Shield support without front beam of shield support and withdrawing method

A technology of shielding brackets and shielding beams, which is applied to mine roof brackets, earth-moving drilling, mining equipment, etc., can solve the problems of inconvenient movement and high quality, and achieve the effects of convenient movement, low resistance and improved safety factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

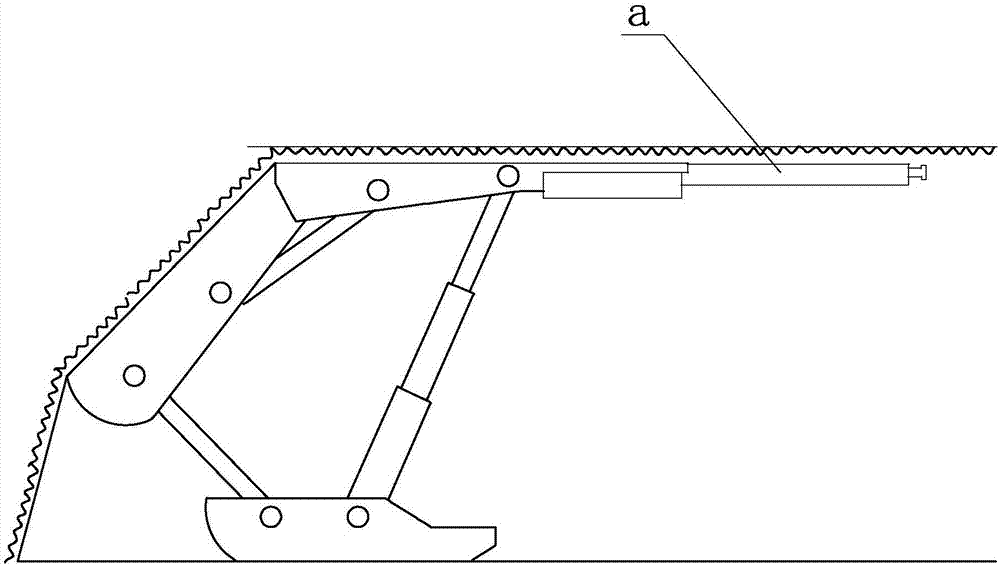

[0031] Specific implementation mode one: combine figure 2 To describe this embodiment,

[0032] 1. A cover bracket for removing the front beam of the cover bracket, characterized in that it includes a base 1, a cover beam 2, a top beam 3, a cover beam hydraulic prop 4, a cover beam connecting plate or a cover beam connecting rod 5, and a top beam hydraulic column 6. One end of the base 1 is fixed or hinged to one end of the cover beam connecting plate or the cover beam connecting rod 5, and the middle part of the base 1 is fixed or hinged to the lower end of the top beam hydraulic column 6; one end of the cover beam 2 is hinged to the cover beam The other end of the connecting plate or the cover beam connecting rod 5; the other end of the cover beam 2 is hinged to one end of the roof beam 3, and the other end of the roof beam 3 is the edge of the roof beam. The middle part of the beam 3 hinges the top of the top beam hydraulic column 6; the length of the top beam 3 is 2.1 me...

specific Embodiment approach 2

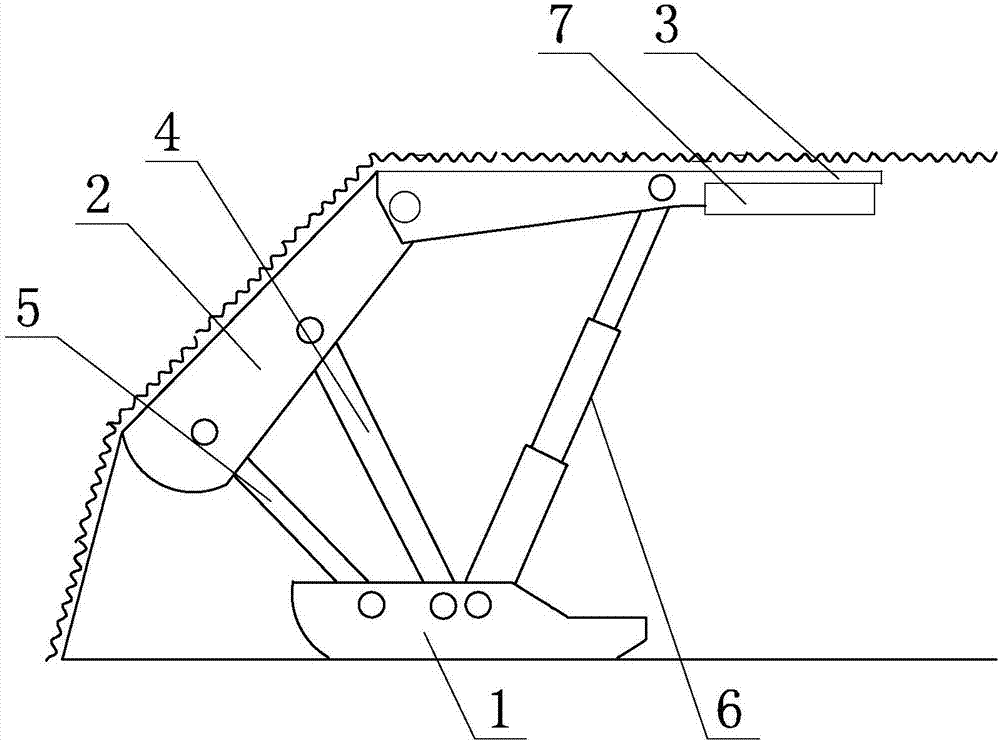

[0035] Specific implementation mode two: combination image 3 and Figure 4 To describe this embodiment,

[0036] The roof beam 3 in this embodiment includes a roof beam rotation shaft 33, a roof beam support shaft 32 and a plurality of roof beam arms 31; And can rotate relative to the top beam arm 31, the top of the top beam hydraulic column 6 is hinged with the middle part of the top beam support shaft 32 and the top beam 3; The top beam arm 31 rotates relatively, and the other end of the shield beam 2 is hinged to the top beam 3 through the top beam rotation axis 33 .

[0037] Other structures and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

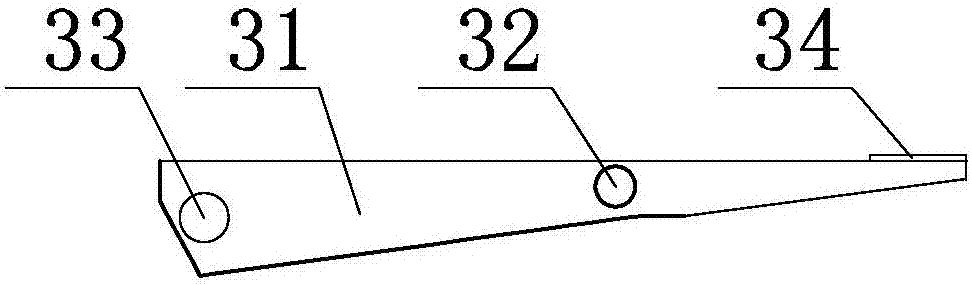

[0038] The top beam arms 31 in this embodiment are connected with lacing plates 34 on their upper ends.

[0039] Other structures and parameters are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com