Patents

Literature

37results about How to "Reduce coal mining costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

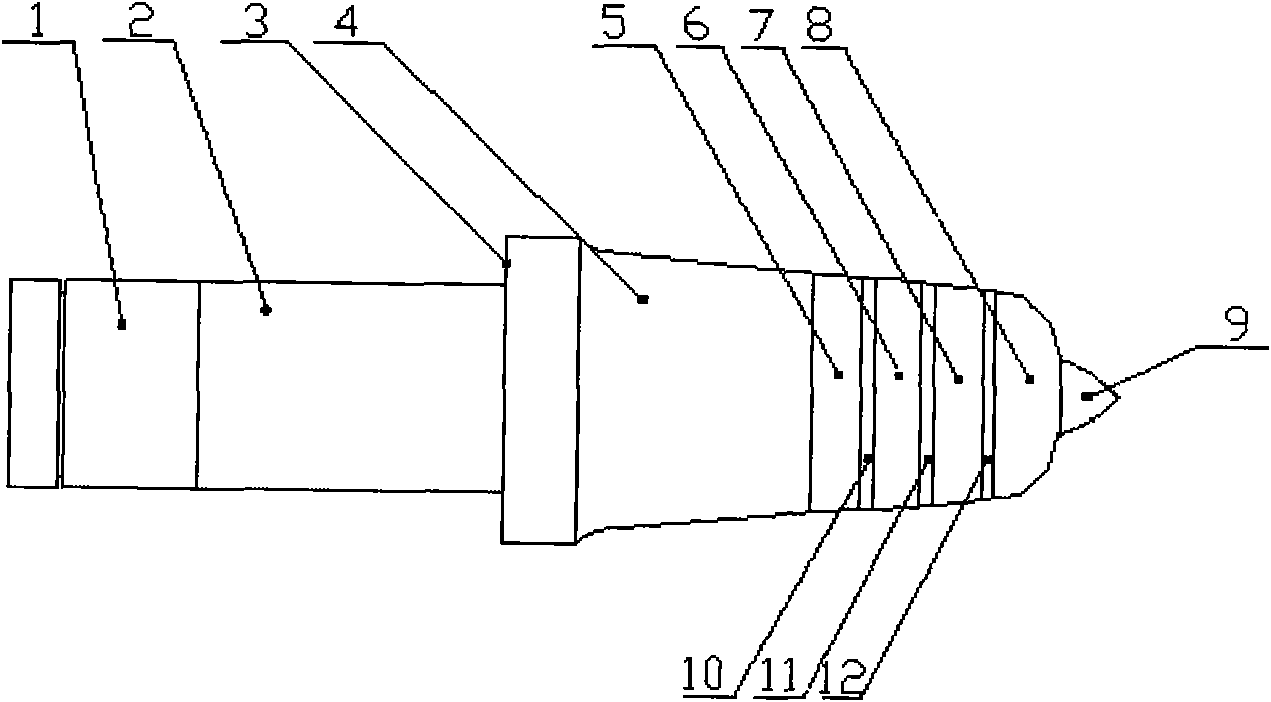

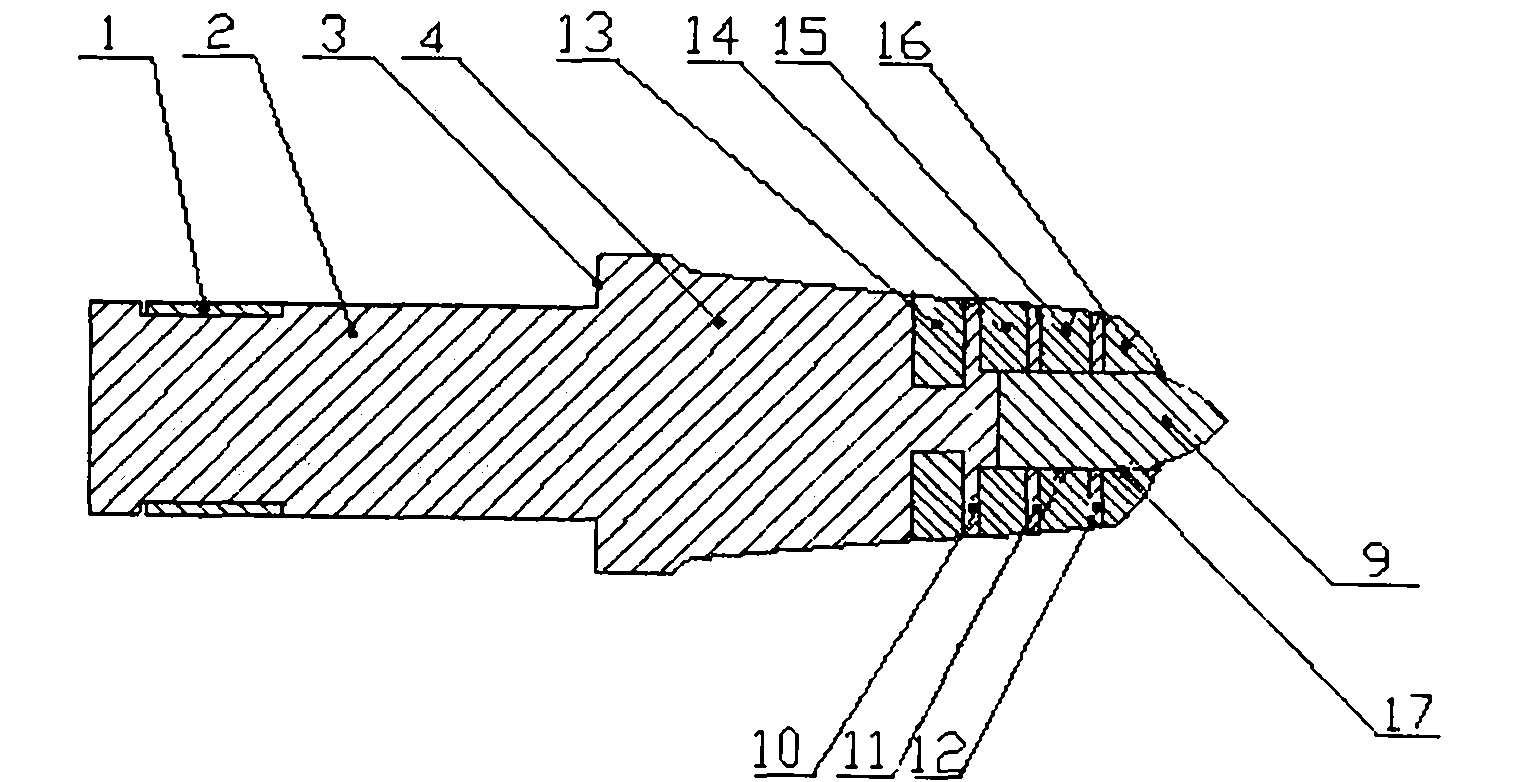

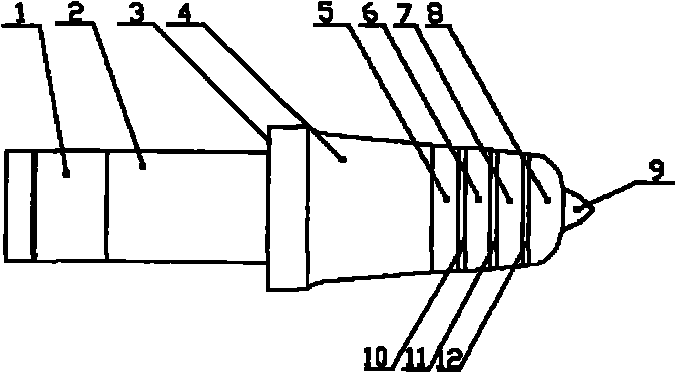

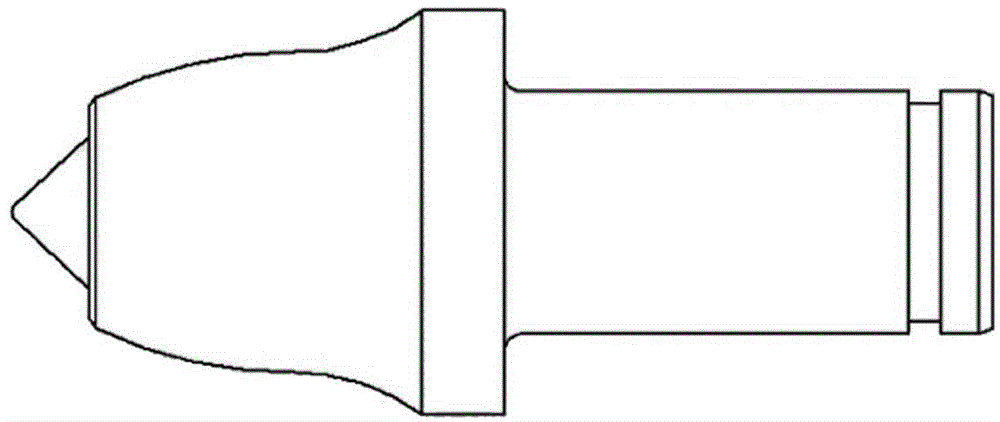

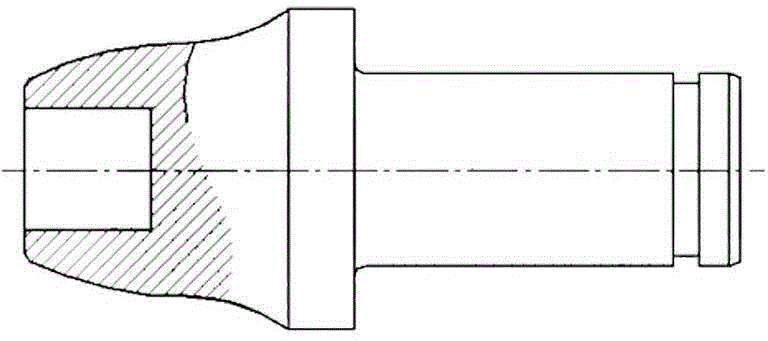

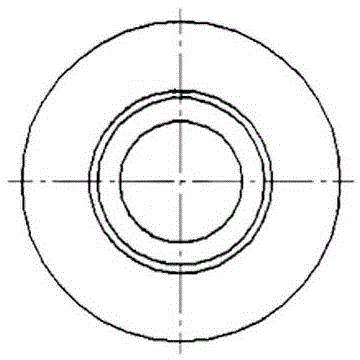

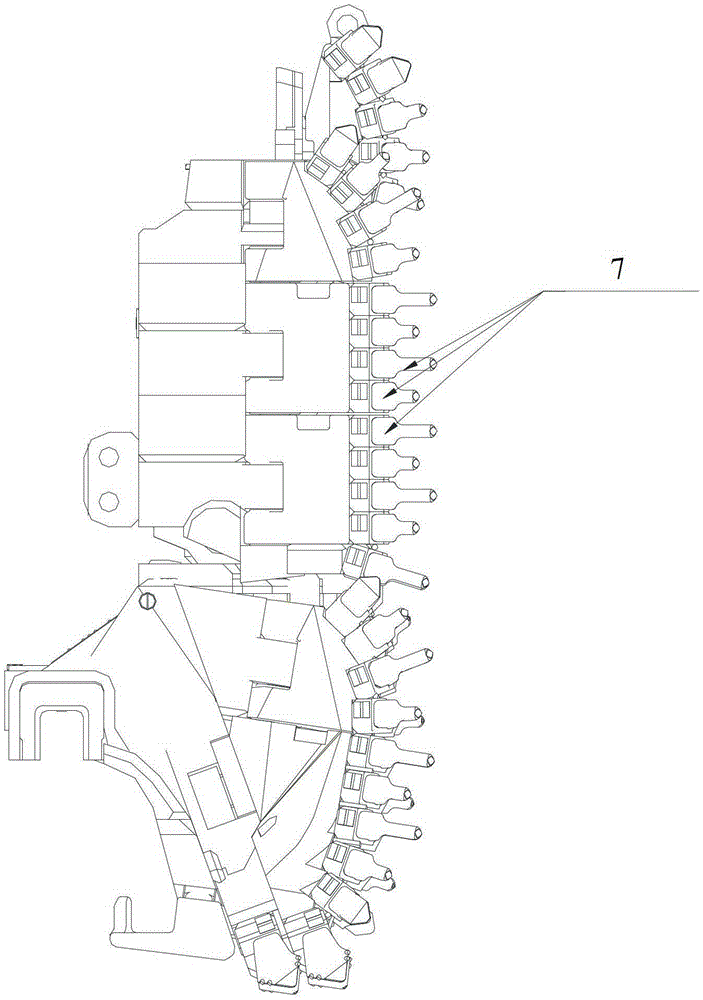

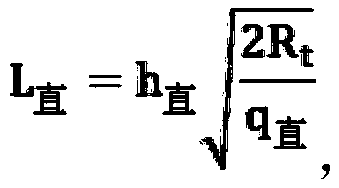

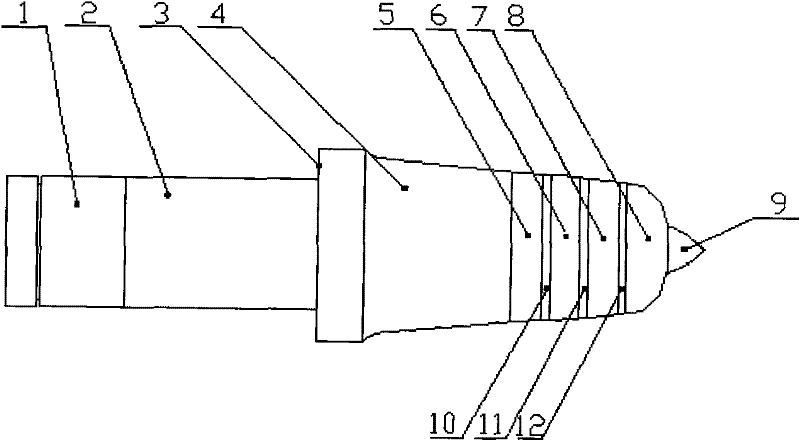

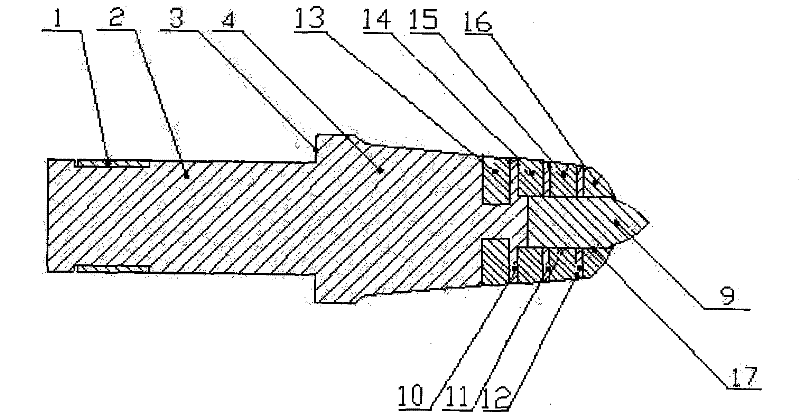

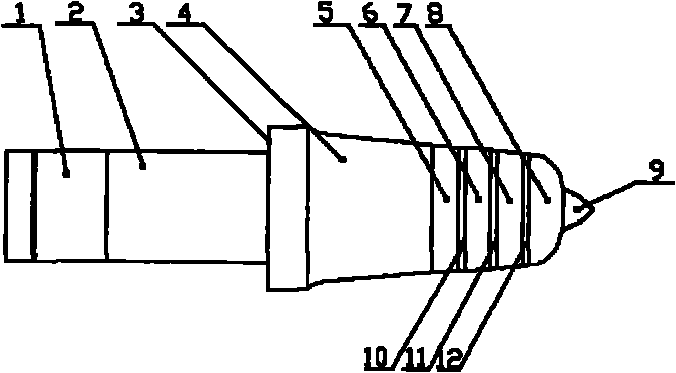

Pick having bimetal structure and preparation method thereof

InactiveCN101787887AMeet the bonding strengthImprove wear resistanceCutting machinesWear resistantMetallic materials

The invention relates to a pick having a bimetal structure and a preparation method thereof, in particular to a pick and a preparation method applicable to coal mining machines and tunneling machines capable of cutting coal seams and rock strata, belonging to the technical field of the research on mining machinery metallic materials and geotechnical engineering. The pick is characterized in that the pick body consists of two metals, wherein the most wear-prone top end of a pick head of the pick is made of tailor-made alloy steel; the wear-resistant lower ends of the pick handle and pick head are made of medium carbon alloy steel; a plurality of ring-shaped grooves are formed below the top end of the pick head; an interlayer is arranged between every two adjacent ring-shaped grooves; the ring-shaped grooves are subjected to full-surfacing process by using the tailor-made alloy steel welding rods; and since the interlayer is thin, the integral wear-resistant tailor-made alloy steel can be formed at the top end of the pick head. The pick of the invention has the advantages of simple structure, novel design, high practicability, convenient fabrication, high hardness and wear resistance and good impact-resisting and corrosion-resisting performance; and according to industrial tests, compared with the homemade pick, the service life of the pick is prolonged by 20 to 30 times, thus saving a great deal of alloy steel materials for our country and reducing the mining cost.

Owner:TAIYUAN UNIV OF TECH +1

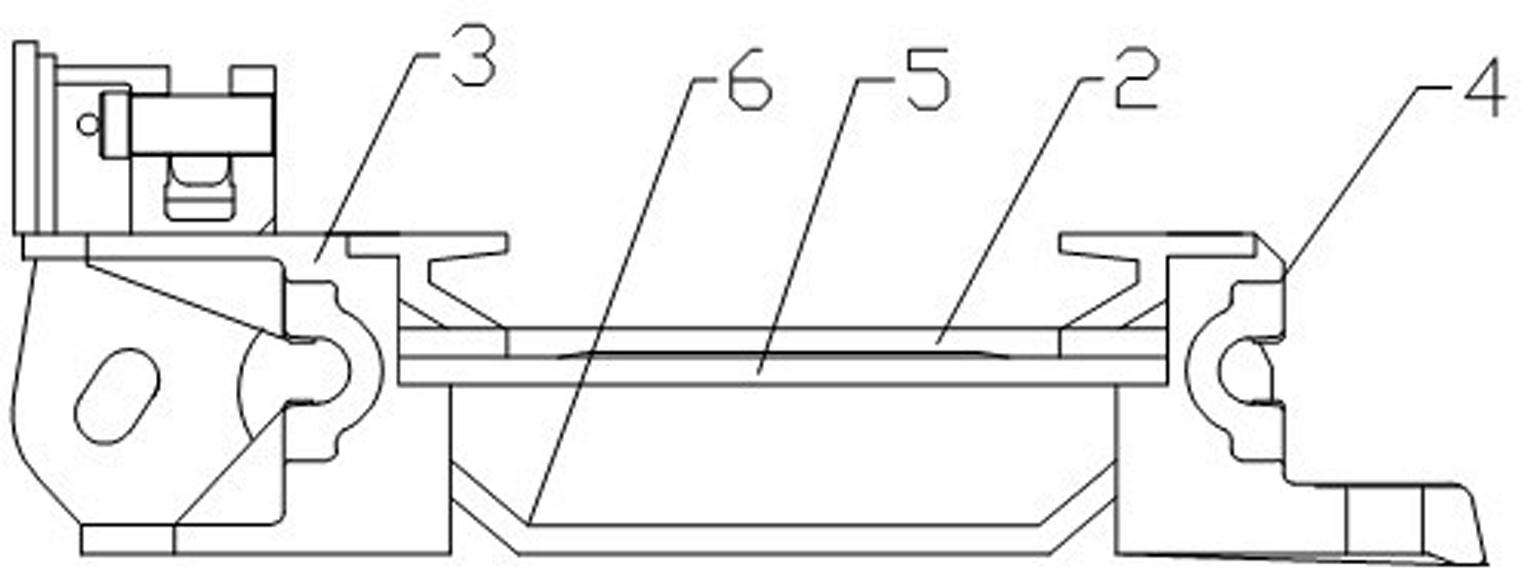

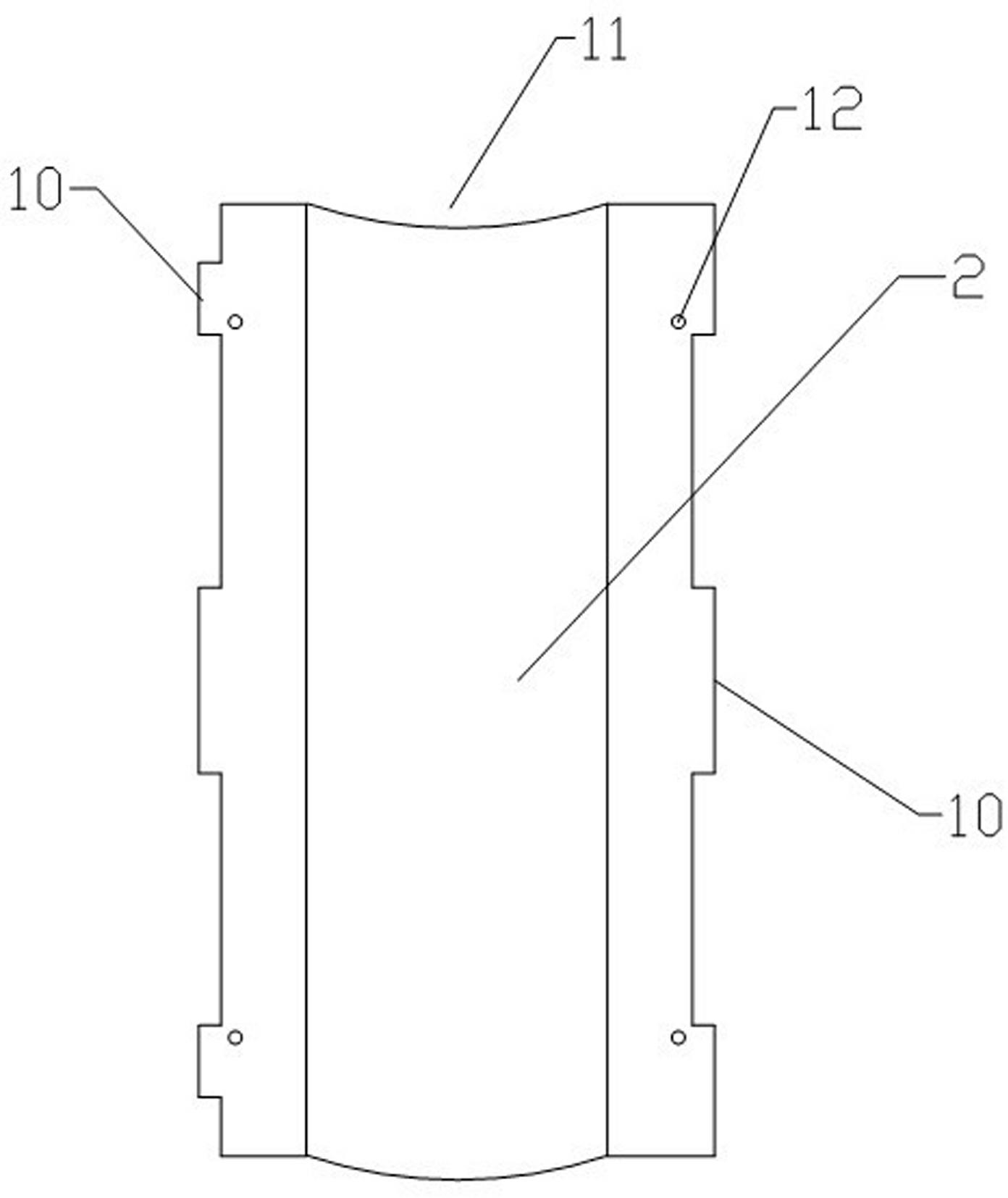

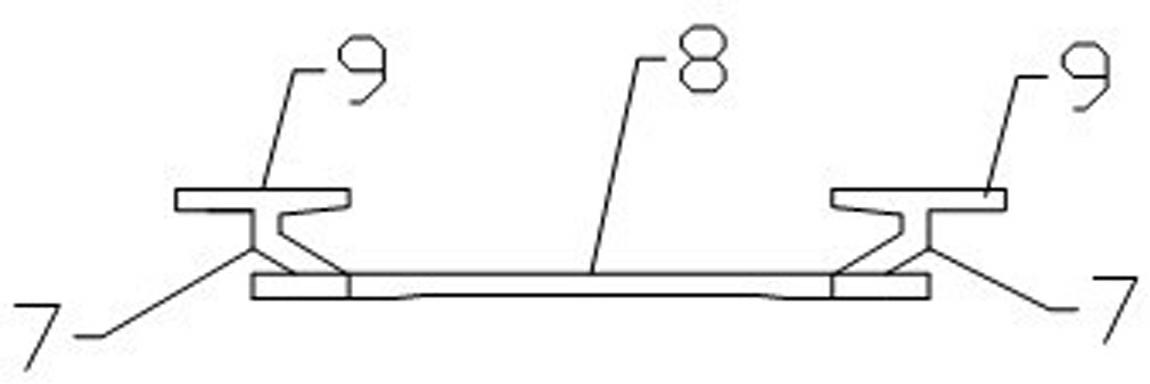

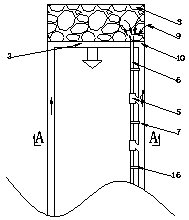

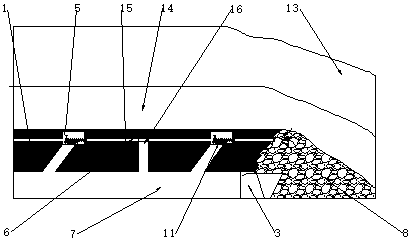

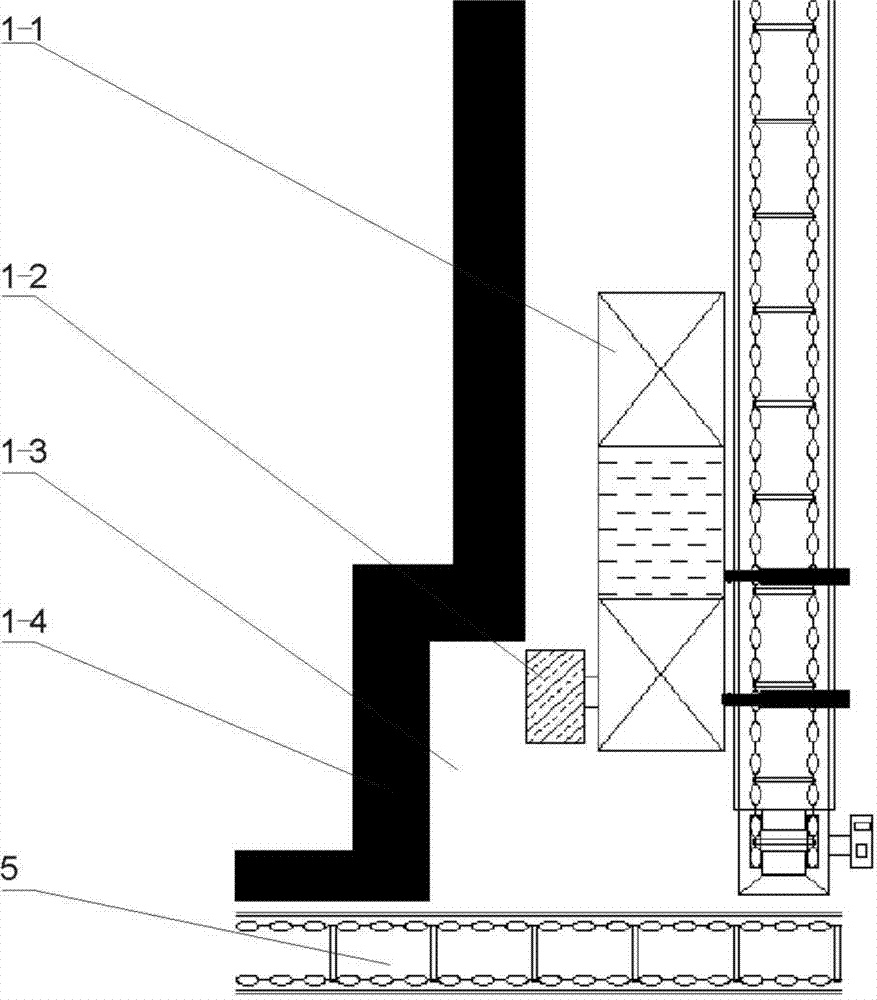

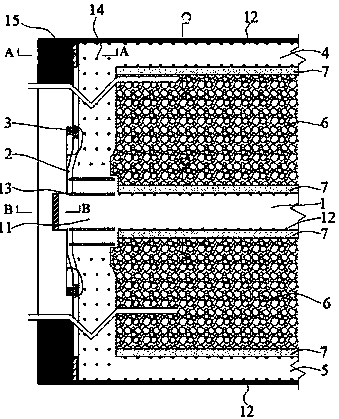

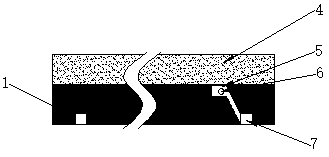

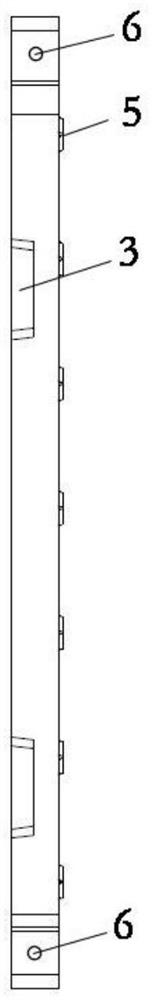

Middle trough for composite trough body scraper conveyor

InactiveCN102502177APlay a protective effectExtended service lifeConveyorsAgricultural engineeringAngle alpha

The invention discloses a middle trough for a composite trough body scraper conveyor. The middle trough comprises a middle trough body, wherein the middle trough body comprises a baffle plate ledge, a shovel plate ledge, a middle plate and a base plate; a lining trough is arranged in a trough cavity on the upper part of the middle plate, and comprises a lining trough base plate and side plates fixedly connected to two sides of the lining trough base plate along the width direction; wing plates are fixedly connected to the tops of the side plates; the cavity of the lining trough is used as an upper scraper chain channel; limiting clamping heads are arranged on the outer sides of the wing plates; an included angle alpha between the inner surface of the ledge of the middle trough and the surface of the middle plate is not less than 90 degrees; limiting clamping openings corresponding to the limiting clamping heads are formed in the baffle plate ledge and the shovel plate ledge; and the limiting clamping heads are correspondingly arranged in the limiting clamping openings. When damaged, the lining trough can be taken down from the trough opening conveniently without opening a middle trough connection piece; time and labor are saved; the middle trough is convenient to maintain quickly; the work efficiency is improved greatly; and the coal mining cost is reduced.

Owner:SHANDONG MINING MASCH GRP CO LTD

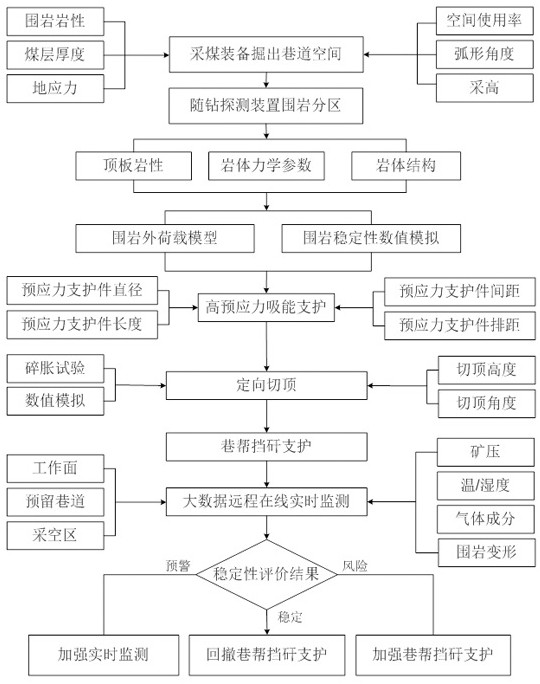

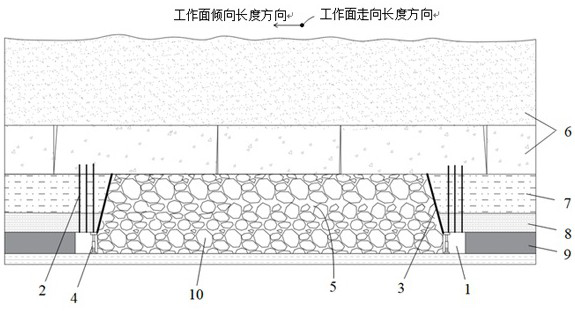

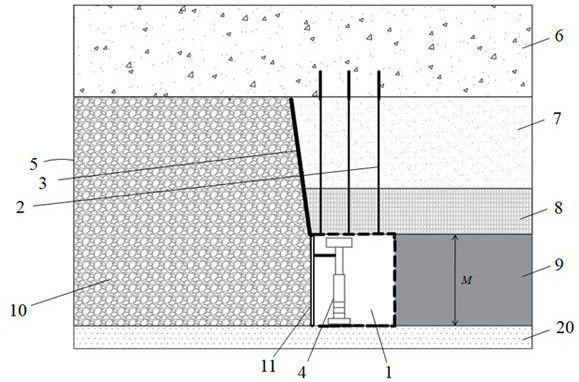

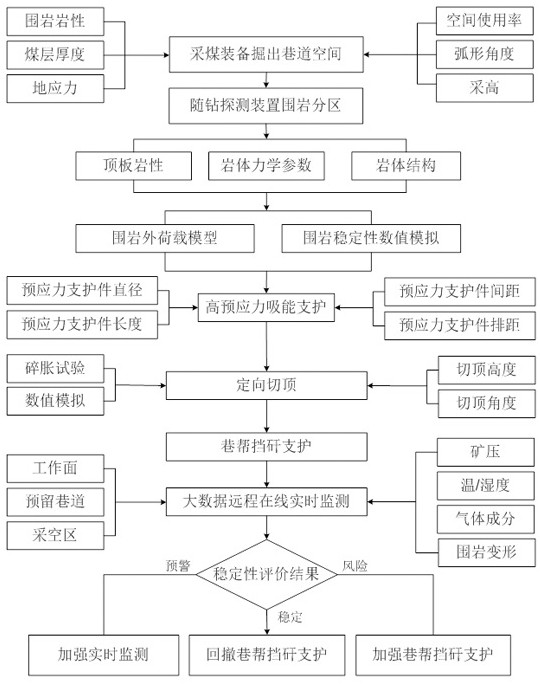

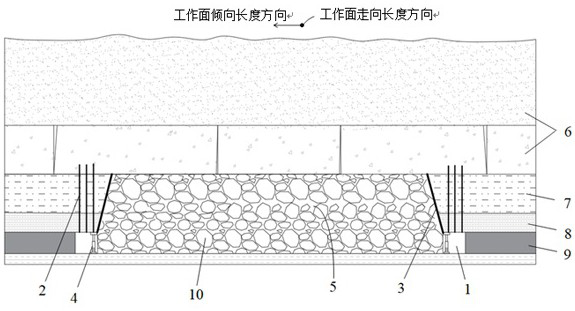

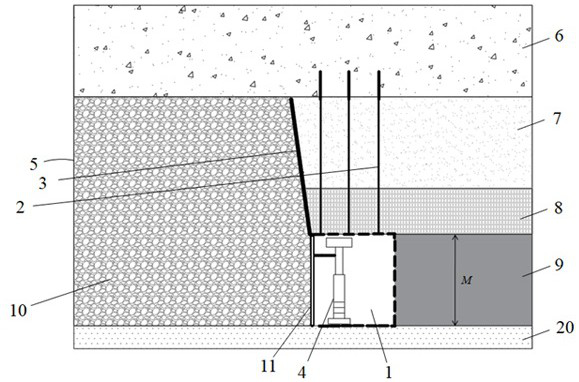

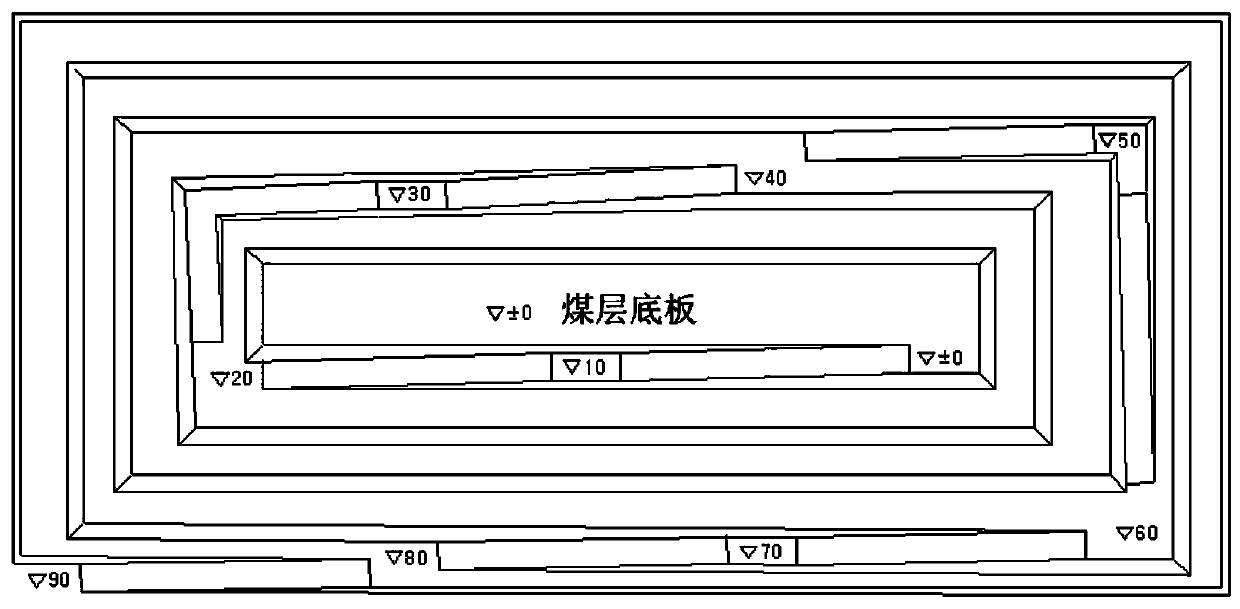

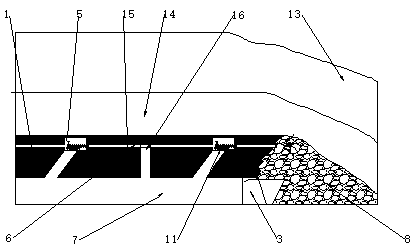

Roof-cutting pressure-relief coal-pillar-free self-roadway-forming mining design and evaluation method

ActiveCN113914862ASave resourcesReduce coal mining costsUnderground miningSurface miningArchitectural engineeringStructural engineering

The invention discloses a roof-cutting pressure-relief coal-pillar-free self-roadway-forming mining design and evaluation method. The method comprises the following steps of: digging a roadway space in a coal mining operation process; performing surrounding rock partitioning on an excavated roadway; determining pre-stress support parameters and top cutting parameters of all the surrounding rock areas; performing high-prestress energy-absorbing support on a top plate, and performing directional roof cutting on the goaf side of the top plate; performing roadway side rock blocking supporting; closing the roadway gangue blocking side to form a reserved roadway; monitoring roadway stability evaluation indexes of the reserved roadway in real time, and evaluating the stability of the reserved roadway based on a self-formed roadway stability evaluation system in real time; and optimizing the reserved roadway according to a stability evaluation result. The roadway is synchronously formed in the working face stoping coal mining process, roadway stability is guaranteed, coal pillars are not reserved, the cost is low, the working efficiency is high, safety and reliability are achieved, and the method is suitable for popularization.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

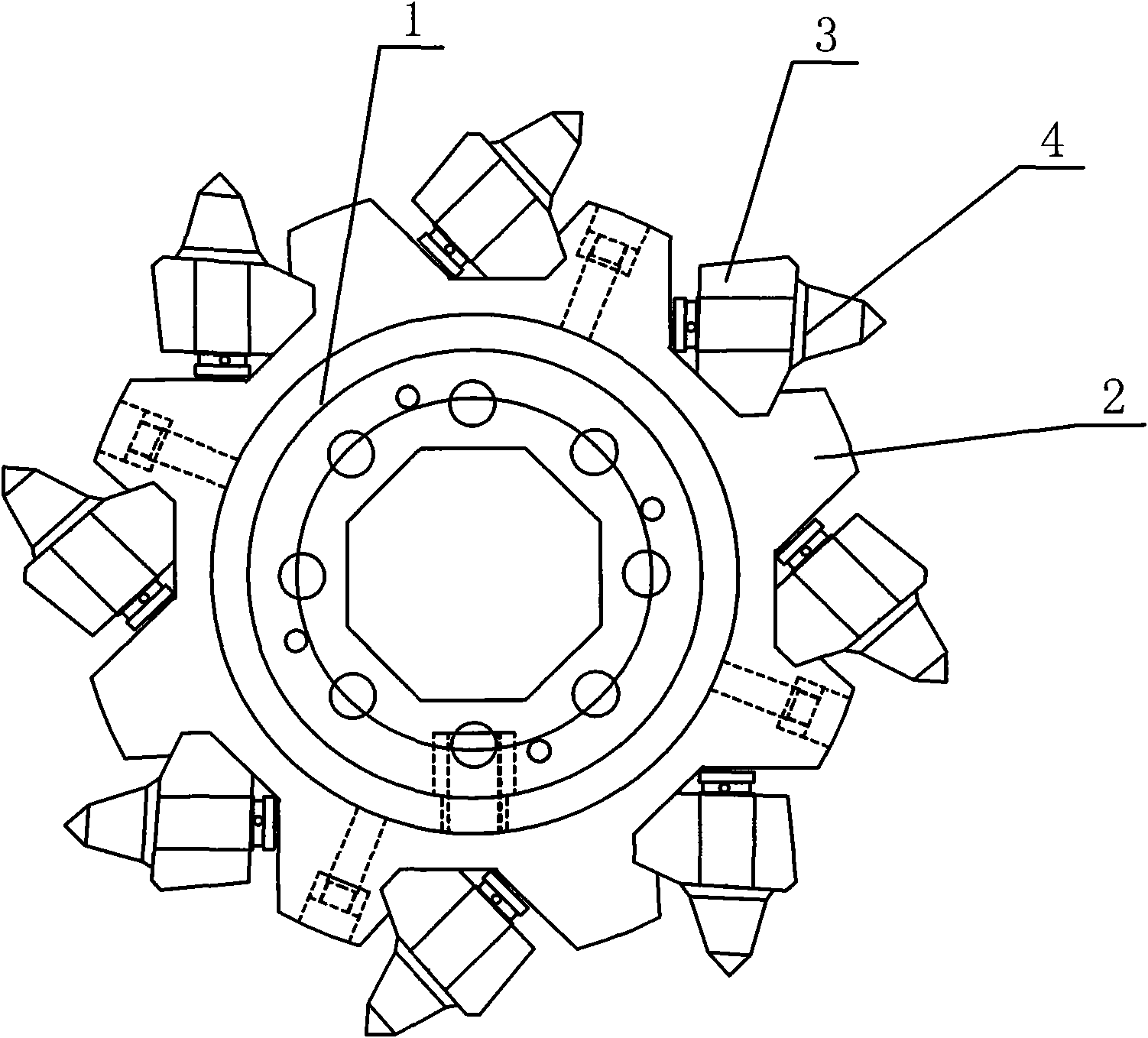

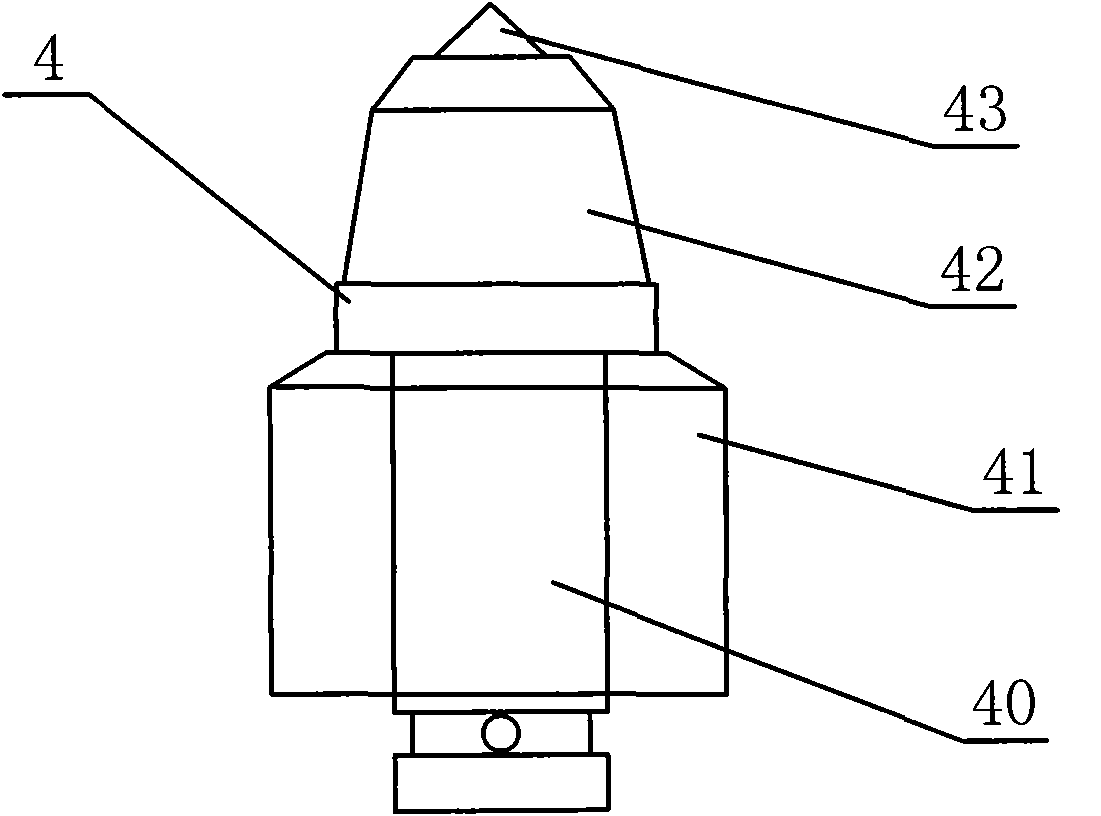

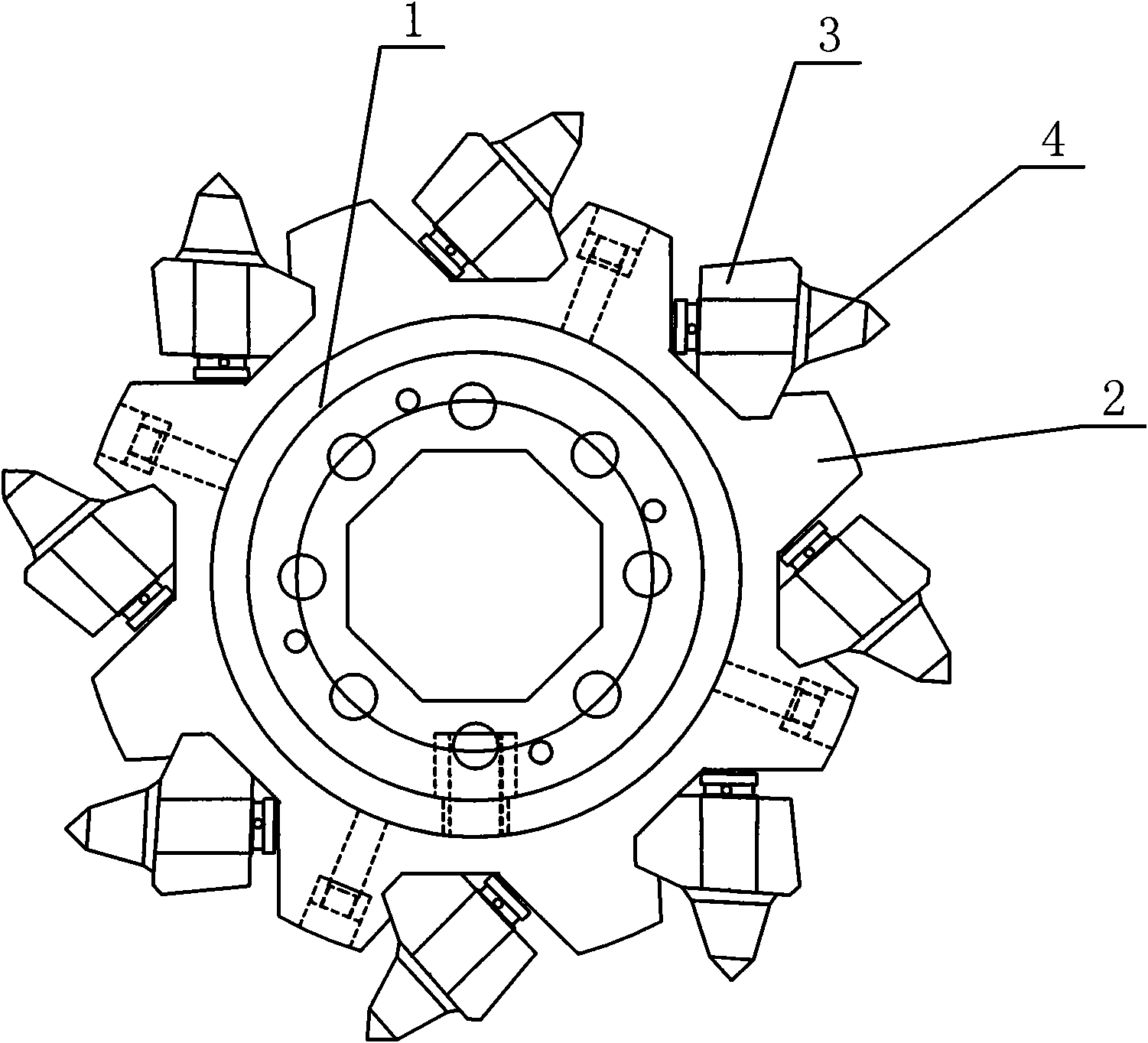

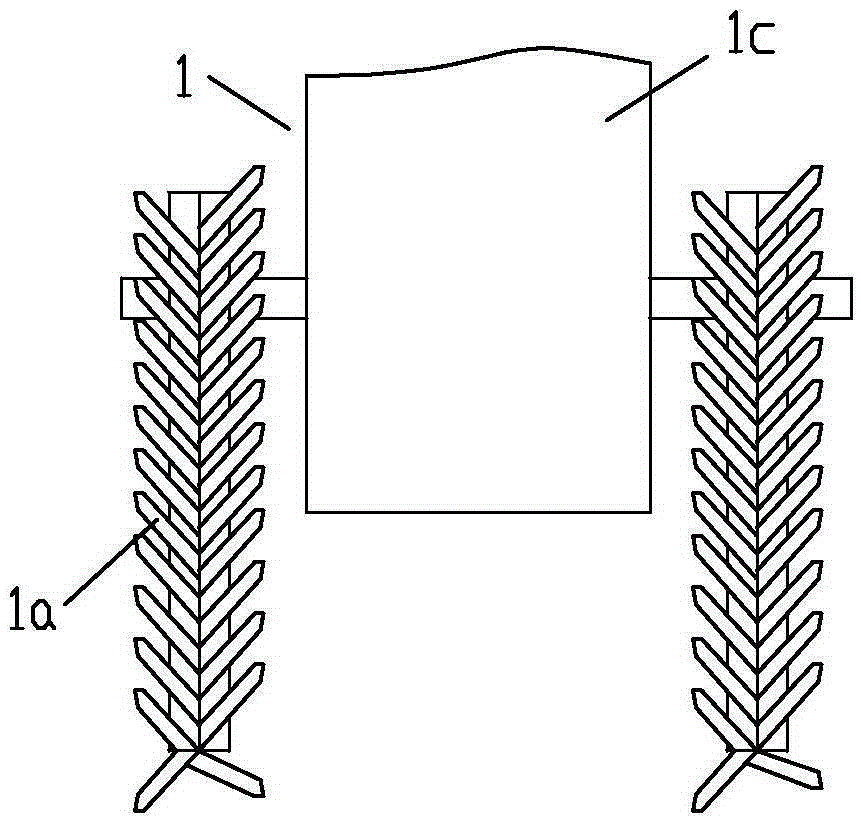

Helical shearer roller

The invention discloses a helical shearer roller. The roller comprises a roller body and combined helical blades arranged on the drum body, wherein pick seats are installed on the helical blades; cutting picks are installed on the pick seats through pick sleeves; the cutting picks comprise rods and heads arranged at one ends of the rods; the heads are of a conical structure; and conical alloy heads are welded at the front ends of the heads. The roller has the following beneficial effects: the heads of the cutting picks of the roller are of a conical structure and the conical alloy heads are fixed at the front ends of the heads, so the mined coal is briquette when the shearer with the cutting picks of such a structure is adopted for mining; and the roller not only has a simple structure but also has high mining efficiency, thus relatively lowering the mining cost.

Owner:无锡市煤科矿山机械厂

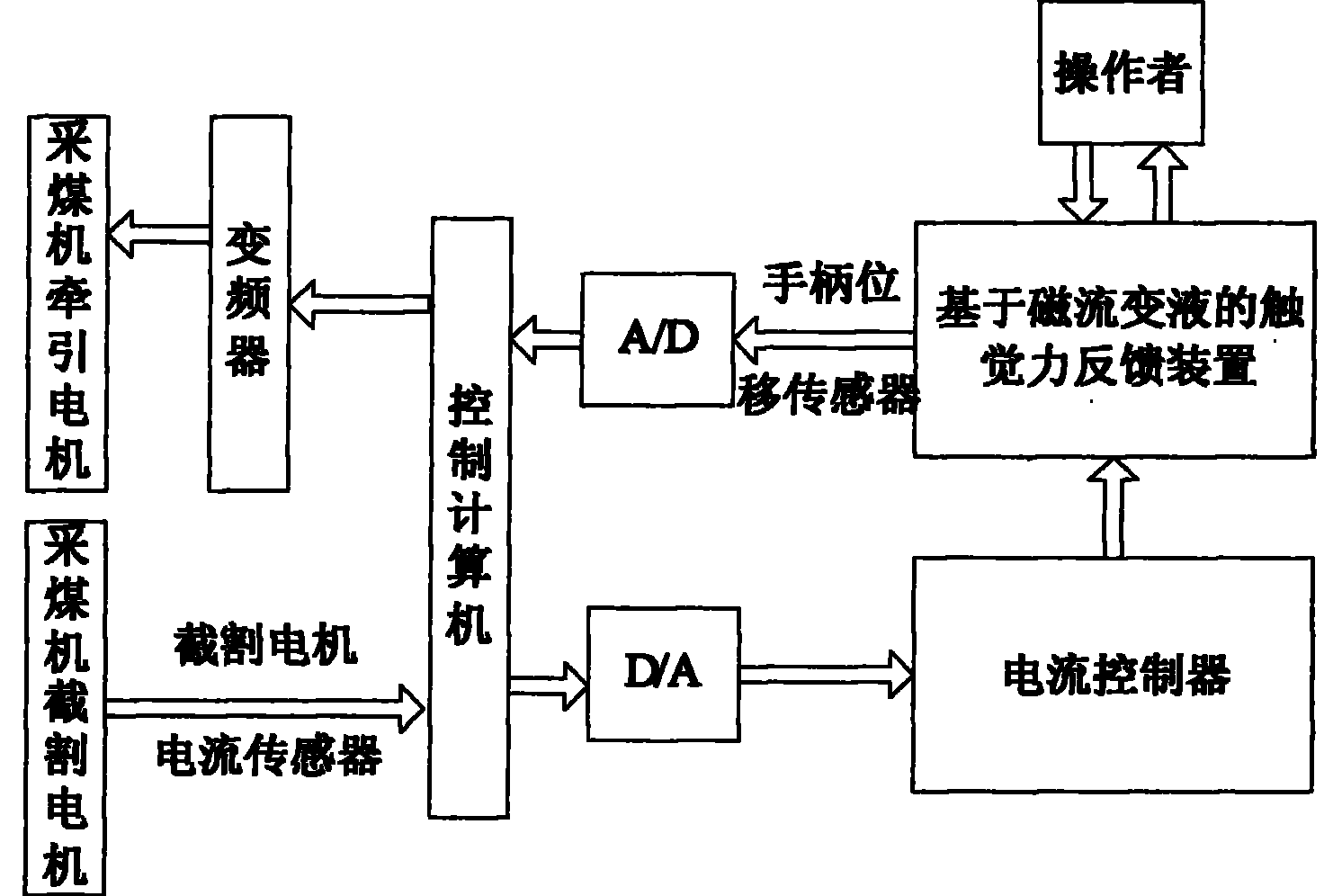

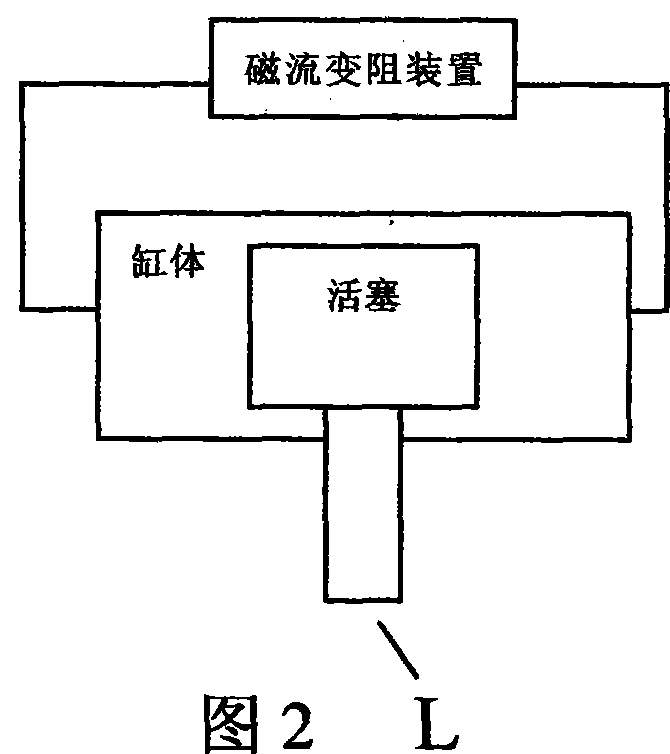

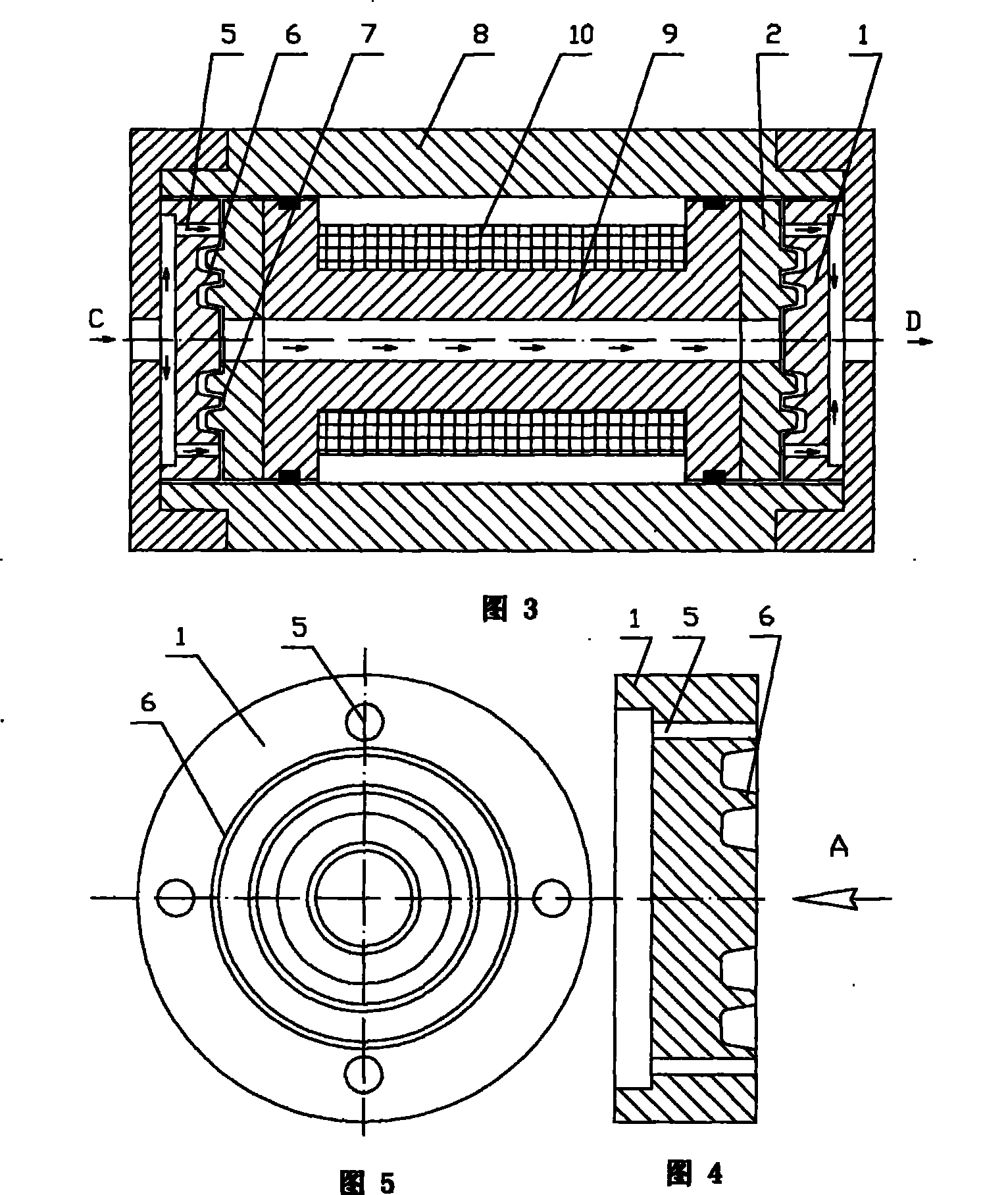

Constant power control method for coal mining machine and operating handle

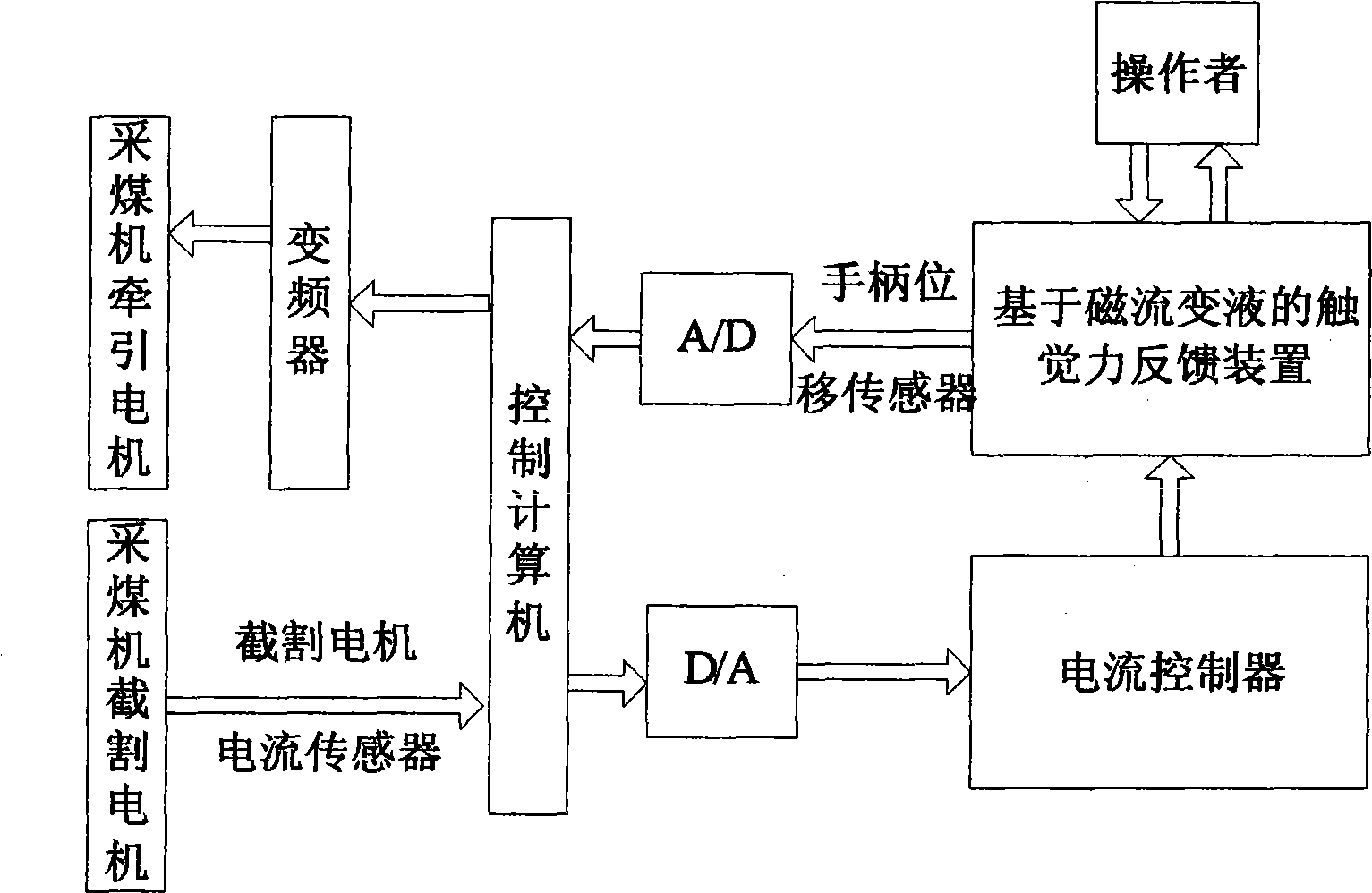

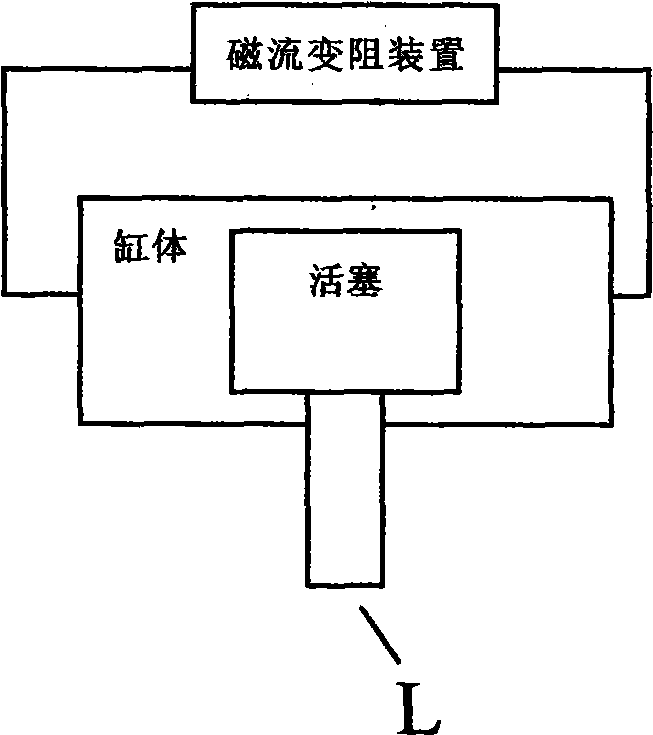

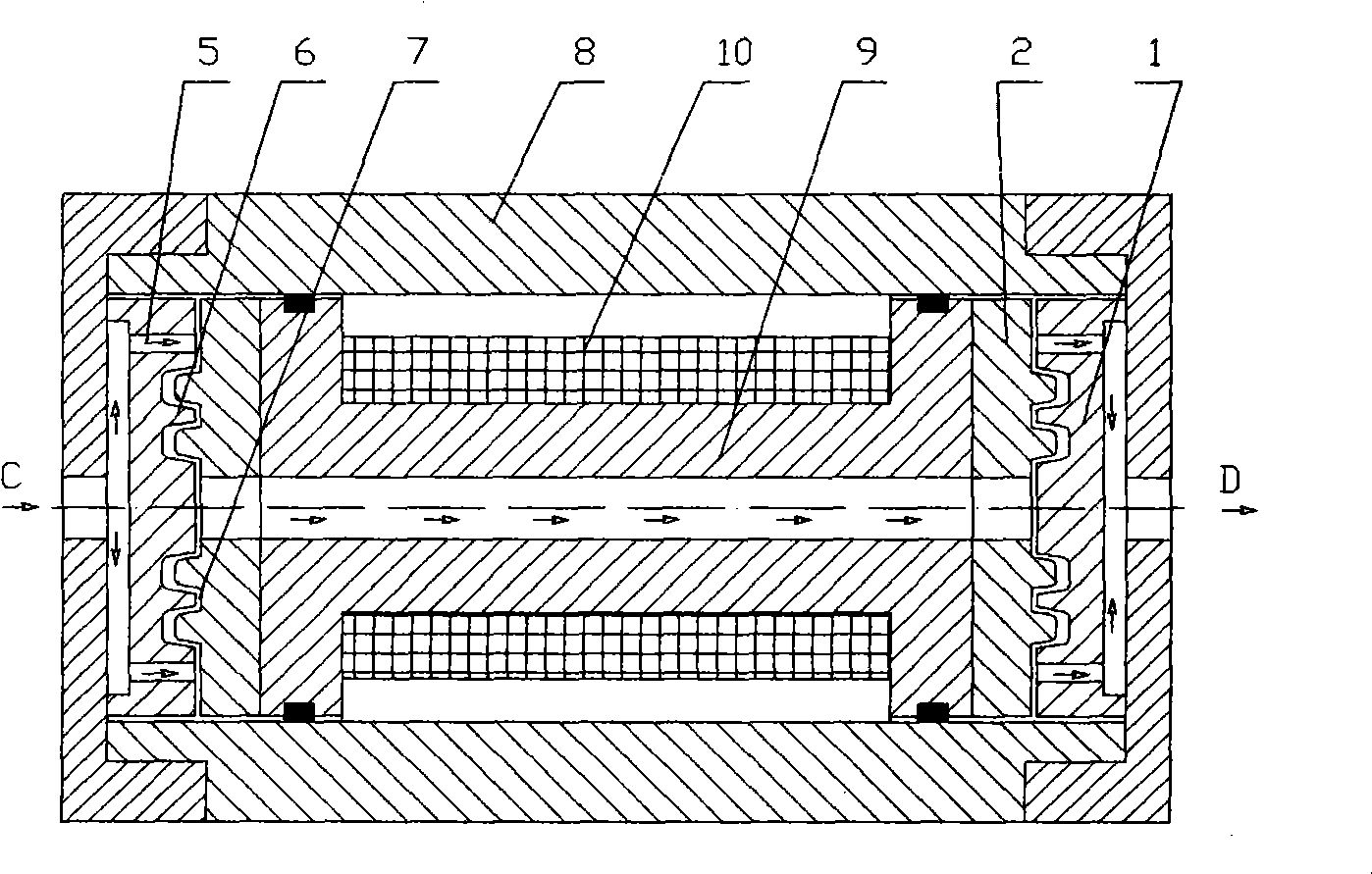

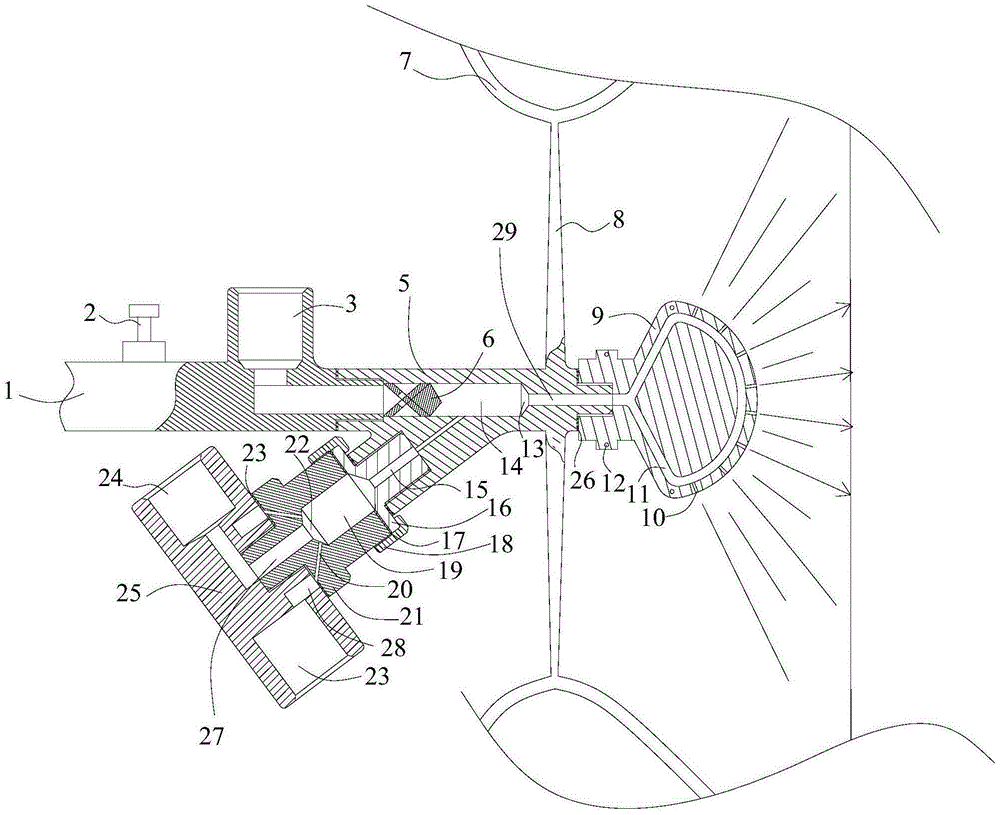

InactiveCN101533287ASolve overloadSolve the load problemFluid-pressure actuator componentsElectric variable regulationConstant powerControl signal

The invention relates to a power control method for a coal mining machine based on touch technology of a magneto-rheological valve and a complete operating handle device. The method is realized by the following steps: (1) extracting output current signals of a cutting motor in a coal mining machine set, and sending the output current signals to a control computer; (2) processing the output current signals in the control computer, and converting the output current signals into control signals through D / A conversion to adjust a current controller; (3) using the output current of the current controller to adjust the current of magnet exciting coils in a magneto-rheological device; (4) setting an operating handle and a moving piston in the magneto-rheological device into fixed connection and synchronous movement to form a state that an operator directly feels the change of the output power in the coal mining machine set during resistance change by means of the operating handle; and (5) quickly adjusting the output power of a pulling motor in the coal mining machine set by means of the pushing and pulling operations of the operating handle so as to stabilize a constant power working state of the coal mining machine set.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

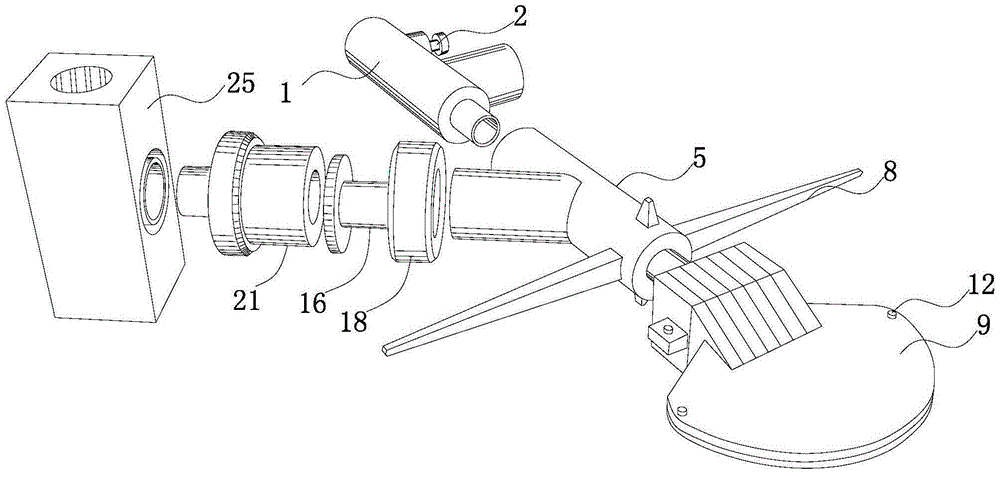

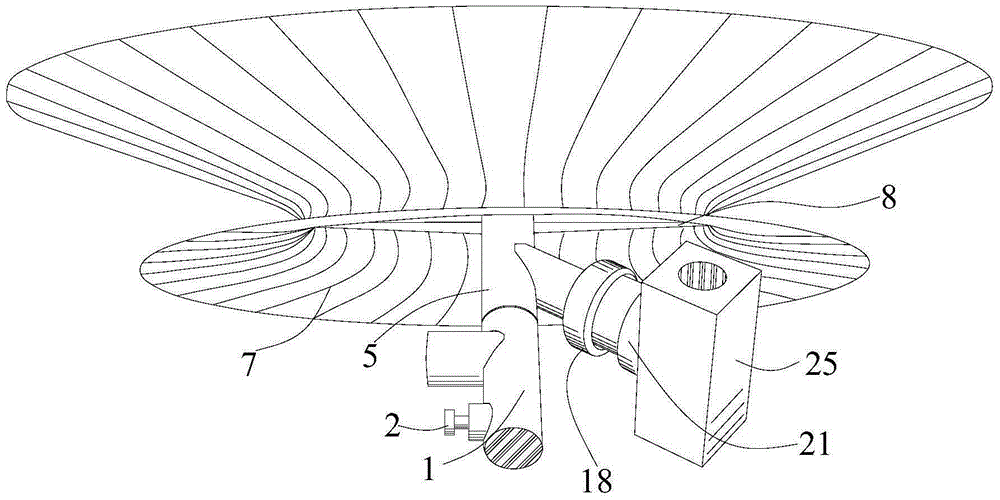

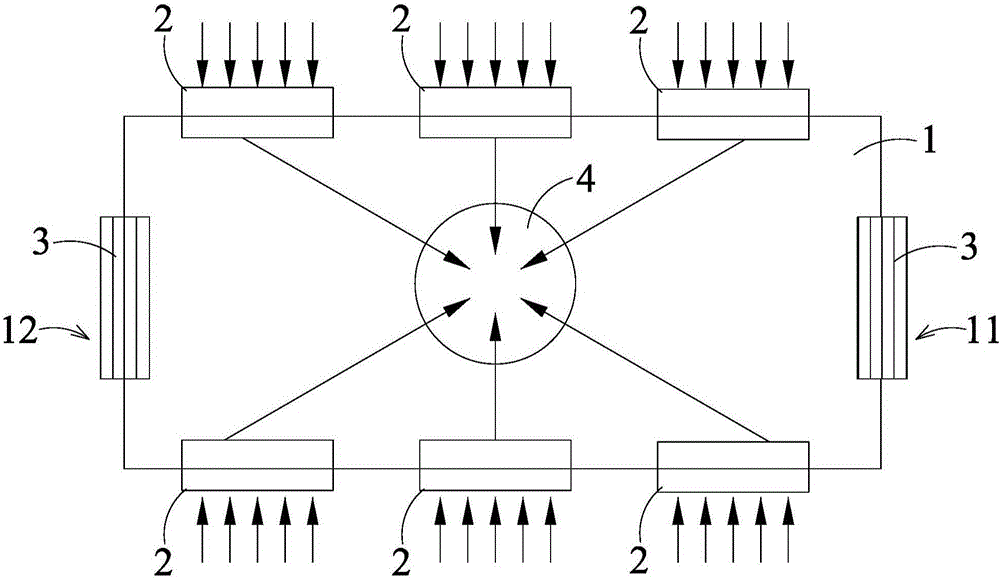

Gas-water injection device and dust control system for dust produced by cutting of coal cutter

ActiveCN105201505ASmall particle sizeReduce dust concentrationSlitting machinesVisibilityDust control

The invention discloses a gas-water injection device and a dust control system for dust produced by cutting of a coal cutter. The dust control system adopts the structure that a rocker is arranged on a coal cutter, a coal cutting roller is arranged at the front end of the rocker, an extracting dust removal blower is arranged on each of two sides of the coal cutter, air intake cylinders of the extracting dust removal blowers are arranged along the rocker and extend to the coal cutting roller; an obliquely arranged mounting bar is arranged on the rocker; the center of the tail end of the mounting bar and the center of the coal cutting roller are located on the same horizontal line; three gas-water injection devices are uniformly arranged at the tail end of the mounting bar with 120 degrees' angles formed among the gas-water injection devices. According to the gas-water injection device and the dust control system, the particle diameters of fog drops are reduced, a compact gas-water curtain with a relatively large gas specific weight is finally formed, dust is controlled by the gas-water curtain generated by the air-water linkage injection device, and dust produced by cutting of the coal cutter is extracted and processed by the extracting dust removal blowers, so that the dust concentration on a coal face is effectively reduced, the dust control system is formed, and at the same time, the visibility of the working face is improved.

Owner:SHANDONG UNIV OF SCI & TECH

Large diameter bedding drill hole drainage goaf along roof and upper corner gas technology

ActiveCN108798758AEliminate overrun functionReduce the amount of constructionGas removalEngineeringStreamflow

The invention relates to a large diameter bedding drill hole drainage goaf along a roof and upper corner gas technology. The large diameter bedding drill hole drainage goaf along the roof and upper corner gas technology is characterized by comprising that steps that a high level coal seam drilling field is constructed in a return airway; (1), a crawler-type electric drilling machine is used for constructing a long-distance large-diameter drill hole in a drilling field in the mining direction separately forwards and backwards, after a drill tool is exited, a processed borehole protection sleevewith sieve holes of a certain length is pushed into the large-diameter drill hole to seal the large-diameter drill hole; (2), in the main roadway or up a hill, the borehole protection sleeve with thesieve holes and the corresponding extraction pipeline are connected to extract gas in a goaf and upper corner. The amount of drilling construction is nearly 50% less than that of fan-shaped arrangement in a high level drilling field, the cost is low, the large-diameter drill hole is constructed in a coal seam, the construction speed is faster than rock stratum holes, part of the coal is extractedduring the construction to save the cost of coal mining, gas extraction flow rate is large, the borehole protection sleeve is arranged in the large-diameter drill hole, holes are not prone to collapsing, the gas extraction effect is better, and the overlimit function of gas in roadways is effectively eliminated.

Owner:CCTEG SHENYANG RES INST

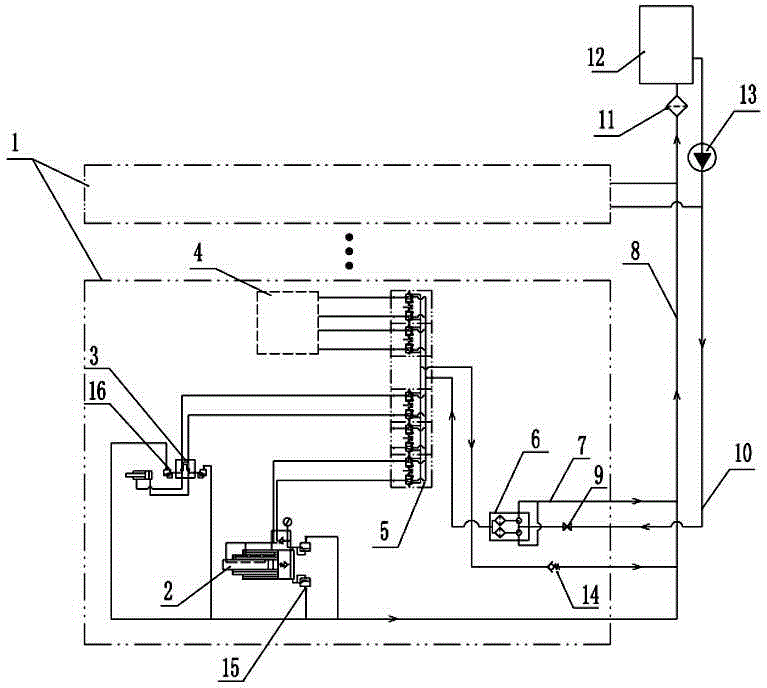

Hydraulic system used for recycling emulsified liquid of coal face

InactiveCN104533478AReduce consumptionReduce coal mining costsMine roof supportsProps/chocksCoalHydraulic equipment

The invention discloses a hydraulic system used for recycling emulsified liquid of a coal face. The hydraulic system comprises hydraulic control units. Each hydraulic control unit comprises a hydraulic stand column, a hydraulic jack reversible lock, hydraulic equipment and a hydraulic control valve set used for controlling the hydraulic stand column, the hydraulic jack reversible lock and the hydraulic equipment, wherein a back flush emulsified liquid inlet of the hydraulic control valve set is communicated with an outlet of a back flush filter; a liquid drain outlet of the back flush filter is communicated with a liquid return pipeline through a pipeline; an inlet of the back flush filter is communicated with a high-pressure liquid inlet pipeline through a stop valve; the liquid return pipeline is communicated with an inlet of an emulsified liquid pump box through a liquid return filter; an outlet of the emulsified liquid pump box is communicated with the high-pressure liquid inlet pipeline through an emulsified liquid pump station; a back flush emulsified liquid return port of the hydraulic control valve set is communicated with the liquid return pipeline through a break valve; a diversion interface of a stand column safety valve of the hydraulic stand column and a diversion interface of a jack safety valve of the hydraulic jack reversible lock are communicated with the liquid return pipeline through pipelines.

Owner:ZHENGZHOU COAL MINING MACHINERY GRP

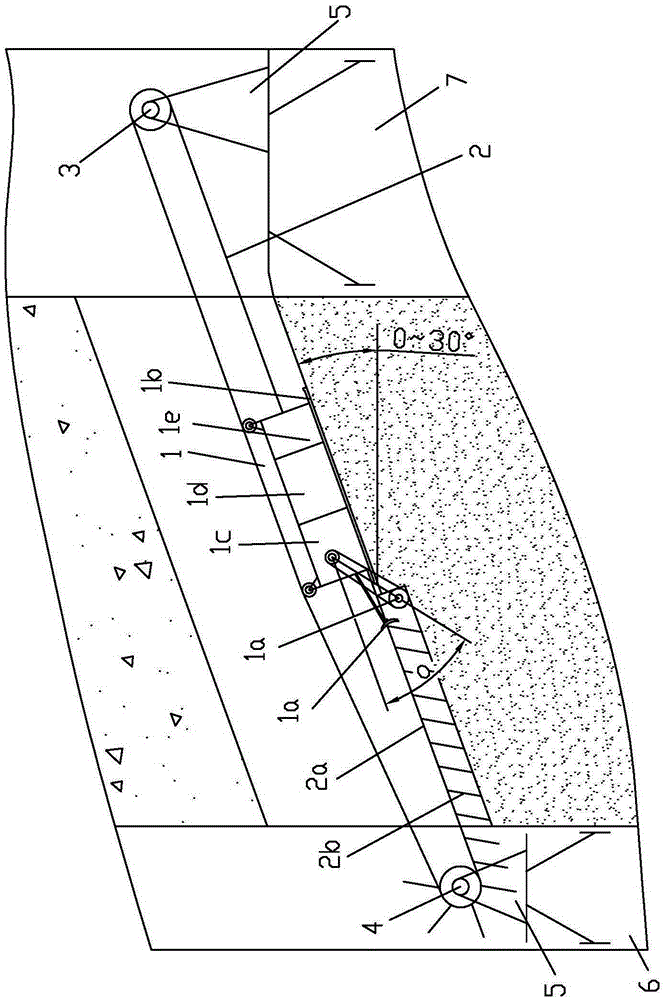

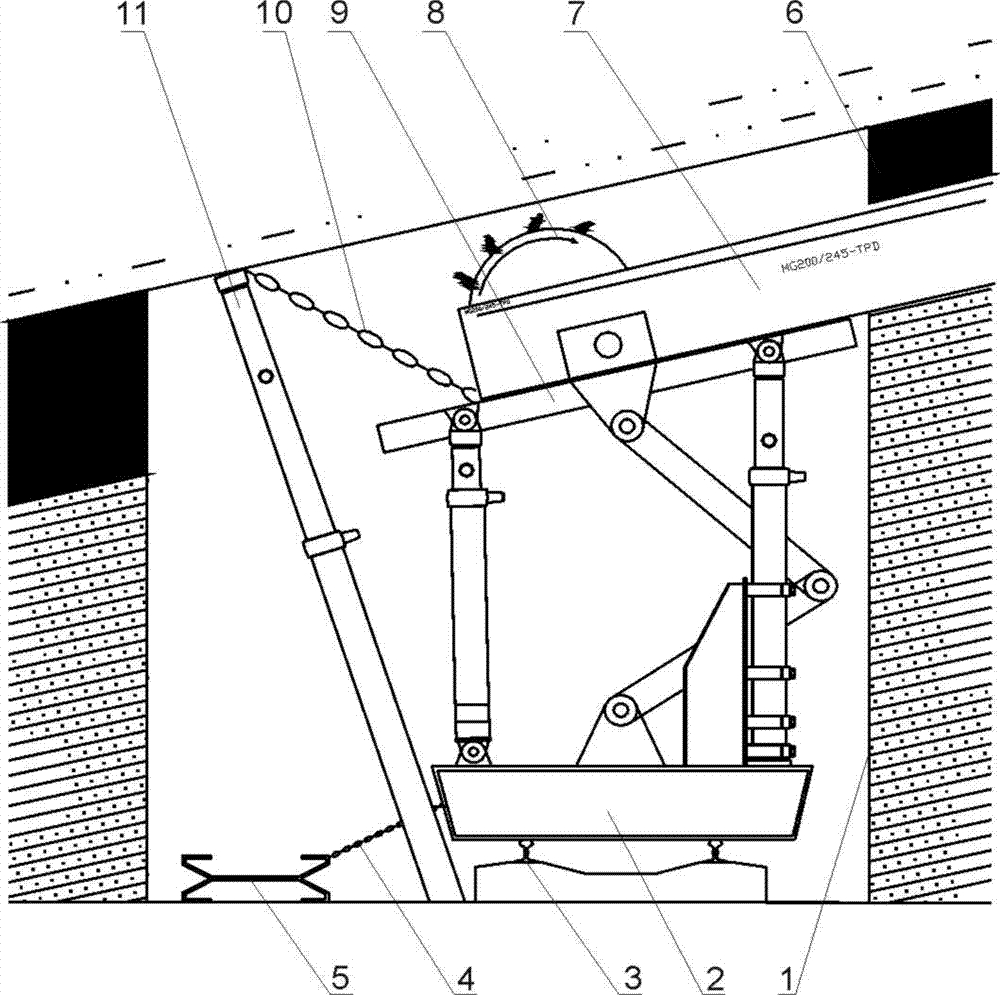

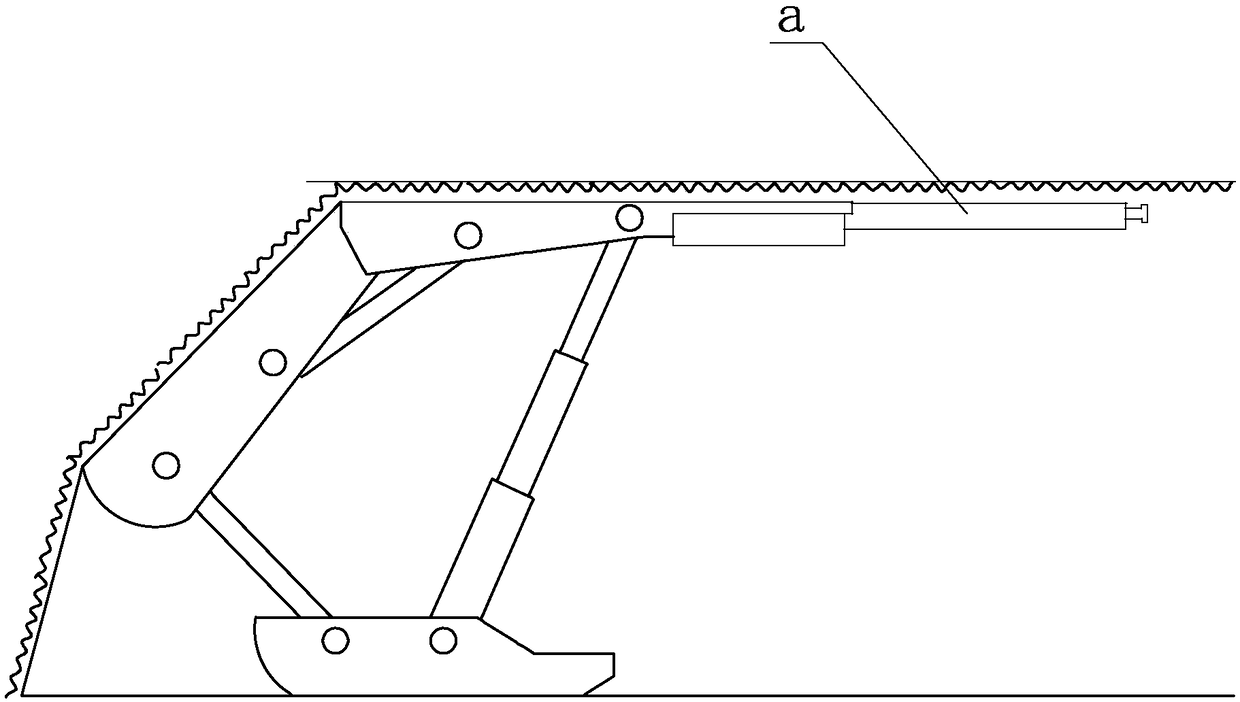

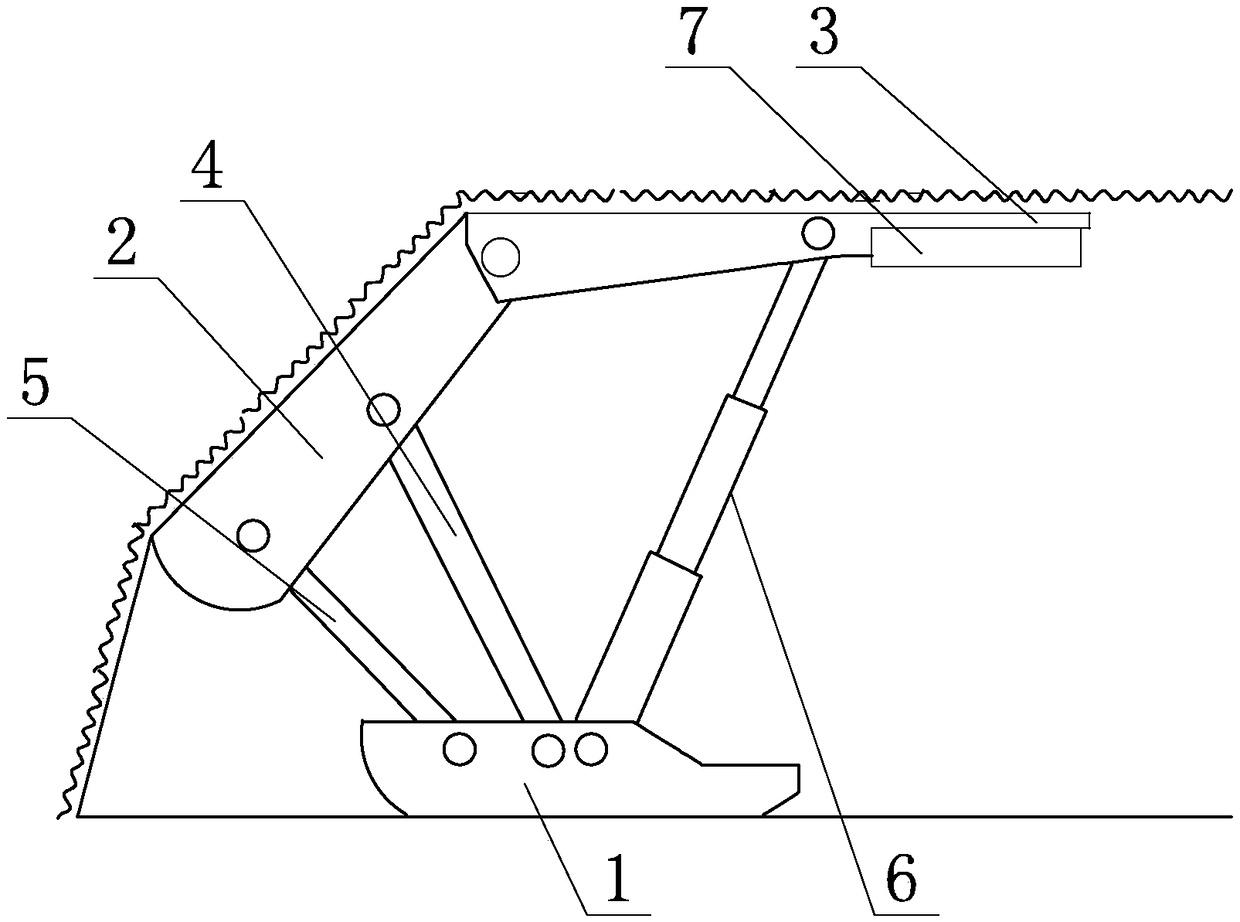

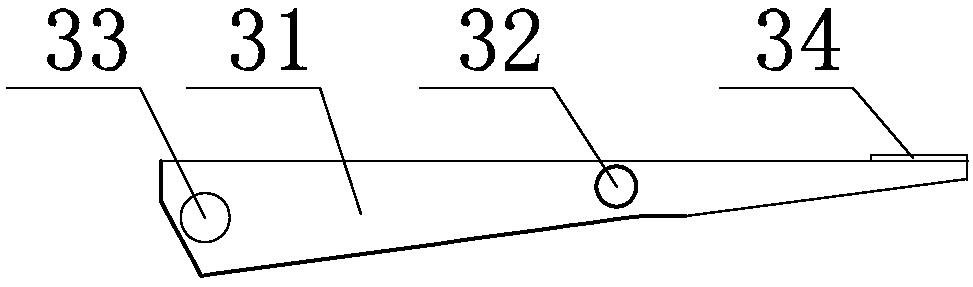

Steep coal-seam coal mining and transportation apparatus and coal mining and transportation method

InactiveCN105257291AImprove coal mining efficiencyReduce coal mining costsMine roof supportsCutting machinesCoal miningChain structure

The invention discloses a steep coal-seam coal mining and transportation apparatus and coal mining and transportation method. The steep coal-seam coal mining and transportation apparatus comprises a coal mining unit, a coal transportation unit and a control system, wherein the front end and the rear end of the coal mining unit are serially connected onto an annular flexible traction element, the flexible traction element is driven by a positive-inversion-output rotating drive unit to drive the coal mining unit to go forward or withdraw, and the rear part of the coal mining unit is provided with a coal mining part for intercepting a lower coal and rock mass to form a trough; the flexible traction element of a set length which is arranged behind the coal mining unit is of a traction chain structure, a plurality of rows of coal scraper plates which can go deep into the trough are distributed in the length direction of a traction chain section, and the traction chain and the coal scraper plates form the coal transportation unit. The method is implemented by utilizing the steep coal mining and transportation apparatus. The method comprises the following steps: facilitating the forward rotation of the drive unit, and driving the coal mining unit to go forward to intercept coal; enabling the drive unit to rotate reversely, and driving the coal scraper plates on the traction chain to transport the coal by virtue of the trough formed after the coal is intercepted. The apparatus and the method have the beneficial effects that the coal mining apparatus is simple in structure and low in manufacture cost, and the coal mining method is high in coal mining efficiency and safe in coal mining.

Owner:王洁

Process for novel preparing cutting tooth of coal cutter

InactiveCN104451352ATightly boundExtended service lifeFurnace typesHeat treatment furnacesInterference fitThermal compression

The invention relates to a process for preparing a novel cutting tooth of a coal cutter. A tooth body of the cutting tooth is formed by casting; and according to components of the cutting tooth body, a nano-composite abrasion-resistant alloy used for abrasion-resistant steel is added into medium-carbon low-alloy steel to improve the abrasion resistance of the cutting tooth body. The ratio of the abrasion-resistant alloy added into the novel cutting tooth is 2 to 15 percent, and the medium-carbon low-alloy steel accounts for 95 to 98 percent of total mass of molten steel. According to the process for preparing the novel cutting tooth, the components are homogenized by smelting, and then the cutting tooth body is obtained by casting; the casted cutting tooth body is machined and reinforced; and cemented carbide is pressed into a hole at the front end of a tooth head by a hot-press technology, the inner diameter of the hole at the front end of the tooth head and the outer diameter of a cemented carbide column are in interference fit, and the magnitude of interference is less than 0.005mm.

Owner:SHENYANG POLYTECHNIC UNIV

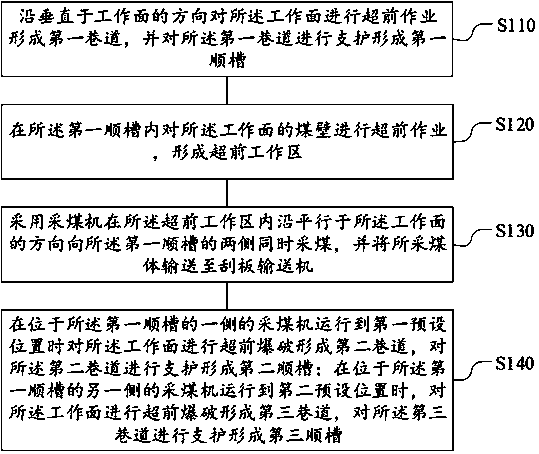

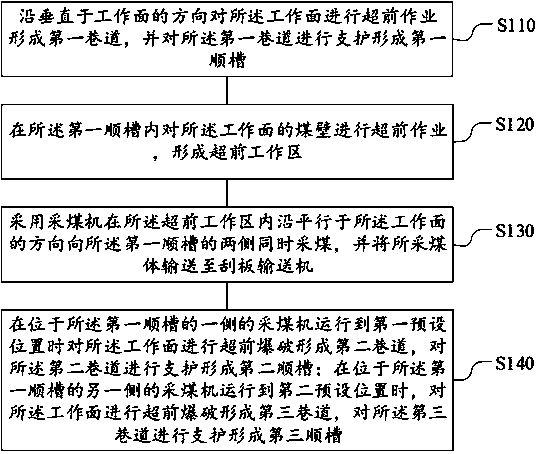

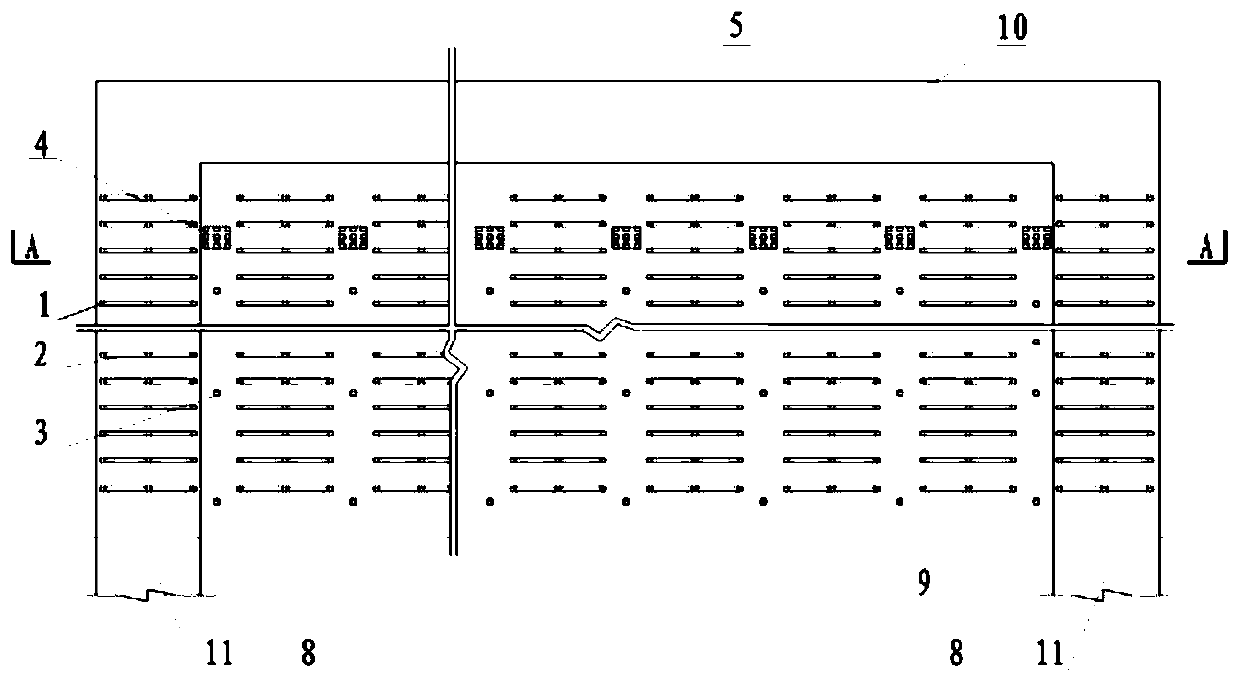

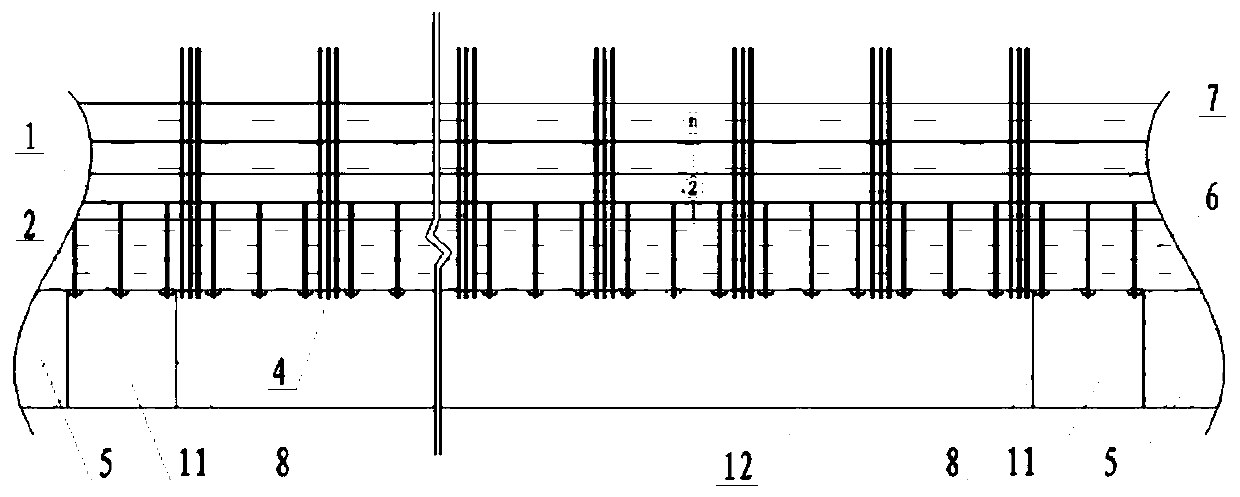

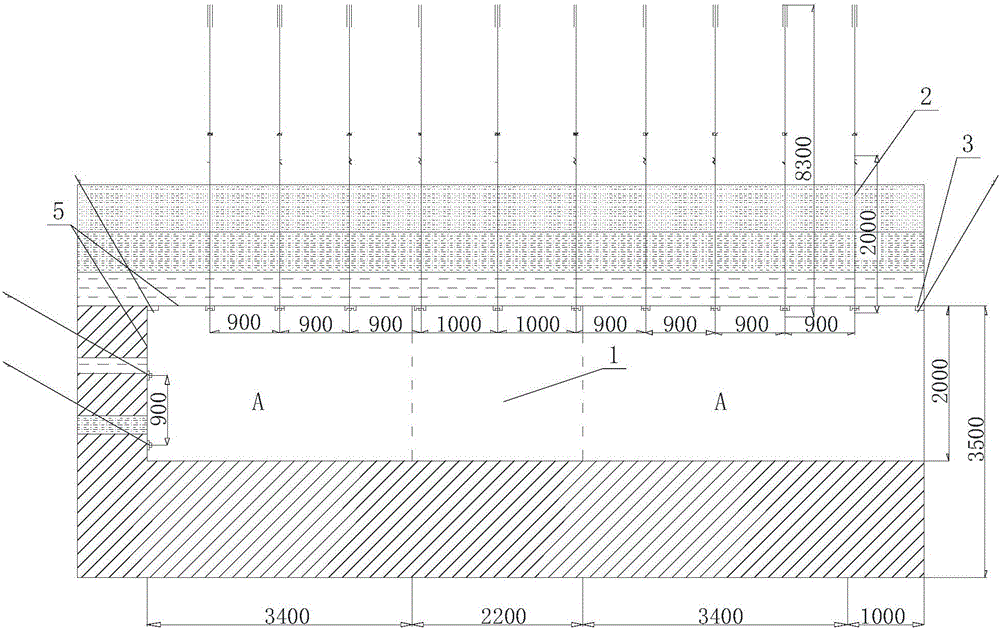

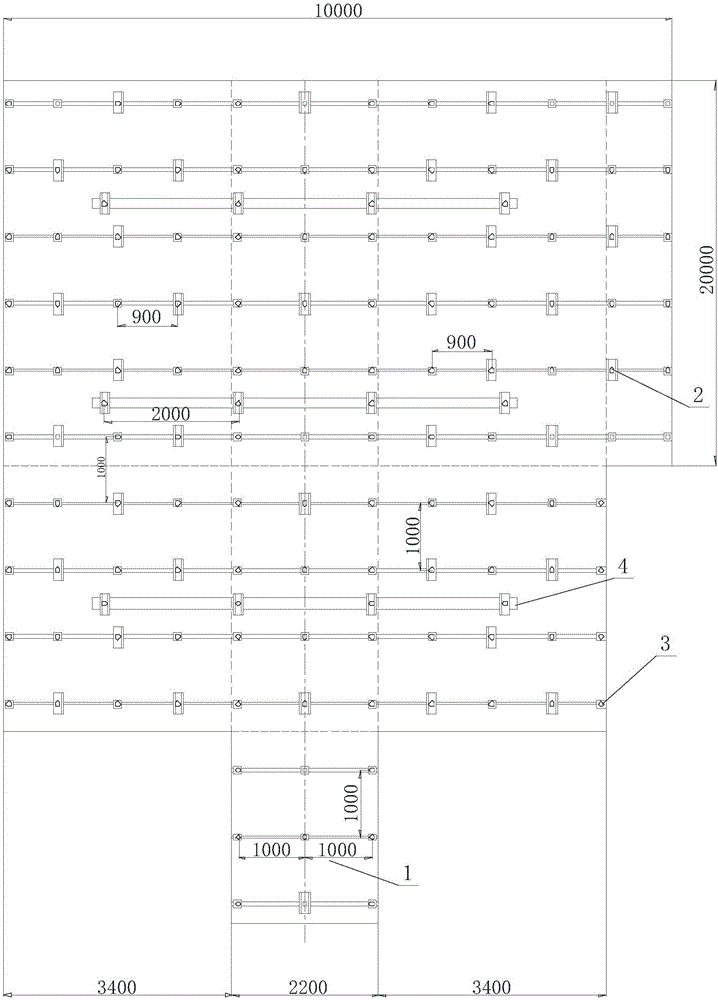

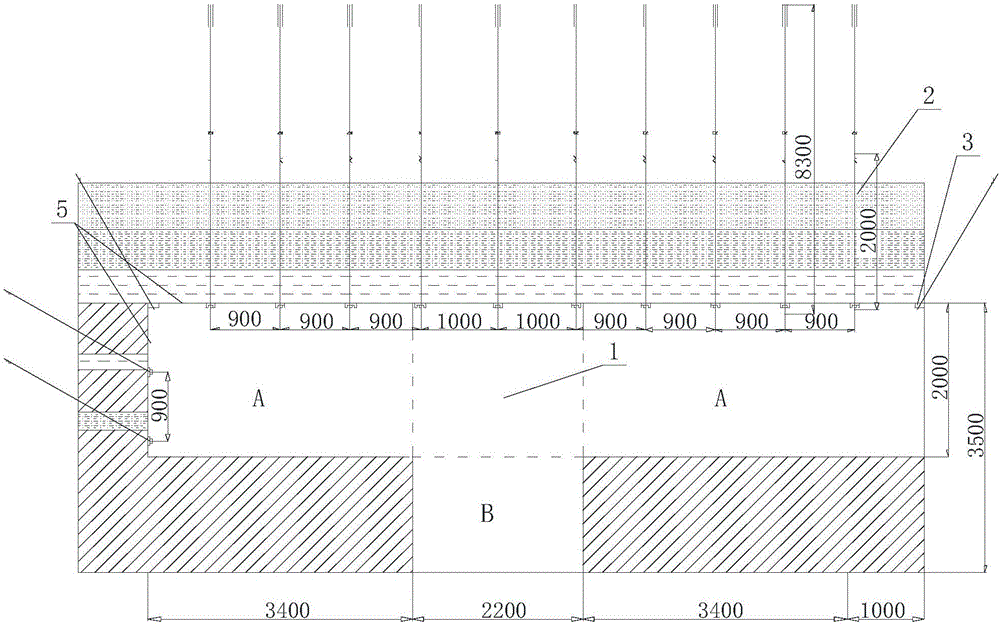

Ultra-thin coal seam longwall mining method based on N00 construction method

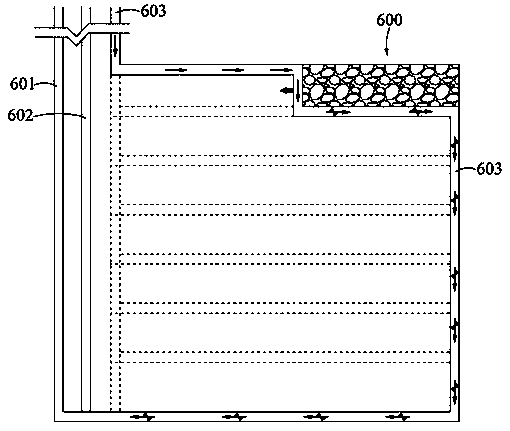

ActiveCN111219191AAvoid early excavationAvoid wastingUnderground miningTunnel/mines ventillationLongwall miningMining engineering

The invention provides an ultra-thin coal seam longwall mining method based on an N000 construction method, and relates to the technical field of mining. The ultra-thin coal seam longwall mining method includes the steps that advancing operation is performed on a working face in the direction perpendicular to the working face to form a first roadway, and the first roadway is supported to form a first gate road; an advance working area is formed in the first gate road; coal mining machines are adopted to simultaneously mine coal in the advance working area in the direction parallel to the working surface towards both sides of the first gate road, and a mined coal body is transported to a scraper conveyor; when the coal mining machine located on one side of the first gate road runs to a first preset position, the working face is blasted to form a second roadway, and the second roadway is supported to form a second gate road; and when the coal mining machine located on the other side of the first gate road runs to a second preset position, the working face is blasted to form a third roadway, and the third roadway is supported to form a third gate road. According to the ultra-thin coalseam longwall mining method based on the N000 construction method, roadway tunneling in advance can be avoided, the coal mining cost is reduced, the coal mining efficiency is improved, and the wasteof resources is avoided.

Owner:BEIJING ZHONGKUANG INNOVATION ALLIANCE ENERGY & ENVIRONMENTAL SCI RES INST

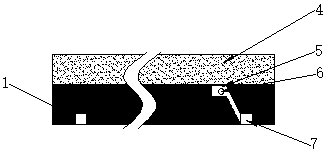

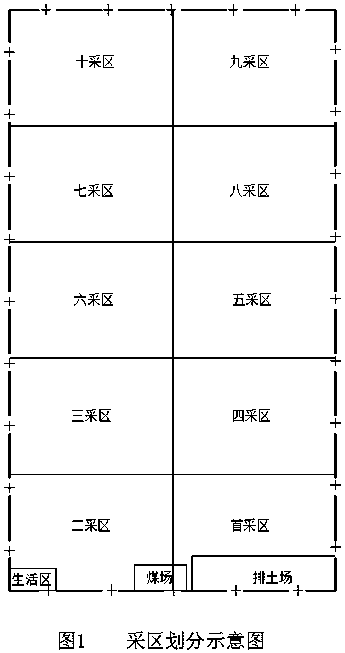

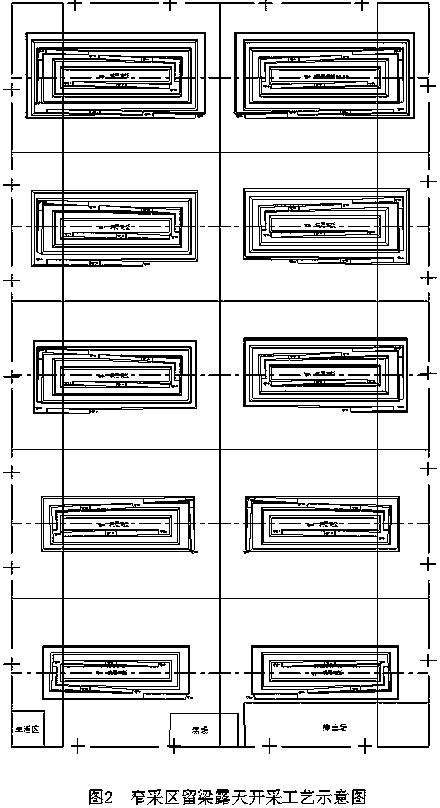

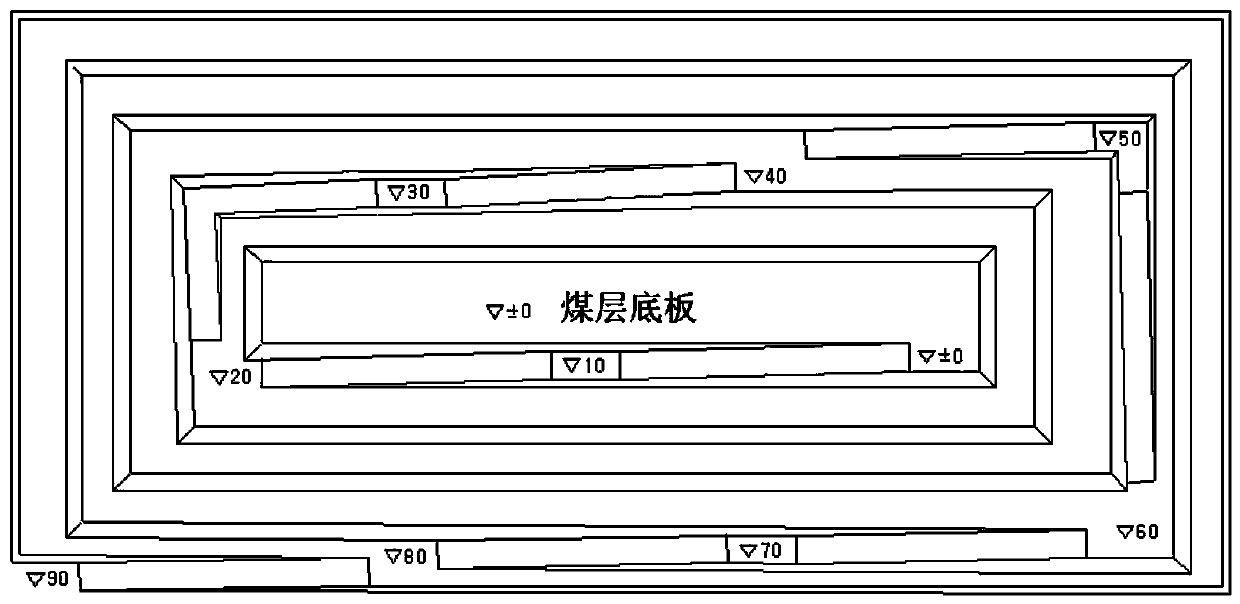

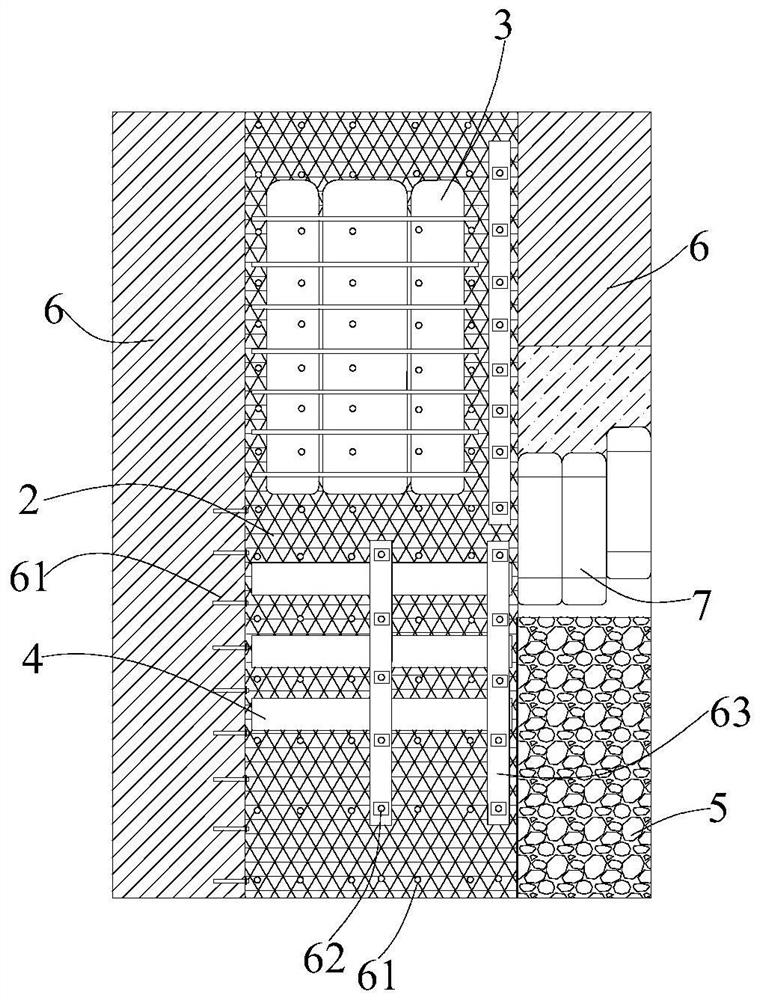

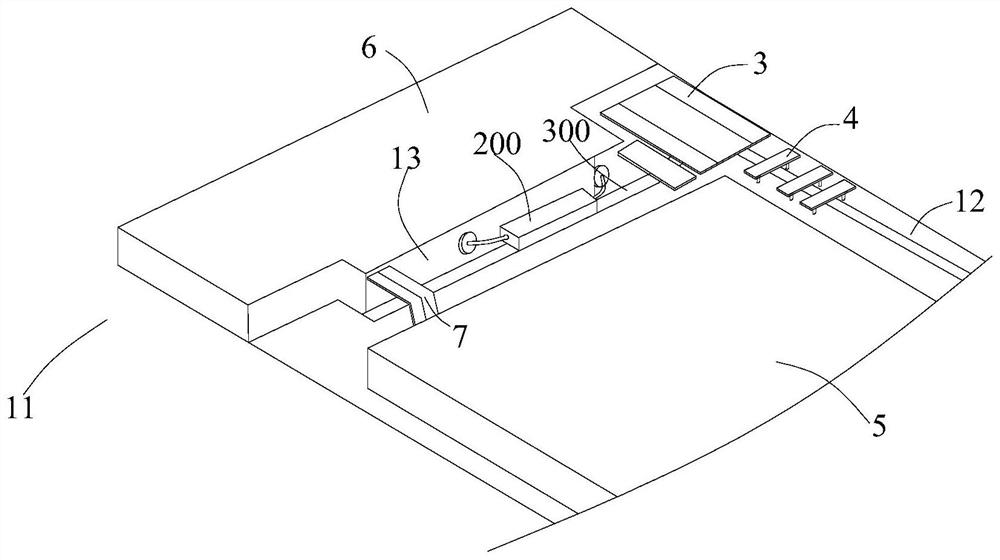

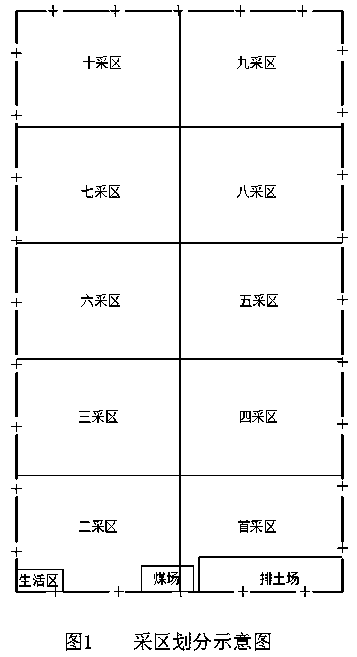

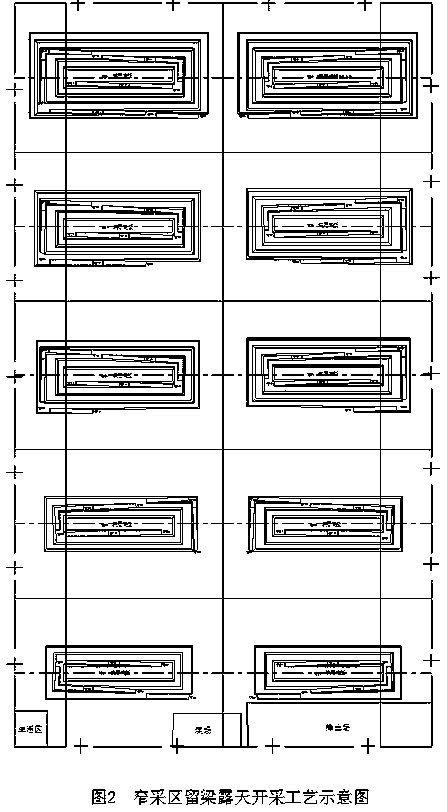

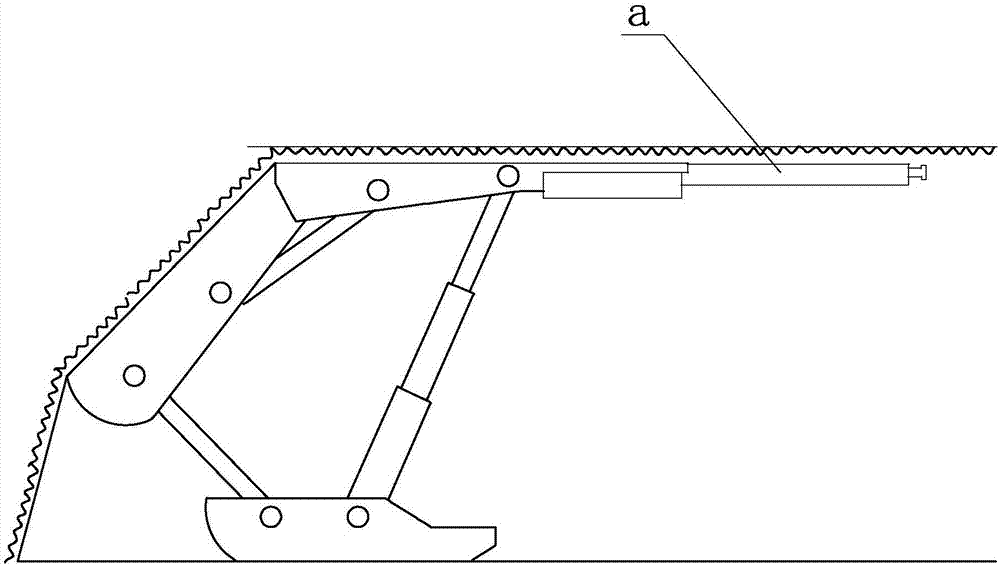

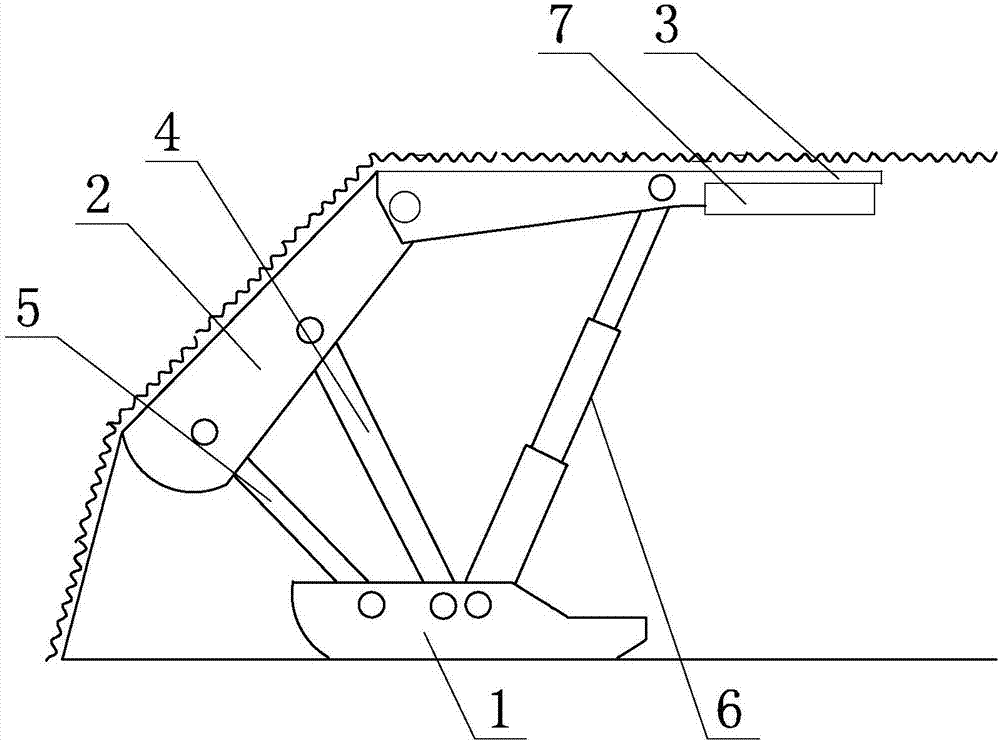

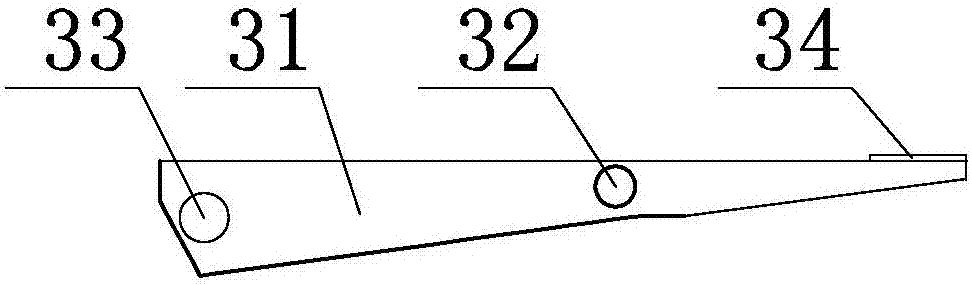

Beam-reserving open pit mining technology in narrow mining area

ActiveCN107654233AReduce dependenceReduce soil dischargeUnderground miningSurface miningAditOpen-pit mining

The invention relates to a beam-reserving open pit mining technology in a narrow mining area. The beam-reserving open pit mining technology comprises the following steps that a, mining areas are divided, an open-pit mining right realm is divided into the multiple long-strip-shaped mining areas, the position of a mining pit is divided in each mining area, and soil beams are reserved between every two adjacent mining pits as well as between the mining pits and the mining right realm; b, excavation equipment is used to conduct mining on the first batch of mining areas, and mining is conducted according to the preset positions of the mining pits; c, mining is conducted on coal, mined from the first batch of mining areas, under the soil beams on the peripheries of the mining pits by using a slope coal cutter; and d, mining is conducted on the second batch of mining areas, mining is conducted according to the preset positions of the mining pits, and the mining pits are subjected to downwardmining through a spiral linear adit mode. The mining method is suitable for all open-pit mines, revolutionary changes can be generated on open-pit mining, and the mining technology further greatly reduces the open-pit mining cost while improving the adaptability of open-pit coal mine mining.

Owner:张忠成

coal plow

ActiveCN103321638BIncreased ability to break hard coalReduce chain downtime accidentsSlitting machinesPunchingReciprocating motion

The invention discloses a coal plow, which comprises: a first plow head, a punching device, a traction assembly for pulling the first plowing head and the punching device, and a carriage guide rail; wherein , the first planer is adjacent to the punching device and is arranged on the carriage guide rail, and can reciprocate along the carriage guide rail through the traction assembly. Therefore, the coal plow of the present invention can effectively reduce chain-breaking shutdown accidents caused by the plow head stuck in the coal wall.

Owner:SANY HEAVY EQUIP

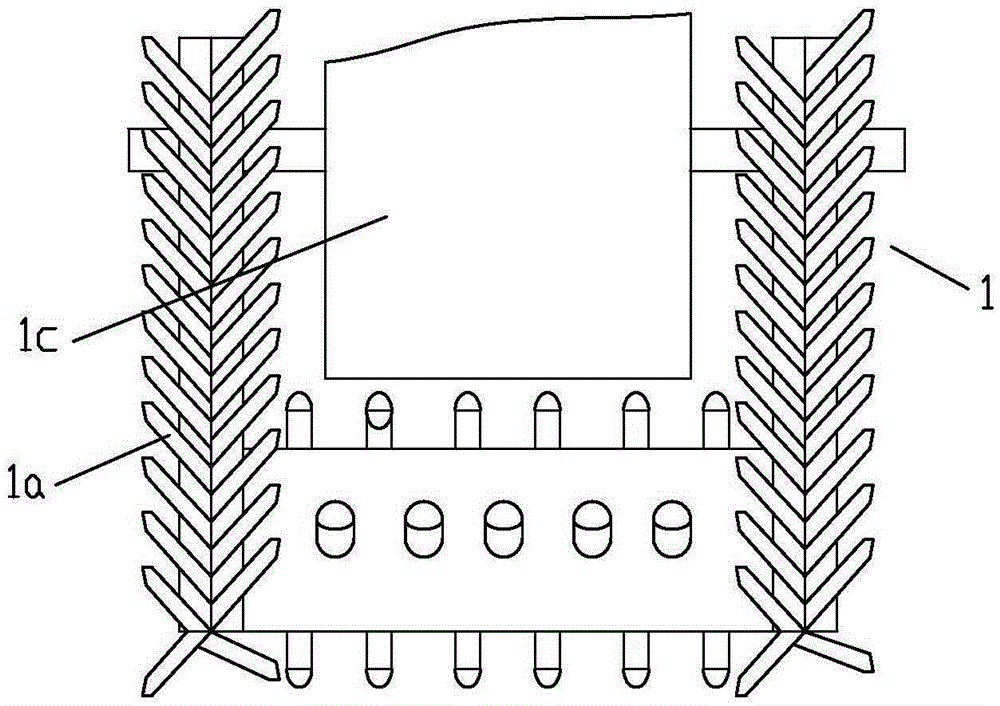

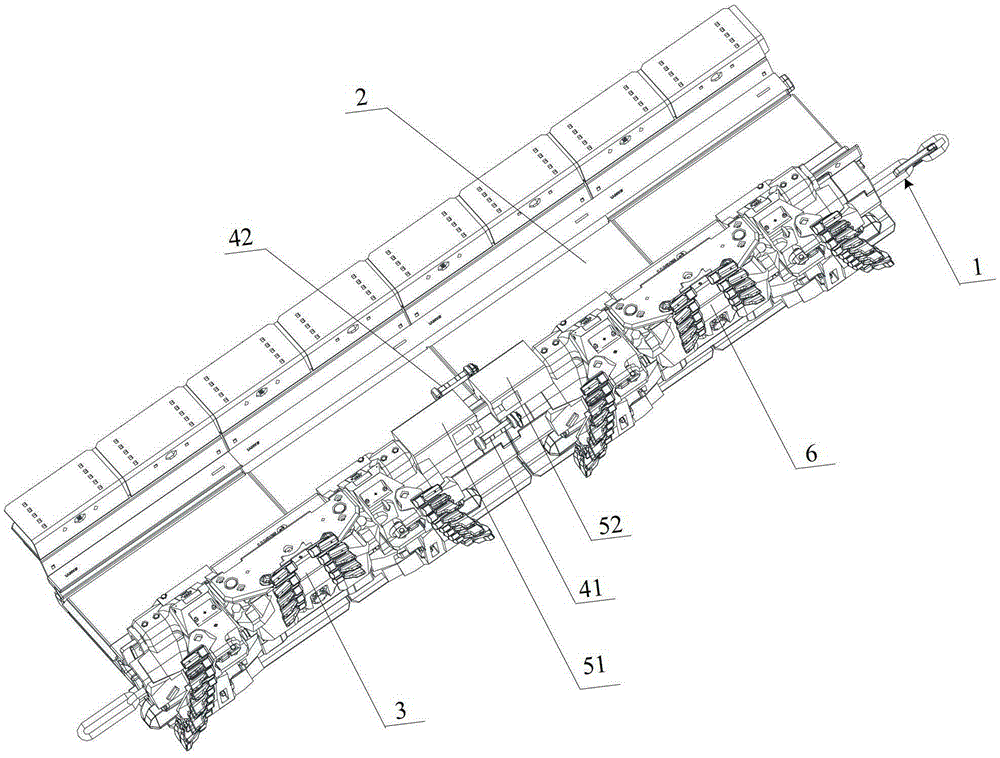

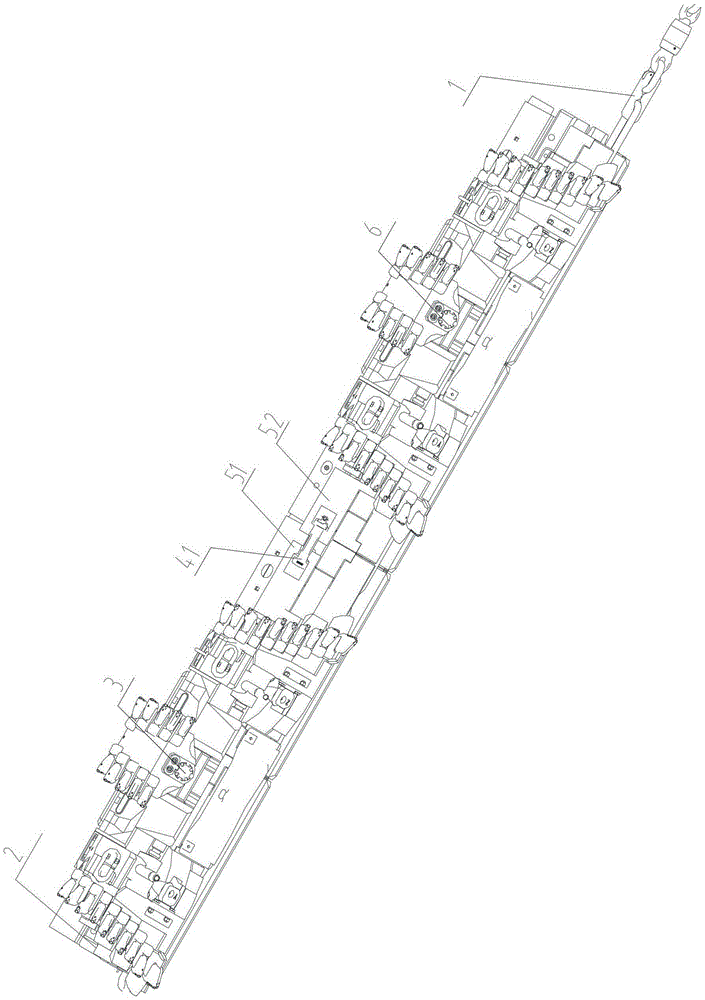

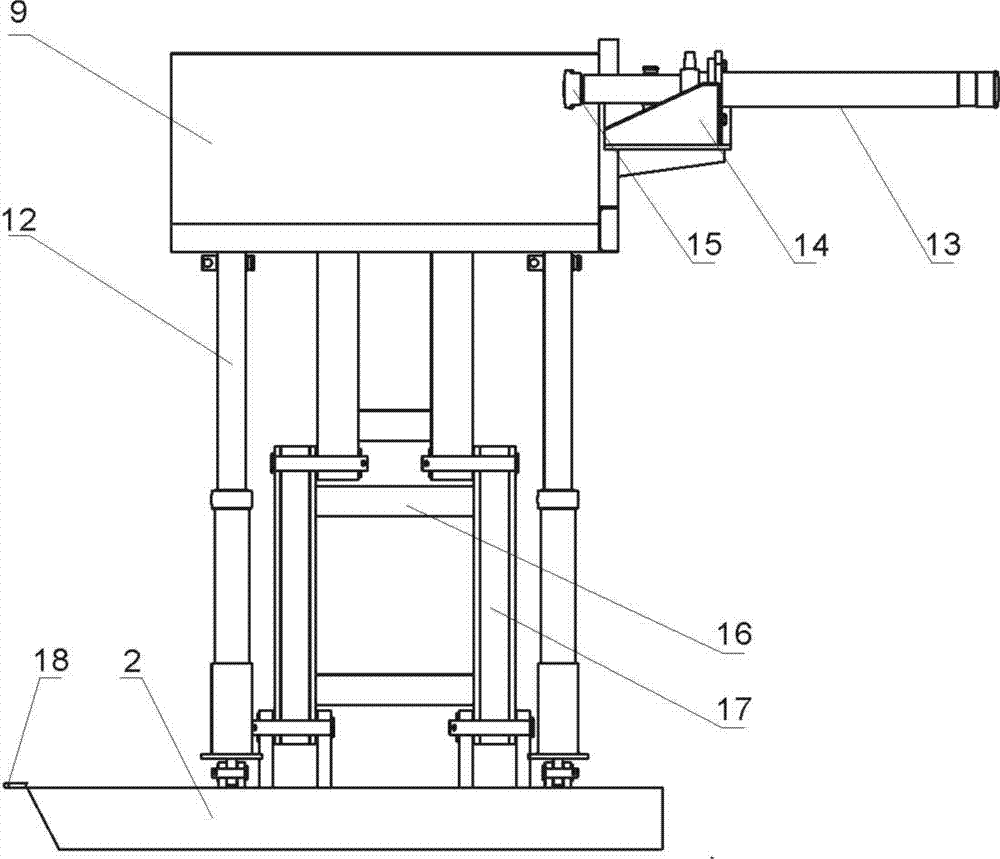

A complete set of equipment for non-gap cutting in the coal mining face of thin and extremely thin coal seams

InactiveCN104863585BImprove coal mining efficiencyImprove coal mining safetyCutting machinesNotchingCoal mining

The invention relates to a thin and ultrathin coal seam coal mining face non-gap feeding complete device. The device comprises a coal cutter and a scraper conveyor. A coal cutter support trolley is arranged in a mechanical roadway and comprises a top support platform and a bottom bearing platform, and a support which is adjustable in height is arranged between the support platform and the bearing platform. A coal cutter roller end push unit is further arranged on the side of the support platform. The coal cutter support trolley is drawn by the scraper conveyor through a traction chain. By means of the complete device, the worker labor intensity can be reduced effectively, the process preparation link is reduced, the normal circulation rate is improved, the per unit area yield is improved greatly, the safety guarantee degree is improved, and the device is worth popularizing.

Owner:BOLIN COAL MINE OF SICHUAN DAZHU COAL POWER GRP CO LTD

Design and evaluation method of self-forming roadway mining without coal pillars by roof cutting and pressure relief

ActiveCN113914862BSave resourcesReduce coal mining costsUnderground miningSurface miningEnergy absorptionArchitectural engineering

The invention discloses a mining design and evaluation method for roof-cutting, pressure-relief, and coal-pillar-free self-formed roadway, which includes: simultaneously digging out the roadway space during the coal mining operation; dividing the surrounding rock of the excavated roadway; determining the prestress of each surrounding rock area Support parameters and roof cutting parameters; high prestressed energy-absorbing support for the roof, and directional roof cutting for the goaf side of the roof at the same time; gangue-blocking support for the roadway; gangue-blocking side of the roadway is closed to form a reserved roadway; Carry out real-time monitoring of roadway stability evaluation indicators for the reserved roadway, and conduct real-time evaluation of the stability of the reserved roadway based on the self-contained roadway stability evaluation system; optimize the reserved roadway according to the stability evaluation results. The invention realizes synchronous formation of roadway in the process of coal recovery and mining at the working face, ensures the stability of the roadway, does not leave coal pillars, has low cost, high working efficiency, safety and reliability, and is suitable for popularization.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Longwall Mining Method of Ultra-thin Coal Seam Based on n00 Construction Method

ActiveCN111219191BAvoid early excavationAvoid wastingUnderground miningTunnel/mines ventillationLongwall miningMining engineering

The present disclosure provides an extremely thin coal seam longwall mining method based on the N00 method, and relates to the technical field of mining. The mining method comprises the following steps: performing an advanced operation on a working face along a direction perpendicular to the working face to form a first roadway, supporting the first roadway to form a first trough; forming an advanced working area in the first trough; and using a shearer In the advanced working area, the coal is mined simultaneously on both sides of the first trough along the direction parallel to the working face, and the mined coal is transported to the scraper conveyor; the shearer on one side of the first trough runs When reaching the first preset position, the working face is blasted to form a second roadway, and the second roadway is supported to form a second trough; the shearer on the other side of the first trough runs to the second preset position. When in position, blast the working face to form the third roadway, and support the third roadway to form the third trough. The mining method of the present disclosure can avoid excavating the roadway in advance, reduce the cost of coal mining, improve the efficiency of coal mining, and avoid waste of resources.

Owner:BEIJING ZHONGKUANG INNOVATION ALLIANCE ENERGY & ENVIRONMENTAL SCI RES INST

Anti-freezing system and method for well mouth of auxiliary well of mine

The invention discloses an anti-freezing system and method for a well mouth of an auxiliary well of a mine. The anti-freezing system and method are used for the mine. The mine comprises a main well and the auxiliary well communicating with the main well. The main well is provided with a draught fan. The auxiliary well supplies air to the main well under the effect of the draught fan. The anti-freezing system for the well mouth of the auxiliary well of the mine comprises a well mouth room, heat exchangers and hot air curtains. The well mouth room is arranged at the well mouth of the auxiliary well, and the well mouth is sealed in the well mouth room. The heat exchangers conduct heat exchange by means of geothermal water in the main well. The hot air curtains are arranged at the top of a room door of the well mouth room, and air curtains used for preventing air exchange from being conducted on the room door are formed. The well mouth room is in a sealed state, negative pressure is formed under the effect of the draught fan, and hot air is delivered into the well mouth through inlets of the heat exchangers. According to the anti-freezing system and method for the well mouth of the auxiliary well of the mine, the geothermal water is used as a heat source, fire coal is not needed, energy is saved, and environmental friendliness is achieved; and the heat exchangers are used for supplying hot air, negative pressure is achieved in the well mouth room, the effect that hot air is provided through the auxiliary well is guaranteed, scalding is prevented, and safety and reliability are guaranteed.

Owner:何满潮

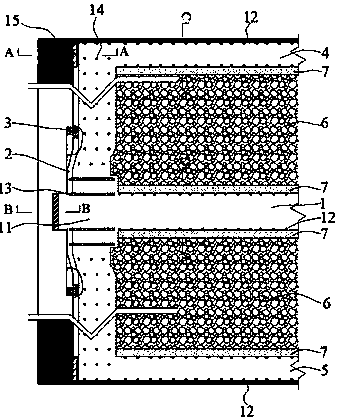

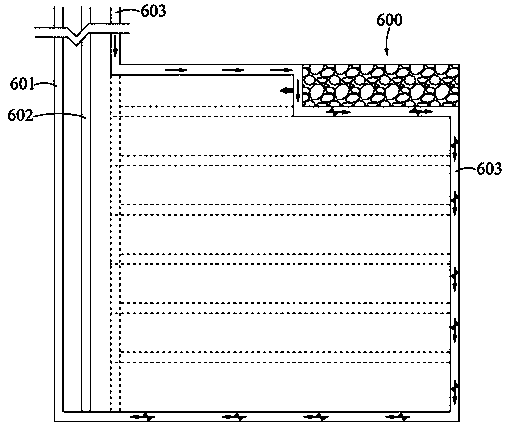

Supporting system of entry retaining area based on n00 mining method

ActiveCN111456789BAvoid fixed arrangementsAvoid early excavationUnderground chambersMine roof supportsSupporting systemArchitectural engineering

The disclosure provides a roadway retaining area support system based on the N00 mining method, and relates to the technical field of coal mine roadway support. The support system includes a retaining roadway, a protective net, an end support assembly and a portal support assembly, wherein: the retaining roadway has a first side wall and a second side wall arranged oppositely and is connected to the first side wall The roof between the roof and the second side wall, and the roadway retained is a roadway formed by the operation of the hook machine device; the protective net is fixed on the surface of the roof, the first side wall and the second side wall, and is used to prevent rocks in the roadway body drop; the end support component is set at the corner of the roadway and is against the protective net; the portal support component is located on the side of the shearer away from the coal mining face and is used for retaining the roadway. The roadway is supported in real time. The support system of the present disclosure can prevent the rock mass in the top and side walls of the roadway from falling, form a stable roadway side, and ensure the safety of workers.

Owner:BEIJING ZHONGKUANG INNOVATION ALLIANCE ENERGY & ENVIRONMENTAL SCI RES INST

A Open-pit Mining Technology with Beam in Narrow Mining Area

ActiveCN107654233BReduce manufacturing costReduce dependenceUnderground miningSurface miningAditOpen-pit mining

The invention relates to a beam-reserving open pit mining technology in a narrow mining area. The beam-reserving open pit mining technology comprises the following steps that a, mining areas are divided, an open-pit mining right realm is divided into the multiple long-strip-shaped mining areas, the position of a mining pit is divided in each mining area, and soil beams are reserved between every two adjacent mining pits as well as between the mining pits and the mining right realm; b, excavation equipment is used to conduct mining on the first batch of mining areas, and mining is conducted according to the preset positions of the mining pits; c, mining is conducted on coal, mined from the first batch of mining areas, under the soil beams on the peripheries of the mining pits by using a slope coal cutter; and d, mining is conducted on the second batch of mining areas, mining is conducted according to the preset positions of the mining pits, and the mining pits are subjected to downwardmining through a spiral linear adit mode. The mining method is suitable for all open-pit mines, revolutionary changes can be generated on open-pit mining, and the mining technology further greatly reduces the open-pit mining cost while improving the adaptability of open-pit coal mine mining.

Owner:张忠成

Constant power control method for coal mining machine and operating handle

InactiveCN101533287BSolve overloadSolve the load problemFluid-pressure actuator componentsElectric variable regulationConstant powerControl signal

The invention relates to a power control method for a coal mining machine based on touch technology of a magneto-rheological valve and a complete operating handle device. The method is realized by the following steps: (1) extracting output current signals of a cutting motor in a coal mining machine set, and sending the output current signals to a control computer; (2) processing the output current signals in the control computer, and converting the output current signals into control signals through D / A conversion to adjust a current controller; (3) using the output current of the current controller to adjust the current of magnet exciting coils in a magneto-rheological device; (4) setting an operating handle and a moving piston in the magneto-rheological device into fixed connection and synchronous movement to form a state that an operator directly feels the change of the output power in the coal mining machine set during resistance change by means of the operating handle; and (5) quickly adjusting the output power of a pulling motor in the coal mining machine set by means of the pushing and pulling operations of the operating handle so as to stabilize a constant power working state of the coal mining machine set.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

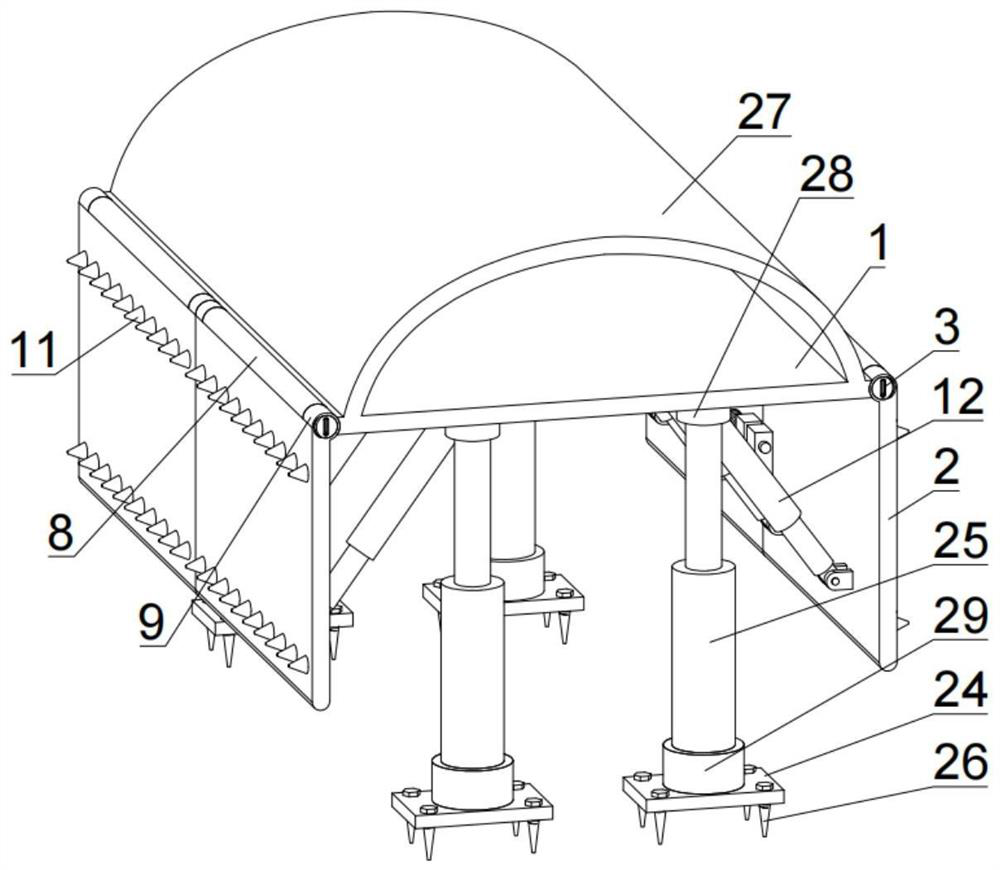

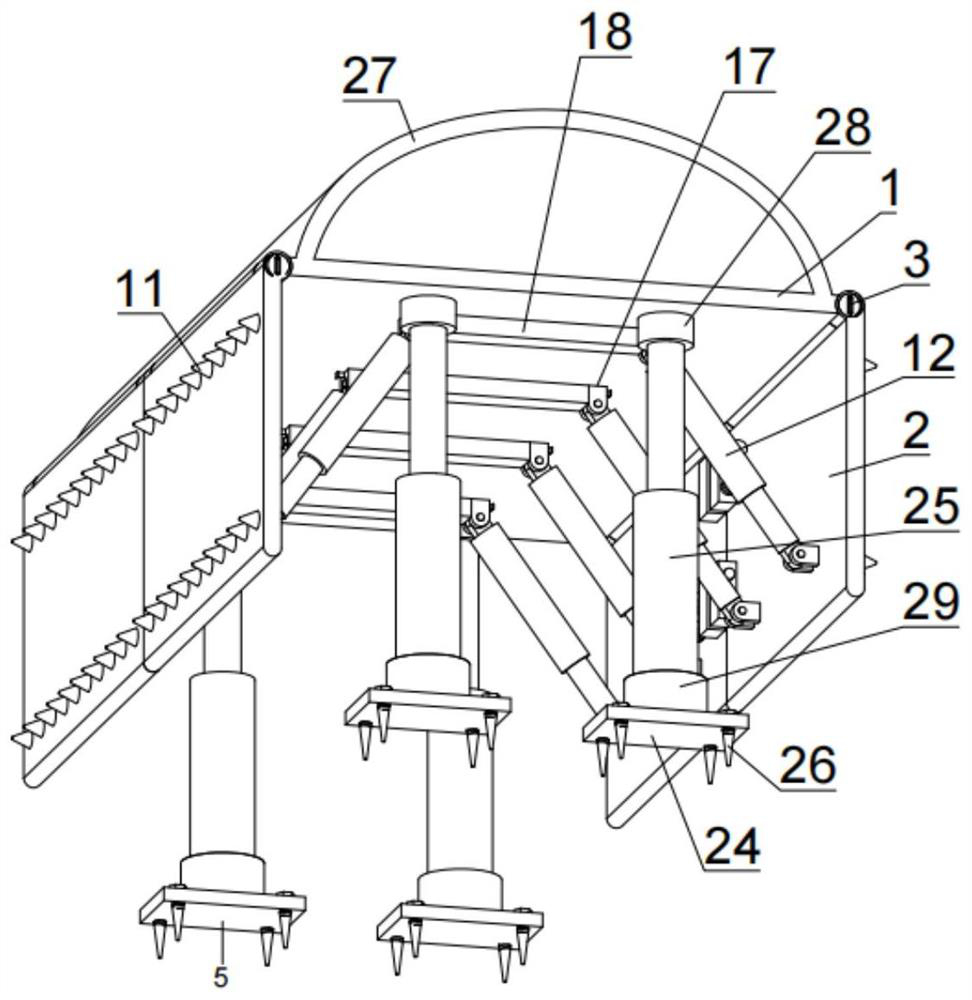

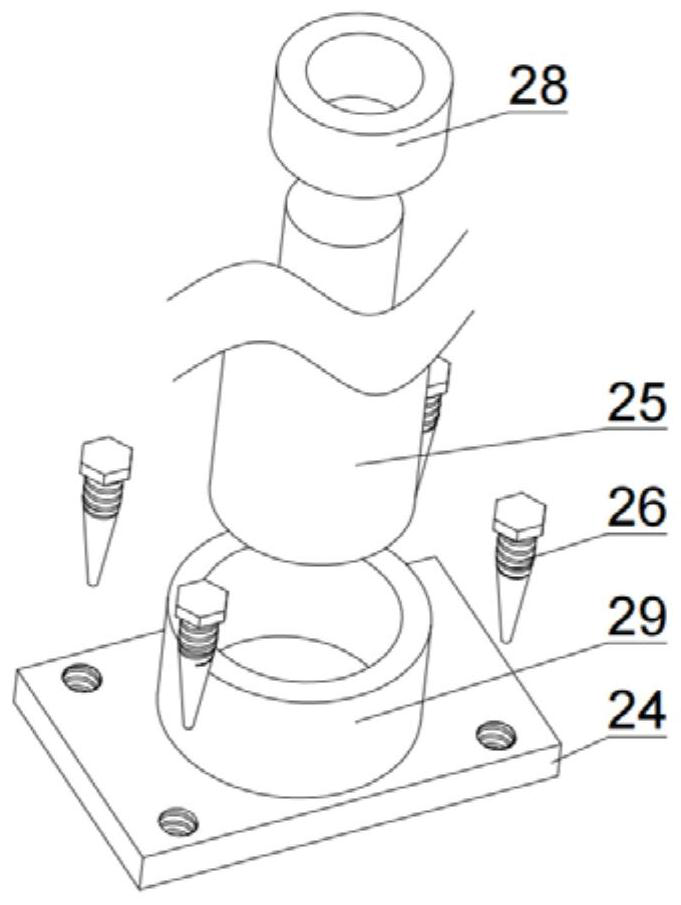

Advanced support device for roadway with super-long working face

PendingCN114320397AImprove versatilityReduce coal mining costsProtective coversCoal miningStructural engineering

The invention provides a forepoling device for an ultra-long working face roadway. The forepoling device comprises a top protection plate; the upper ends of the first driving parts are detachably connected with the top protection plate, and the lower ends of the first driving parts are detachably connected with the ground of the roadway; the two groups of side protection plates are detachably hinged with the side parts of the top protection plate; and the upper ends of the second driving parts are detachably connected with the top protection plate, and the lower ends of the second driving parts are detachably connected with the side protection plates. Compared with the prior art, the split type supporting device has the advantages that the split type supporting device is achieved through detachable connecting structures among all the components, and the supporting effect is good; according to the supporting device, all the components can be transported in the roadway respectively, so that the whole supporting device can carry out supporting in the small roadway, the universality of the whole supporting device is improved, and the coal mining cost is reduced.

Owner:陕西陕煤榆北煤业有限公司 +3

Shield support without front beam of shield support and withdrawing method

The invention discloses a shield support without a front beam of the shield support and a withdrawing method and relates to a shield hydraulic support and a withdrawing method by means of the shield support. The invention aims to solve the problem that an existing shield hydraulic bracket needs to be provided with the front beam of the shield support, which is large in weight and inconvenient to move. One end of a base is fixedly connected or hinged to one end of a shield beam connecting plate or a shield beam connecting rod, and the middle of the base is fixedly connected or hinged to the low end of a top beam hydraulic column; one end of the shield beam is hinged to the other end of the shield beam connecting plate or the shield beam connecting rod; the other end of the shield beam is hinged to one end of the top beam while the other end of the top beam is a top beam edge which is not connected to any devices, and the middle of the top beam is hinged to the top end of the top beam hydraulic column; the top beam is 2.1m long; and one end of the shield beam hydraulic support column is hinged to the middle of the shield beam while the other end of the shield beam hydraulic support column is hinged to the base. The shield support disclosed by the invention is suitable for the withdrawing operation of a hydraulic bracket on an underground coal face.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

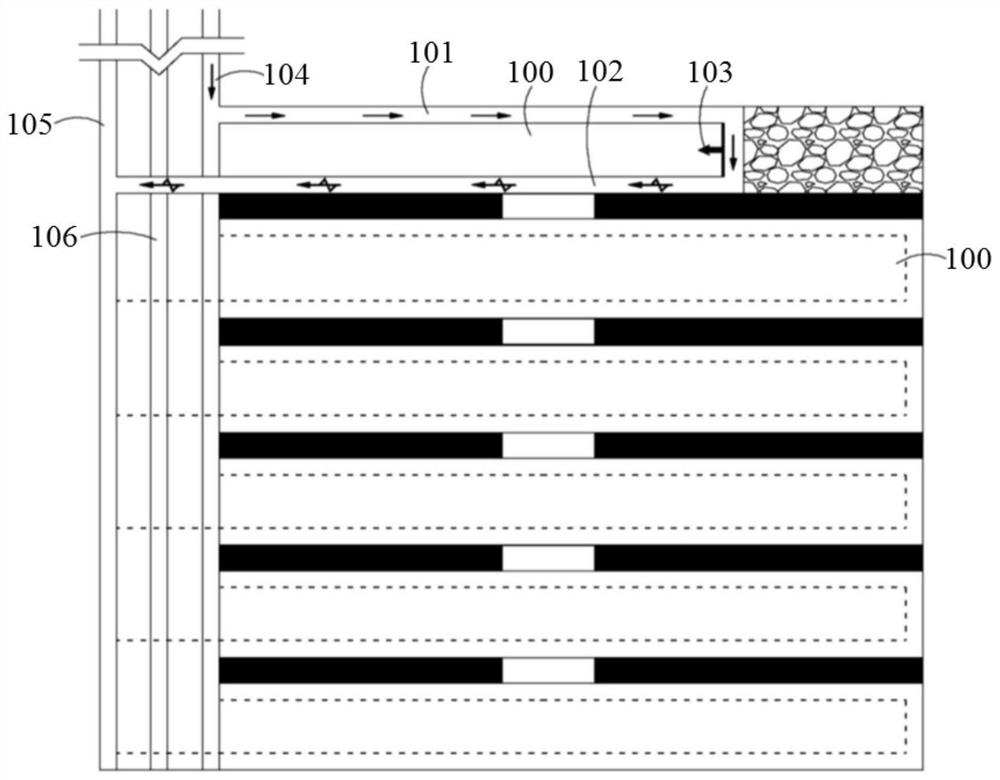

A kind of advancing coal mining method adopting goaf roof support in underground coal mine

ActiveCN108979687BAvoid cycleCaving controlUnderground chambersTunnel liningMining engineeringCoal pillar

The invention relates to a support method for a top board in an underground coal mine, belonging to the technical field of mining technology and environment protection. The method comprises the following steps: acquiring an initial caving step pitch of an immediate roof of a working surface, an initial fracture step pitch of an upper roof, lithological characters and thicknesses of the immediate roof and the upper roof in the underground coal mine; according to the initial caving step pitch of the immediate roof, synchronously supporting the immediate roof of a goaf through anchor rods, anchorbeams and anchor cables during formation of the goaf; adopting an anchor cable group to support the upper roof through the immediate roof of the goaf when the unsupported roof distance of the goaf isless than the initial fracture step pitch range of the upper roof; and determining the model, the length and the inter-row space of the anchor cable group till finishing advancing of a working surface; as the working surface is advanced, keeping a crossheading in the working surface in the goaf in order to form passages for production, ventilation, transport, drainage and safety and till advancing of the working surface is finished. A forward-type coal mining method adopting the top board to support in the goaf of the underground coal mine has features such as no coal column and tunnel; a simple method; and easy operation. Additionally, the top board is controlled not to collapse.

Owner:BEIJING YZH COAL ENG DESIGN

Pick having bimetal structure and preparation method thereof

InactiveCN101787887BMeet the bonding strengthImprove wear resistanceCutting machinesWear resistantMetallic materials

The invention relates to a pick having a bimetal structure and a preparation method thereof, in particular to a pick and a preparation method applicable to coal mining machines and tunneling machines capable of cutting coal seams and rock strata, belonging to the technical field of the research on mining machinery metallic materials and geotechnical engineering. The pick is characterized in thatthe pick body consists of two metals, wherein the most wear-prone top end of a pick head of the pick is made of tailor-made alloy steel; the wear-resistant lower ends of the pick handle and pick headare made of medium carbon alloy steel; a plurality of ring-shaped grooves are formed below the top end of the pick head; an interlayer is arranged between every two adjacent ring-shaped grooves; the ring-shaped grooves are subjected to full-surfacing process by using the tailor-made alloy steel welding rods; and since the interlayer is thin, the integral wear-resistant tailor-made alloy steel canbe formed at the top end of the pick head. The pick of the invention has the advantages of simple structure, novel design, high practicability, convenient fabrication, high hardness and wear resistance and good impact-resisting and corrosion-resisting performance; and according to industrial tests, compared with the homemade pick, the service life of the pick is prolonged by 20 to 30 times, thus saving a great deal of alloy steel materials for our country and reducing the mining cost.

Owner:TAIYUAN UNIV OF TECH +1

Hole cutting and slope expansion construction technology for fully-mechanized working face of complex coal bed

InactiveCN106703816AReduce exposure timeReduce labor intensityUnderground chambersTunnel liningEngineeringWorkload

The invention discloses a hole cutting and slope expansion construction technology for a fully-mechanized working face of a complex coal bed, and relates to the technical field of coal mining. The construction technology solves the problems that an existing mining method is low in efficiency and safety coefficient, high in labor intensity and long in construction period, and safety production and rapid installation of cut holes are not facilitated. The construction technology includes the steps: firstly, respectively performing slope expansion on two sides of an original hole cutting area by the aid of a shipment system of an original cut hole; secondly, performing undercutting for an area below the original hole cutting area; finally respectively performing undercutting for two sides of the area below the original hole cutting area until hole cutting and slope expansion are finished. Simultaneous slope expansion of two sides of the original hole cutting area are performed, double drilling machines can parallelly work on the working surface, exposed time of roofs is shortened, working efficiency is improved, workload manually sweeping coat is reduced, and labor intensity of workers is relieved. Compared with a past construction method which is characterized in that roof brushing is firstly performed, slope expansion is performed, and upper coal is reserved, secondary supporting caused by roof brushing is avoided, and coal mining cost is reduced.

Owner:SICHUAN CHUANMEI HUARONG ENERGY CO LTD

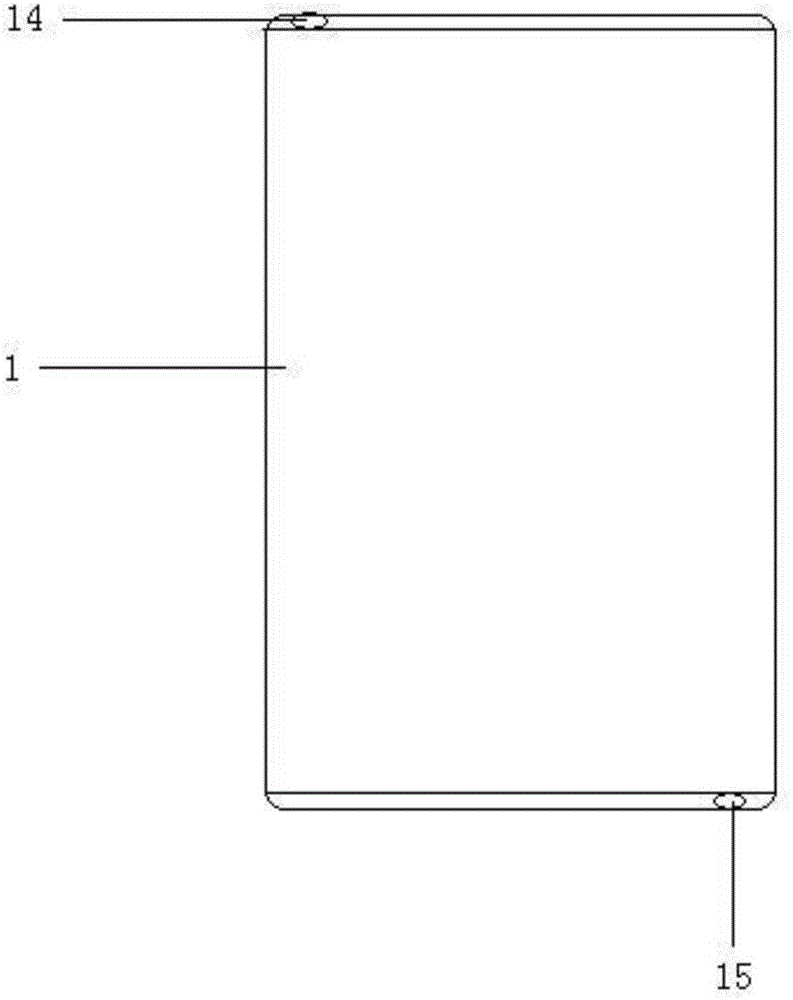

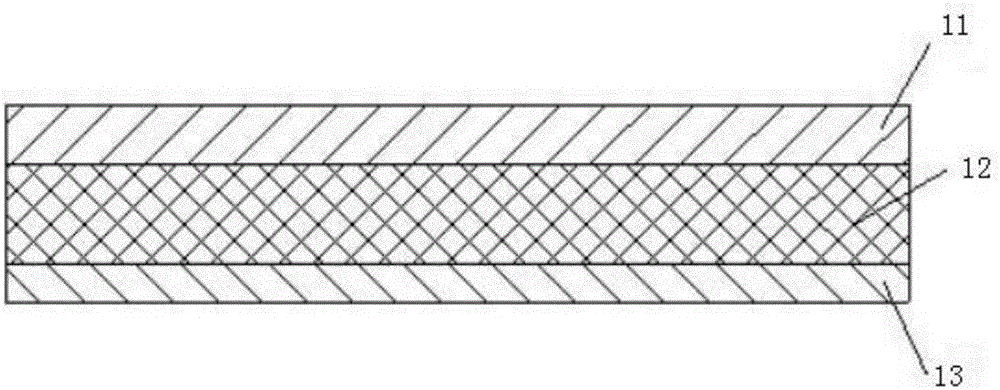

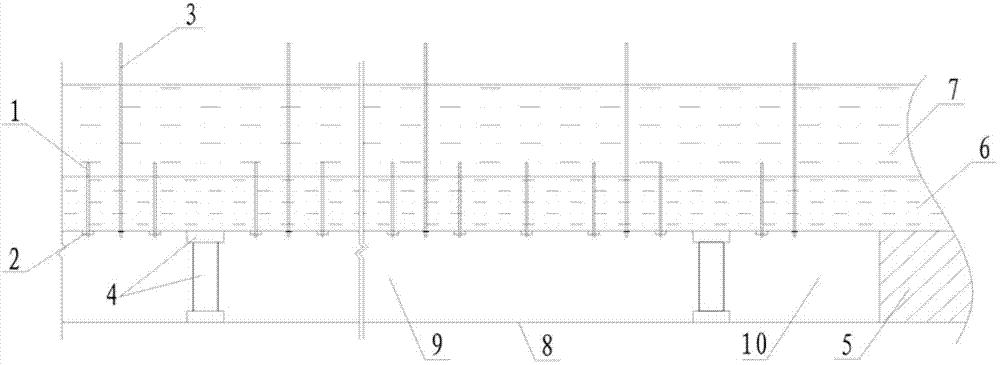

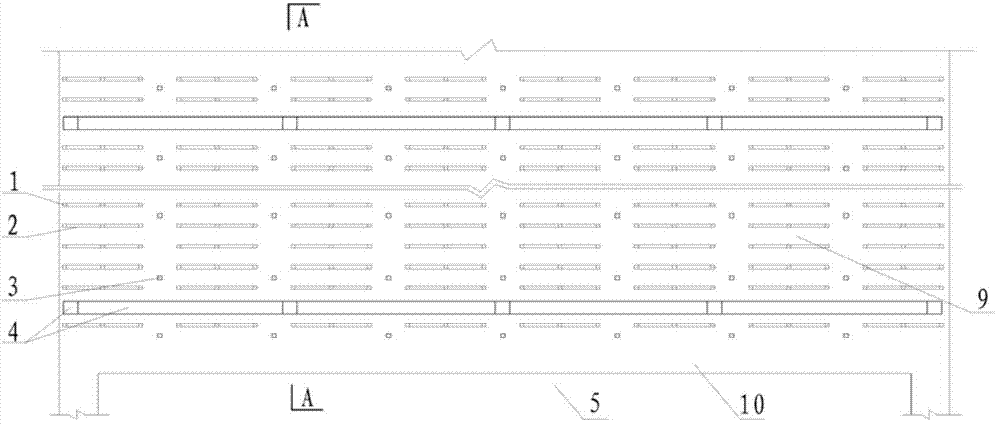

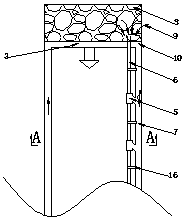

A high-strength composite ice pack and its temporary filling method

InactiveCN104653223BLow costSimple filling processMaterial fill-upThermal insulationUltimate tensile strength

The invention discloses a high-strength composite ice bag and a temporary filling method. The ice bag is connected with a rapid freezer, and comprises a thermal insulation layer, a high-strength silk chemical fiber layer, a fiber reinforced plastic layer, a water injection hole and a drainage hole, wherein the thermal insulation layer is an outermost layer of the ice bag; the high-strength silk chemical fiber layer is a middle layer of the ice bag; the fiber reinforced plastic layer is an internal filler of the ice bag; the top end of the ice bag is provided with the water injection hole; the bottom end of the ice bag is provided with the drainage hole. The temporary filling method of the ice bag comprises the following steps: (1) arranging the ice bags on the rear side of a working face support according to a certain inter-row space; (2) filling the ice bags by using mine water; (3) starting the rapid freezer to rapidly freeze water in the ice bags; (4) supporting a gob roof by the frozen ice bags at a rational inter-row space to realize filling of a gob. The high-strength composite ice bag is low in manufacturing cost, the filling process is simple, the coal mining cost is reduced, and the overall labor efficiency is high.

Owner:XIAN UNIV OF SCI & TECH

Support method for underground goaf roof of coal mine

The invention relates to a support method for an underground goaf roof of a coal mine, and belongs to the technical field of mining techniques and environmental protection. The method comprises the following steps: getting the initial caving interval of an immediate roof of an underground working face of the coal mine and the initial fracture length of a main roof, as well as the lithology and the thickness of each of the immediate roof and the main roof; adopting an anchor rod, an anchor beam and an anchor rope to synchronously support the immediate roof of a goaf during the process of forming the goaf according to the initial caving interval of the immediate roof; determining the type and length of each of the anchor beam, the anchor rope and the anchor rod for constituting a support structure, as well as the inter-row spacing among the anchor beam, the anchor rope and the anchor rod; adopting steel beam columns or preformed reinforced concrete beam columns to support the main roof through the immediate roof of the goaf within the range that the unsupported back span of the goaf is less than the initial fracture length of the main roof; determining the type, length and inter-row spacing of the steel beam columns or the preformed reinforced concrete beam columns; and operating till the completion of the propulsion work on the working face. The method has the characteristics of simple method, easiness in operation and capabilities of controlling the roof and avoiding caving.

Owner:BEIJING YZH COAL ENG DESIGN

Drainage goaf and upper corner gas technology by bed-based drilling with large diameter along the top

ActiveCN108798758BEliminate overrun functionReduce the amount of constructionGas removalMining engineeringStructural engineering

The invention relates to a large diameter bedding drill hole drainage goaf along a roof and upper corner gas technology. The large diameter bedding drill hole drainage goaf along the roof and upper corner gas technology is characterized by comprising that steps that a high level coal seam drilling field is constructed in a return airway; (1), a crawler-type electric drilling machine is used for constructing a long-distance large-diameter drill hole in a drilling field in the mining direction separately forwards and backwards, after a drill tool is exited, a processed borehole protection sleevewith sieve holes of a certain length is pushed into the large-diameter drill hole to seal the large-diameter drill hole; (2), in the main roadway or up a hill, the borehole protection sleeve with thesieve holes and the corresponding extraction pipeline are connected to extract gas in a goaf and upper corner. The amount of drilling construction is nearly 50% less than that of fan-shaped arrangement in a high level drilling field, the cost is low, the large-diameter drill hole is constructed in a coal seam, the construction speed is faster than rock stratum holes, part of the coal is extractedduring the construction to save the cost of coal mining, gas extraction flow rate is large, the borehole protection sleeve is arranged in the large-diameter drill hole, holes are not prone to collapsing, the gas extraction effect is better, and the overlimit function of gas in roadways is effectively eliminated.

Owner:CCTEG SHENYANG RES INST

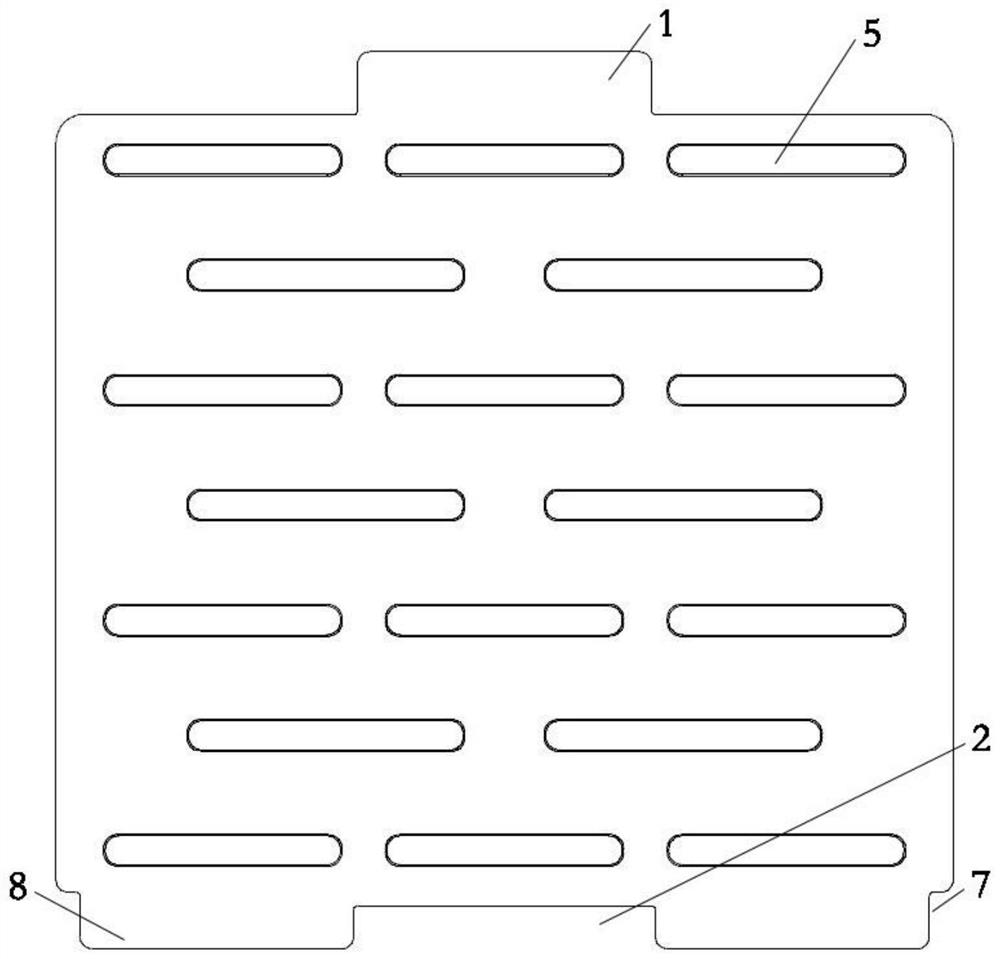

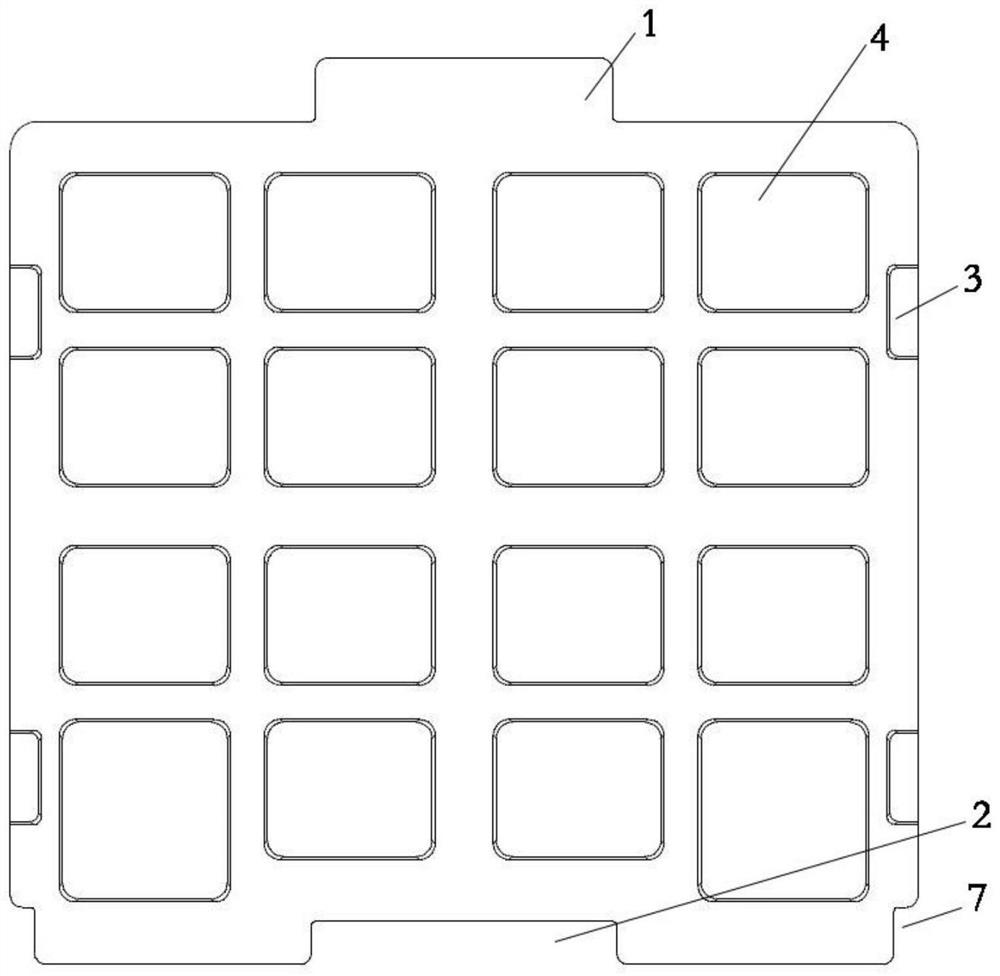

Pressure bearing plate for coal mine and manufacturing method thereof

PendingCN114214886AMeet volume demandShorten the timeSingle unit pavingsFlat articlesMining engineeringRoad surface

The invention relates to a coal mine pressure bearing plate and a manufacturing method thereof, the coal mine pressure bearing plate comprises an ultra-high molecular weight polyethylene plate body, a clamping block is arranged in the middle of a first side edge of the plate body, an opening matched with the clamping block is formed in a second side edge opposite to the first side edge, a plurality of grooves are formed in the back surface of the plate body, and the grooves are matched with the clamping block. The bearing plate is made of ultra-high molecular weight polyethylene with the molecular weight not lower than 350,000 and double-resistance master batch in a mold pressing mode according to the proportion not larger than 3: 2. When in use, the pressure-bearing plates are directly spliced on the road surface, and after splicing is completed, a support transfer trolley can pass through the pressure-bearing plates. Compared with the prior art, the method has the advantages that the existing hardening process required by cement is omitted, the splicing operation is fast and convenient, the pavement can be hardened more efficiently, the coal mining operation is accelerated to a certain extent, and the coal mining cost is saved.

Owner:山东科元塑业有限公司

A kind of cover support and withdrawal method for removing the front beam of the cover support

The invention discloses a shield support without a front beam of the shield support and a withdrawing method and relates to a shield hydraulic support and a withdrawing method by means of the shield support. The invention aims to solve the problem that an existing shield hydraulic bracket needs to be provided with the front beam of the shield support, which is large in weight and inconvenient to move. One end of a base is fixedly connected or hinged to one end of a shield beam connecting plate or a shield beam connecting rod, and the middle of the base is fixedly connected or hinged to the low end of a top beam hydraulic column; one end of the shield beam is hinged to the other end of the shield beam connecting plate or the shield beam connecting rod; the other end of the shield beam is hinged to one end of the top beam while the other end of the top beam is a top beam edge which is not connected to any devices, and the middle of the top beam is hinged to the top end of the top beam hydraulic column; the top beam is 2.1m long; and one end of the shield beam hydraulic support column is hinged to the middle of the shield beam while the other end of the shield beam hydraulic support column is hinged to the base. The shield support disclosed by the invention is suitable for the withdrawing operation of a hydraulic bracket on an underground coal face.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com