Underground continuous wall with socket-type steel lattice framework and construction method thereof

An underground diaphragm wall and steel lattice structure technology, which is applied to infrastructure engineering, sheet pile walls, buildings, etc. Protection strength requirements, convenient and efficient construction, uniform bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

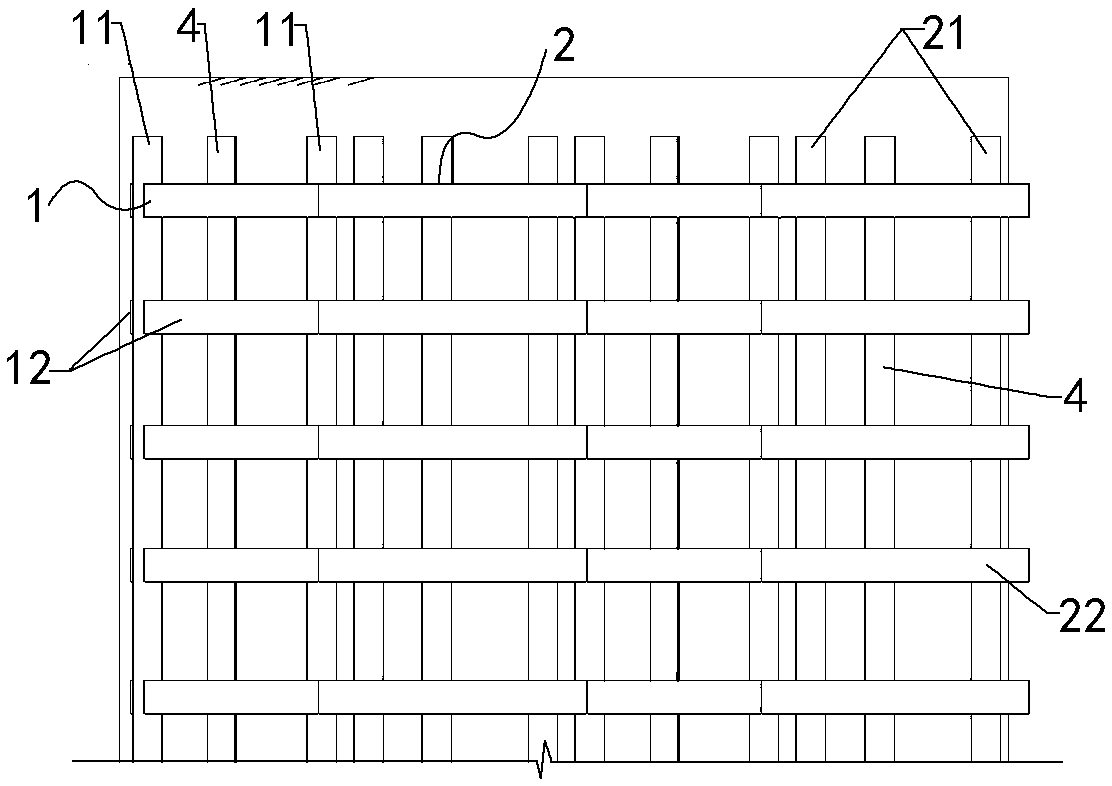

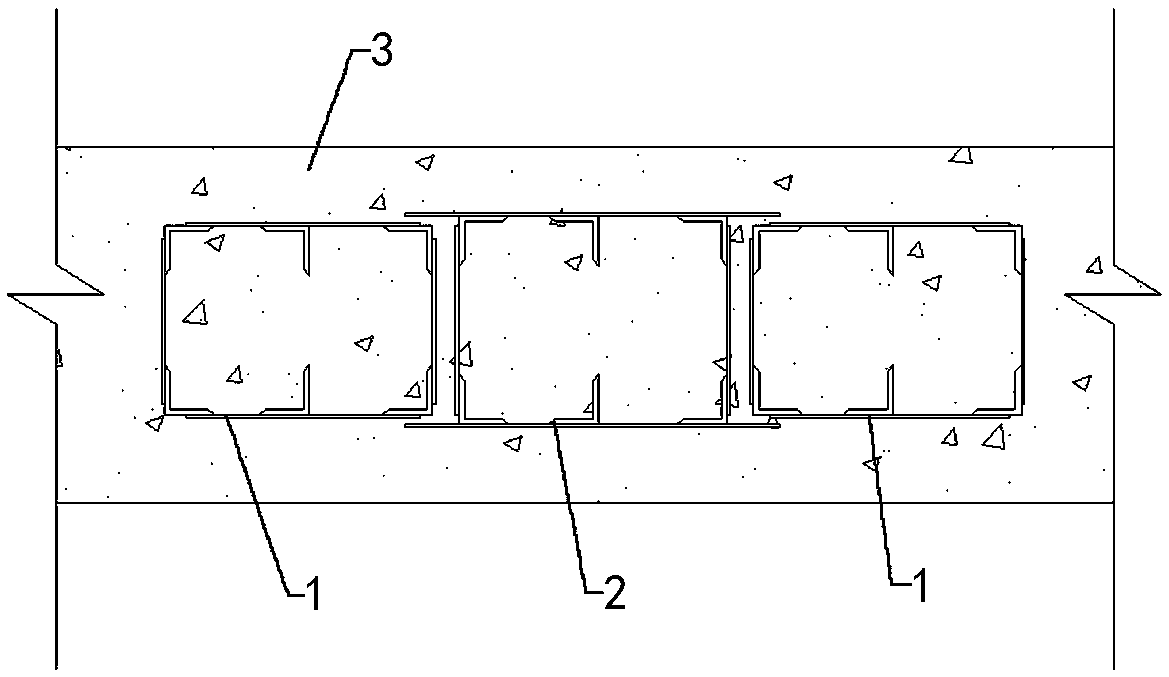

[0042] Such as Figure 1 to Figure 2 As shown, the underground continuous wall of the socket-type steel lattice skeleton of the present invention includes a skeleton structure and concrete 3, and the skeleton structure is formed by interlacing the first lattice columns 1 and the second lattice columns 2, and the first lattice The socket connection between the column 1 and the second lattice column 2 .

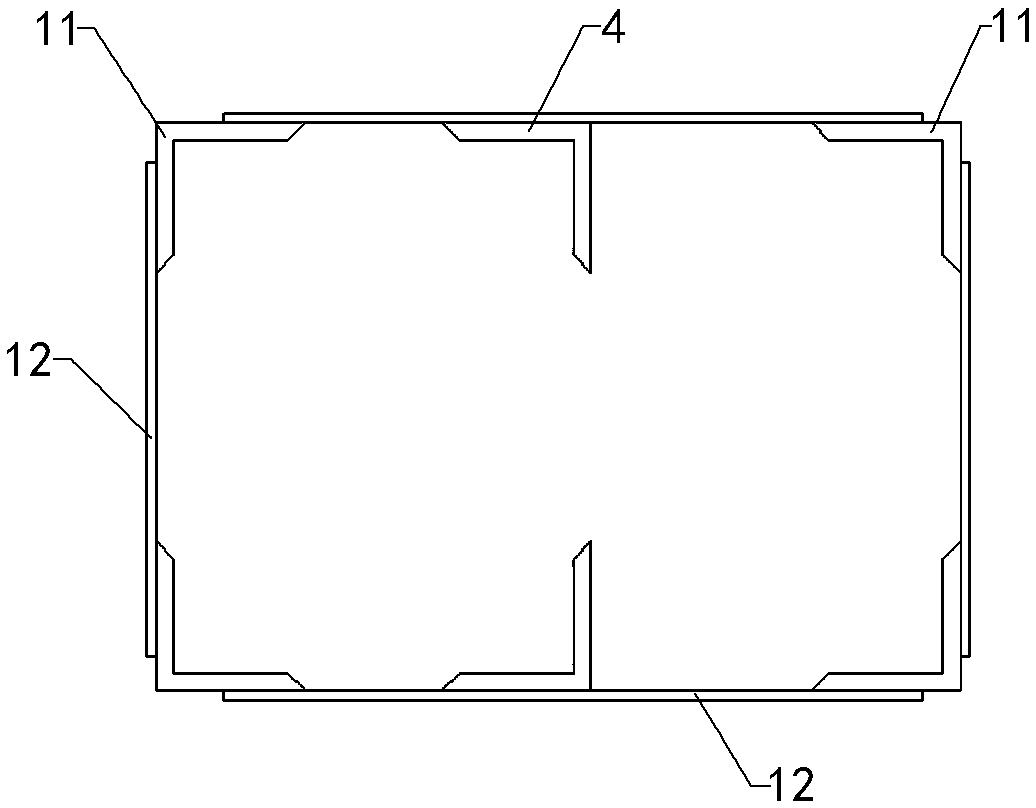

[0043] Such as image 3 As shown, the cross-section of the first lattice column 1 is rectangular, and the length of the cross-section is not less than 900 mm. The rectangular frame band 12 around the first end pole 11, the first end pole 11 is an angle steel, which is relatively buckled and arranged, and the rectangular frame band 12 is arranged at intervals along the length direction of the first end pole 11, up and down The distance between adjacent rectangular frame strips 12 is not more than 500mm, and the rectangular frame strips 12 are surrounded by steel strips with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com