Helical shearer roller

A technology of helical drum and shearer, applied in cutting machinery, earthwork drilling and other directions, can solve the problems of design quality affecting coal mining efficiency of fully mechanized mining units, high cost, low mining efficiency, etc. The effect of high coal cost and mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

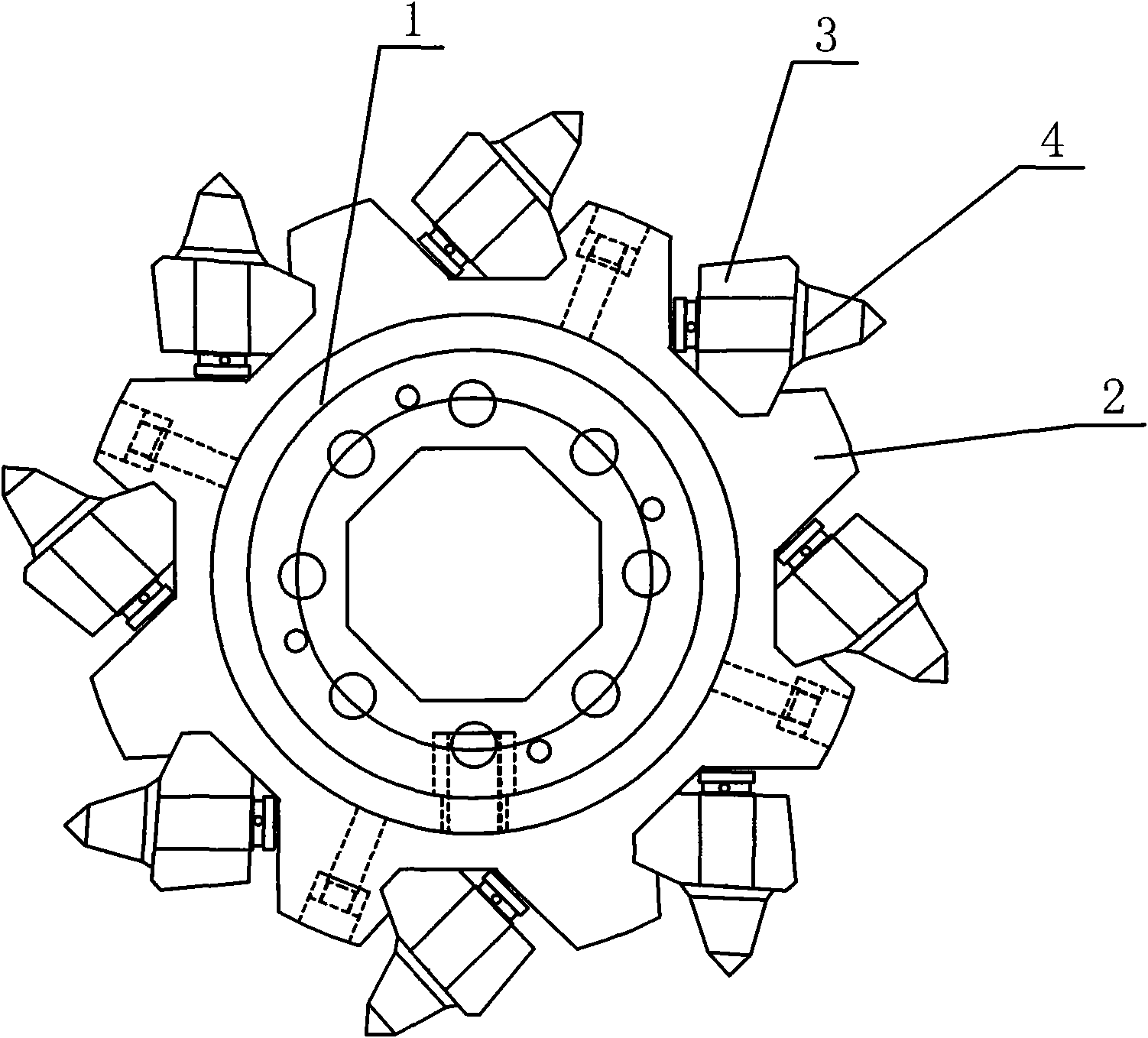

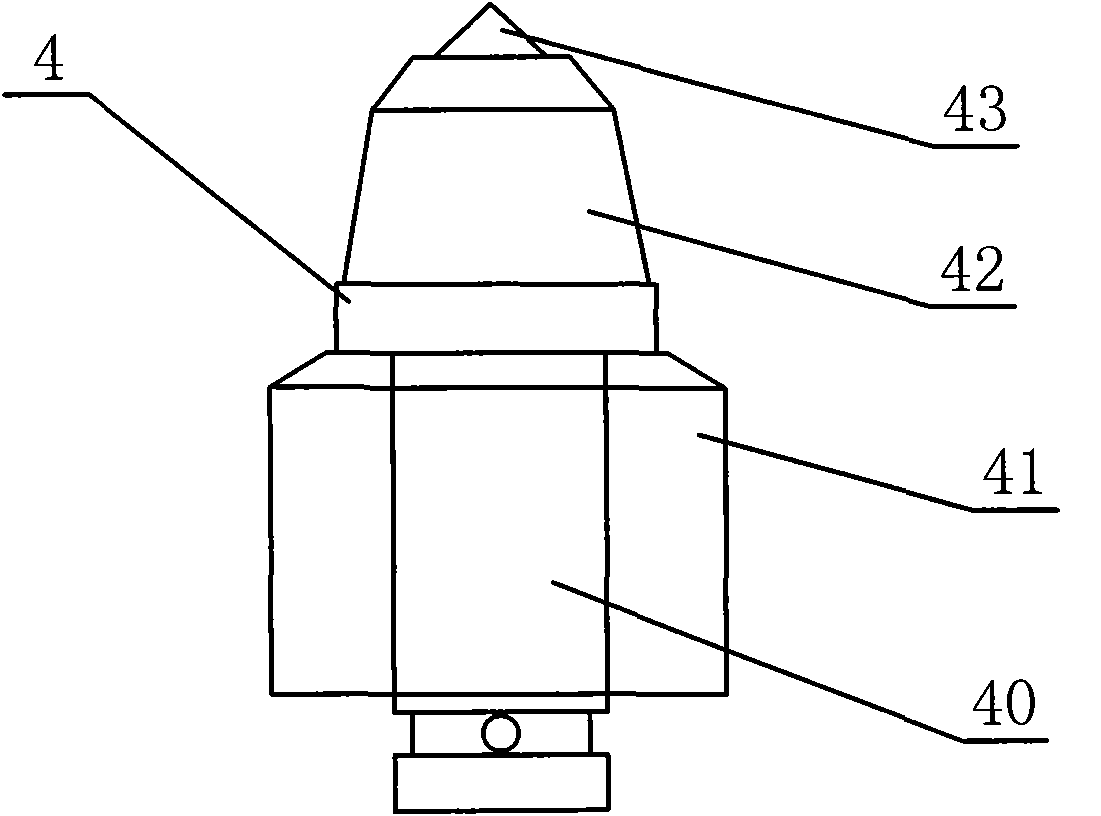

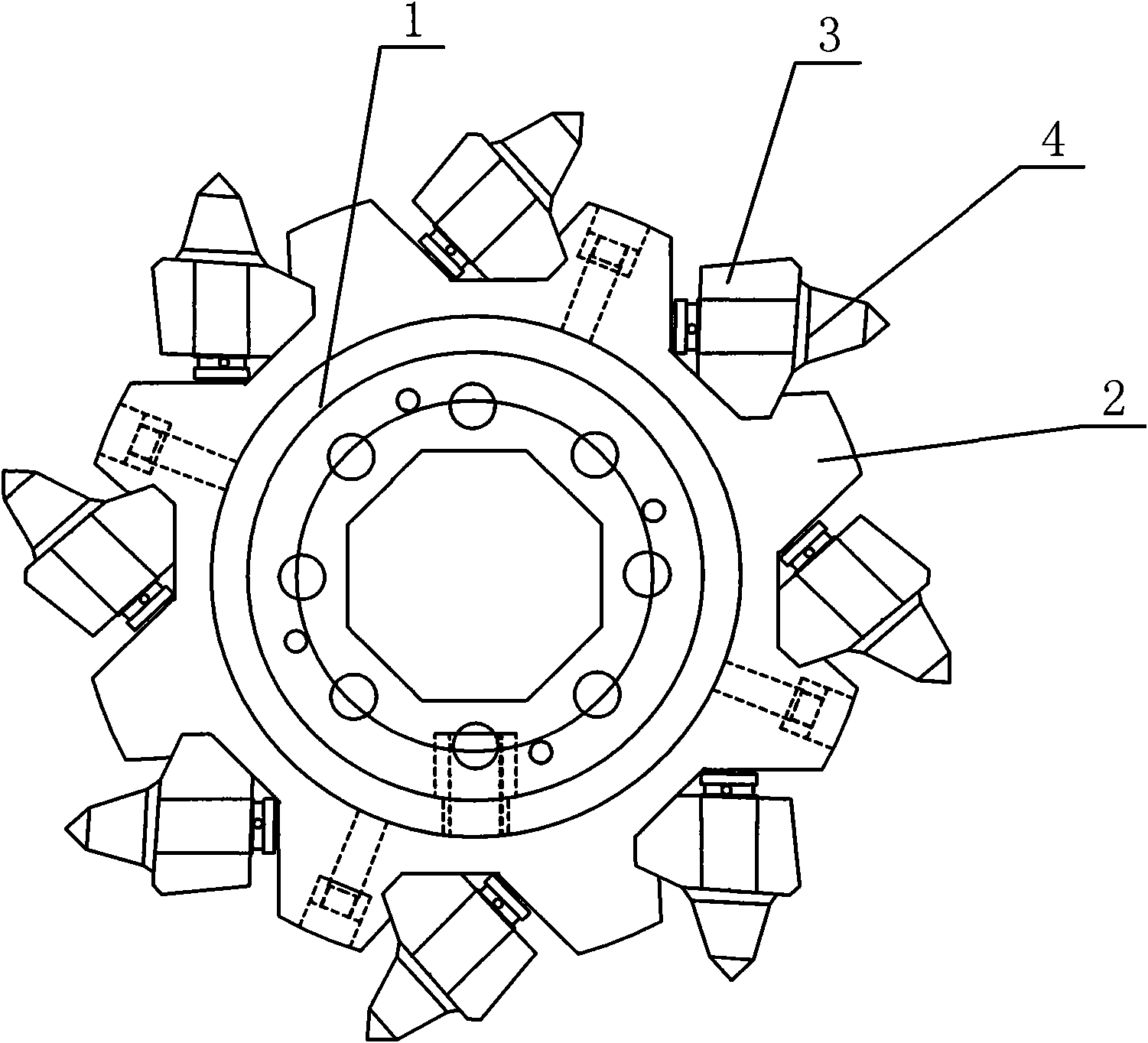

[0014] Please refer to figure 1 and figure 2 As shown, figure 1 It is a side view of the spiral drum of the shearer of the present invention; figure 2 It is a cross-sectional view of the pick of the spiral drum of the shearer of the present invention. In this embodiment, the spiral drum of the shearer includes a drum body 1, a combined spiral blade 2 arranged on the drum body 1, and a conical tooth seat 3 is installed on the spiral blade 2; 4 includes a rack 40 and a tooth head 42 arranged at one end of the rack 40. The tooth head 42 has a conical structure, and the front end of the tooth head 42 is welded with a conical alloy head 43, the welding strength is greater than 490MPa, so The tapered pick 4 is installed on the tapered gear seat 3 through the gear sleeve 41 with a gear rod 40.

[0015] The spiral drum of the above-mentioned shearer adopts conical picks, and the front end of the conical picks is welded with a conical alloy head, so that when the shearer is mining coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com