A high-strength composite ice pack and its temporary filling method

A composite ice bag and filling method technology, which is applied in the direction of filling, earth cube drilling, safety devices, etc., can solve the problems of low labor efficiency, too many process links, and high equipment requirements, so as to reduce coal mining costs, simple filling process, The effect of high labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with reference to the drawings and embodiments.

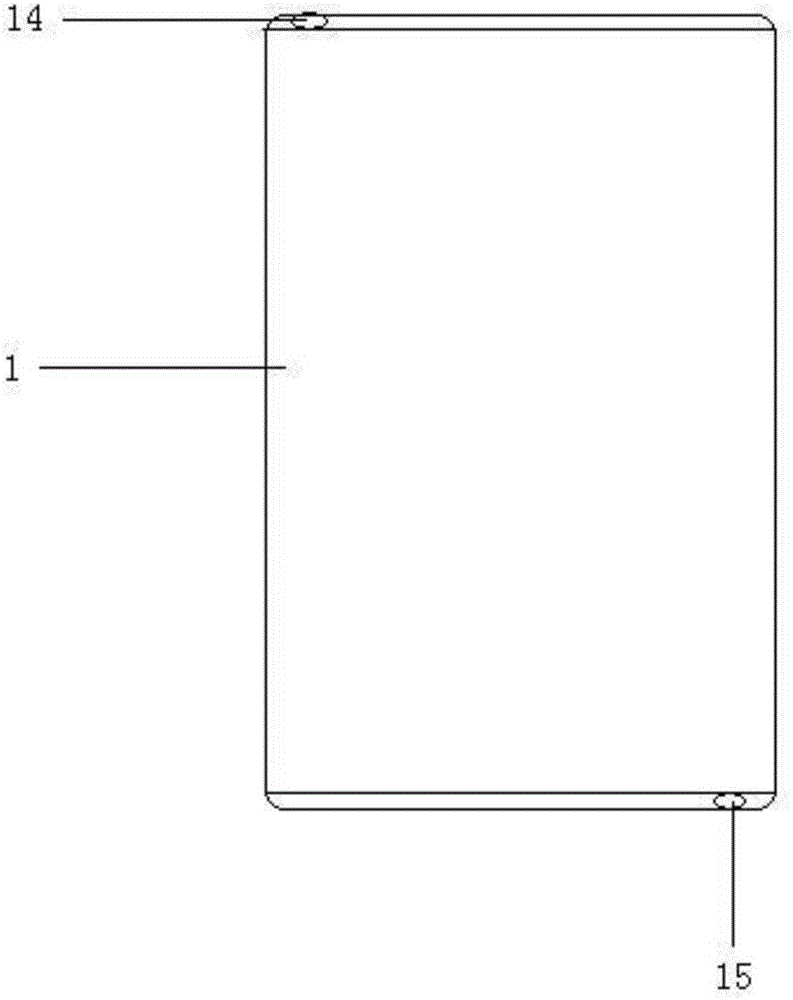

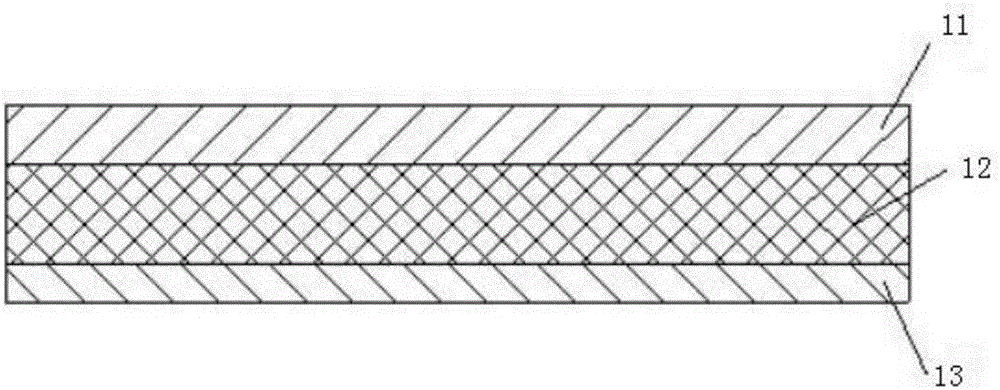

[0018] Such as Figure 1-2 As shown, a high-strength composite ice bag includes an ice bag 1, the ice bag 1 is connected to a quick freezer, and the ice bag 1 includes a temperature insulation layer 11, a high-strength silk fiber layer 12, a fiber reinforced plastic layer 13, and a water injection hole 14. And drainage holes 15, the temperature insulating layer 11 is the outer layer of the ice pack 1, the high-strength silk fiber layer 12 is the middle layer of the ice pack 1, and the fiber reinforced plastic layer 13 is the inner filling of the ice pack 1, A water injection hole 14 is reserved at the top end of the ice bag 1, and a drainage hole 15 is reserved at the bottom end of the ice bag 1.

[0019] A temporary filling method of a high-strength composite ice pack includes the following steps:

[0020] (1) Arrange ice packs at a certain interval behind the support of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com