A treatment method for grout running out of prefabricated piles planted in crushed stone layers

A prefabricated pile and gravel layer technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of cement-soil slurry running, achieve not easy hole collapse, improve self stability, and prevent pile hole slurry loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

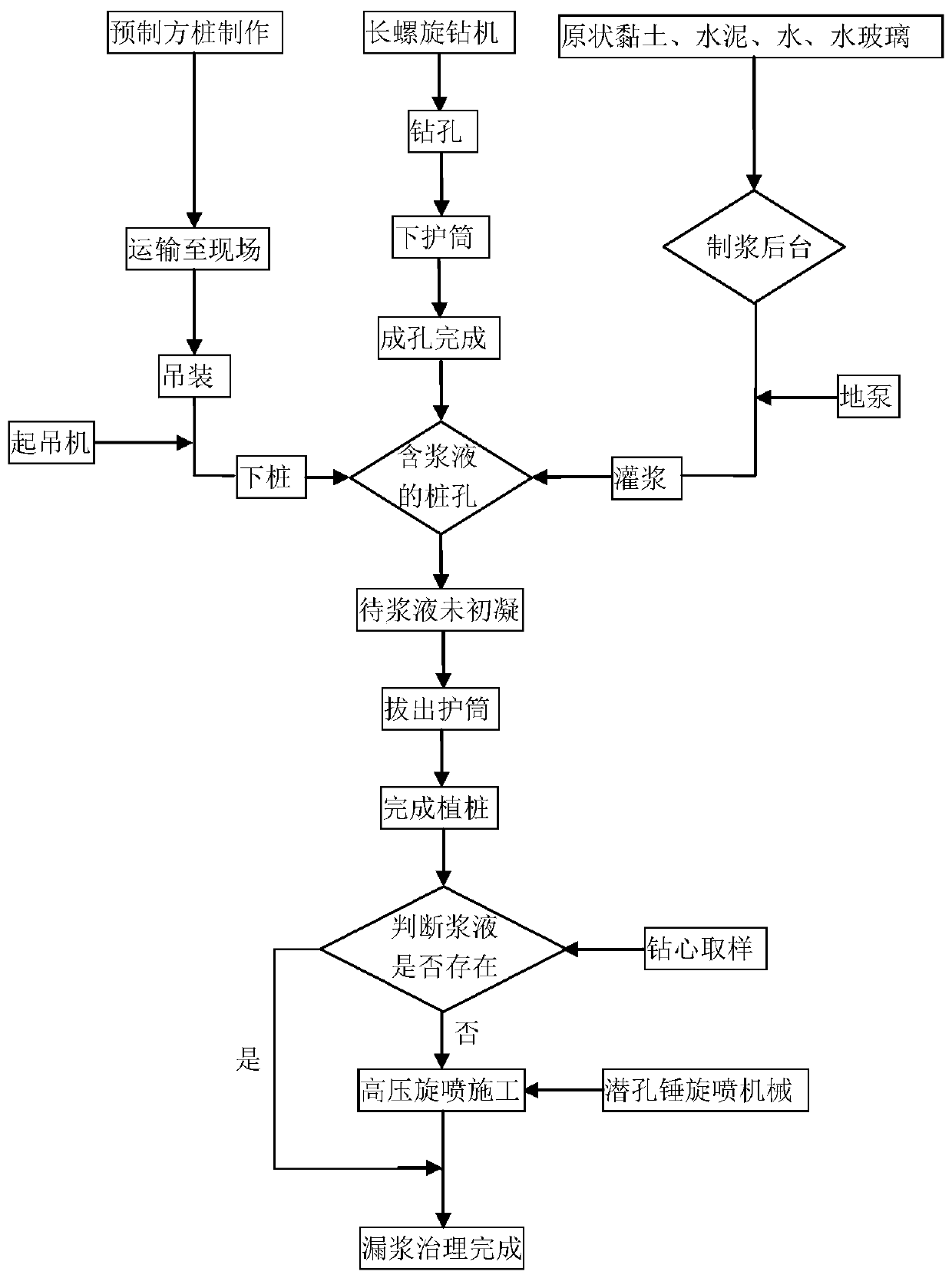

[0073] The method of running mortar for planting precast piles in gravel layers adopts the following steps:

[0074] Step 1: Fabrication and transportation of precast piles.

[0075] Make precast square piles in the precast pile factory and transport the precast piles to the pile planting site.

[0076] The length of the prefabricated square pile is 24m, and the side length is 700mm×700mm.

[0077] The prefabricated square piles are provided with hoisting rings for loading and unloading with equipment.

[0078] Step 2: Measure the laying-out and hole planting.

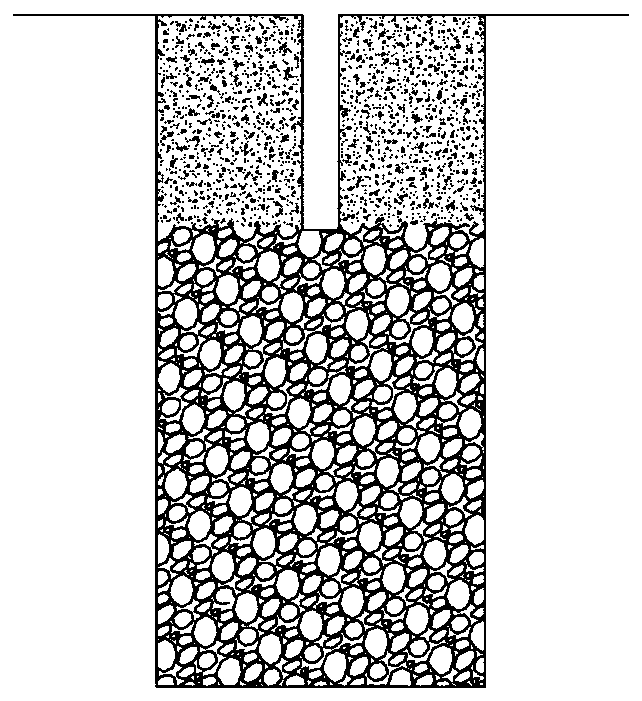

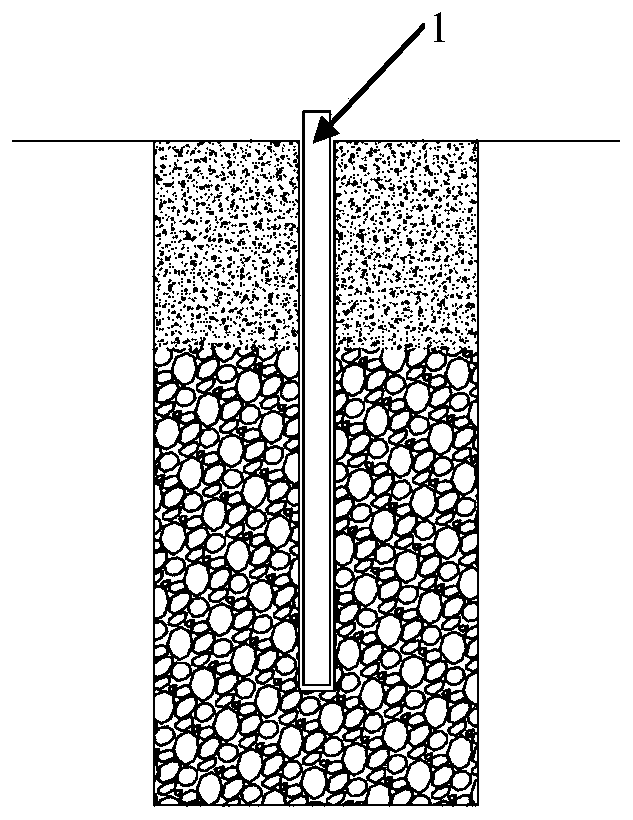

[0079] Use the total station to determine the hole position of the precast pile and construct the guide groove of the precast pile position; use the dual-power-head long auger drill to drill the hole with a hole diameter of 1100mm. When drilling to the gravel soil layer, use the drill to follow the drill bit. The hole is drilled to the elevation of the bottom of the hole, and the hole depth is 24m; the prefabricated square pile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com