Hole cutting and slope expansion construction technology for fully-mechanized working face of complex coal bed

A technology of fully mechanized mining face and construction technology, applied in mining equipment, earthwork drilling, shaft equipment, etc., can solve the problems of unfavorable safety production, rapid installation of cutting holes, low safety factor, high labor intensity, etc., to avoid secondary The effect of supporting problems, reducing coal mining costs and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

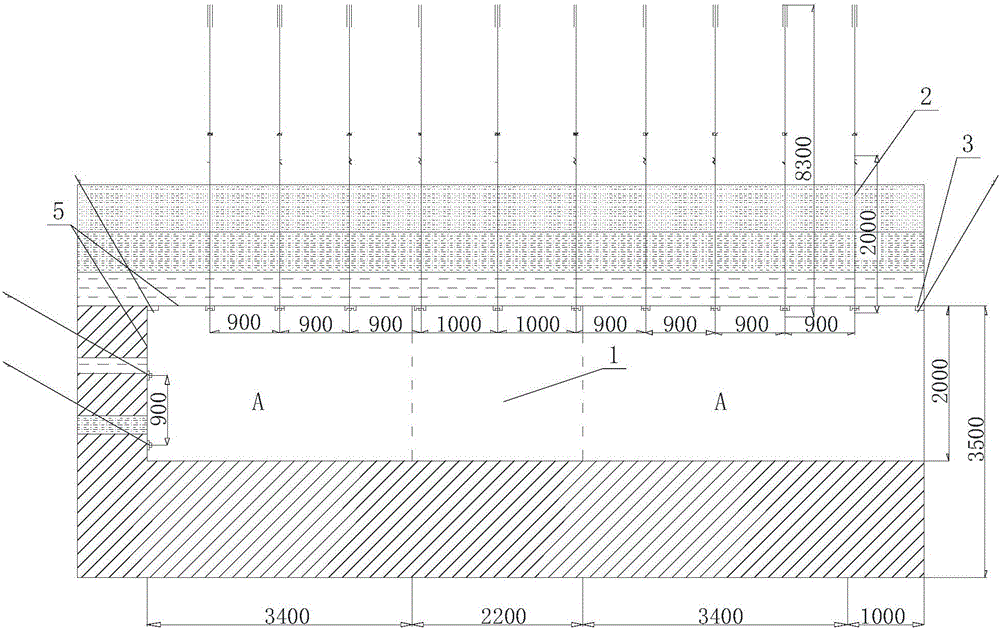

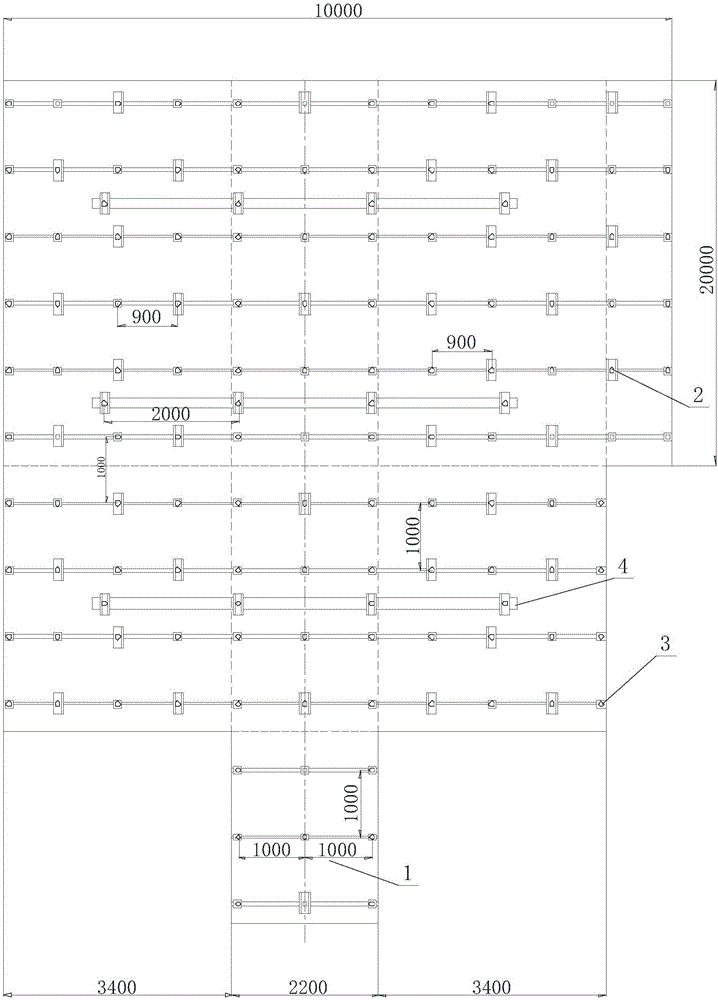

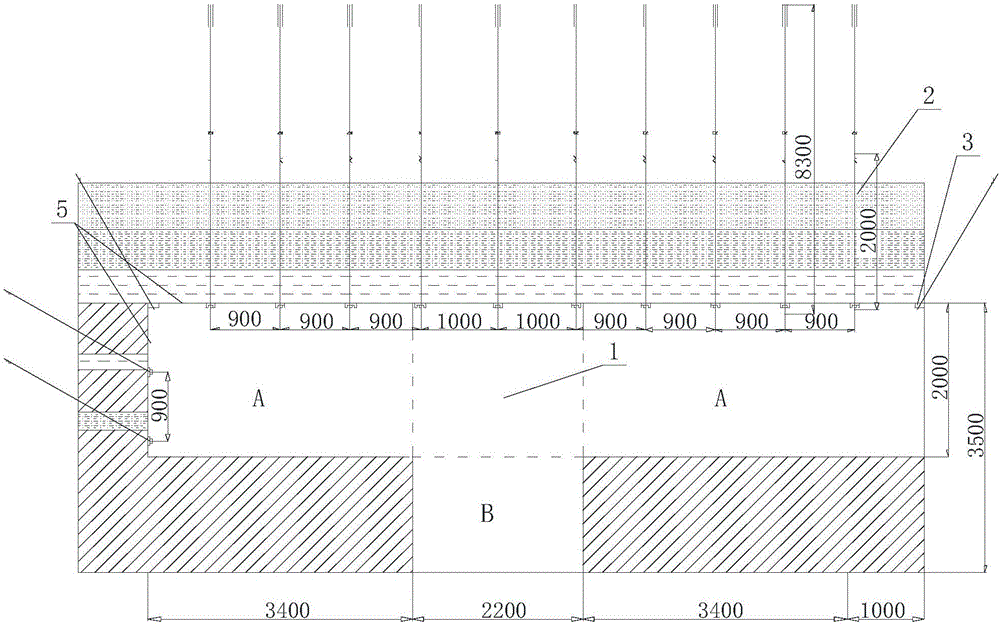

[0021] In the present invention, the construction process of side cutting and side expansion in the complex coal seam fully mechanized mining face first uses the delivery system of the original cut side to expand the sides on both sides of the original side cut area 1, and completes the supporting work required for the side expansion. like figure 1 and figure 2 As shown, the progress of the cycle operation is 1m, the width of the original incision area 1 is 2.2m, and the two sides of the original incision area 1 are respectively marked as area A, that is, the side is expanded by 3.4m in area A by using the original incision shipping system . The cycle work progress is based on 0.8-2.0m. On both sides of the original eye-cut area 1, the sides are expanded respectively, one side is expanded by 3.4m, and the other side is widened by 1.0m in addition to the expansion of 3.4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com