Anti-freezing system and method for well mouth of auxiliary well of mine

An anti-freezing system and auxiliary shaft technology, which are applied in the ventilation of mines/tunnels, mining equipment, earth-moving drilling, etc., can solve the problems of energy waste and heavy load, and achieve the effects of improving safety, saving resources and high economic value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

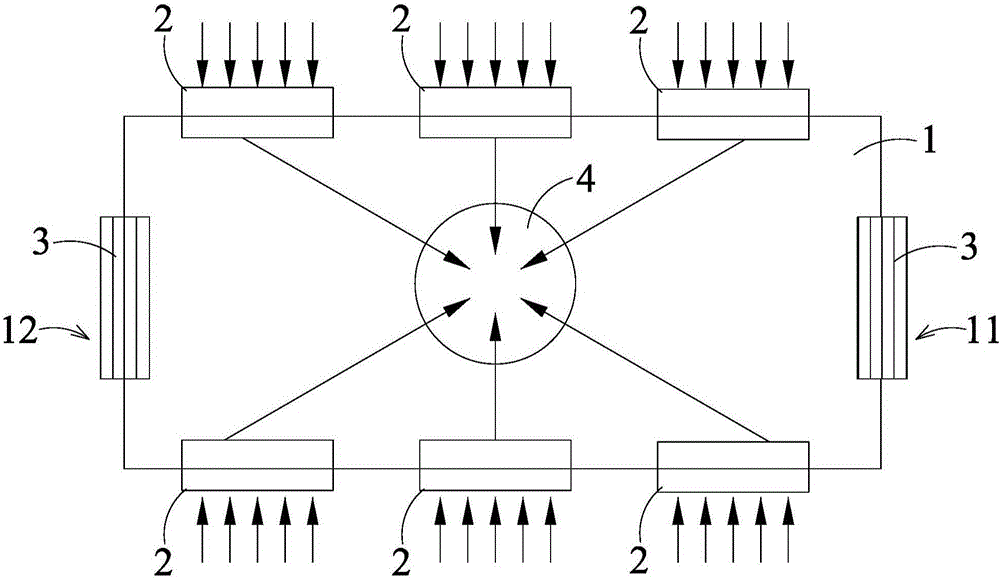

[0023] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and drawings therein are illustrative in nature and not limiting. this invention.

[0024] Most of the mines in the central and eastern part of my country have rich mine geothermal resources after deep mining, which can replace coal-fired boilers to achieve ground heating. However, the temperature of the hot water produced by the geothermal system is only 60°C. Directly supplying heat according to the existing method cannot guarantee that the wellhead will not freeze, and cannot meet the requirements of antifreeze heating. Therefore, the main purpose of the present invention is to realize the use of mine geothermal energy for wellhead antifreez...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com