An anti-collapse hole device and method for synchronous waterproofing

A technology of anti-collapse holes and pile holes, which is applied in construction, foundation structure engineering, sheet pile walls, etc., can solve the problems of difficult pressing of steel casings and high construction costs, so as to reduce construction costs, facilitate disassembly, and reduce pile holes The effect of hole collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

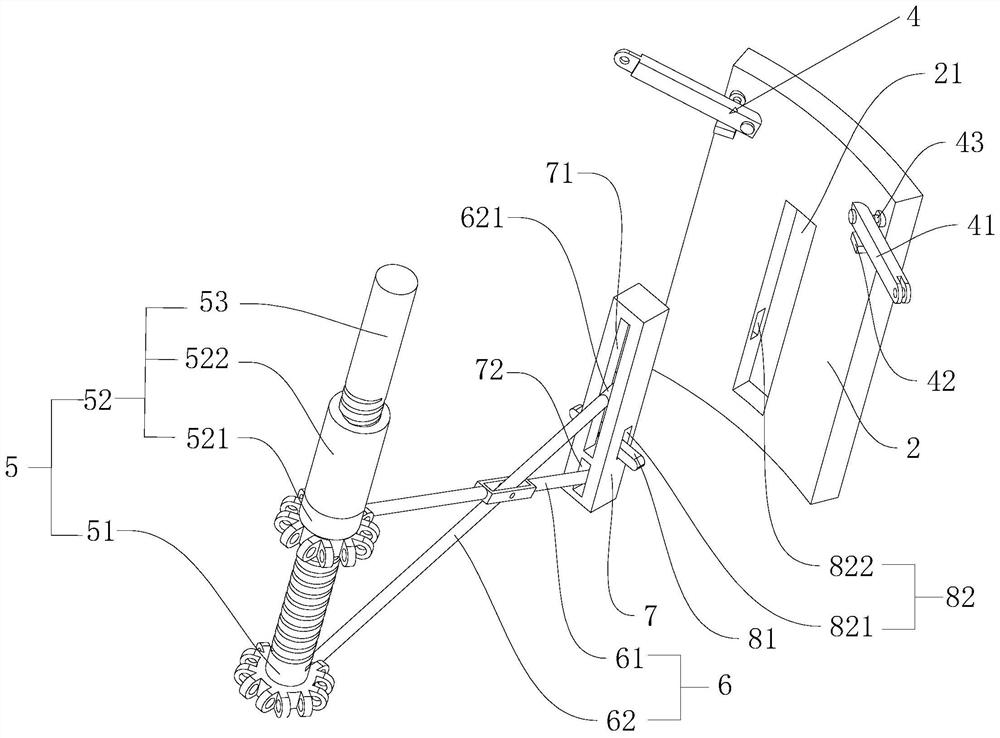

[0036] The following is attached Figure 1-3 The application is described in further detail.

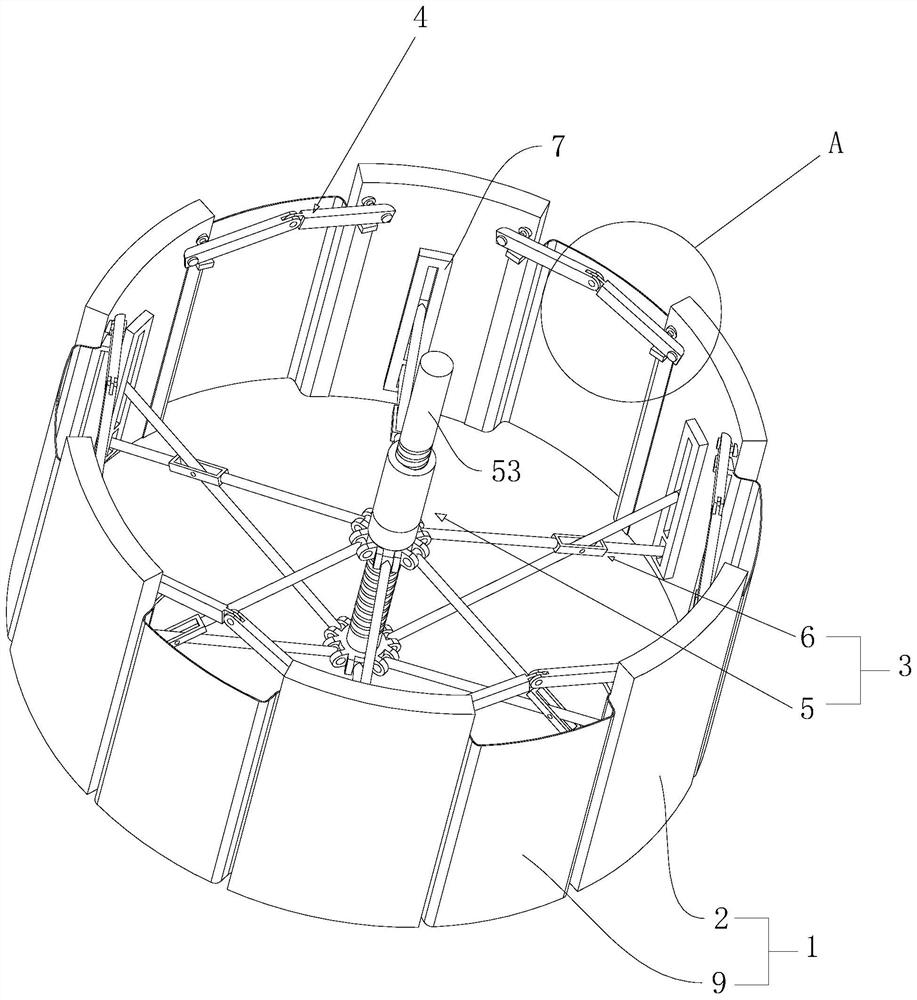

[0037] Embodiment 1 of the present application discloses a synchronous waterproof anti-collapse device. refer to figure 1 The anti-collapse hole device includes a casing main body 1 and an expansion assembly 3 located at the center of the casing main body 1 , and the expansion assembly 3 is detachably connected to the casing main body 1 .

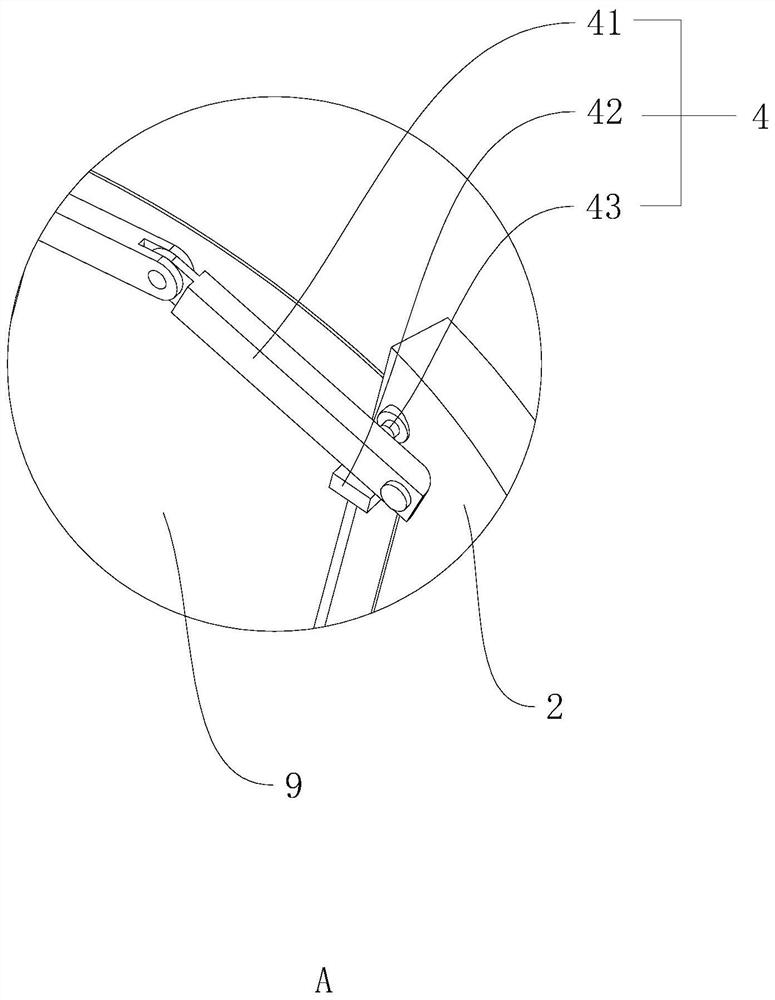

[0038] The casing main body 1 is cylindrical, and the casing main body 1 includes several casing panels 2 that are spliced with each other. The connecting flexible baffles 9 between adjacent casing panels 2 and the adjacent casing panels 2 are provided with locking Component 4, the staff can increase the number of locking components 4 according to the size of the pile hole and the quality requirements of the pile. In order to facilitate the understanding of the scheme, the gap between adjacent casing plates 2 in the figure is relatively large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com