Vibration and extrusion type drilling machine

A drilling machine and extrusion technology, which is used in drilling equipment and methods, drilling equipment, earth-moving drilling and mining, etc., can solve the problems of environmental pollution, high energy consumption, low efficiency, etc. Low consumption and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

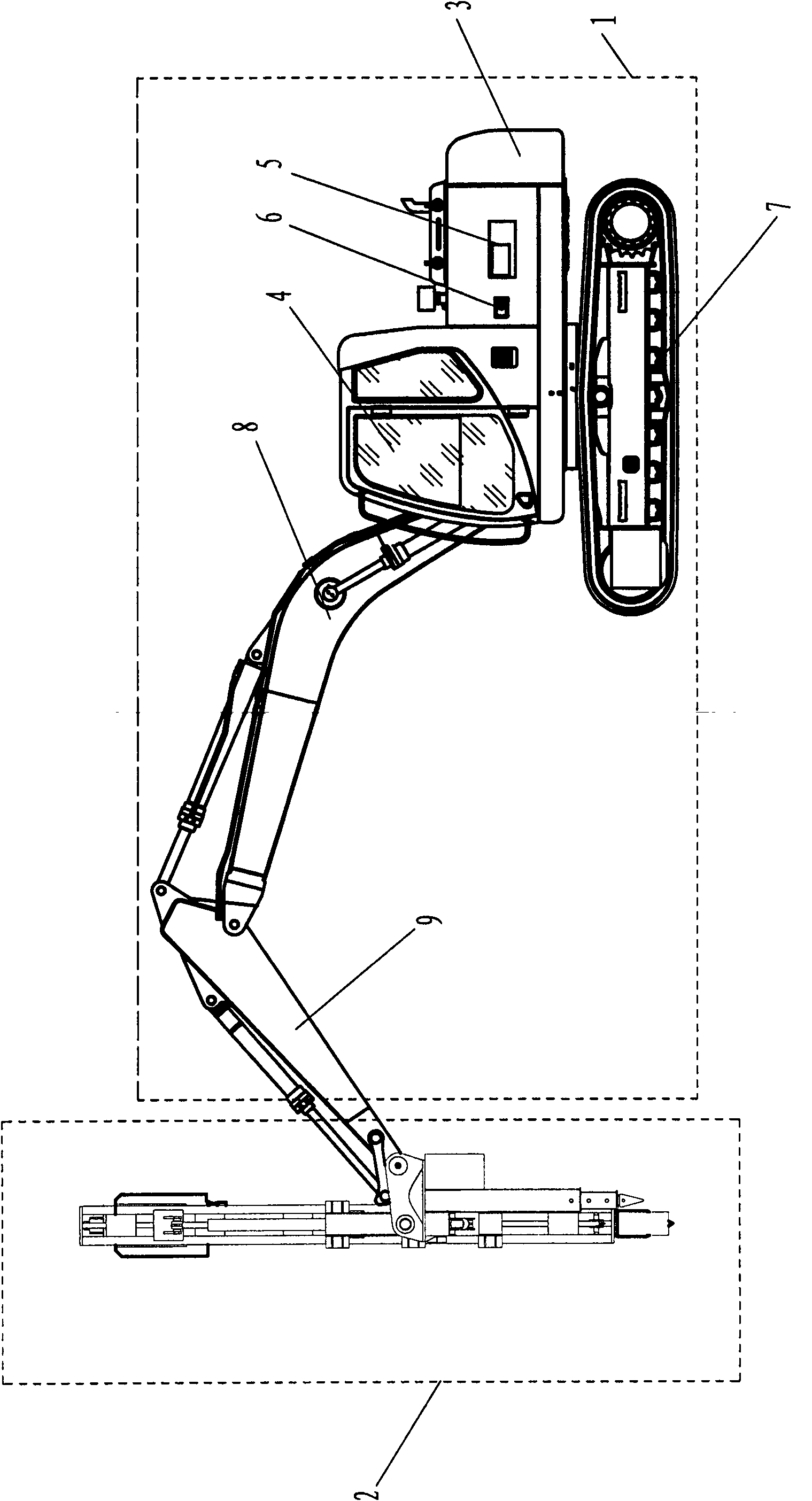

[0038] refer to figure 1 , the present invention is made up of chassis mechanism 1 and drilling mechanism 2. Chassis mechanism 1 is mainly composed of body 3, cab 4, engine 5, hydraulic system 6, traveling mechanism 7, boom 8, forearm 9, etc., cab 4, engine 5, hydraulic system 6, boom 8 and forearm 9 is installed on the body 3, the traveling mechanism 7 is installed below the body 3, and the boom 8 and the small arm 9 are controlled by the hydraulic system 6. The present invention can also adopt crawler or wheeled hydraulic excavator as the chassis mechanism of the present invention.

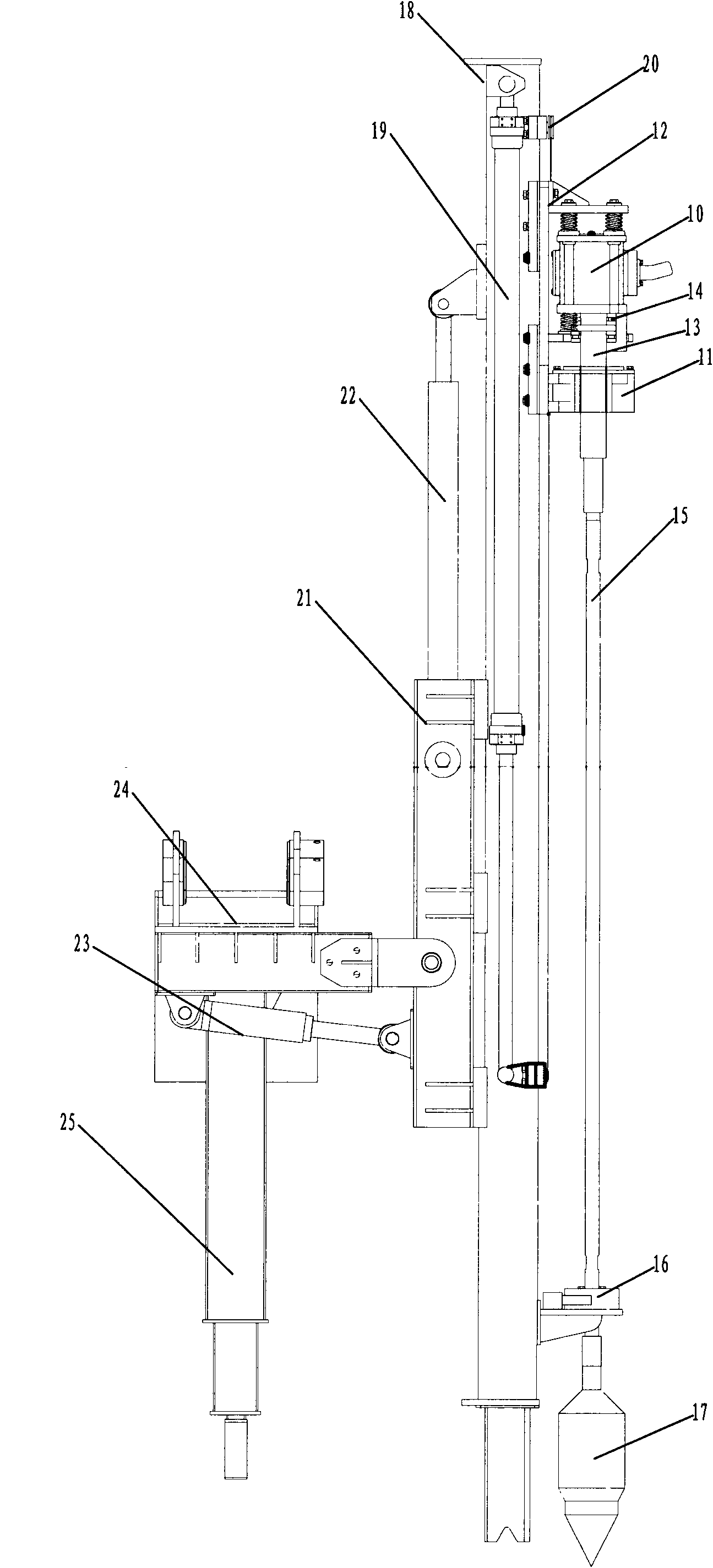

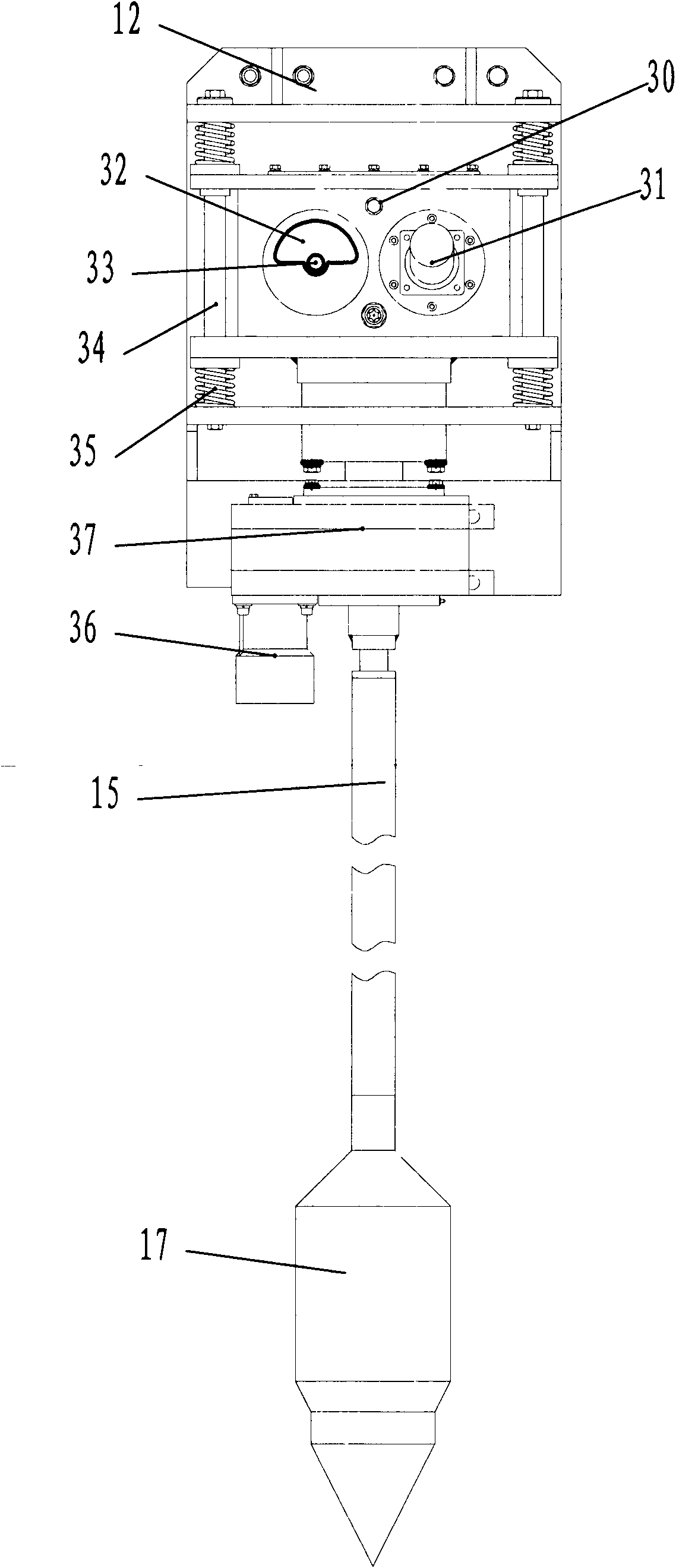

[0039] figure 2 It is a structural schematic diagram of the drilling mechanism 2. The drilling mechanism 2 is mainly composed of the propulsion beam 18, the carriage beam 21, the connecting seat 24, the vibration mechanism 10, the rotation mechanism 11, the drill pipe 15 and the extruding head 17. One side of the propulsion beam 18 passes through the sliding pair and the carriage beam. 21 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com