A Open-pit Mining Technology with Beam in Narrow Mining Area

A technology for open-pit mining and mining areas, applied in ground mining, earth square drilling, underground mining, etc., can solve the problems of reducing the cost of open-pit mining and the limited scope of application of open-pit mining, and achieve the effect of reducing the amount of soil discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] An open-pit mining technique with beams in a narrow mining area, comprising the following steps.

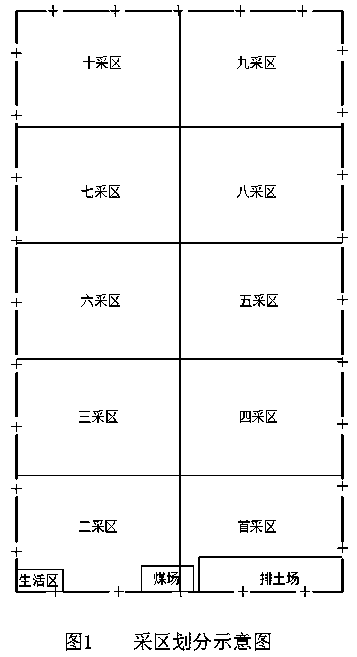

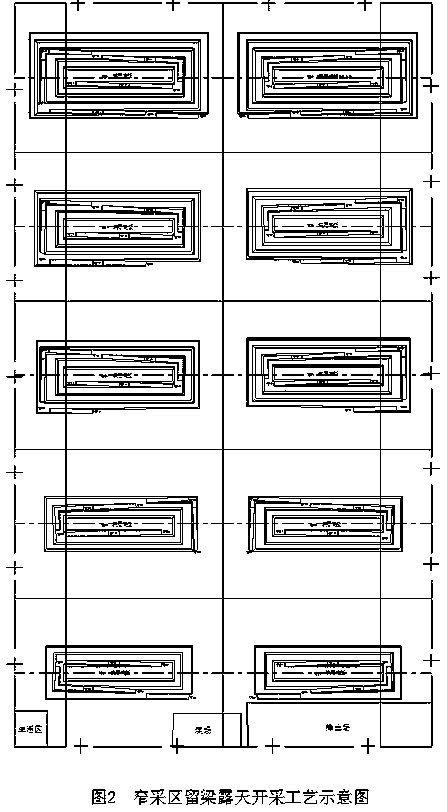

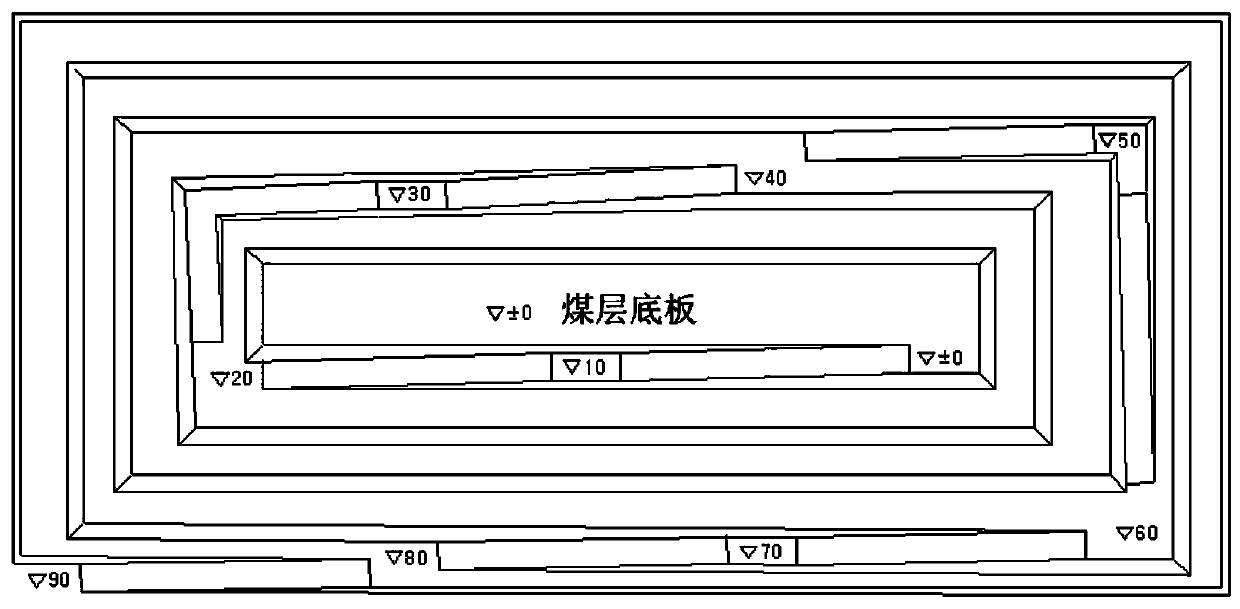

[0022] The division of the mining area divides the open-pit mining right boundary into a plurality of strip-shaped mining areas, generally will be divided into more than a dozen mining areas, like the open-pit mine of the example of the present invention, the ore field area is only 2.65km 2 For open-pit mines, normal open-pit mining can only be divided into one mining area, but after adopting the narrow mining area beam open-pit mining technology, it must be divided into 10 mining areas. Considering the limitation of transportation equipment, the length of each mining area is set between 465-920 meters, and the width is set between 335-435 meters. Then divide the scope of the mining pit in each mining area, the scope of the mining pit is smaller than the scope of the mining area, so that there are soil beams between the mining pits, and between the mining pits and the bord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com