Wing-added hole-expanding pile and wing-added hole expander

A technology of reaming piles and reamers, which is applied to sheet pile walls, earthmoving machines/shovels, construction, etc., can solve the problems of difficulty in giving full play to the potential of foundation soil, small application range and high cost of pile foundations. Simple structure, improved single pile uplift resistance, good matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

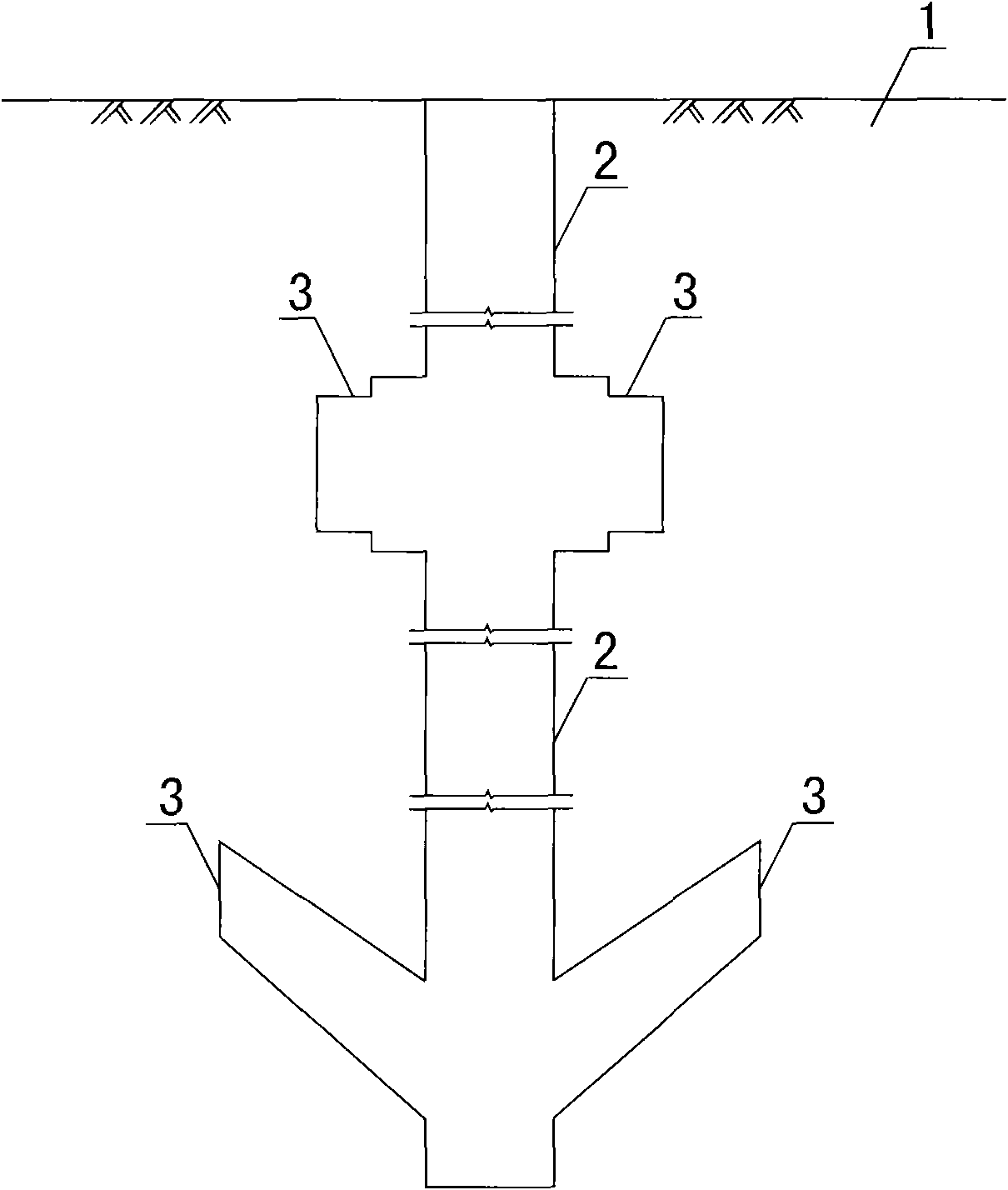

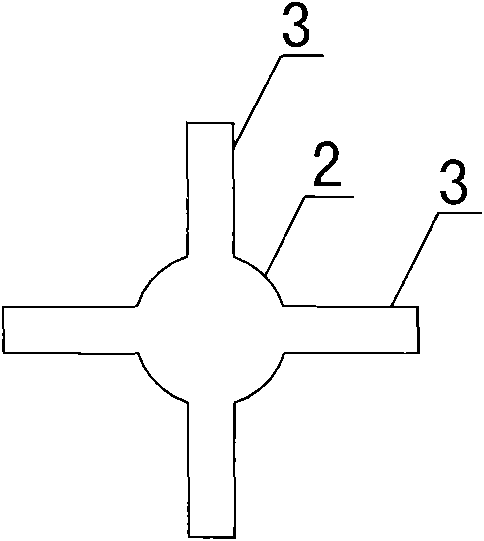

[0020] As an embodiment of the wing-increasing reaming pile and the used wing-increasing reamer of the present invention, holes are first drilled at the pile position to form the pile hole before the reaming construction, and then such as Figure 4 The first type of wing-enhancing reamer shown is placed in the position to be reamed along the pile hole, and its direction is as follows: Figure 4 The shown first type of wing reamer positioning oil cylinder 4 is filled with high-pressure liquid, so that the shrinkage is as follows: Figure 4 The wing-increasing piston rod 5 of the first type of wing-increasing hole reamer positioning oil cylinder 4 shown in the first type stretches out, and inserts such as figure 1 In the rock and soil mass 1 around the shown pile hole, it can be Figure 4 The shown first type wing-increasing reamer wing-increasing piston rod 5 is set as a multi-stage piston rod to increase the reaming range. Figure 4 The shown first type wing-increasing reame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com