High-water-level long spiral well completion construction process

A construction technique and long helical technology, applied in drilling equipment, flushing wellbore, wellbore/well components, etc., can solve the problems of hole collapse and poor protection effect of the sidewall of the drilled hole, so as to improve the efficiency and speed up the construction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

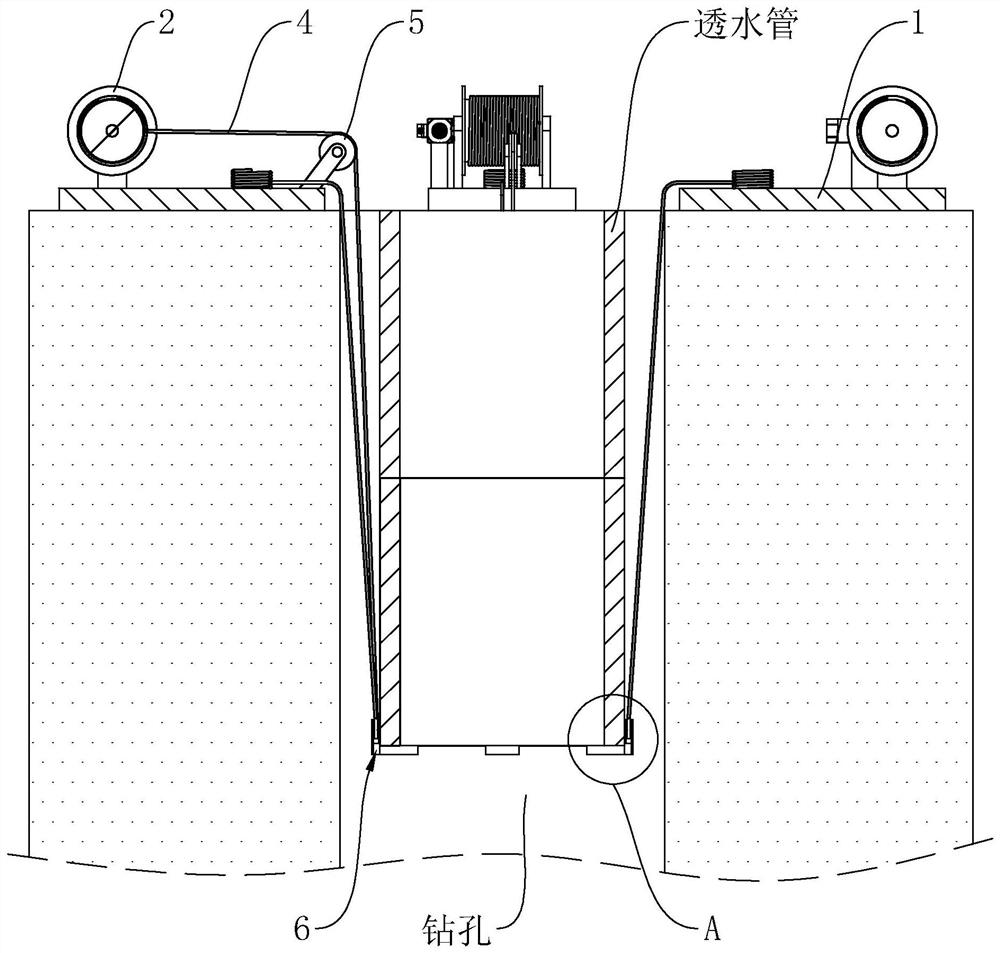

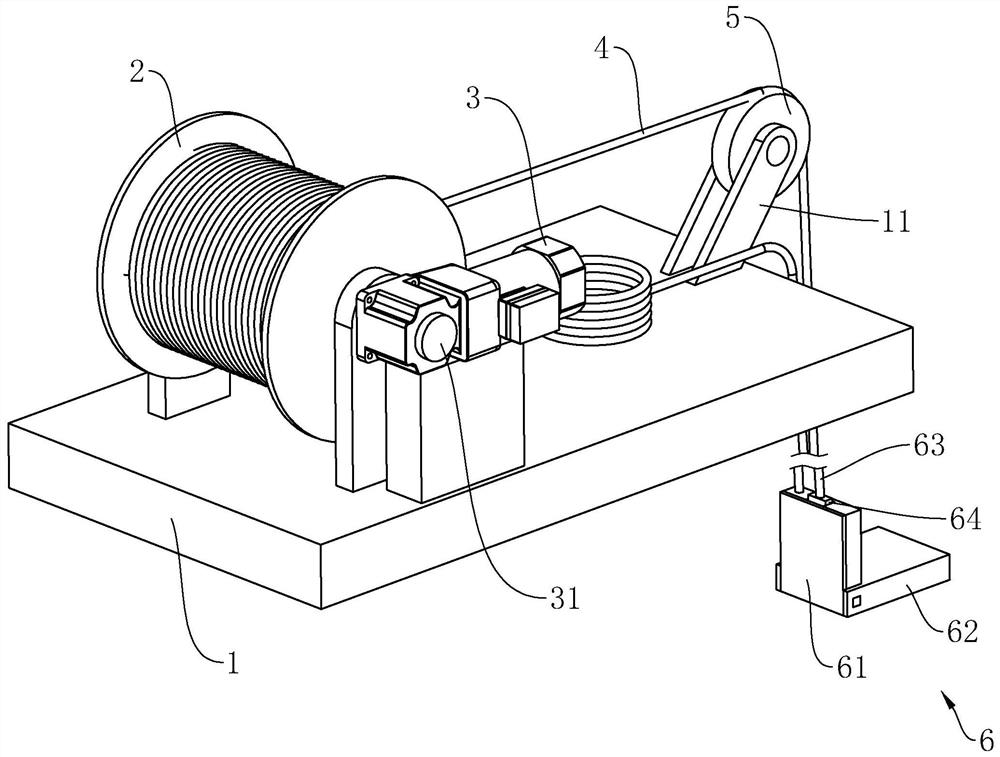

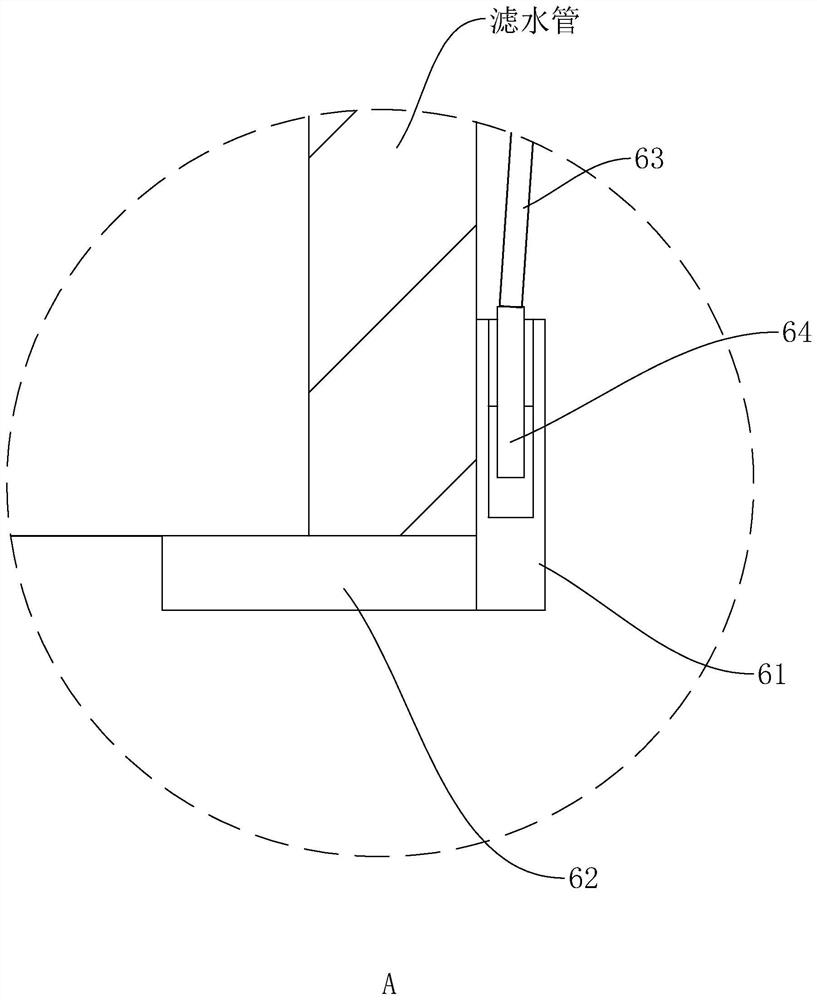

[0040] The following is attached Figure 1-5 The application is described in further detail.

[0041] The embodiment of the present application discloses a high-water-level long-spiral well-forming construction technology.

[0042] S1, drilling

[0043] Drilling is carried out with a long auger drilling rig. According to the design dimensions of the diameter and depth of the well, and in combination with the height of the groundwater level, a corresponding type of long auger drilling rig is selected. In this embodiment, the long auger drilling rig of model JZB90 is used as an example.

[0044] Before drilling, the surface should be cleaned and leveled according to the location of the water intake well, and the location of the water intake well should be marked. After moving the drilling rig to the designated position, do a good job of machine leveling, equipment layout, equipment stacking, etc., and then position the drill pipe of the drilling rig and adjust the verticality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com