A method for constructing a high-strength chamber at the bottom of a vertical well

A construction method and technology for vertical wells, applied in wellbore/well components, drilling equipment and methods, construction, etc., can solve problems such as irregular cavity shape, unfavorable cavity stability, high height, sudden transition, etc., and it is not easy to achieve Effects of hole collapse, high formation strength, and regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

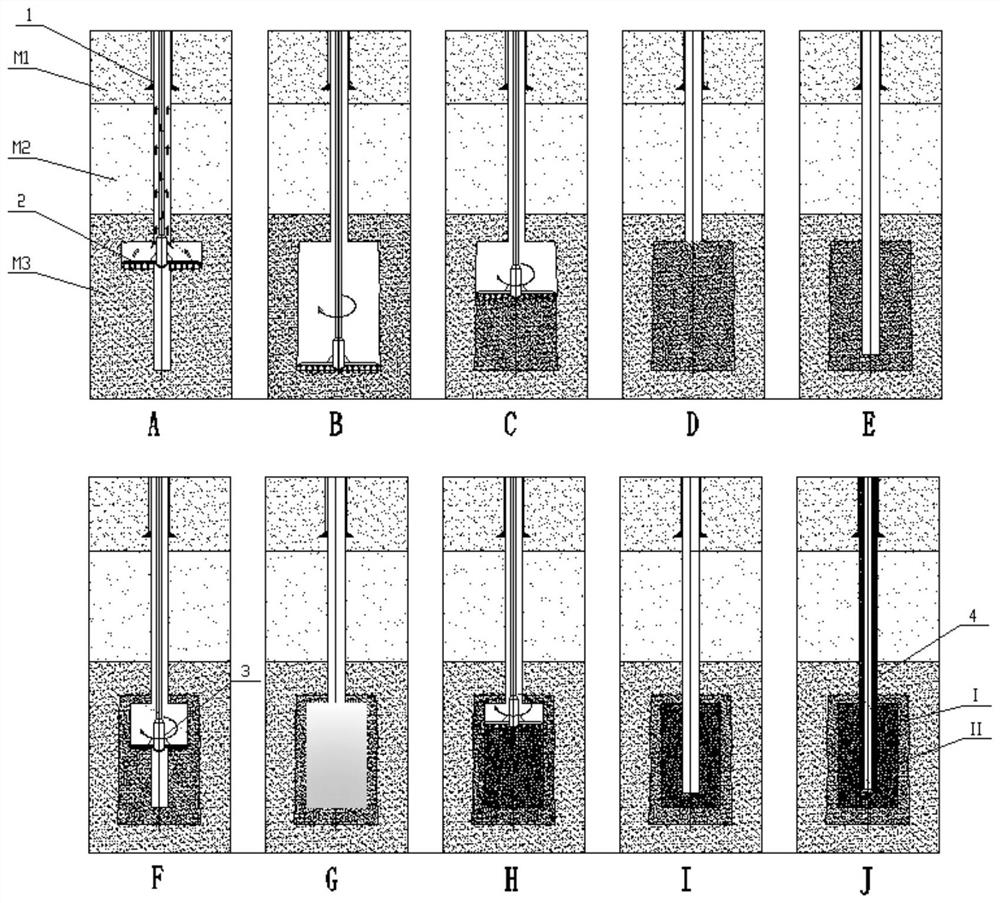

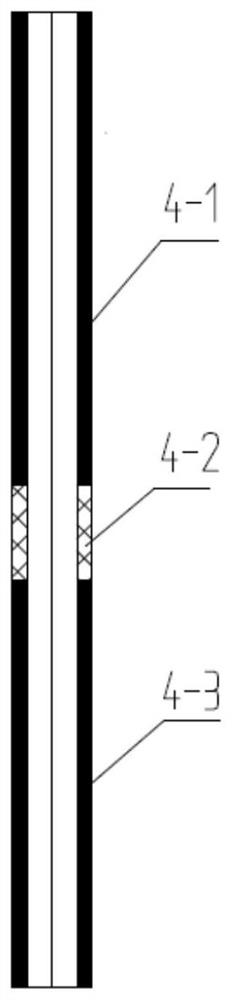

[0025] The construction method of the high-strength chamber at the bottom of the natural gas hydrate vertical well in the sea area of the present invention is a process method carried out by adopting the technology of reaming cast-in-place piles. Two cavities with different diameters are respectively constructed through two chamber expansions. The first The secondary cavity expansion is carried out on the formation below the hydrate floor. The formation is soft, and the jet cavity expansion can be carried out by pumping high-pressure mud into the jet expansion bit. Pump high-strength cement slurry in the jet expansion drill bit for initial pile grouting. Since the perfusion was performed without lifting the drill, the shape and size of the cavity could not be measured, and the requirement of the cavity rule could not be met. Based on the above reasons, it is necessary to carry out secondary cavity expansion on the basis of the high-strength cement primary pile, and pour a pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com