Long spiral extrusion pile drilling machine and drilling method thereof

A drilling method and a technology for extruding and expanding piles, which are applied in drilling equipment and methods, directional drilling, earth-moving drilling, etc., can solve the problems of difficult downward drilling, collapsed holes, high density of pebbles, etc., and improve construction efficiency. , the effect of reducing the phenomenon of collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

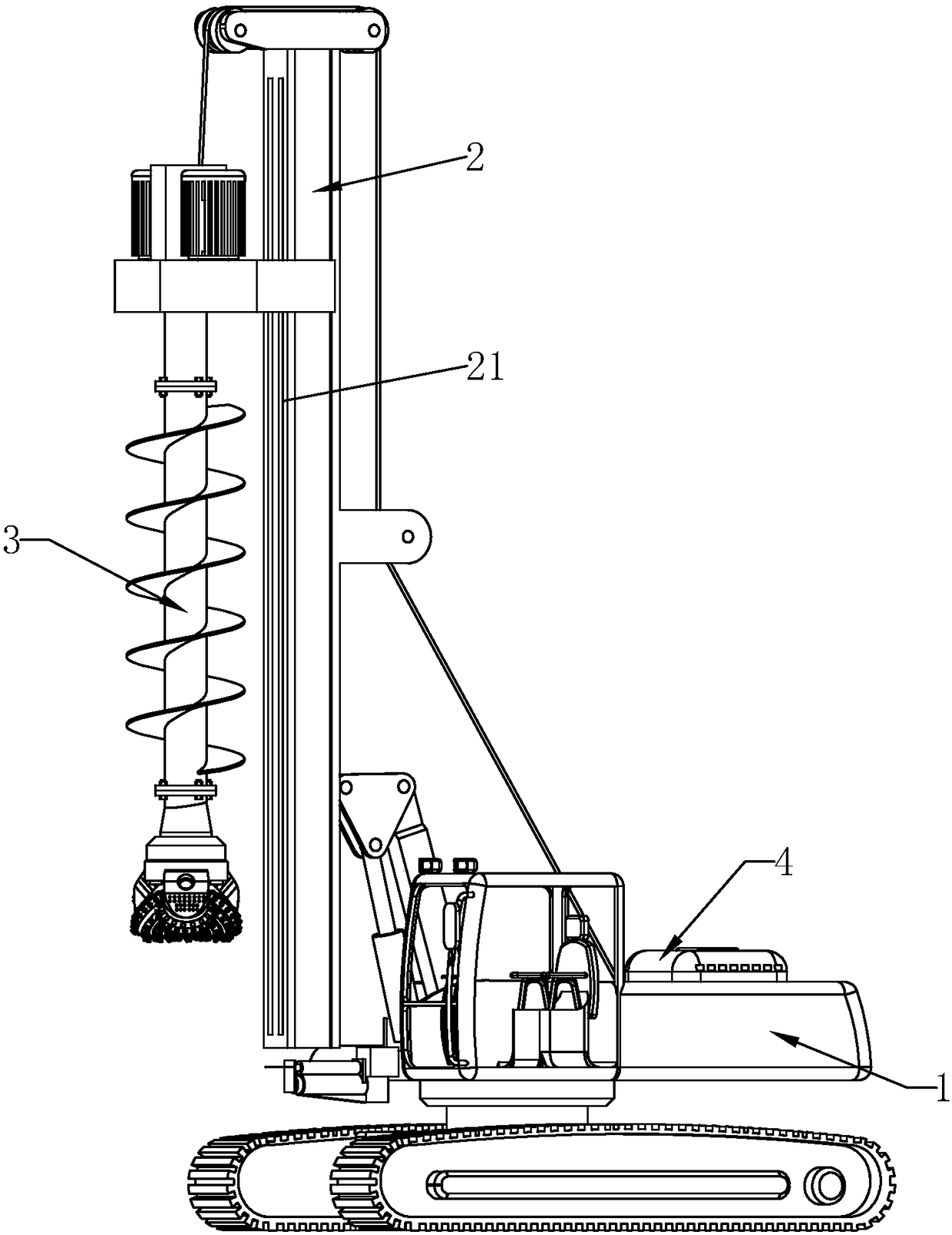

[0040] A long spiral extruded and expanded pile drilling machine, such as figure 1 As shown, it includes an extruder body 1, a pile frame 2 fixed vertically on the extruder body 1, a drilling mechanism 3 slidably arranged on the pile frame 2, and an extruder body 1 for The hoisting mechanism 4 that drives the drilling mechanism 3 up and down, wherein, the extruding machine body 1 is provided with a walking mechanism that drives the overall body to walk, and is used to drive the extruding machine to travel and turn so as to better locate the pile position. The rotary mechanism, when in use, drives the drilling mechanism 3 to find the pile position by the traveling mechanism, the rotary mechanism, etc., and then drives the drilling mechanism 3 to lift up and down by using the winch mechanism 4 to punch holes.

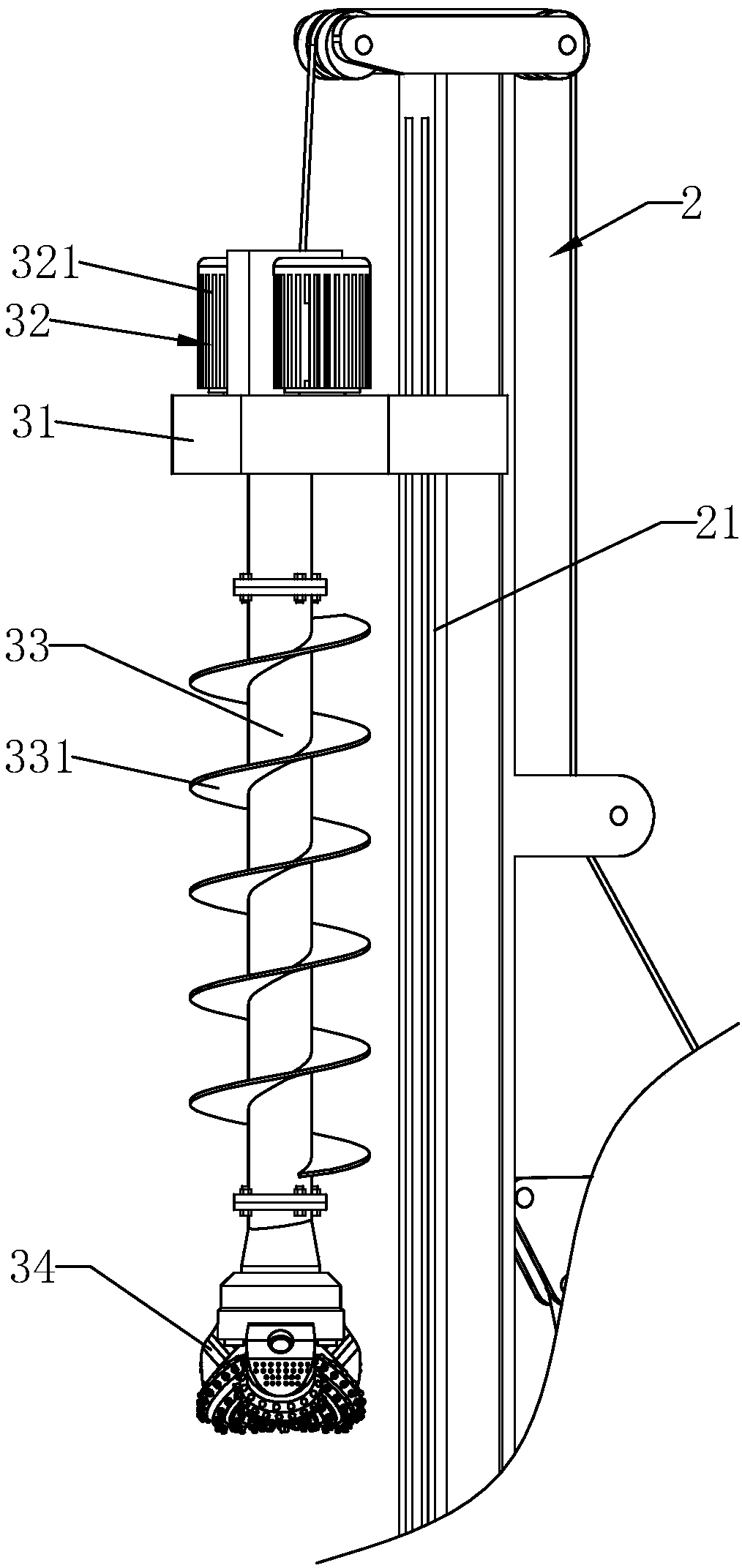

[0041] Such as figure 2 As shown, wherein, a slide rail 21 is fixedly arranged on the pile frame 2, and the drilling mechanism 3 slides on the slide rail 21.

[0042]T...

Embodiment 2

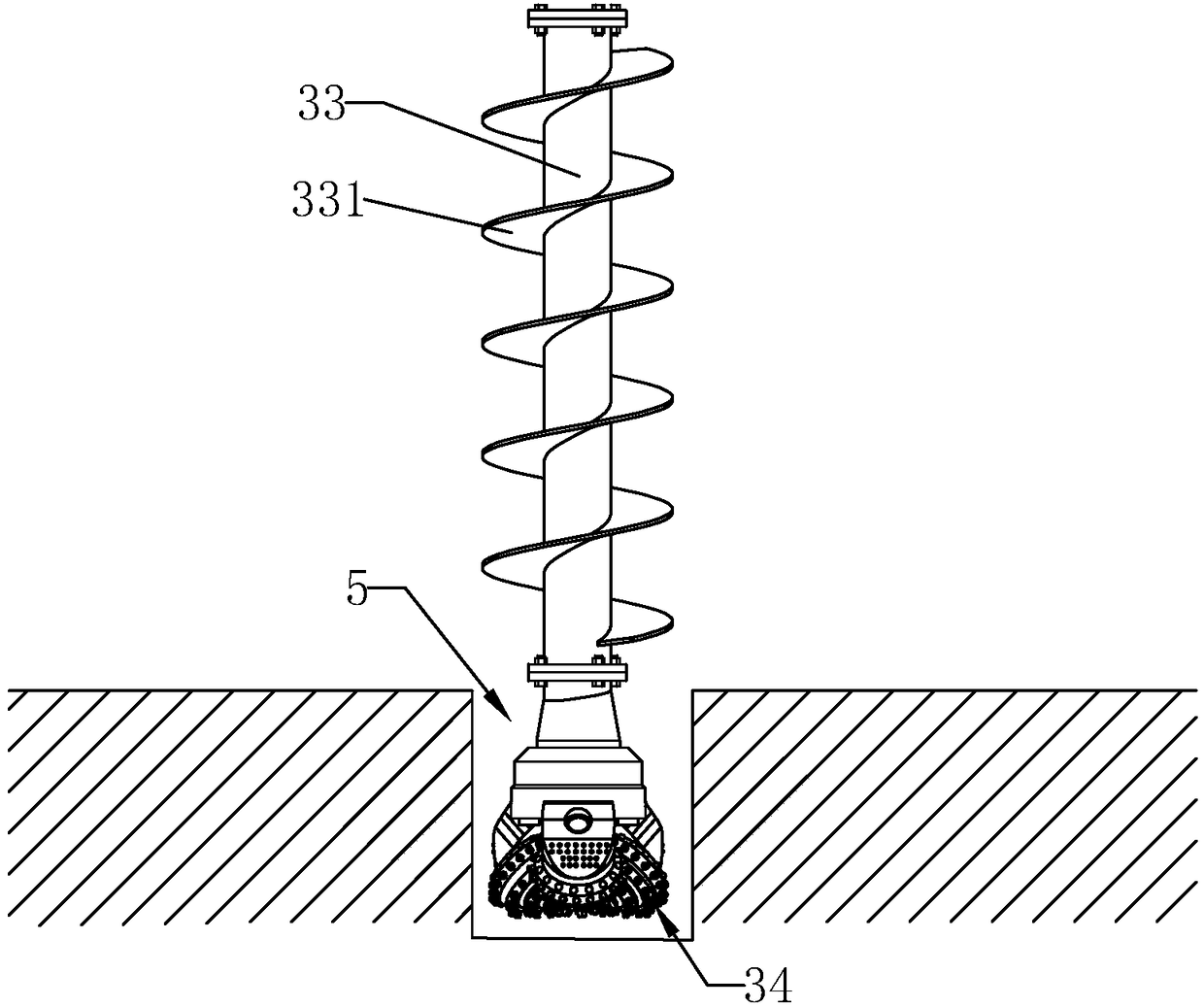

[0049] A kind of drilling method of long spiral extruded and expanded pile drilling machine, such as image 3 shown, including the following construction steps:

[0050] Step a, such as image 3 As shown, the driving drill rod 33 is drilled into the hole vertically downwards;

[0051] Step b, such as Figure 4 As shown, when drilling into a certain depth, the drill rod 33 is lifted to drill, so that the drill rod 33 is separated from the borehole 5;

[0052] Step c, add auxiliary extruder 51 to the drilled hole 5, drill into the shape;

[0053] Step d, repeating the steps S2 and S3 until the drilling 5 is formed.

[0054] In step a, before implementation, the extruder main body 1 is first driven by the traveling mechanism to move to the position where the hole 5 is to be drilled, and the drill rod 33 is driven to rotate by the rotary mechanism so that the drill rod 33 can be aligned to the position for drilling. hole.

[0055] In the drilling process, different situation...

Embodiment 3

[0059] combine Figure 4 and Figure 5 As shown, the difference between this embodiment and Embodiment 2 lies in the structure of the geological layer: when the geological layer is gravel, and when there is no water in the borehole 5, an auxiliary extrusion 51 is added to the borehole 5, and the auxiliary extrusion 51 is selected Clay is then drilled into, and the clay is squeezed between the gravel gaps by the extrusion effect of the roller cone bit 34, and the borehole 5 is reinforced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com