Drainage goaf and upper corner gas technology by bed-based drilling with large diameter along the top

A bed-by-bed drilling and large-diameter technology, which is applied in the field of gob drainage along the top and large-diameter bed-by-bed drilling and gas technology in the upper corner, can solve the problems of affecting the drainage effect, high cost, and small borehole diameter. problems, to achieve the effects of saving coal mining costs, preventing gas overruns, and preventing hole collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

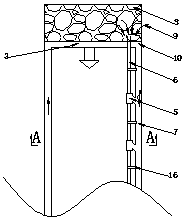

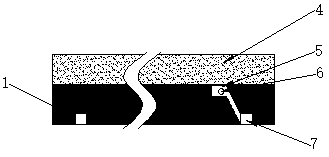

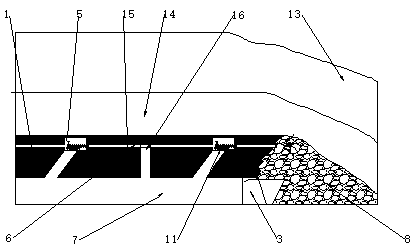

[0015] For a first example, see figure 1 , figure 2 , image 3 , a technology for extracting gas from the goaf 8 and the upper corner along the top and large-diameter bedding boreholes. In the drilling field, drill holes 6 with a long distance of 100-200 meters and a large diameter of 500-1000 mm forward and backward respectively along the recovery direction. After exiting the drilling tool, the processed 1-2 meter long The retaining wall casing 15 is pushed into the large-diameter borehole 6, and the large-diameter borehole 6 is sealed. ② Connect the retaining wall casing 15 with sieve holes and the corresponding extraction pipeline in the road or up the mountain. The goaf and the upper corner 10 gas are extracted.

[0016] It effectively replaces the fan-shaped arrangement of drill holes in the roof 4 to drain the gas in the goaf.

no. 2 example

[0017] For a second embodiment, see figure 1 , figure 2 , image 3 , a technology for extracting gas from the goaf 8 and the upper corner along the top and large-diameter bedding boreholes. In the drilling field, drill holes 6 with a long distance of 100-200 meters and a large diameter of 500-1000 mm forward and backward respectively along the recovery direction. After exiting the drilling tool, the processed 1-2 meter long The retaining wall casing 15 is pushed into the large-diameter borehole 6, and the large-diameter borehole 6 is sealed. ② Connect the retaining wall casing 15 with sieve holes and the corresponding extraction pipeline in the road or up the mountain. The goaf and the upper corner 10 gas are extracted.

[0018] Wherein: 3. when large-length and large-diameter boreholes 6 are needed, construct a coal seam high-level drilling site 5 at intervals of 200-400 meters from the return airway 7, and in all coal seam high-level drilling sites 5, repeat step 1. A s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com