Construction method for full-casing full-slewing drilling machine pile foundation adjacent to subway

A technology of full rotary drilling rig and construction method, which is applied in basic structure engineering, excavation, sheet pile wall and other directions, can solve the problems of large soil disturbance, low safety, easy to collapse holes in subway tunnels, etc., so as to save construction period and improve Safety and the effect of not easily collapsing holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

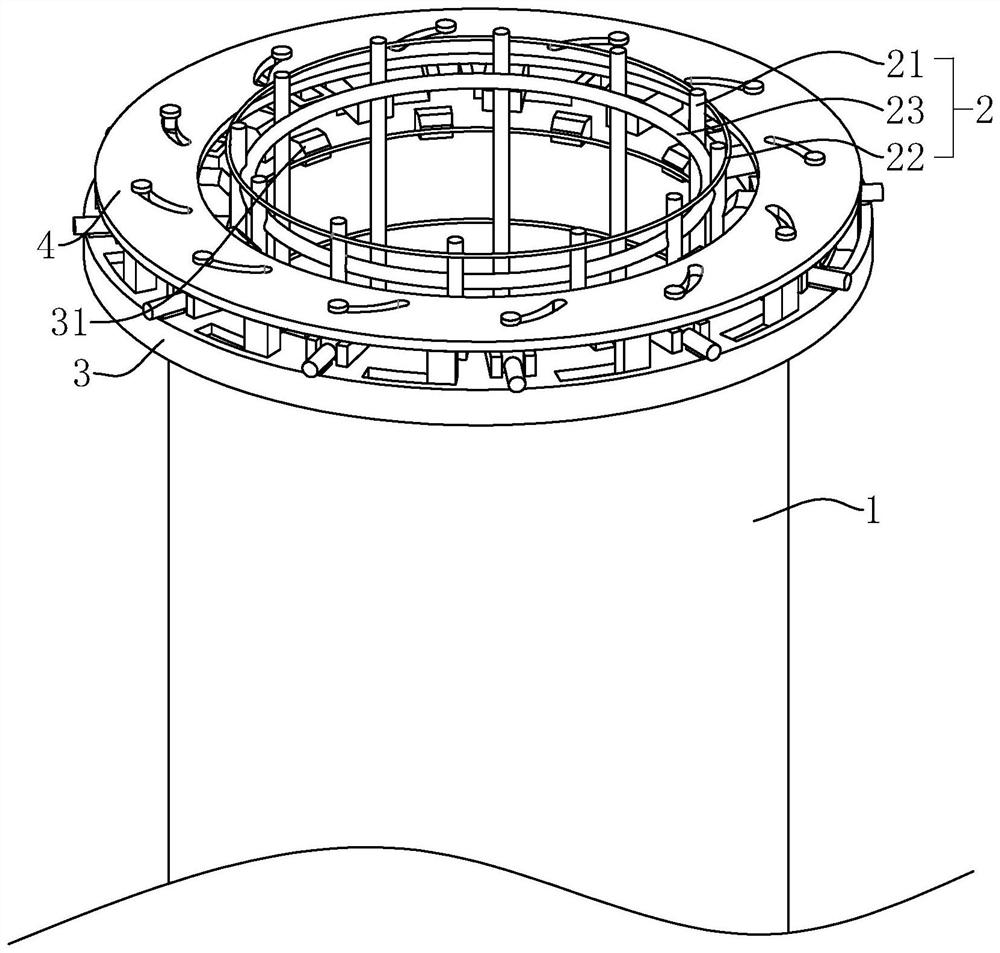

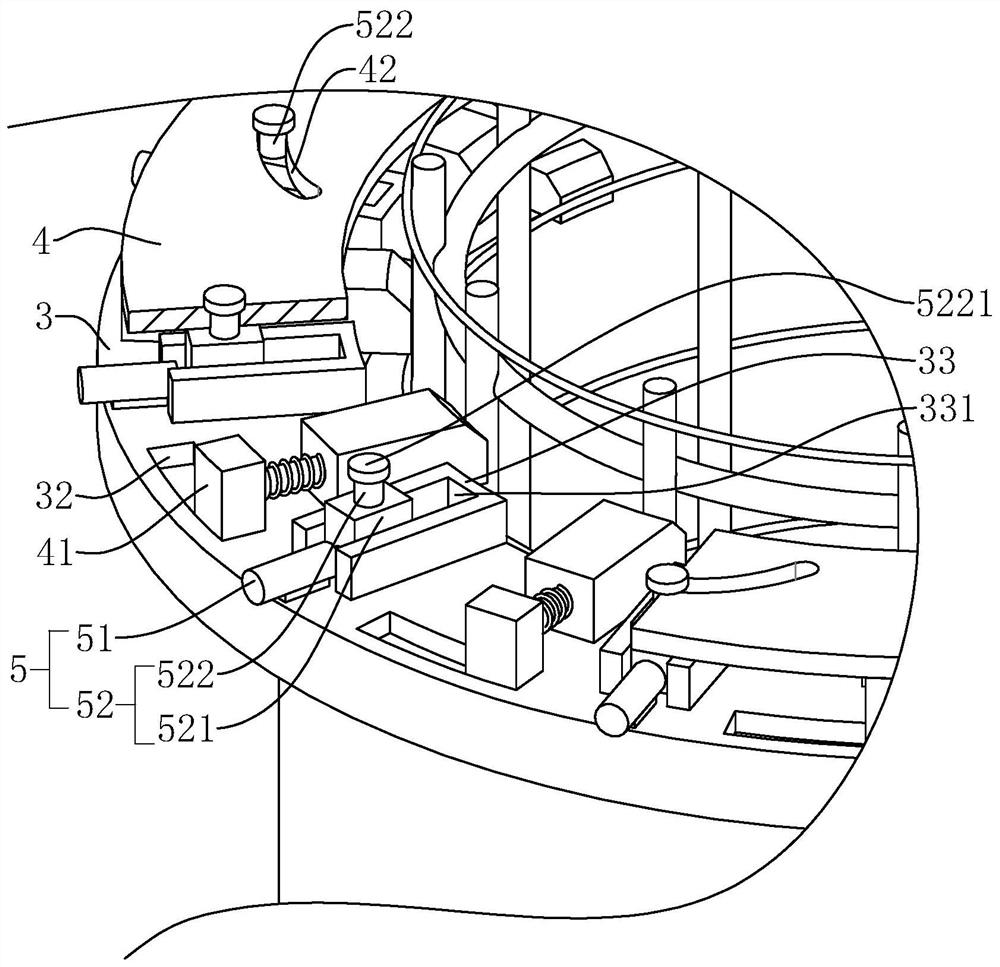

[0045] The following is attached Figure 1-6 The application is described in further detail.

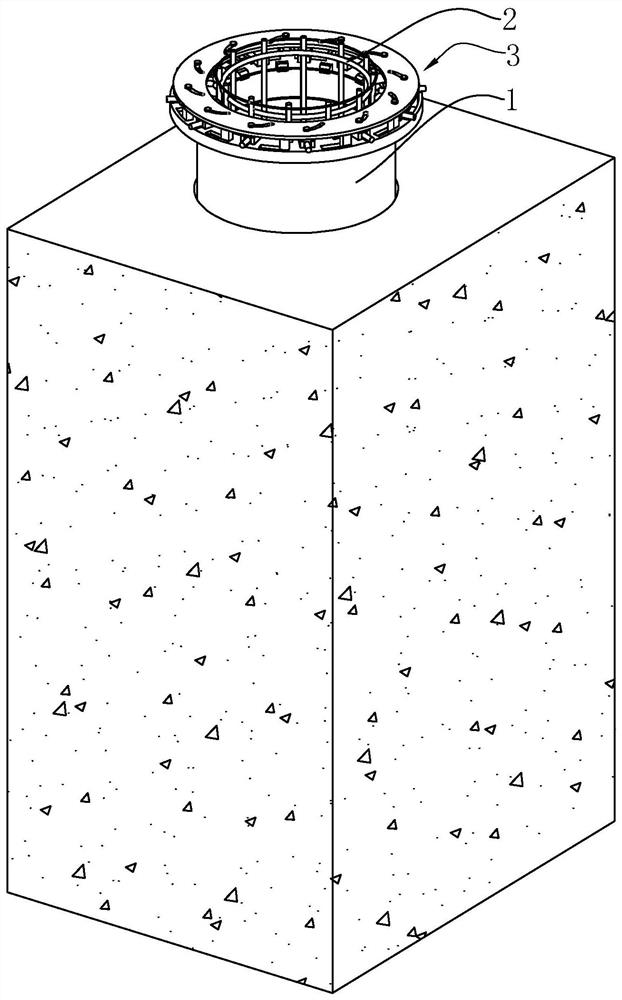

[0046] The embodiment of the present application discloses a pile foundation construction method of a full-casing full-rotary drilling rig adjacent to a subway.

[0047] combine Figure 1 to Figure 6 A construction method for a pile foundation with a full-casing full-rotary drilling rig adjacent to a subway, comprising the following steps:

[0048] S1, measuring and setting out:

[0049] After the site is leveled and compacted, the coordinate positioning method is used, and the total station is used to measure the axis, measure the line, and determine the pile position.

[0050] S2. The full-rotary drilling rig is in place:

[0051] First install the base of the rotary drilling rig with a crane, pull the cross line up on the round mouth of the base to align the center of the base with the center of the pile position, and then fix it so that the center of the base of the full-rotary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com