Constant power control method for coal mining machine and operating handle

A technology of constant power control and operating handle, applied in control/regulation systems, mechanical equipment, instruments, etc., can solve problems such as differences in operation level and response speed, increase aging of key control components, and inability to adjust traction speed, etc. The effect of improving work stability, saving coal mining energy and reducing coal mining costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

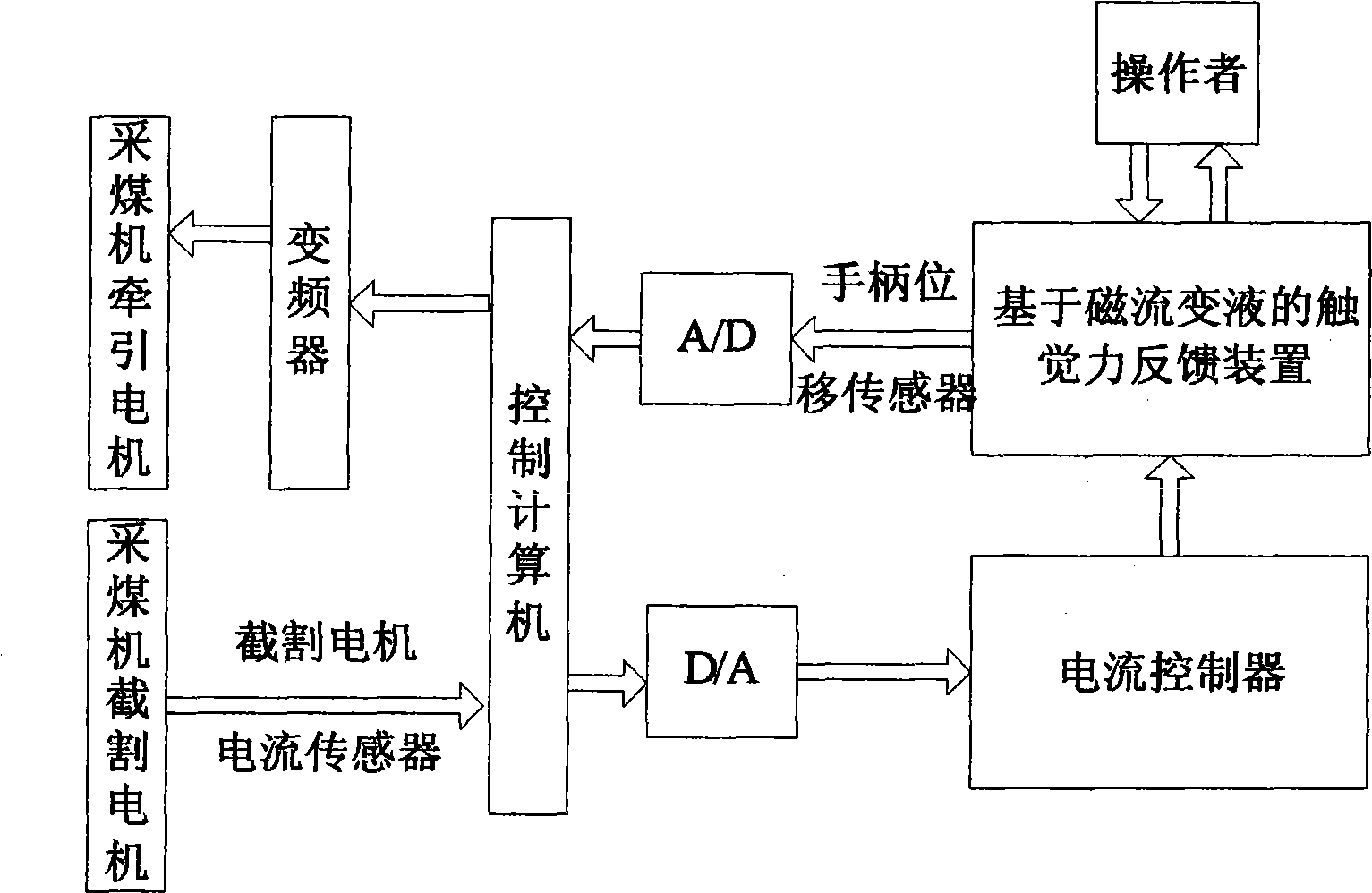

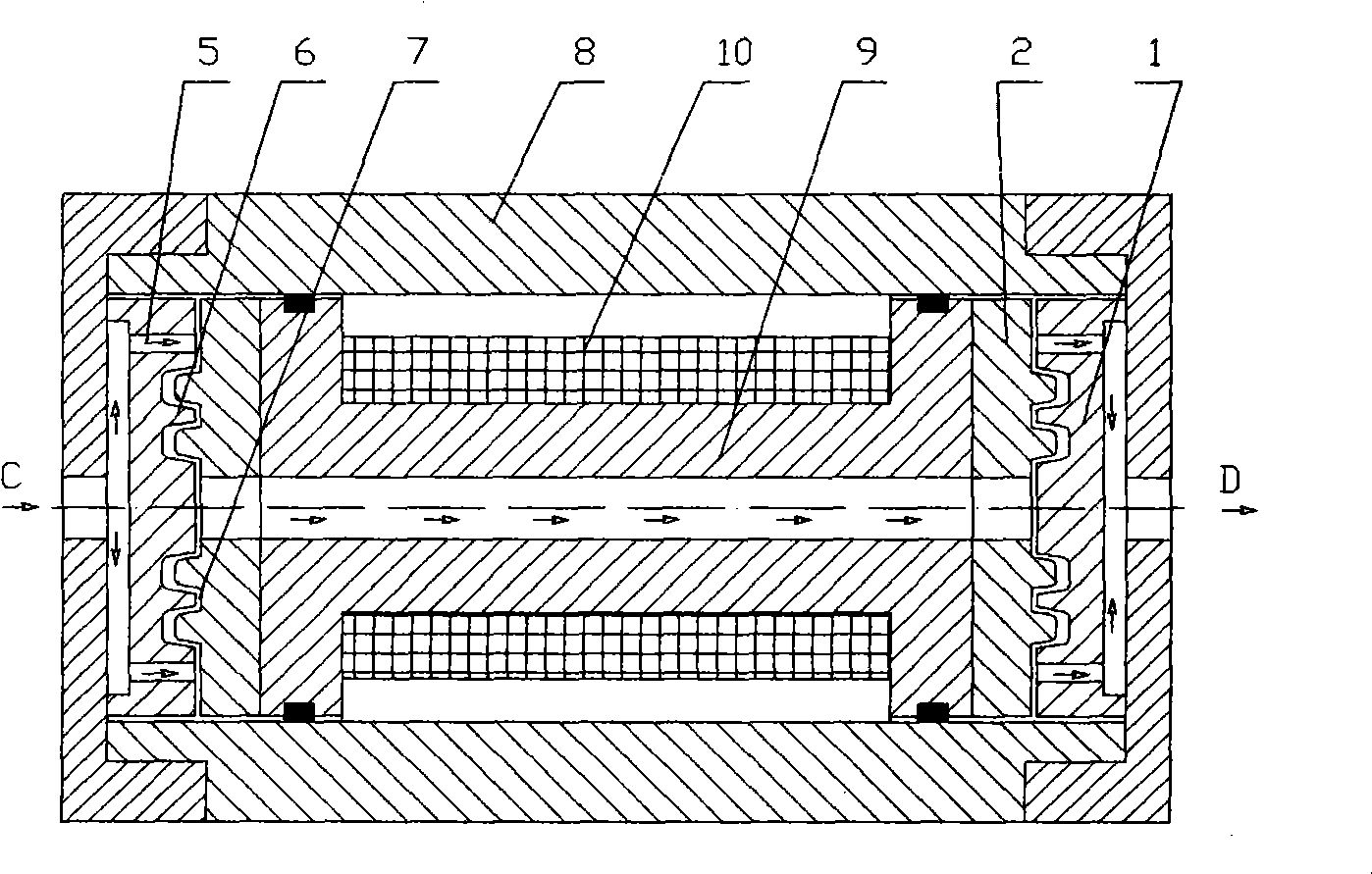

[0026] Referring to the accompanying drawings, it can be clearly seen that the method involved in the present invention is realized with the support of the control computer of the coal mining unit and the supporting management software, and the key lies in the adjustment of the output power of the traction motor in the coal mining unit The quick control of the operating handle has been added in , which can be realized by the following steps;

[0027] ① Extract the output current signal of the cutting motor in the online coal mining unit through the current transformer, and convert the A / D speed signal of the cutting motor into a digital signal and send it to the control computer.

[0028] ②In the control computer, the signal comparison and proportional adjustment are performed according to the set parameters, and the control code is output, and the output current of the current controller is adjusted through D / A conversion into a control signal.

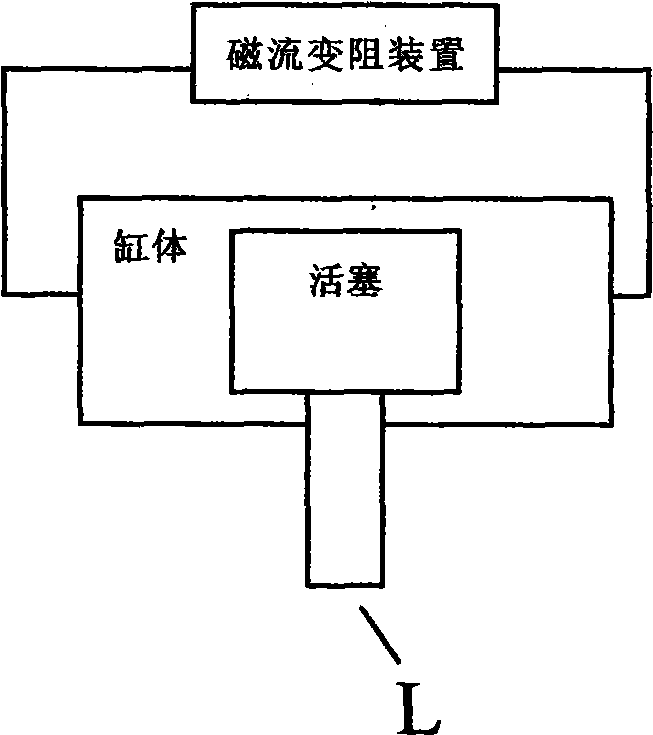

[0029] ③Use the output curren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com