Hydraulic system used for recycling emulsified liquid of coal face

A technology for coal mining face and emulsion, which is applied in mining equipment, earthwork drilling, pillars/supports, etc., can solve the problems of waste of emulsion, groundwater and environmental pollution, and achieves reduction of pollution, consumption and coal mining. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

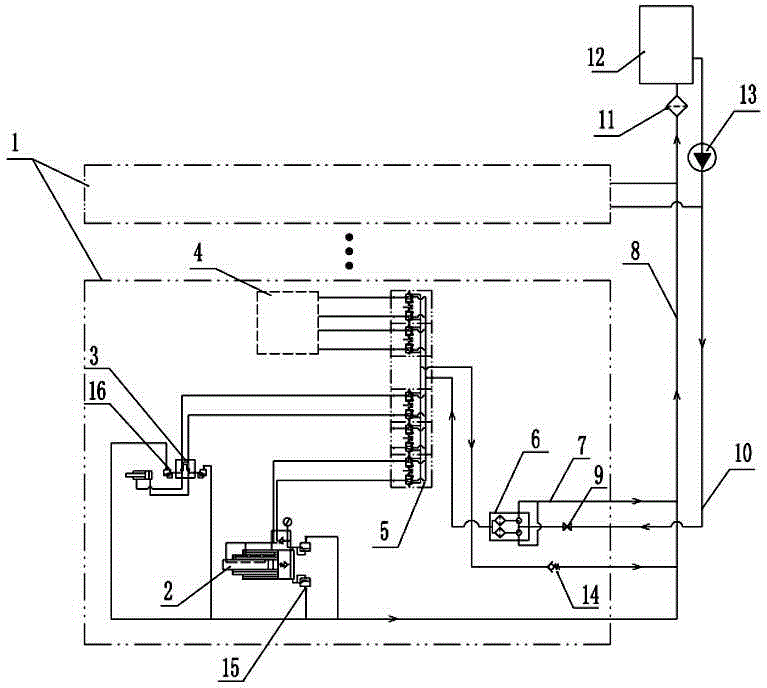

[0008] Such as figure 1 As shown, the hydraulic system for recovering emulsion in the coal mining face of the present invention includes a plurality of hydraulic support hydraulic control units 1 arranged on the underground coal mining face, and each hydraulic support hydraulic control unit 1 includes Hydraulic column 2, hydraulic jack two-way lock 3 and hydraulic equipment 4 matching the hydraulic support, and a hydraulic control valve group 5 for controlling the hydraulic column 2, hydraulic jack two-way lock 3, and hydraulic equipment 4 supporting the hydraulic support, The backwash emulsion inlet of the hydraulic control valve group 5 communicates with the liquid outlet of the backwash filter 6, and the liquid discharge port of the backwash filter 6 communicates with the liquid return pipeline 8 through the sewage pipeline 7, and the backwash filter The liquid inlet of the device 6 communicates with the high-pressure liquid inlet pipeline 10 through the stop valve 9, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com