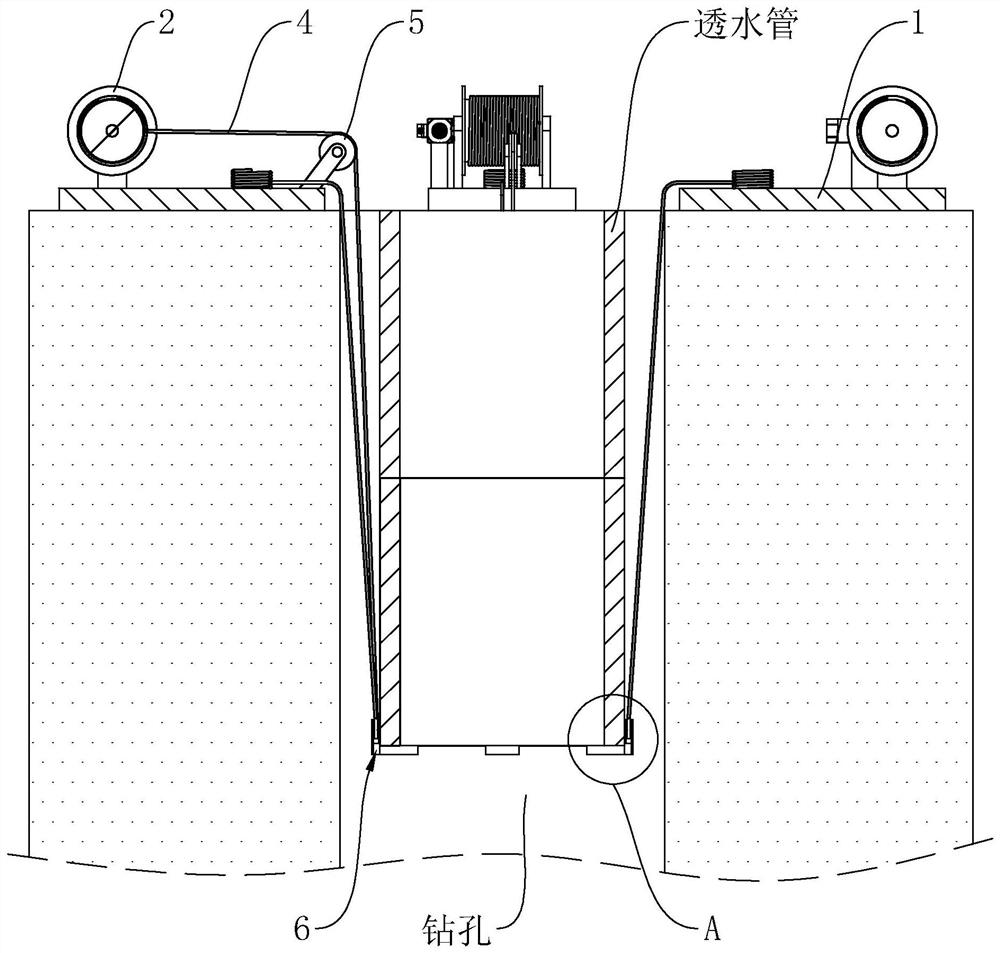

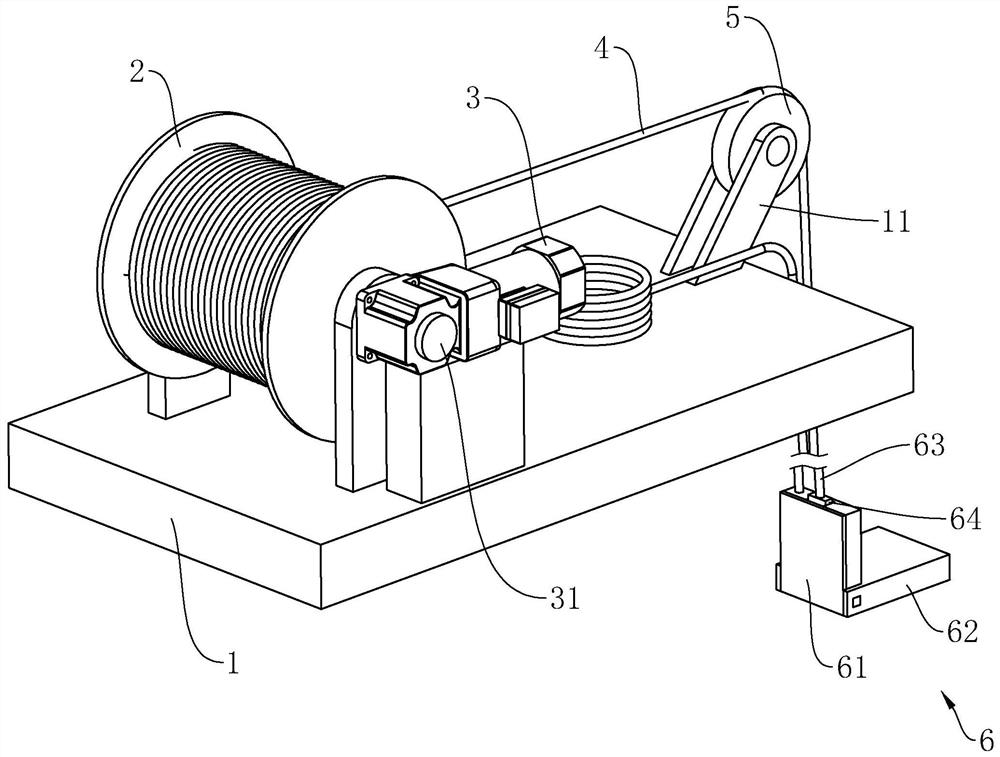

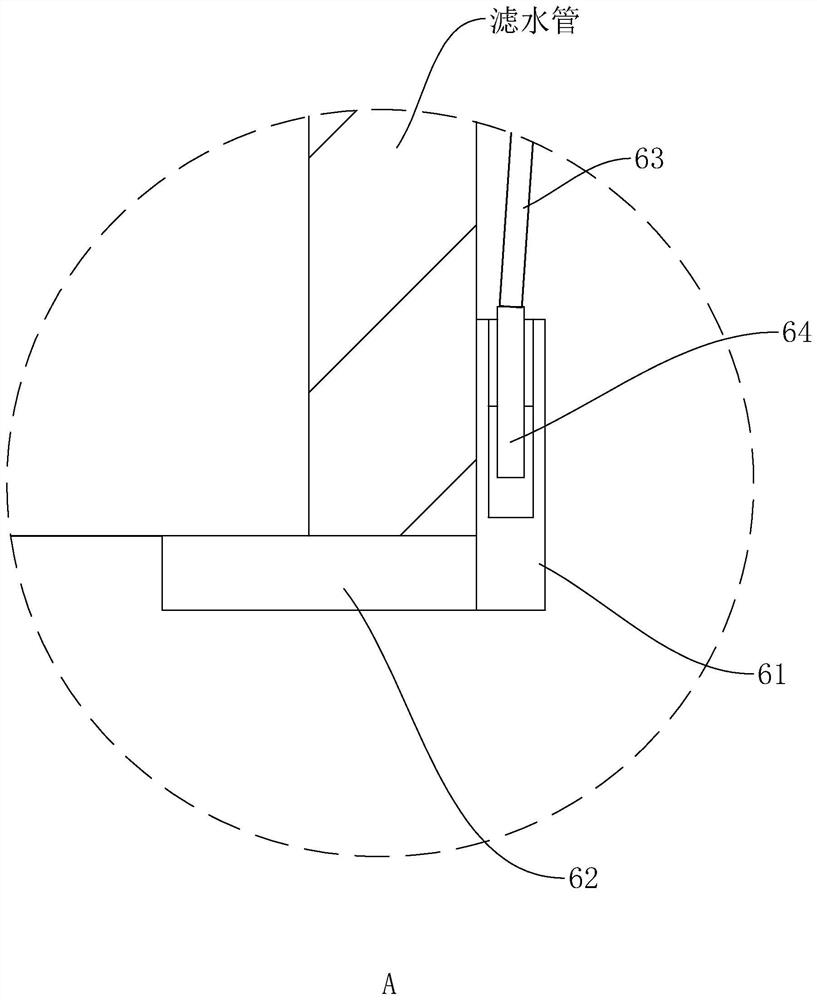

Overlying strata separation water pumping and draining structure and construction method

PendingCN114776374AReduce water inrushNot easy to collapse holesFluid removalDrainageMining engineeringPipe

The invention relates to the technical field of mineral resource mining, in particular to a structure for pumping and draining overlying strata separation water and a construction method.According to the structure, a drainage well is arranged above a mining working area or above an adjacent goaf and penetrates through a separation space, a screen pipe is arranged in the drainage well, and accumulated water above the mining area is effectively pumped and drained through the structure; the drainage well is supported by the screen pipe and not prone to hole collapse, water in the aquifer can be continuously drained to the separation space, accumulated water in the aquifer can be fully drained as much as possible, and the possibility of water inrush in the mining operation area is reduced. According to the method, the positioning hole is firstly formed, the positioning hole drill bit is small in hole diameter, and the positioning effect is good. The hole diameter of the second-order drill hole is large, and after the second-order drill hole is inserted into a protection wall, hole blockage caused by collapse after a drill bit is pulled out when the first-order hole is formed can be prevented. And the second-order drill hole is formed to the water-bearing layer, the water-bearing layer is hard rock, and therefore the supporting effect on the second-order casing pipe is good. And finally, the drainage device is placed in the hole, and construction work is completed.

Owner:李连刚

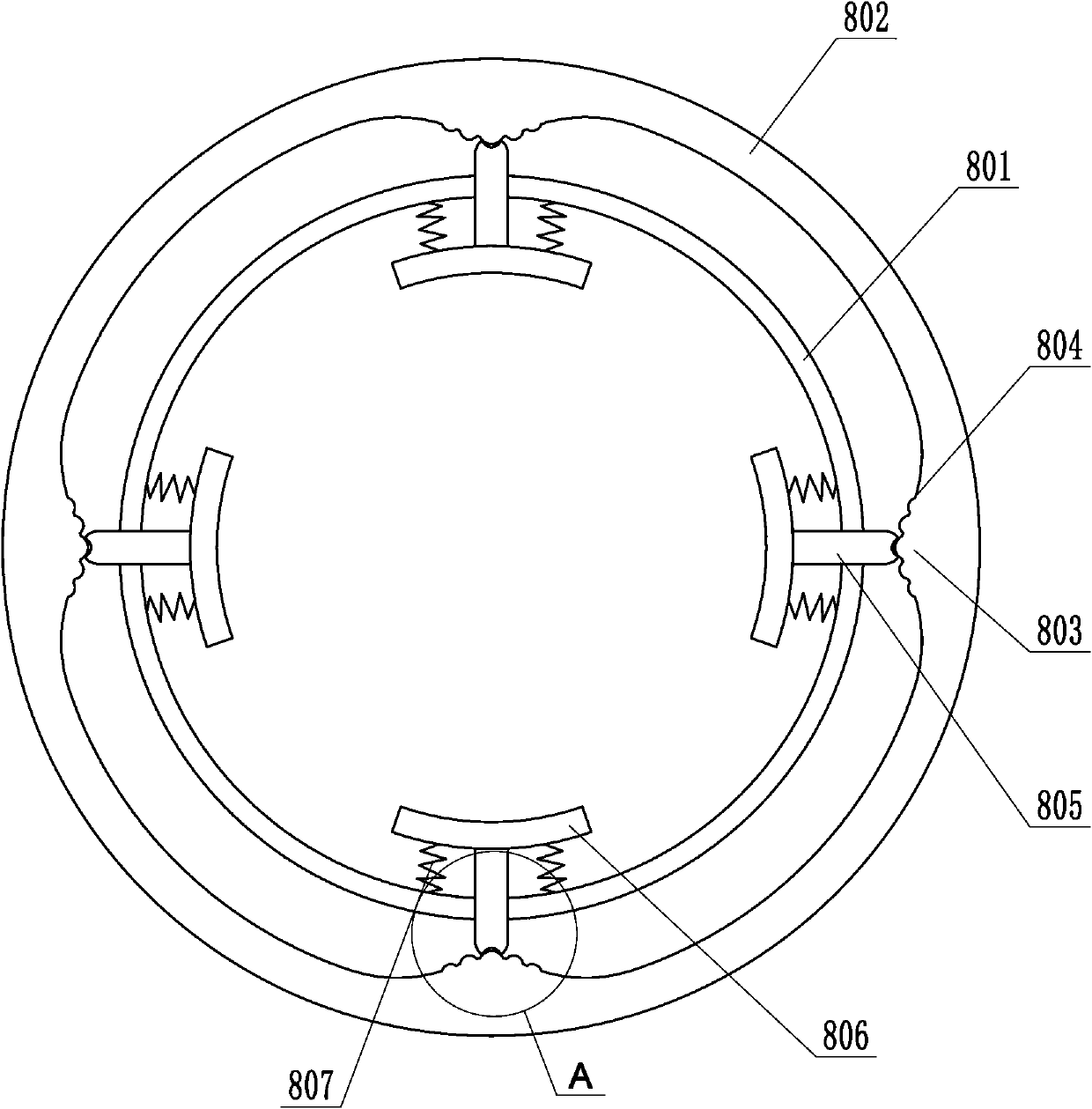

A self-expanding device for bottom expansion

ActiveCN108978646BReduce disturbanceShorten construction timeBulkheads/pilesClassical mechanicsMechanical engineering

The invention discloses a self-expanding device for expanding the bottom, which comprises an outer wall of a self-expanding box and an I-shaped structure; The upward and downward expansion force of the expansion material is suppressed, so that it can only expand horizontally. The invention can pour expansion material into the device, utilize the expansion performance of the expansion material to form an expansion head, the formation of the expansion head has no pollution such as noise and dust, is economical, easy to operate, has a wide application range, and can well meet the requirements for bearing capacity and pullout resistance. Design requirements for pile foundations with higher force requirements.

Owner:荆州市华升新型材料股份有限公司 +1

Construction method for full-casing full-slewing drilling machine pile foundation adjacent to subway

ActiveCN113668512AReduce disturbanceReduce security risksDerricks/mastsDirectional drillingArchitectural engineeringRebar

The invention discloses a construction method for a full-casing full-slewing drilling machine pile foundation adjacent to a subway. The construction method comprises the following steps that S2, a full-slewing drilling machine is placed in place, the center of a base of the full-slewing drilling machine is aligned with the center of a pile placing position, and the base is adjusted to a horizontal state; S3, steel casing sections are connected on site to reach the preset length of a pile casing, and a drill bit is arranged at the end of the first steel casing section; S4, the pile casing is hoisted and the pile casing is connected with the full-slewing drilling machine; S5, the pile casing is vertically driven into a soil layer, a pile hole is sequentially divided into an upper section, a middle section and a lower section from top to bottom for construction, and the subway structure is located within the range of the middle section; S6, after the drilled hole reaches the required depth and the pile hole is checked to be qualified, the hole is cleaned; and S7, a reinforcement cage is hoisted, and in the hoisting process, the reinforcement cage is kept vertical all the time and is coaxial with the pile casing. The construction method for the full-casing full-slewing drilling machine pile foundation adjacent to the subway has the effects that disturbance of pile foundation construction to soil around the subway tunnel is reduced, hole collapse is not prone to occurring, and safety risks caused by pile foundation construction to the subway structure and subway operation are reduced.

Owner:CRPCEC SHENZHEN ENG +1

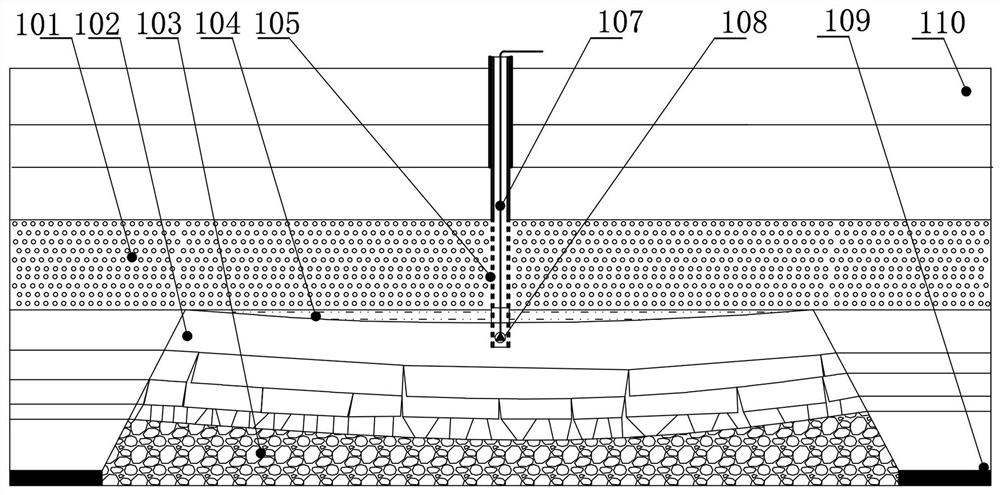

High-water-level long spiral well completion construction process

PendingCN113187381ANot prone to hole collapseNot easy to collapse holesFlushingSealing/packingDrill holeWater pipe

The invention relates to a high-water-level long spiral well completion construction process, and belongs to the technical field of water intake well construction. The construction process comprises the following construction steps: a long spiral drilling machine is used for drilling to a designed depth; a drill rod is pulled out of a drill hole, and slurry is poured into the drill hole; after the drill rod is completely pulled out, a permeable pipe is put down into the drill hole; high-concentration slurry in the drill hole is replaced with low-concentration slurry; an annular gap between the permeable pipe and the drill hole is filled with gravel; and clean water is used for well washing operation. The long spiral drilling machine is adopted for drilling construction, compared with a direct circulation drilling machine or a reverse circulation drilling machine, a drilled hole is formed at a time, the drill rod of the long spiral drilling machine is continuously located in the drilled hole in the drilling process, the drill rod plays a role in supporting the side wall of the drilled hole, and the phenomenon that the drilled hole collapses is not prone to occurring.

Owner:中基发展建设工程有限责任公司

Device for self-expanding of expanded base

ActiveCN108978646AReduce disturbanceShorten construction timeBulkheads/pilesEngineeringSelf expansion

The invention discloses a device for self-expanding of an expanded base, The device comprises an outer wall of a self-expansion box body and an I-shaped structure, wherein an self-expansion material is filled in the self-expansion box body, the self-expansion box body and the I-shaped structure limit the upward and downward expansion force of the expansion material, so that the self-expansion material can only horizontally expand. According to the device, the self-expansion material can be poured into the device, the expansion performance of the self-expansion material is utilized to form an expansion head, the formation of the expansion head is free of pollutant of noise, dust and the like, and is economical and practical, operation is convenient and application range is wide, the designrequirement of a pile foundation with relatively high requirement on the bearing capacity and the pulling resistance can be well met.

Owner:荆州市华升新型材料股份有限公司 +1

Novel reverse circulation drilling method

PendingCN111550181AGood hole indexNot easy to collapse holesSurveyFlushingSlurryPetroleum engineering

The invention belongs to the technical field of reverse circulation drilling, and particularly relates to a novel reverse circulation drilling method. The novel reverse circulation drilling method comprises the following steps of arranging a circulating pool, preparing slurry, drilling holes and detecting formed holes. The novel reverse circulation drilling method has the beneficial effects that the holes are not easy to collapse in the drilling process; the multiple adjacent holes do not influence one another during construction; and the hole forming index is good.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

Method for constructing high-strength cavity at bottom of vertical well

ActiveCN110017120AHigh hardnessImprove formation strengthDrilling rodsConstructionsHorizontal wellsSlag

A method for constructing a high-strength cavity at the bottom of a vertical well is used for exploiting natural gas hydrates in sea areas, and comprises the following construction steps that drillinghydrate overlying strata; drilling a stratum below a hydrate bottom plate; expanding a cavity at the stratum under the hydrate bottom plate; pouring high-pressure cement paste without lifting a drillto form a high-strength cement primary pile; drilling the high-strength cement primary pile; secondary cavity expanding; removing slag in the cavity; cavity expanding detection; cementing and filling; and completing the vertical well bottom cavity construction. A reaming cast-in-place pile technology is adopted, by means of two-time cavity expanding and two-time pouring pile forming, the diameterof the primary pile is large, the final pile is subjected to cavity expanding pouring on the basis of the primary pile, the final pile is high in strength and regular in shape, the vertical well bottom cavity is built on the final pile, the stratum strength around the cavity is high, and the requirement on gathering gas production from multiple well groups of horizontal wells to the vertical wellcan be met.

Owner:EXPLORATION TECH RES INST OF CHINESE ACADEMY OF GEOLOGICAL SCI +1

A method for constructing a high-strength chamber at the bottom of a vertical well

ActiveCN110017120BHigh hardnessImprove formation strengthDrilling rodsConstructionsHorizontal wellsWell cementing

A method for constructing a high-strength chamber at the bottom of a vertical well, which is used for exploiting natural gas hydrates in sea areas, comprising the following construction steps: drilling into the stratum overlying the hydrate; drilling into the stratum below the hydrate floor; expanding the cavity in the stratum below the hydrate floor High-strength cement primary piles are formed by pouring high-pressure cement slurry without drilling; drilling of high-strength cement primary piles; secondary cavity expansion; chamber slag cleaning; cavity expansion inspection; The invention adopts the technology of reaming cast-in-place piles, through two times of cavity expansion and two times of pouring into piles, the diameter of the initial pile is relatively large, and the final pile is filled with cavity expansion on the basis of the initial pile, and the final pile has high strength and regular shape. The bottom hole chamber of the vertical well is built on the terminal pile, and the formation strength around the chamber is high, which can meet the requirements of gathering gas from horizontal wells to vertical wells in multiple well groups.

Owner:EXPLORATION TECH RES INST OF CHINESE ACADEMY OF GEOLOGICAL SCI +1

Energy-saving type open caisson vibroflotation pile composite foundation construction technology

The invention discloses an energy-saving type open caisson vibroflotation pile composite foundation construction technology. A construction method of the technology includes the following steps that a, positioning is carried out; b, pile casing embedding is carried out; c, vibroflotation sinking debugging is carried out; d, prefabricated tube well embedding is carried out; e, vibroflotation sinking is carried out; f, prefabricated tube well spreading is carried out; g, vibroflotation sinking is continuously carried out; h, energy-saving mixing material pouring is carried out; k, vibration and pile forming are carried out; and m, transposition is carried out. The energy-saving type open caisson vibroflotation pile composite foundation construction technology has the beneficial effects that the technology is reliable, construction is easy and convenient, the construction cost is low, re-utilization of resources can be achieved, hole collapsing is not prone to occurring in the hole forming process, the pile body quality is easily guaranteed, the foundation stabilization speed is high, the foundation stabilization effect is good, and the foundation bearing force is high.

Owner:IANGSU COLLEGE OF ENG & TECH

Guide hole type static pile driver and construction method of guide hole type static pile driver

InactiveCN114215060AAvoid breakingNot easy to collapse holesBulkheads/pilesArchitectural engineeringPile driver

The invention provides a guide hole type static pile driver. The guide hole type static pile driver comprises a static pile driver, a side pile and guide hole equipment, the hole guiding equipment comprises a hole guiding base and a hole guiding mechanism, the hole guiding base is installed on the static pile driver, the hole guiding mechanism is detachably installed on the hole guiding base, the hole guiding base is at least provided with a first installation position and a second installation position, and when the hole guiding mechanism is installed at the first installation position, the hole guiding mechanism corresponds to a pile pressing mechanism of the static pile driver. The hole guiding mechanism is arranged corresponding to the pile pressing mechanism of the side pile when being mounted at the second mounting position; the hole guiding mechanism comprises a hole guiding device and a spiral drill rod, the spiral drill rod is installed on the hole guiding device, the hole guiding device is used for driving the spiral drill rod to rotate, and the maximum diameter of the spiral drill rod is smaller than the diameter of the inner ring of the prefabricated pipe pile. Meanwhile, the invention further provides a construction method of the guide hole type static pile driver. Compared with the prior art, the guide hole type static pile driver and the construction method thereof can better guarantee the construction quality of the prefabricated pipe pile.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

A bolt drilling device for foundation pit slope in soft soil layer

ActiveCN111550197BDoes not compromise integrityReduce dustDrilling rodsReciprocating drilling machinesClassical mechanicsRock bolt

The invention relates to a soft soil layer foundation pit side slope anchor rod drilling device, which comprises a mounting bracket arranged on the breaking hammer head of a hydraulic breaker, a first mounting plate arranged at the bottom of the mounting bracket, and a The steel pipe used for drilling on the board; the present invention forms a drill rod by installing a steel pipe on the breaking hammer head of a hydraulic breaker, and uses the hydraulic function of the breaking hammer to push the steel pipe into the soil layer and form a hole after reaching the designed depth. Suitable for soft soil slopes.

Owner:HEBEI ROAD & BRIDGE GROUP

Vibration and extrusion type drilling machine

InactiveCN102409974BNo pollution in the processImprove efficiencyDrilling drivesDrilling machines and methodsDrilling machinesPetroleum engineering

Owner:HENR TECH GUANGXI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com